Automatic small winding machine

1. High-speed winding: It can complete the winding and packaging of items at a faster speed, greatly improving packaging efficiency, and is suitable for large-scale production and packaging tasks.

2. Continuous operation: It can operate continuously and stably for a long time, reduce downtime, and further improve overall production efficiency.

3. Precise control: Through advanced control systems, such as PLC controllers, etc., it can accurately adjust the winding speed, number of turns, tension and other parameters.

4. Accurate positioning: During the winding process, it can accurately control the starting and ending positions of the packaging material to avoid packaging offset or misalignment and improve packaging accuracy.

5. Multiple packaging modes: It supports different winding methods and packaging modes, such as spiral winding, horizontal winding, etc. It can also flexibly adjust the packaging parameters according to different shapes, sizes and packaging requirements of items to achieve diversified packaging needs.

The automatic small wrapping machine mainly operates based on the principle of automation control technology and mechanical transmission. The items to be packaged are placed on the carrier. After the equipment is started, the motor drives the rotating platform to rotate steadily at the preset speed. At the same time, the supply device releases the film at the appropriate tension, speed and angle under the precise control of the control system, and wraps the film around the rotating items.

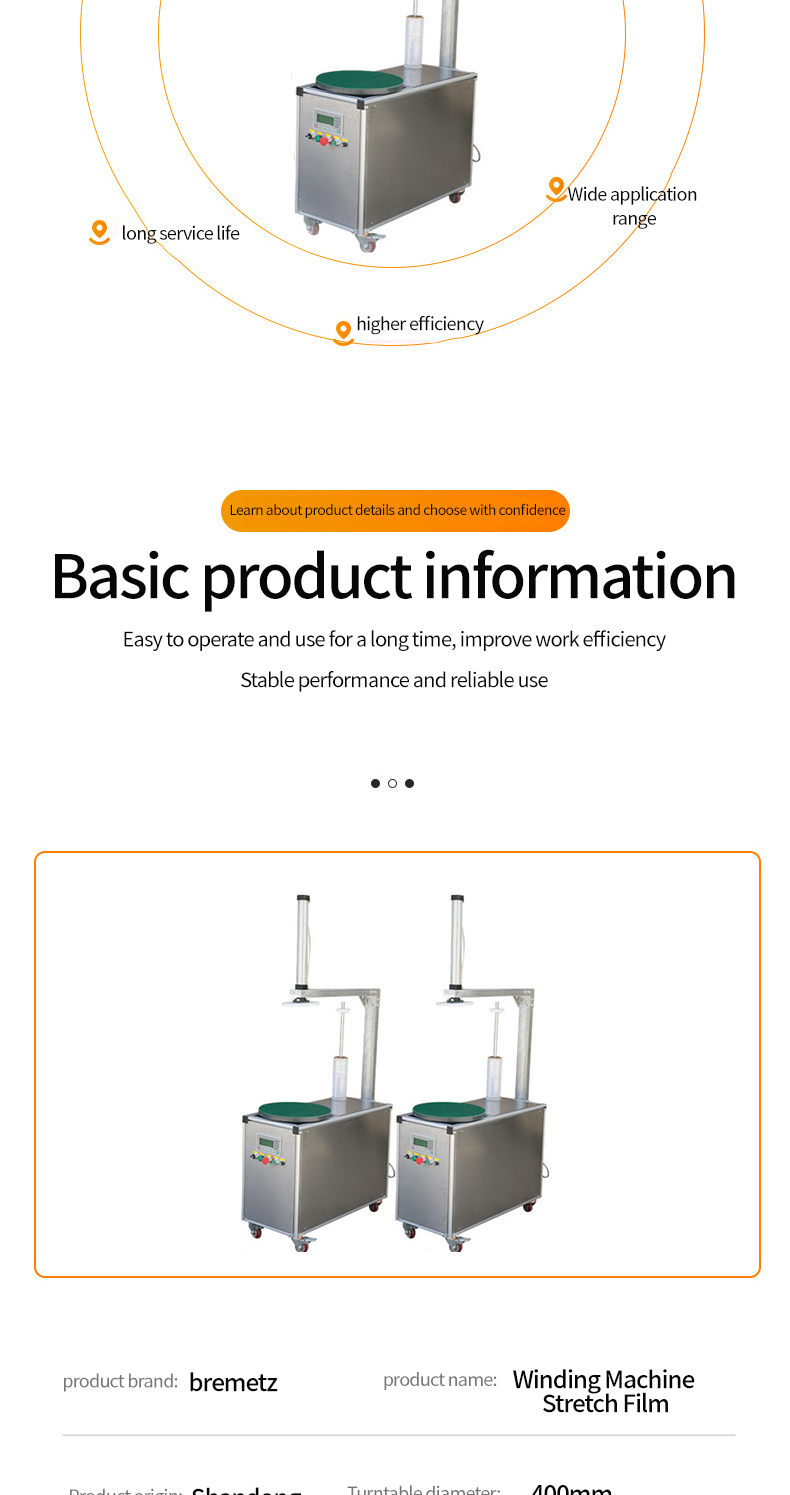

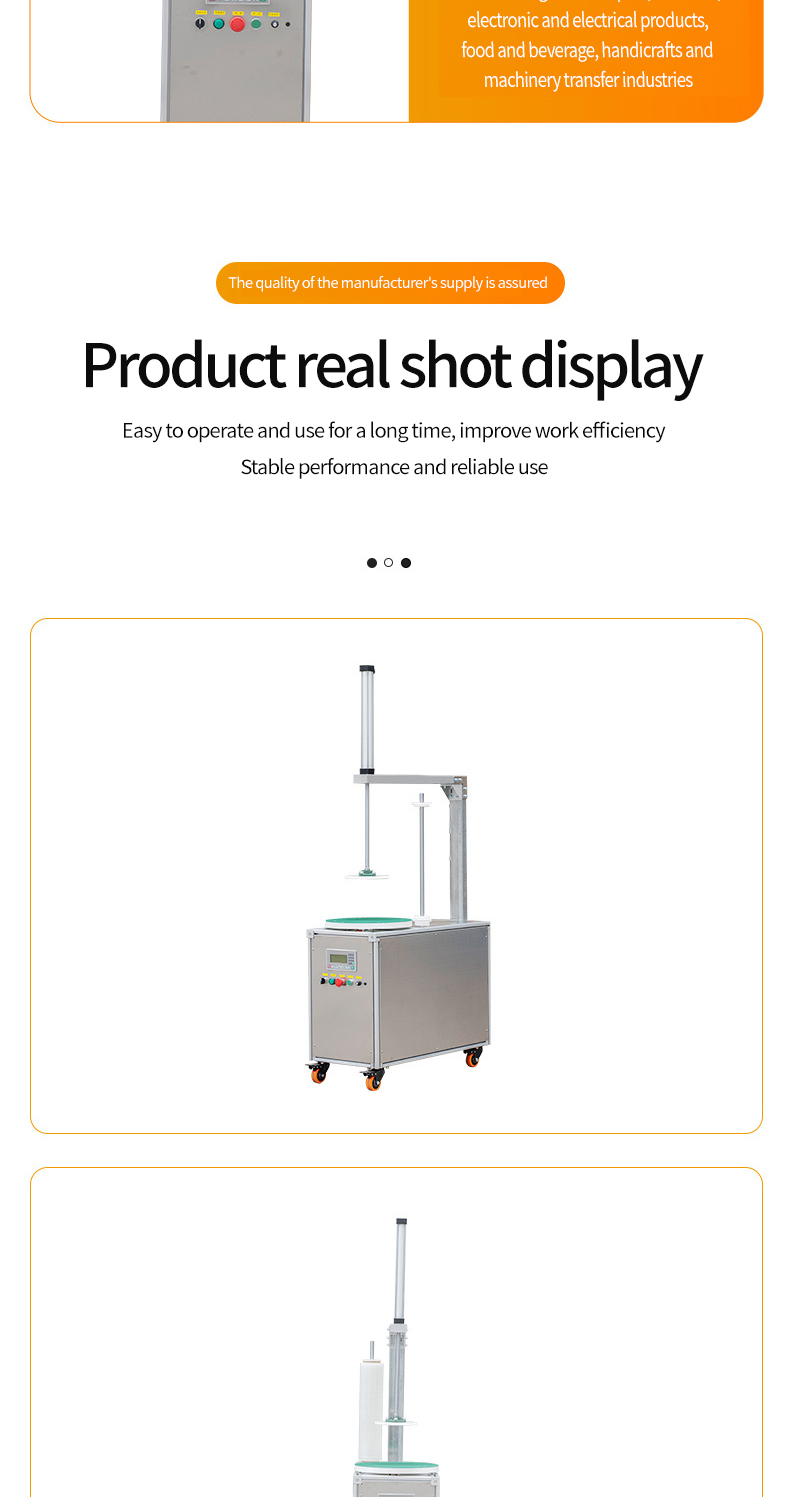

The overall structure is compact and occupies a small area, making it easy to place in various production workshops, warehouses or small commercial places. Its shell is usually made of a combination of sturdy and corrosion-resistant metal and engineering plastics, which not only ensures the mechanical strength and stability of the equipment, but also reduces the weight and improves the appearance to a certain extent.

