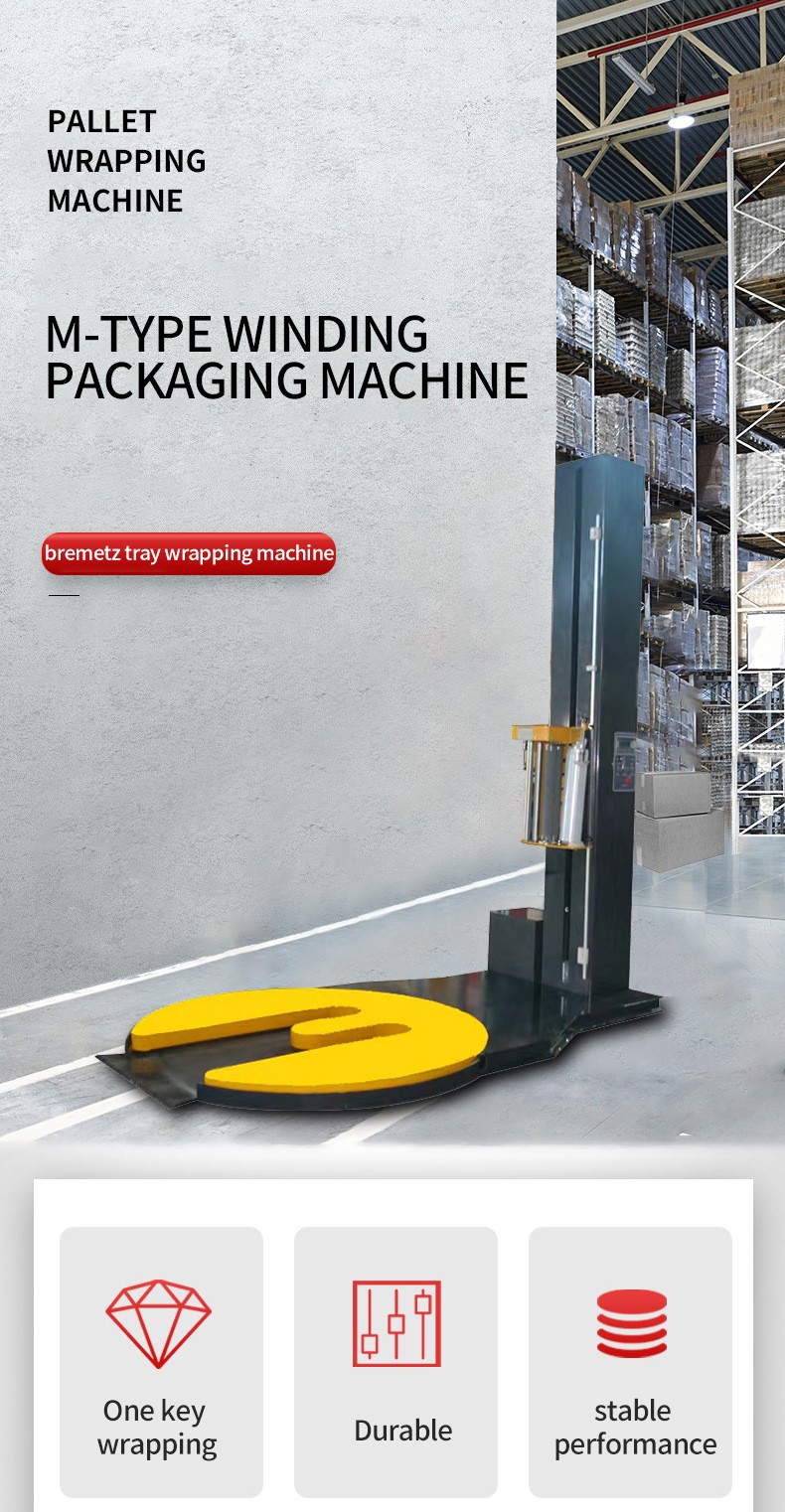

M-type winding wrapping machine

1. Efficient packaging: With advanced mechanical structure and automatic control system, it can wrap and wrap all kinds of goods quickly and stably.

2. Good packaging effect: The unique M-type wrapping method can make the packaging film tightly and evenly cover the surface of the goods, forming an all-round protective layer.

3. Wide range of applications: It has strong versatility and can adapt to the packaging needs of goods of different shapes, sizes and weights.

