Automatic telescopic conveyor

1. The length of the conveyor can be easily changed through the control button according to actual needs, and it can be accurately extended to the required position for material transportation.

2. It can be tilted to any desired angle, and can transfer materials from one height level to another in the manufacturing workshop or warehouse.

3. It can realize bidirectional operation to convey materials, and can also move forward and backward, providing higher functional diversity in the process of material handling and transportation.

4. It can quickly transfer materials between different locations, especially when loading and unloading, it can quickly adjust to the appropriate length.

5. It reduces the need for a large number of people to carry out material handling, reducing labor cost investment.

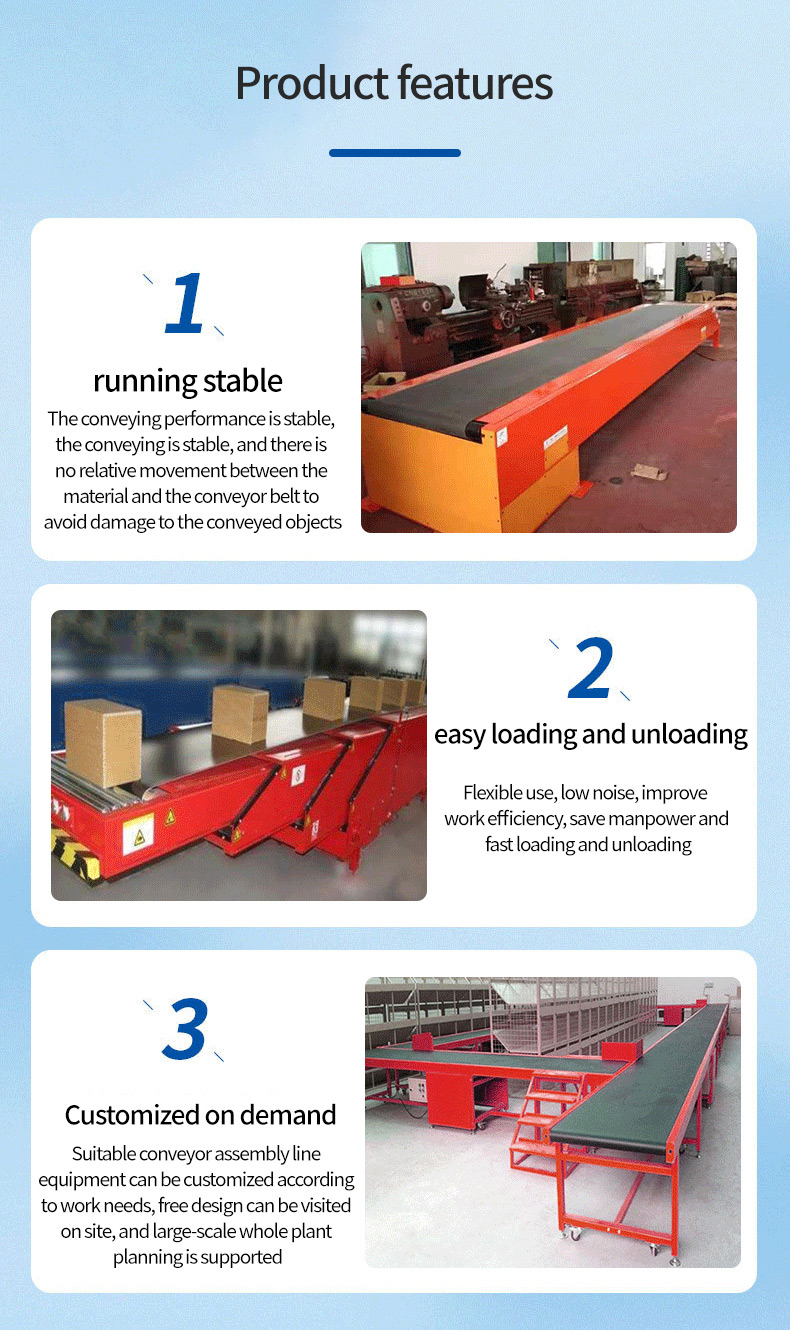

Automatic telescopic conveyor is a kind of equipment that can freely extend and retract in the length direction and can operate in both directions to transport materials. It can cooperate with other conveying equipment and material sorting systems to realize the automation of material storage and warehousing or vehicle loading and unloading.

It can be freely extended and retracted in length according to actual needs, and some parts can also adjust the height and angle, and can be accurately extended to the required position for material transportation.

It can quickly transfer materials between different locations and can continuously transport large amounts of materials. Compared with manual handling or other traditional transportation methods, it can transport more goods per unit time.

It reduces the need for a large number of people to carry out material handling, reduces labor cost investment, and usually has lower energy consumption, which can save enterprises a lot of energy costs in the long term.

It is usually equipped with a variety of safety protection devices, such as emergency stop buttons, anti-slip devices, etc., to ensure that the operation can be stopped in time when an abnormal situation occurs, to ensure the safety of personnel and equipment.

Many automatic telescopic conveyors adopt modular design, and each component is relatively independent, which is convenient for installation, disassembly and replacement. When a component fails, it can be quickly repaired or replaced to reduce equipment downtime.