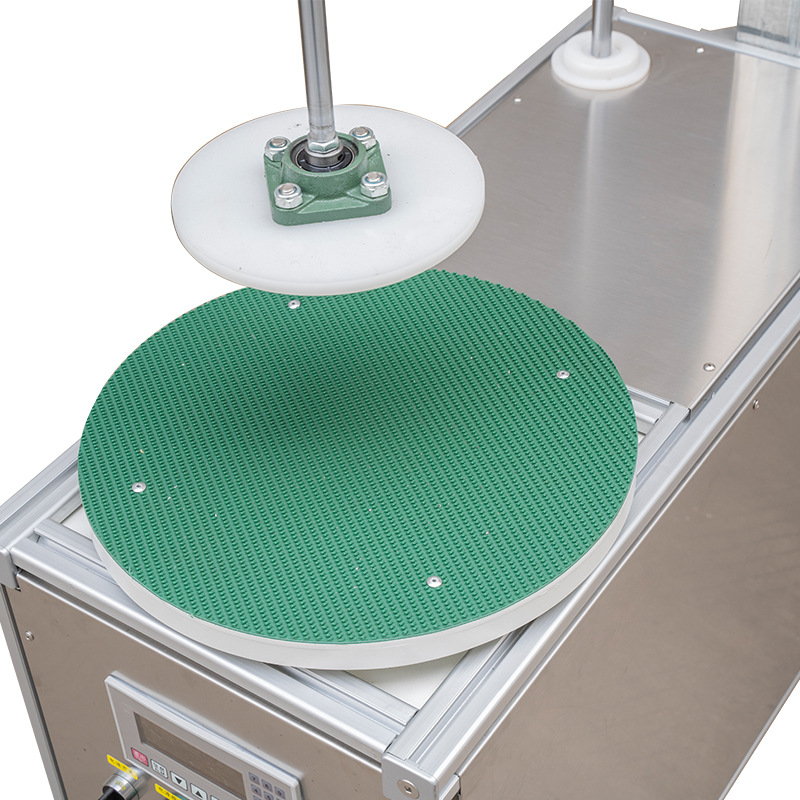

As a key component for placing small items, the rotating platform has high flatness and rotation accuracy. The surface is specially treated to increase friction and prevent the items from shifting during the winding process. The drive motor is energy-efficient. Through the precise reduction mechanism and transmission system, the platform can rotate at a stable and adjustable speed to meet the speed requirements of different items and packaging processes.

