Automatic stacker robot manipulator

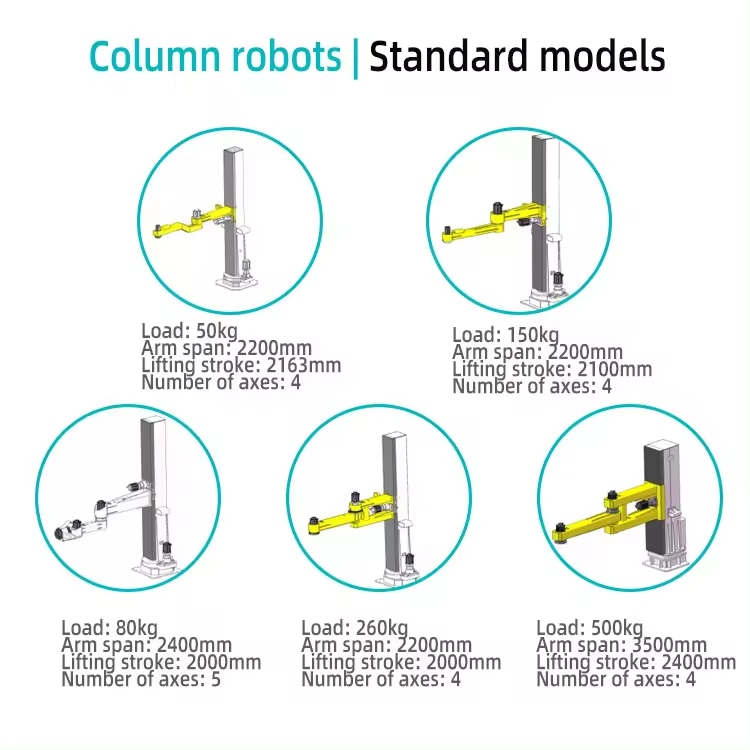

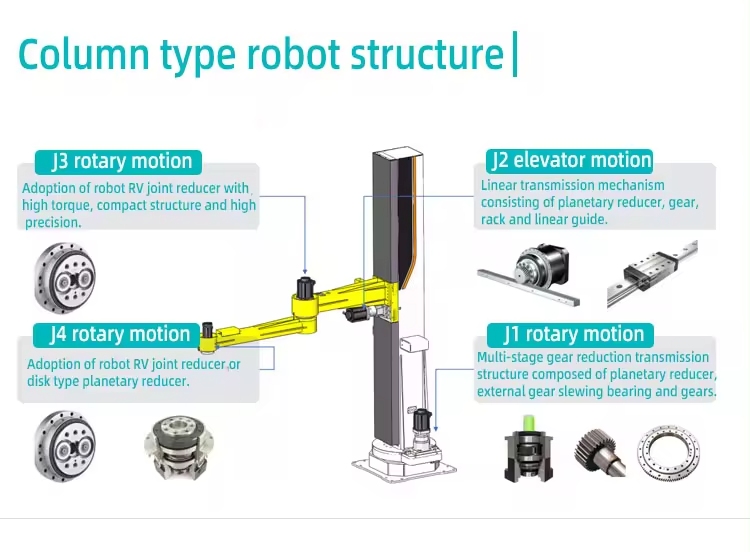

The structure of the column robot mainly consists of a base component, a column component, a big arm component, and a small arm component.

Vertical palletizing robots are designed for fast and precise cargo palletizing operations in industrial environments. Through precision motors and reducers, combined with complex control systems, it achieves a high degree of automation and flexibility, greatly improving production efficiency and operating accuracy. The movement of each joint is controlled by an advanced servo system to ensure precise movement trajectories and stable cargo handling.

The vertical palletizing robot is a kind of palletizing equipment with compact structure and small footprint. It is mainly composed of column assembly, big arm assembly, small arm assembly, lifting mechanism, fork mechanism and electrical control system. When working, the lifting mechanism lifts the fork mechanism to the height of the goods, and the fork mechanism then forks up the goods and moves them to the designated position for palletizing. The vertical palletizing robot has a simple operating principle and is easy to operate. It is suitable for palletizing various small goods. Palletizer is an important production equipment on the modern assembly line. The working process of the palletizer is to place materials packed into containers (such as cartons, woven bags, barrels, etc.) or packaged and unpackaged regular items on pallets in a certain arrangement for automatic stacking. Stack multiple layers and then roll them out to facilitate the next step of packaging or forklift transportation to the warehouse for storage. The column palletizer is an advanced logistics equipment that can automatically palletize goods according to set rules, improving the efficiency and accuracy of logistics operations.