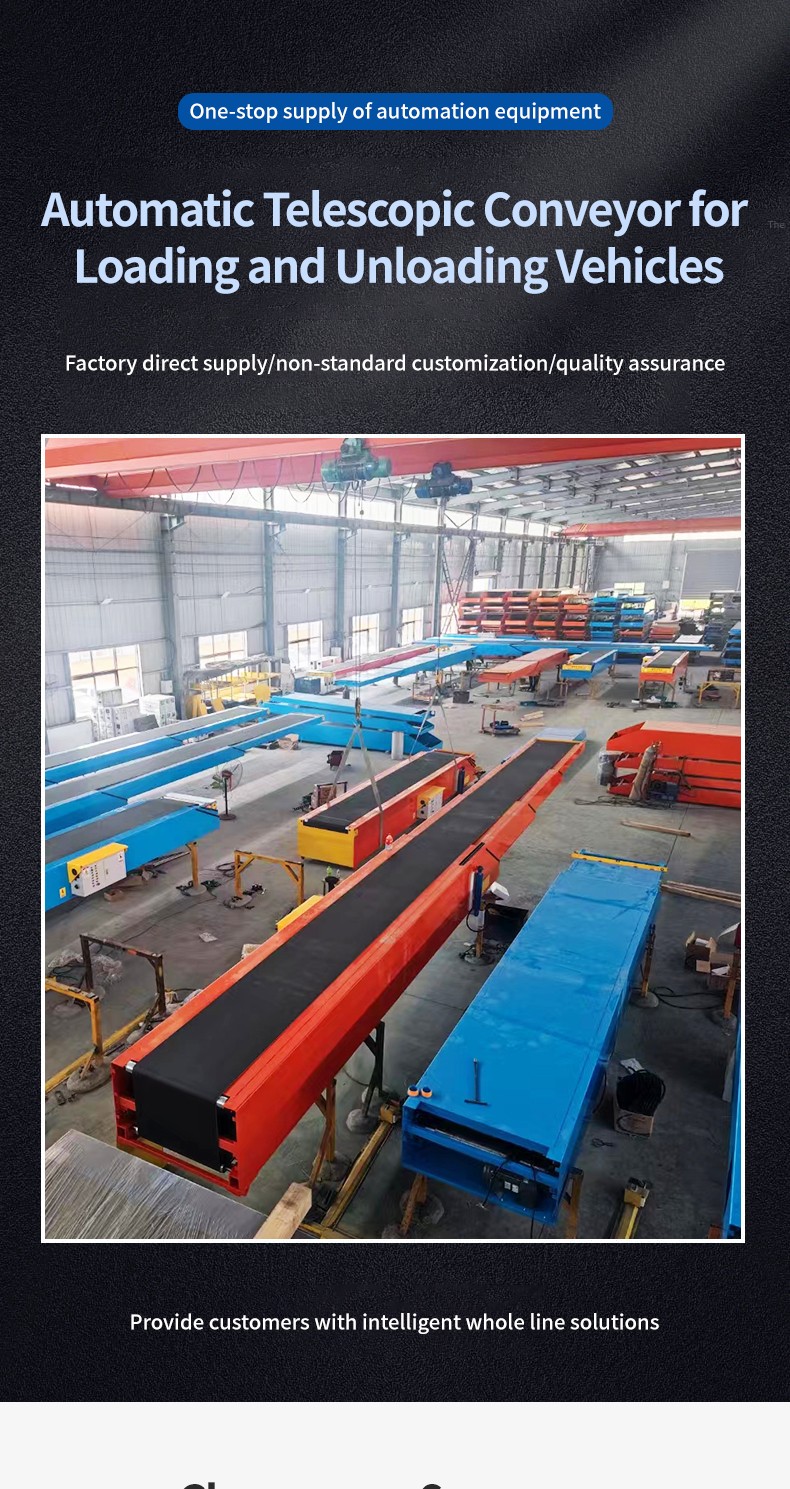

Automatic telescopic conveyor for loading and unloading vehicles

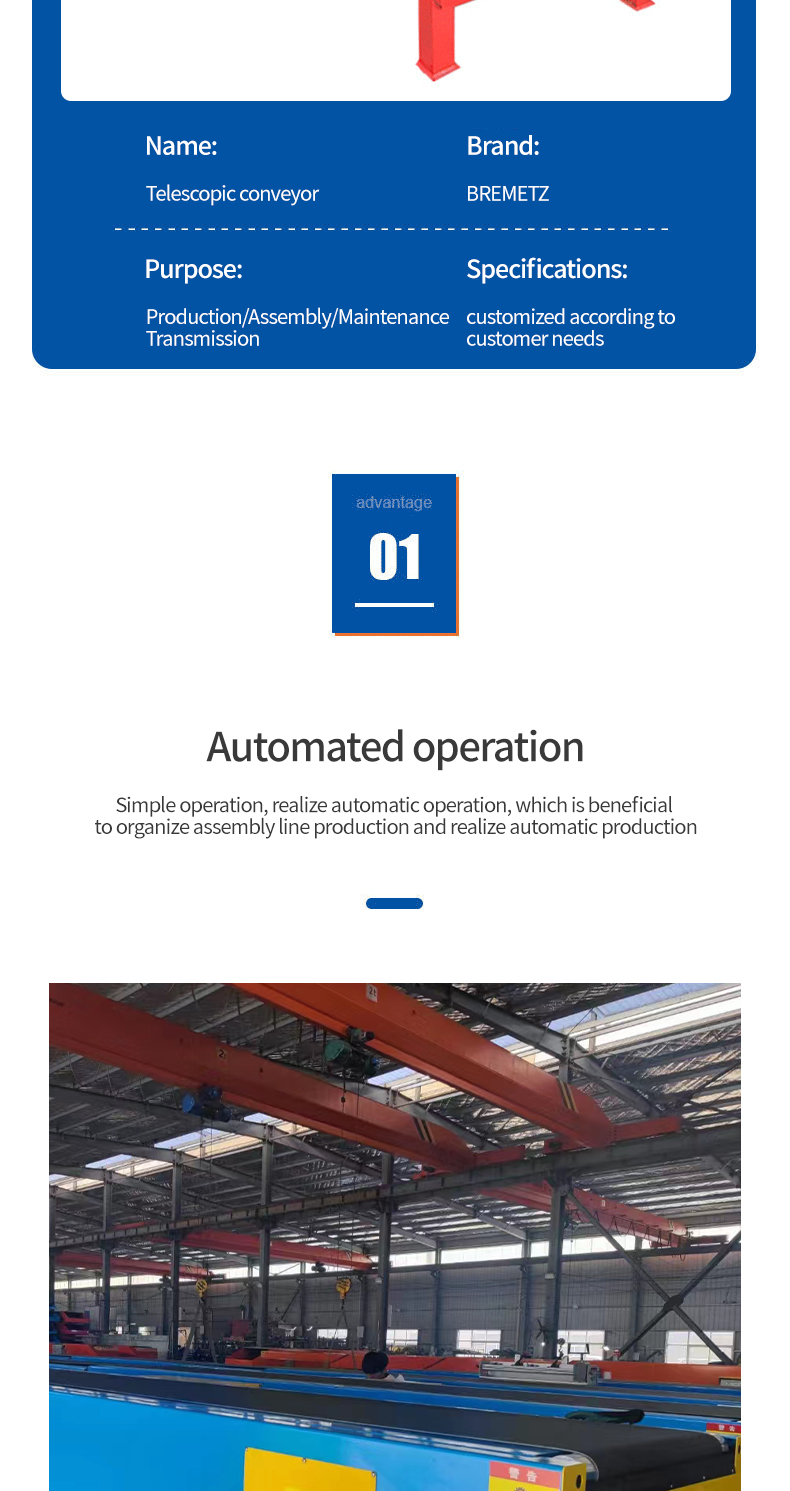

1. Rapid loading and unloading: It can significantly shorten the time for vehicle loading and unloading. Compared with traditional manual loading and unloading methods, the efficiency is greatly improved.