product brand: bremetz

product name: Winding Machine Stretch Film

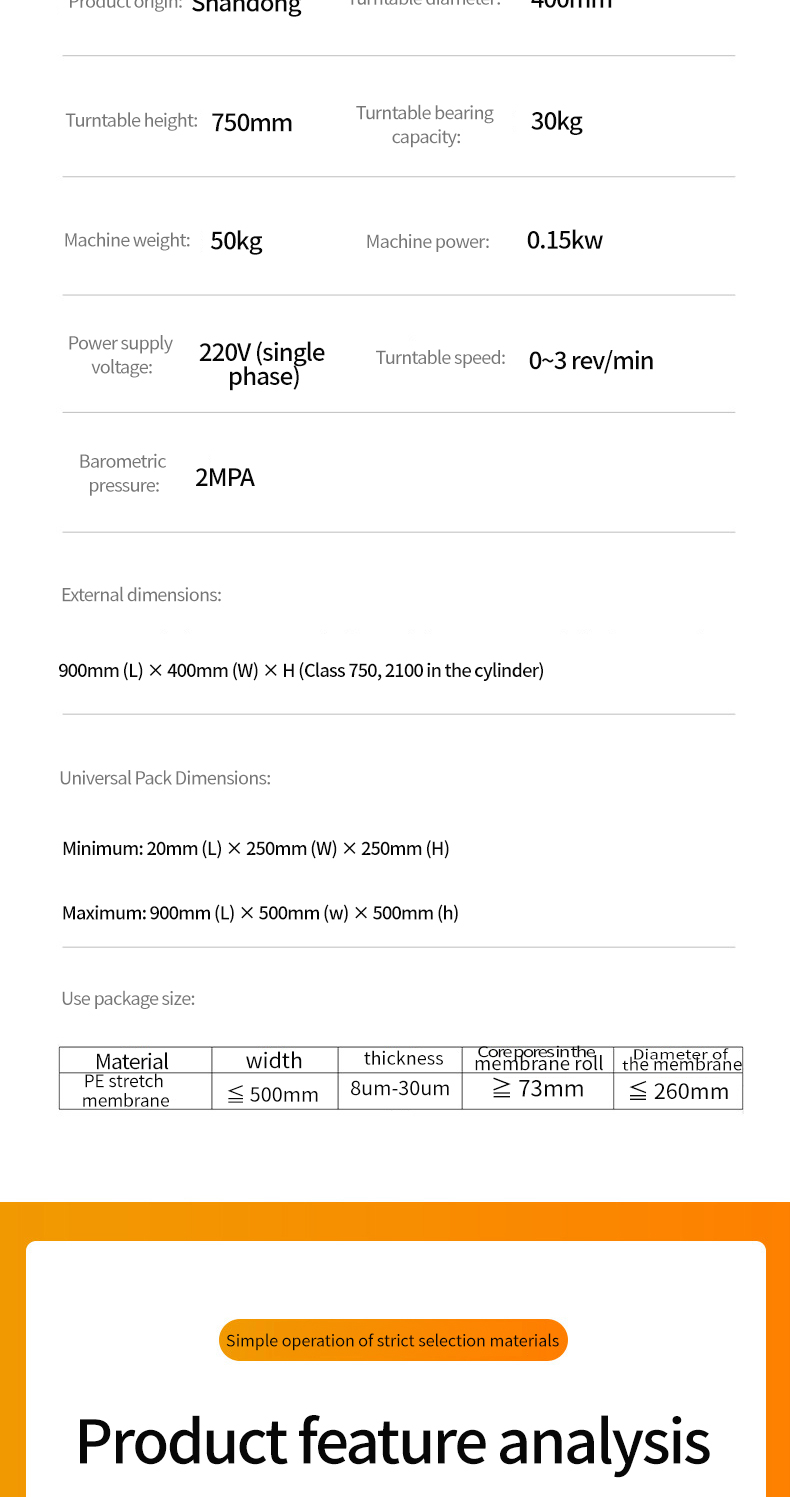

Turntable diameter. 400mm

Turntable height: 750mm

Turntable bearing capacity:30kg

Machine weight: 50kg

Machine power: 0.15kw

Power supply voltage:220V (single phase)

Turntable speed: 0~3 rev/min

Barometric pressure: 2MPA

External dimensions:900mm (L) x 400mm (W) × H (Class 750, 2100 in the cylinder)

Universal Pack Dimensions:Minimum: 20mm (L) × 250mm (W) × 250mm (H)Maximum: 900mm (L) × 500mm (w) x 500mm (h)

Wide applicability: It can be applied to the packaging of small items of various shapes, sizes and materials, whether it is a regular cylinder, a cuboid, or an irregular shaped item, as long as it is within the packaging size range of the equipment, it can achieve a good packaging effect. It is widely used in many industries such as electronic appliances, hardware machinery, stationery gifts, food and medicine, cosmetics, etc., to meet the diverse needs of different industries for small product packaging.

Convenient operation and maintenance: The intelligent control system makes the operation of the equipment extremely simple. Operators only need simple training to master the operation of the equipment. Through the operation interface, they can easily set various packaging parameters and start the equipment. The structure of the equipment is reasonably designed, the parts are easy to disassemble and replace, and the daily cleaning, lubrication and maintenance are simple and easy.

Significant cost savings: On the one hand, automated operations reduce reliance on manual packaging, reduce labor costs, and avoid problems such as packaging material waste and product damage caused by human operating errors; on the other hand, precise film Tension control and reasonable winding methods can make full use of packaging films.

Provide installation and commissioning services to ensure the normal operation of the equipment. Train operators to master the key points of operation and maintenance. There is a warranty period during which faulty parts are repaired or replaced free of charge. Set up an after-sales hotline to quickly respond to repair requests and arrange technicians to come to the door for repair. Supply original spare parts to ensure timely repairs.

Regularly visit customers and collect feedback to improve services and products. Provide equipment upgrade services based on demand to improve performance and functions, enhance customer experience and competitiveness.