4. Save packaging materials: Through precise control system and optimized winding path algorithm, it can minimize the use of packaging film while ensuring the packaging effect.

5. Easy operation: Equipped with an intuitive and easy-to-operate human-machine interface, operators only need simple training to master the operation method of the equipment.

6. Stable and reliable: With high-quality mechanical parts and advanced electrical control system, after strict quality inspection and performance testing, the stability and reliability of the equipment during long-term continuous operation are ensured.

The M-type wrapping machine is a highly efficient equipment widely used in the packaging field. It is specially designed to meet the wrapping needs of various products and pallet goods.

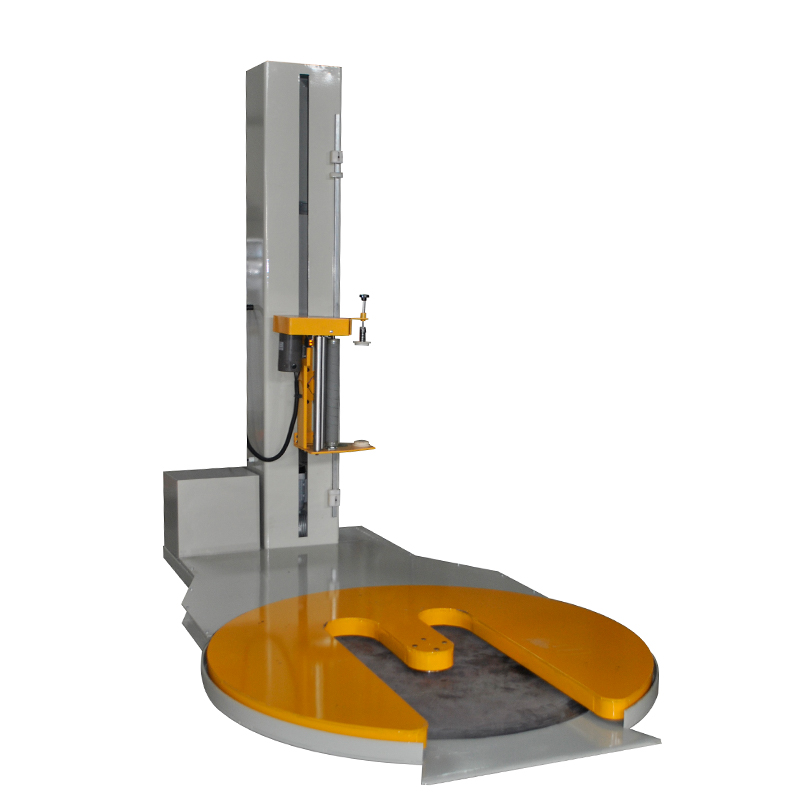

The chassis is made of high-quality steel, which has excellent stability and load-bearing capacity, and can bear heavy goods without shaking or deformation. The turntable surface has been specially treated to ensure the stability of the goods and reduce friction damage to the bottom of the goods.