2. Continuous operation: It can realize long-term continuous and stable loading and unloading operations, reducing time waste caused by frequent starts and stops of equipment, and further improving work efficiency.

3. Telescopic adjustment: Its telescopic function can be flexibly adjusted according to the length and loading and unloading position requirements of different vehicles.

4. Angle adjustment: The conveying angle of some equipment is adjustable and can adapt to different loading and unloading scenarios and cargo stacking requirements.

5. Stable transportation: Use high-quality transmission components and control systems to ensure that the goods run smoothly during the transportation process, and there will be no dangerous situations such as slipping and toppling.

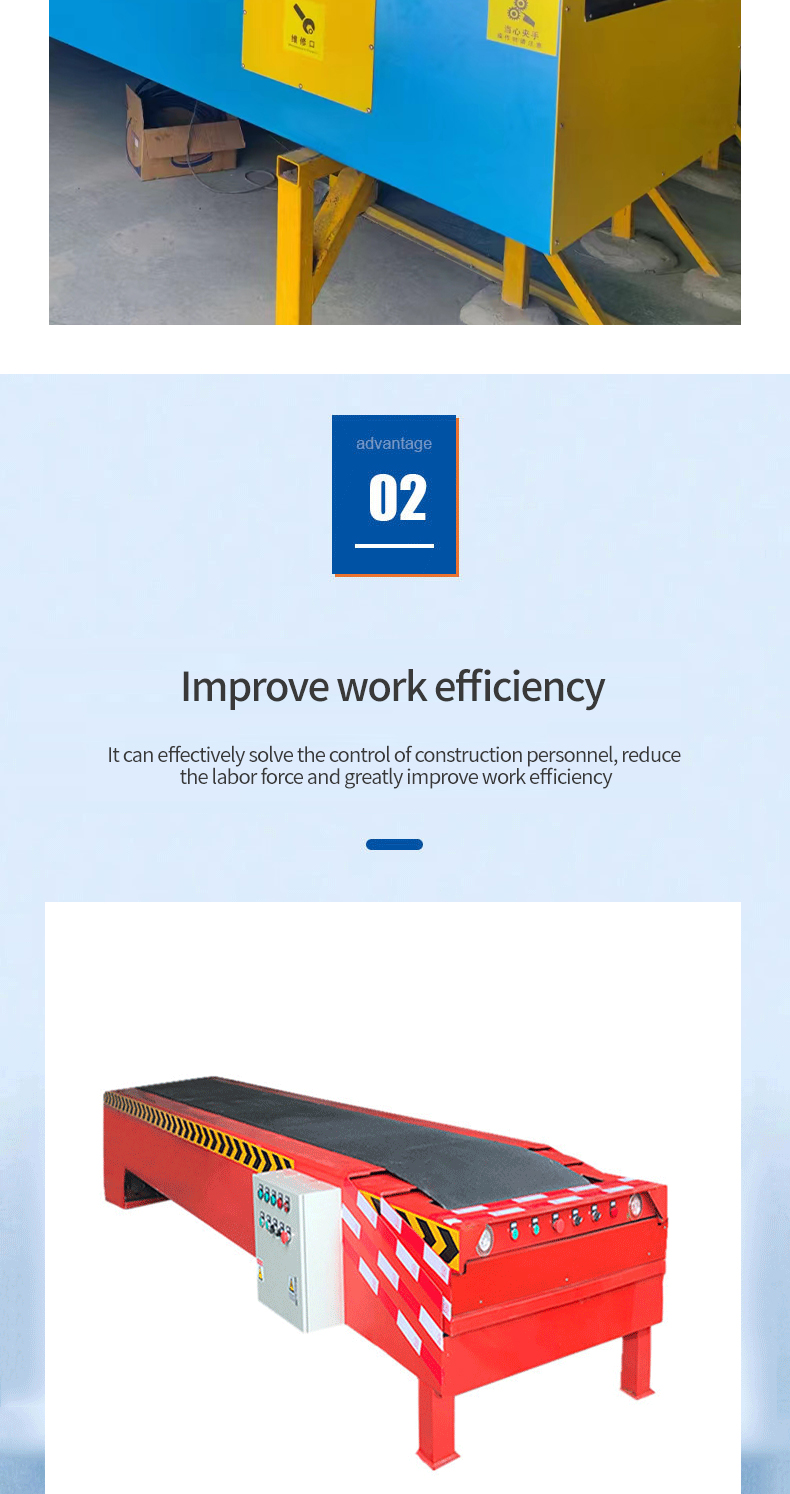

6. Sturdy and durable: The body frame of the equipment is usually made of high-strength steel, with a solid structure, able to withstand large loads and frequent telescopic movements, and has a long service life.

