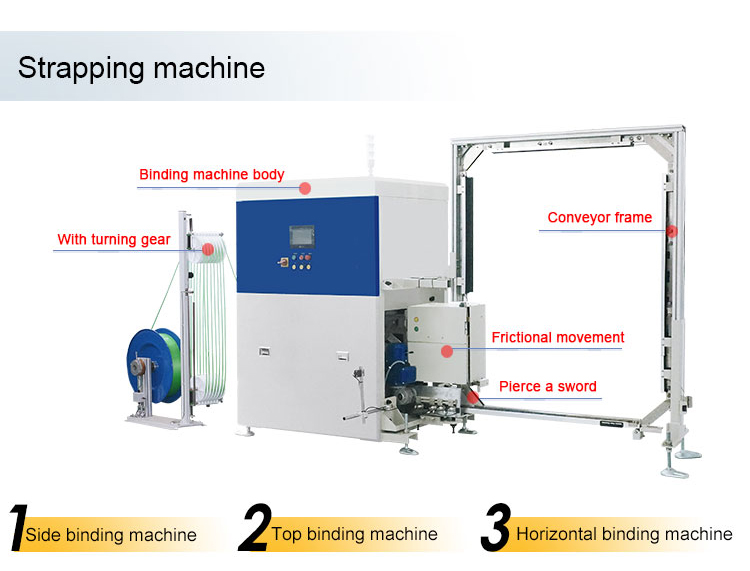

Sword strapping machine

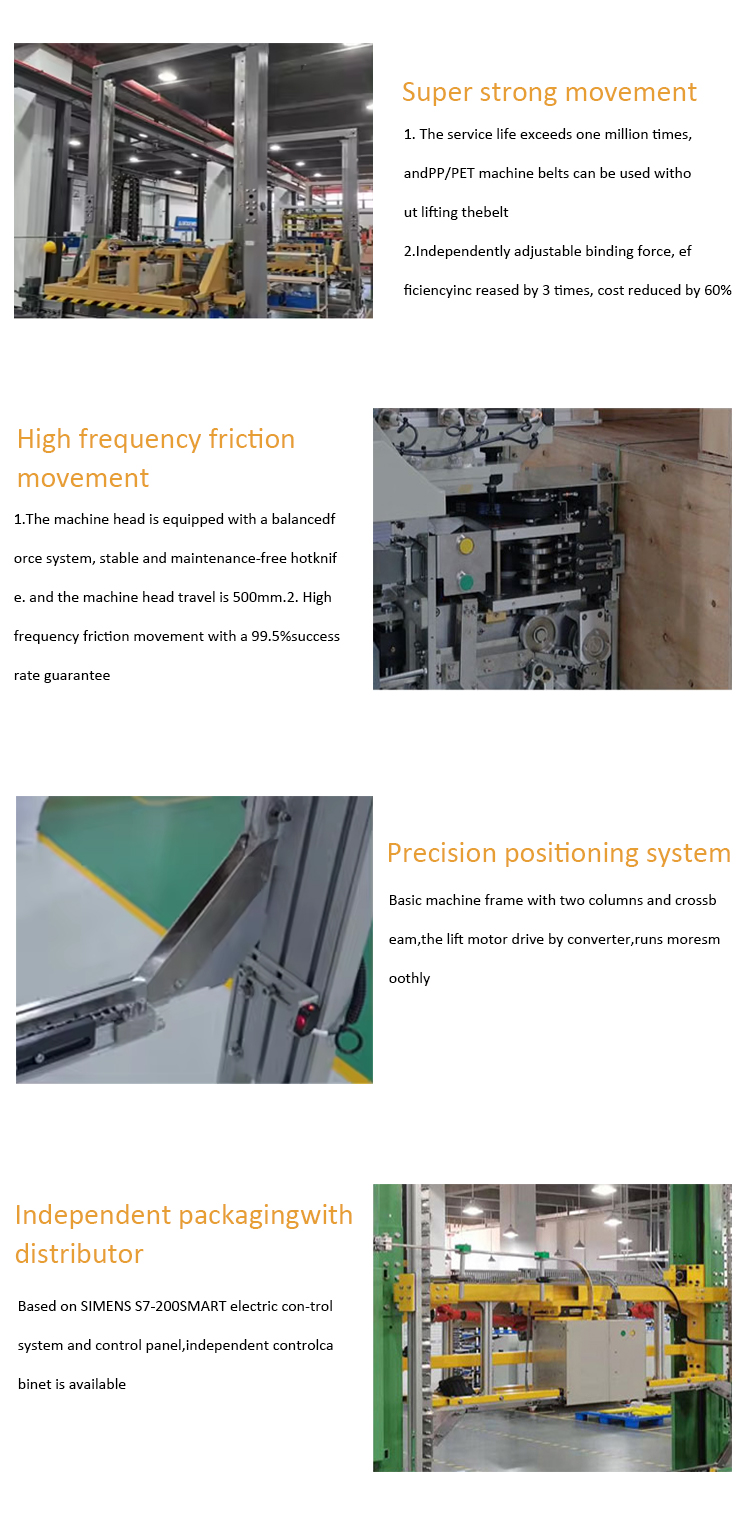

1. The specially designed tightening mechanism and power device can provide strong and stable tightening force to ensure that the goods will not be loosened.

2. Equipped with high-precision sensors and control systems, it can accurately control the length, tightening force and cutting position of the strapping belt.

3. Adopting mature technology and processes verified by the market, its mechanical structure and electrical control system are stable and reliable.

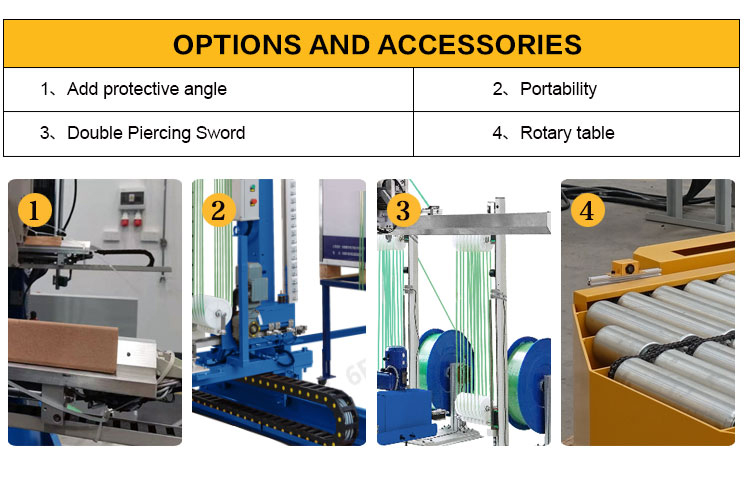

4. The modular design makes it easy to disassemble and replace each component, which is convenient for maintenance personnel to carry out daily maintenance.

5. It is compatible with strapping belts of various specifications and materials, such as PP straps, PET straps, etc., and the width and thickness can be flexibly adjusted within a certain range.

The aluminum alloy bow frame design is easy to disassemble and assemble, and is convenient for transportation, installation and maintenance. It is also convenient to replace or upgrade some components according to different needs.

It adopts a fully automated design and can automatically complete a series of operations such as belt feeding, belt threading, bundling, tightening, and cutting. It is more convenient to operate and can effectively reduce manual operations and improve production efficiency.

The maximum size of the bale is determined by the bow, which can be customized according to the user's needs to accommodate the bundling needs of items of different sizes and shapes.

Usually adopt high-quality components such as motors, reducers, cams, etc., the tightening arm operates stably, has excellent bale tightening force, few failures and easy maintenance.

It adopts advanced electronic technology to realize fully automated operation and management, and can automatically adjust the tension, strapping method, etc. according to the set parameters.