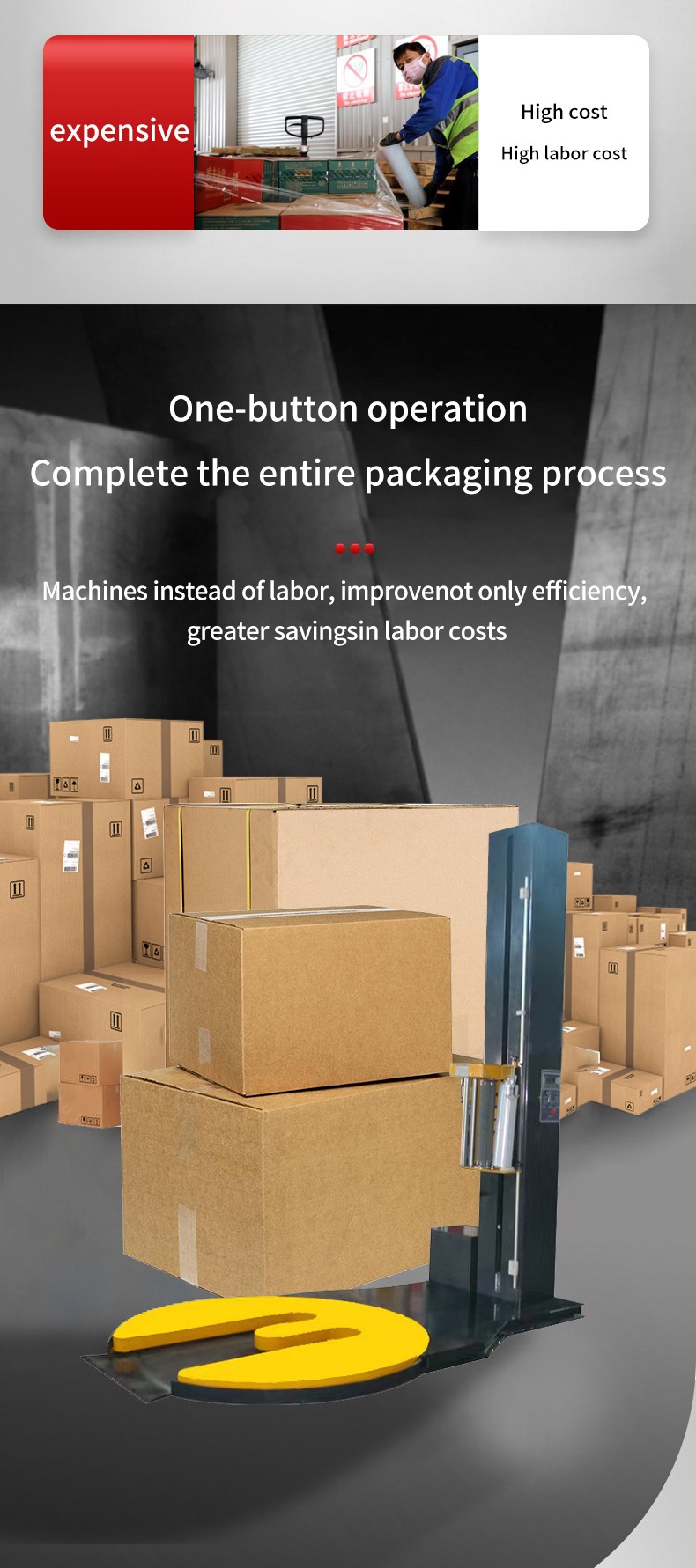

High-efficiency packaging efficiency: With fast packaging speed, it can complete the wrapping and packaging tasks of a large number of goods in a short time. Compared with the traditional manual packaging method, the efficiency can be increased by several times or even dozens of times, which greatly saves packaging time and labor costs, and improves the production efficiency and logistics distribution speed of the enterprise.