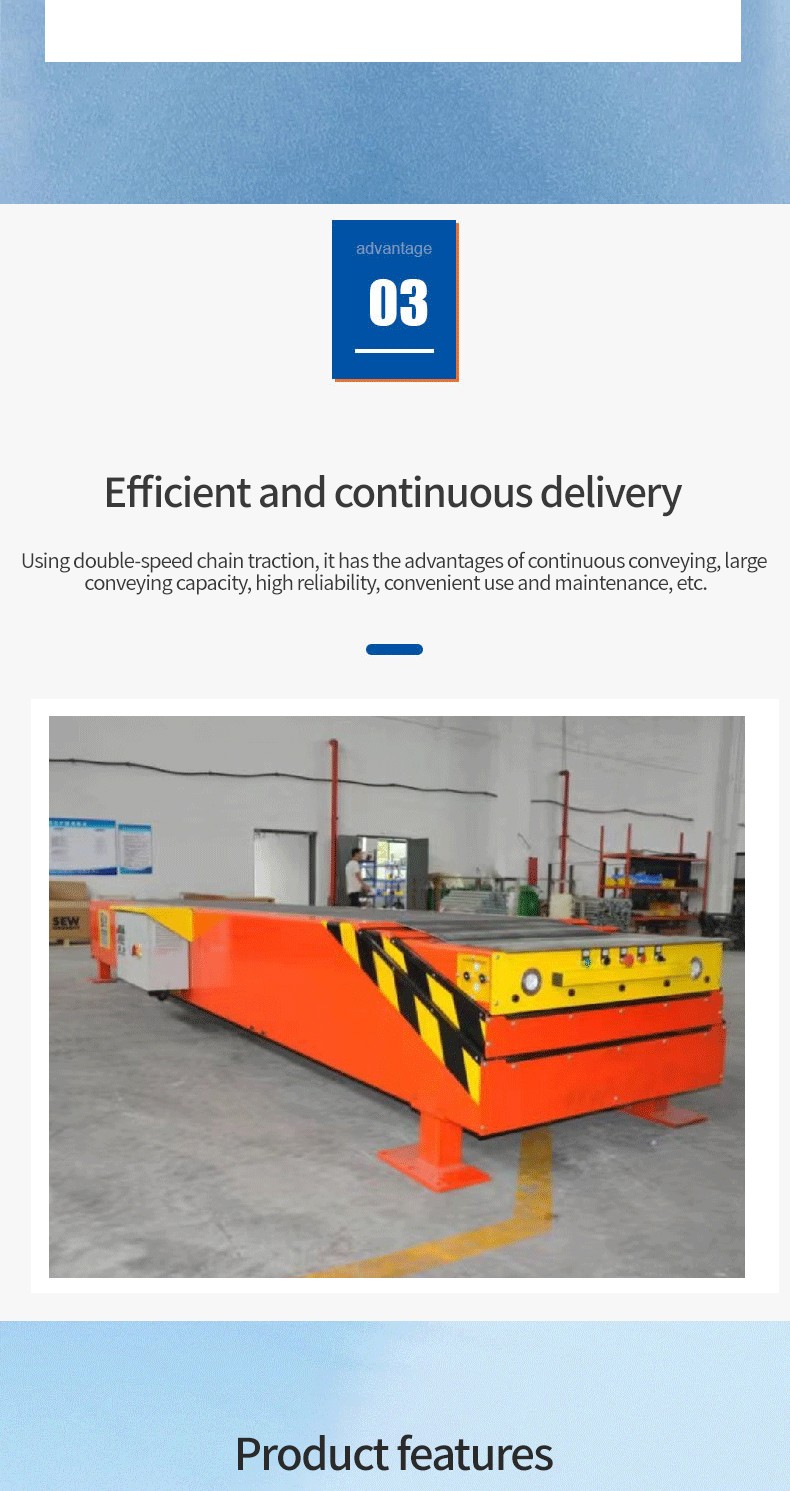

The equipment mainly drives the chain or belt transmission system through a motor, so that the telescopic part of the conveyor can be smoothly extended and retracted along the fixed track.

Sturdy body frame: It is welded with high-strength steel and has good rigidity and stability. It can withstand the pressure of heavy goods and the stress caused by frequent telescopic movements, ensuring that the equipment will not be deformed or damaged during long-term use.

Name:Telescopic conveyor

Brand:BREMETZ

Purpose:Production/Assembly/MaintenanceTransmission

Specifications:customized according to customer needs

It is composed of multiple nested telescopic arms, which are connected by precise guide rails and sliders, and can achieve smooth and stable telescopic movement with high-quality chain or belt drive. The telescopic length can be adjusted according to the type of vehicle and loading and unloading requirements. Generally, the maximum telescopic length can reach several meters, which can meet the loading and unloading requirements of most trucks.

Equipped with wear-resistant and tensile-resistant conveyor belts or chains, the surface is specially treated to increase friction and prevent the goods from slipping during transportation. The driving motor power of the conveying system is reasonably selected according to the load capacity of the equipment, which can provide sufficient power to ensure that the goods are transported at a stable speed. The conveying speed can usually be adjusted within a certain range to adapt to the loading and unloading rhythm of different goods.

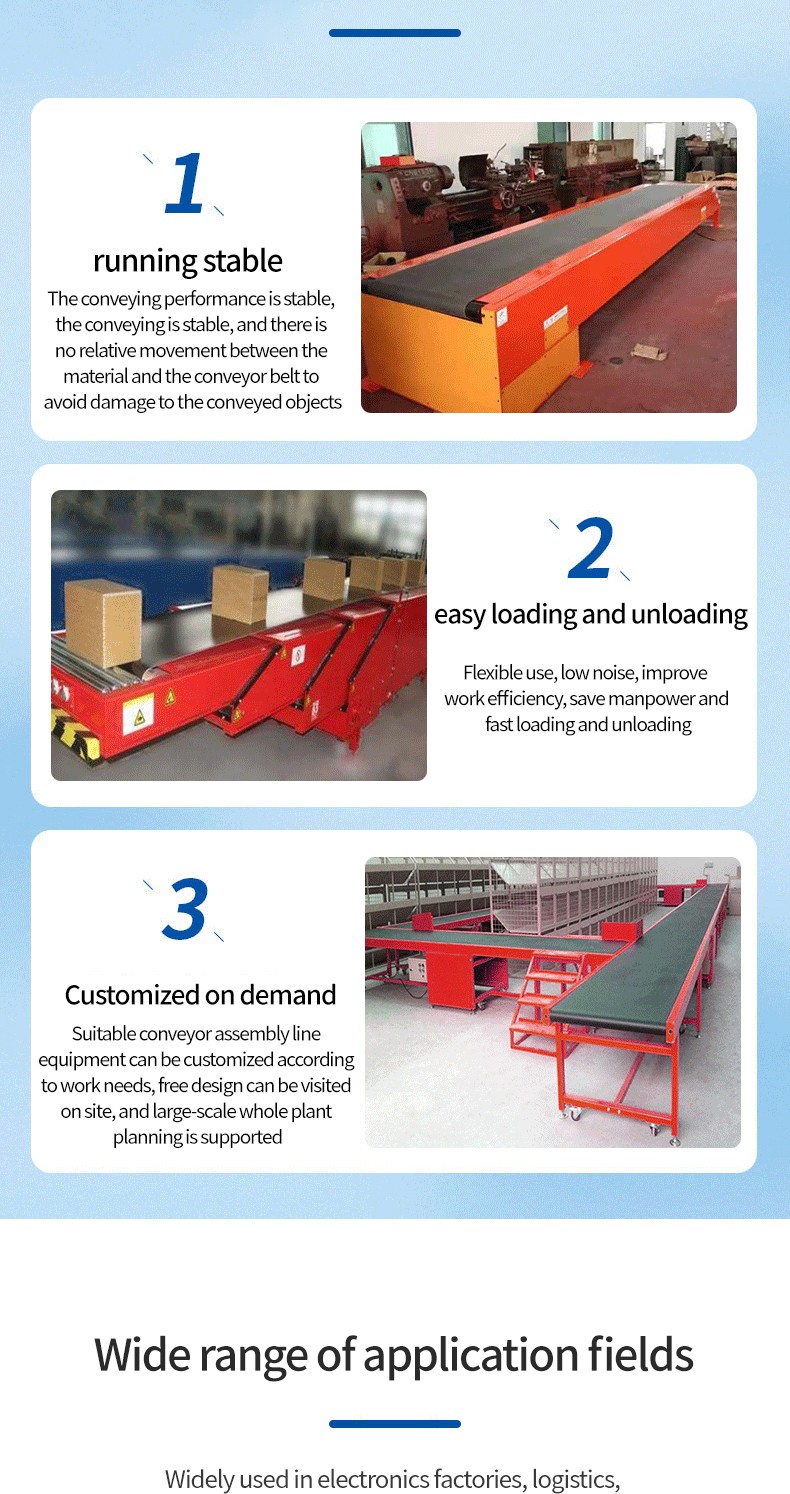

The conveying performance is stable, the conveying is stable, and there is no relative movement between the material and the conveyor belt to avoid damage to the conveyed objects.

Flexible use, low noise, improve work efficiency, save manpower and fast loading and unloading.

Suitable conveyor assembly line equipment can be customized according to work needs, free design can be visited on site, and large-scale whole plant planning is supported.