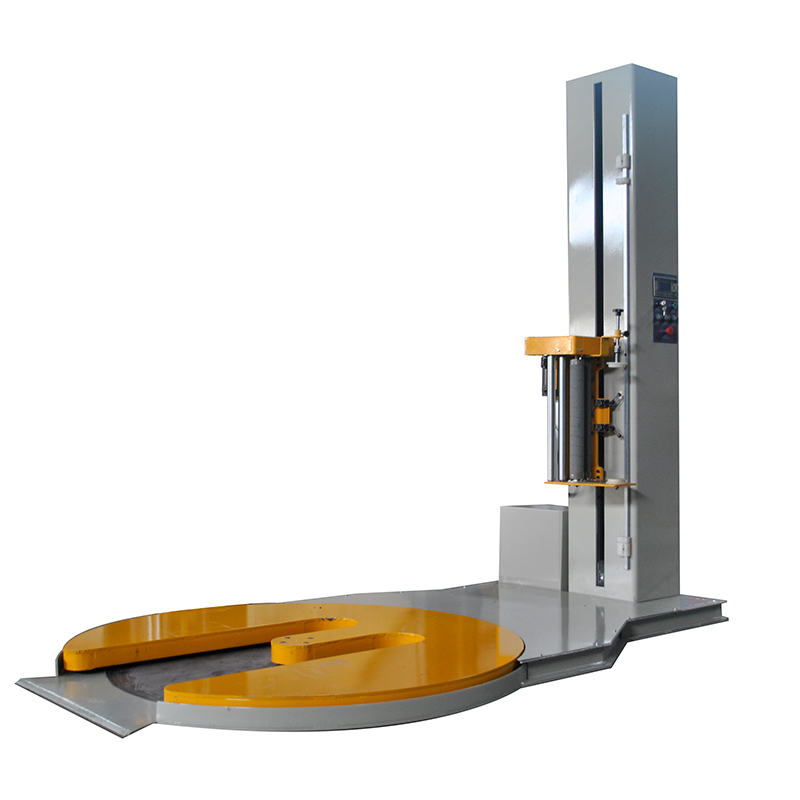

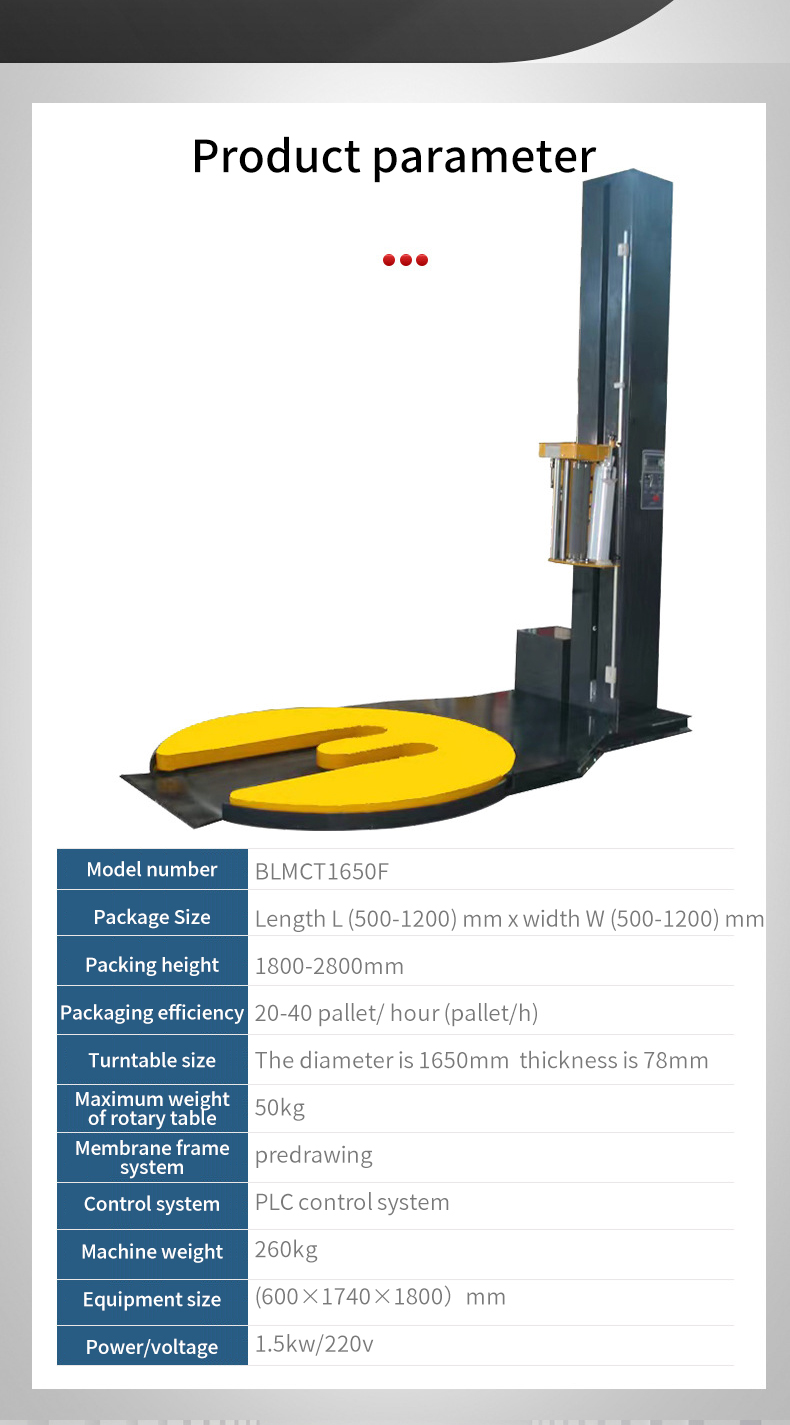

Model number:BLMCT1650F

Package Size:Length L (500-1200) mm x width W (500-1200) mm

Packing height:1800-2800mm

Packaging efficiency:20-40 pallet/hour (pallet/h)