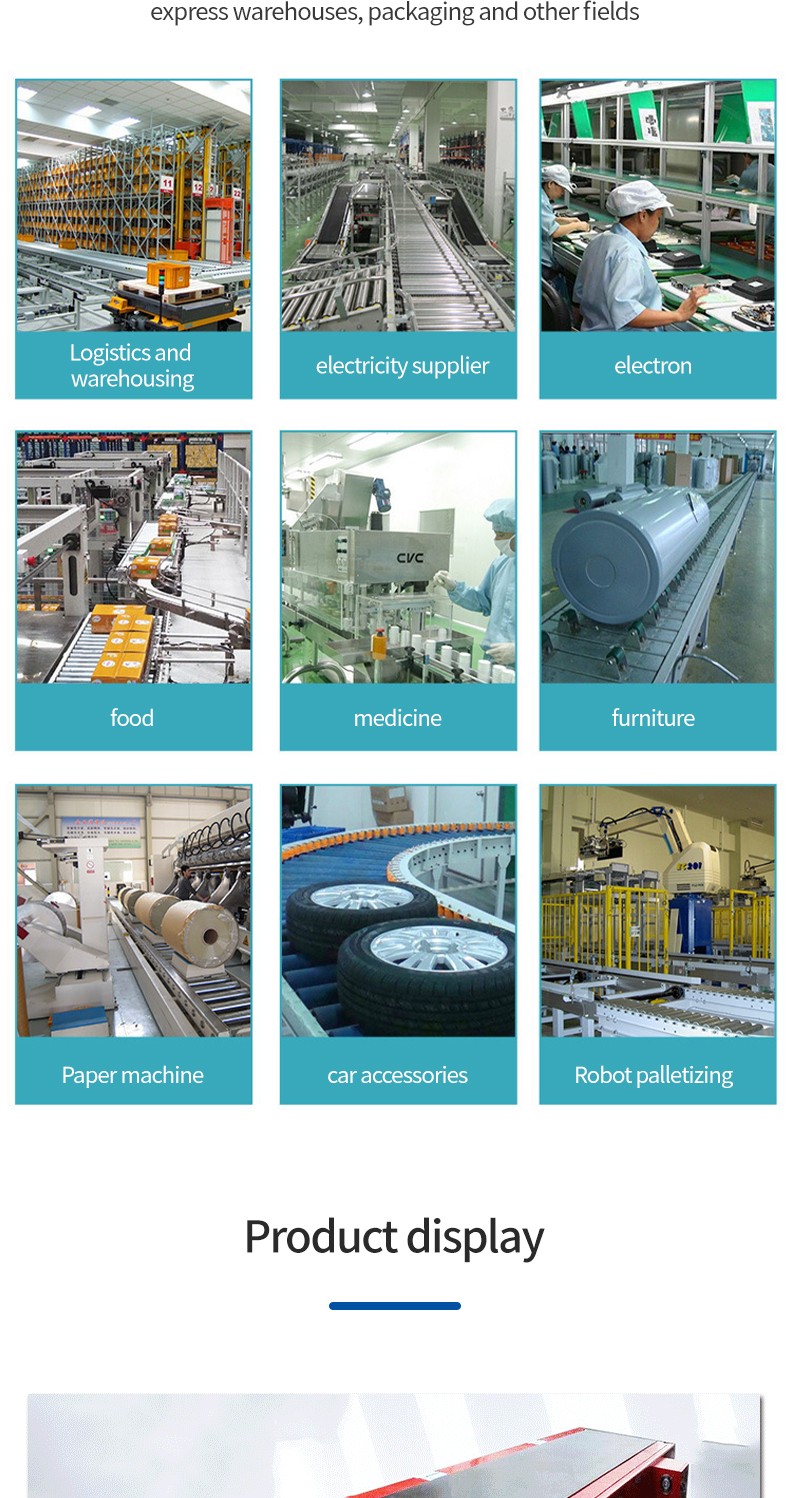

Scope of application:

Logistics and warehousing industry: In logistics centers, warehouses and other places, this conveyor can be used to load and unload various goods, such as cartons, parcels, and pallets.

Manufacturing: For production enterprises, it can be used for loading and unloading raw materials and shipping of finished products, and the goods can be loaded onto transport vehicles quickly and accurately.

Port terminal: In the cargo loading and unloading operations at the port, it can adapt to different types of ships and vehicles to achieve efficient transfer of goods.

Express delivery industry: Express delivery companies can use this equipment to quickly load and unload express parcels, improving the processing speed and delivery efficiency of express delivery.

Professional technicians will provide installation services to customers to ensure that the equipment is properly installed and debugged to achieve optimal operation. During the installation and debugging process, technicians will train the customer's operators to familiarize them with the equipment's operating methods and precautions.

With the continuous development of technology and changes in customer needs, manufacturers will launch equipment upgrade plans in a timely manner and provide equipment upgrade services to customers so that customers' equipment can always maintain advanced performance and high work efficiency.

Guided by customer satisfaction, we have formulated a series of after-sales service commitments, such as time-limited response and regular return visits, to ensure that customers can receive high-quality and efficient after-sales service experience.