Turntable size:The diameter is 1650mm thickness is 78mm

Maximum weight of rotary table:50kg

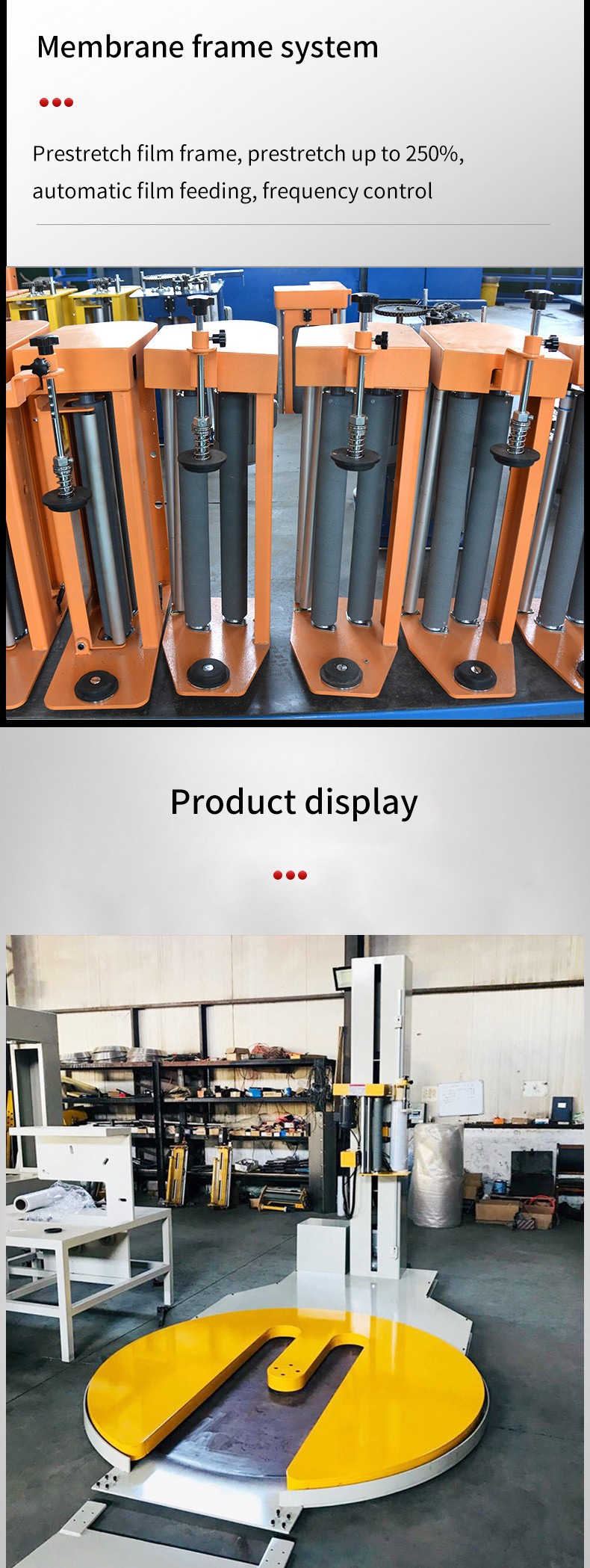

Membrane frame system:predrawing

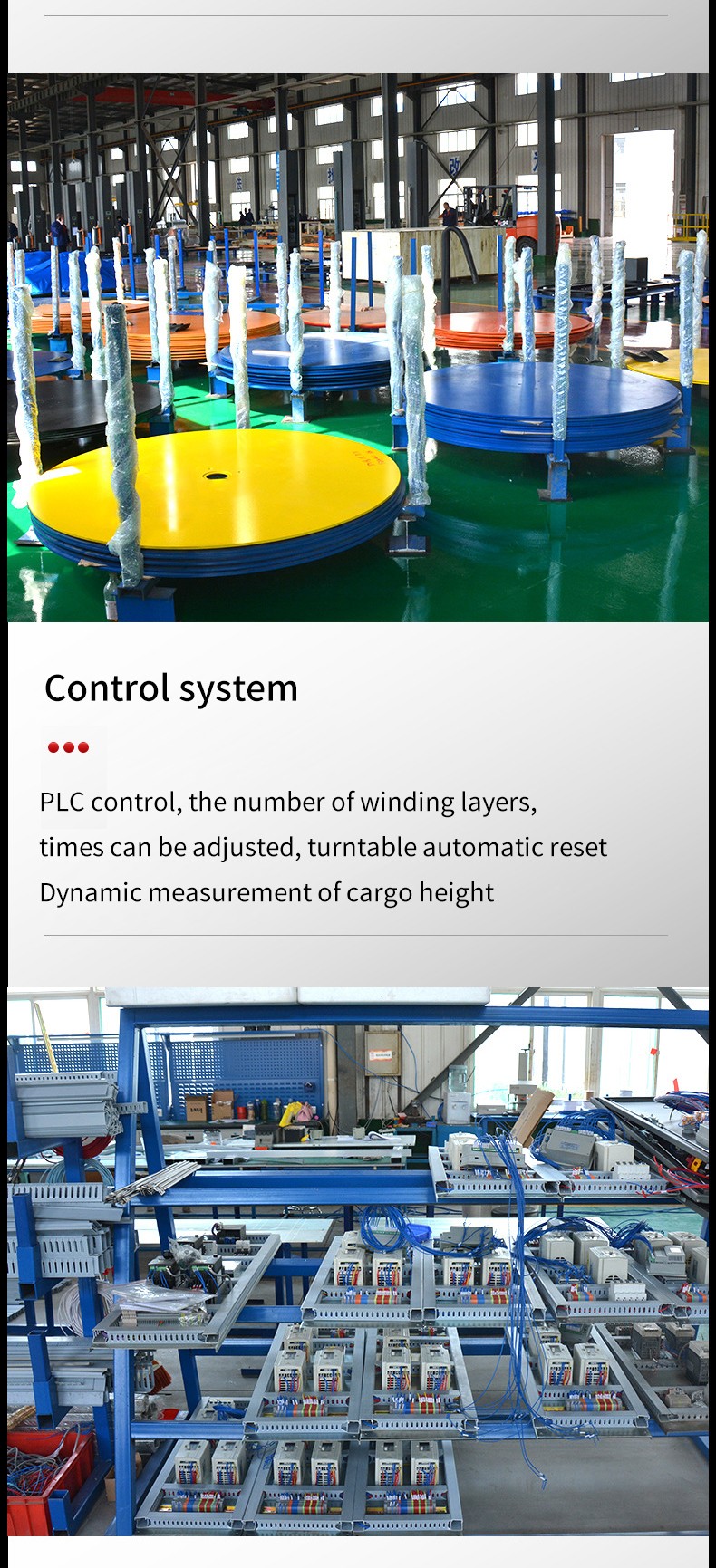

Control system:PLC control system

Machine weight:260kg

Equipment size:(600×1740×1800) mm

Power/voltage:1.5kw/220v

Excellent packaging quality: The M-type wrapping method enables the packaging film to form a tight, continuous and stable protective layer on the surface of the goods, effectively enhancing the goods' resistance to impact, moisture and dust. Whether in long-distance transportation or in warehouse storage, it can protect the integrity and quality of the goods to the greatest extent and reduce the risk of damage to the goods.

Save packaging materials: Through precise film control technology and optimized winding path algorithm, the use of packaging film can be minimized and the cost of packaging materials can be reduced while ensuring the packaging effect, which is also in line with the concept of environmental protection and energy saving.

Wide applicability: It is suitable for packaging goods of various shapes, sizes and materials, including but not limited to cartons, wooden boxes, barreled goods, bagged goods and products of irregular shapes, etc. It can also wrap pallet goods as a whole, meeting the diverse packaging needs of different industries and enterprises.

The humanized operation interface design enables operators to master the operation of the equipment after simple training. The equipment has a reasonable structural design, and each component is easy to disassemble and install, which is convenient for daily maintenance and reduces the maintenance cost and downtime of the equipment.

Provide customers with comprehensive operation training courses, covering the basic operation principles of the equipment, the operation methods of the human-machine interface, the setting skills of various packaging parameters, etc.

Through the combination of theoretical explanation and practical operation, customers' operators can master the skills of starting and shutting down the equipment, switching between manual and automatic operation modes, and handling emergencies.

We have set up a dedicated after-sales service hotline, which customers can call at any time to report equipment failures or consult technical issues. Our customer service staff will record customer information and fault description as soon as they receive the call, and pass the relevant information to the technical maintenance team in a timely manner.