Electric pressure top winding machine

1. Prevent goods from scattering: The electric top-pressing device can firmly press the goods during the rotation of the turntable, effectively preventing the lighter and unstable goods from scattering after palletizing.

2. Adapt to various shapes of goods: The top-pressing device can be adjusted according to the shape and size of the goods, and can flexibly adapt to the packaging needs of different types of goods.

3. Easy to use: Usually a simple and intuitive operating interface such as a touch screen is used, with PLC control and a humanized operation panel design.

4. Automatic sensing and positioning: It has functions such as automatic sensing of cargo height and photoelectric shielding, and can automatically adjust the winding parameters according to the actual situation of the goods.

5. Tight and neat winding: Through a precise control system and a stable mechanical structure, the winding film can be tightly and evenly wound on the surface of the goods.

6. Customizable winding method: The winding method and number of times can be flexibly designed according to the characteristics and packaging requirements of different goods.

The electric pressure top winding machine is designed for efficient and accurate coil winding operations. When working, it uses a precise electric drive system to drive the winding shaft to rotate steadily. Through the cleverly designed pressure top mechanism, it applies moderate and uniform pressure to the winding during the winding process to ensure that the wires are tightly and neatly arranged.

The frame is welded with high-strength steel and is finely polished and rust-proofed. It has excellent earthquake resistance and deformation resistance, laying a solid foundation for the operation of internal precision components. Even under high-speed winding conditions, it can maintain the overall stability of the equipment and ensure winding accuracy.

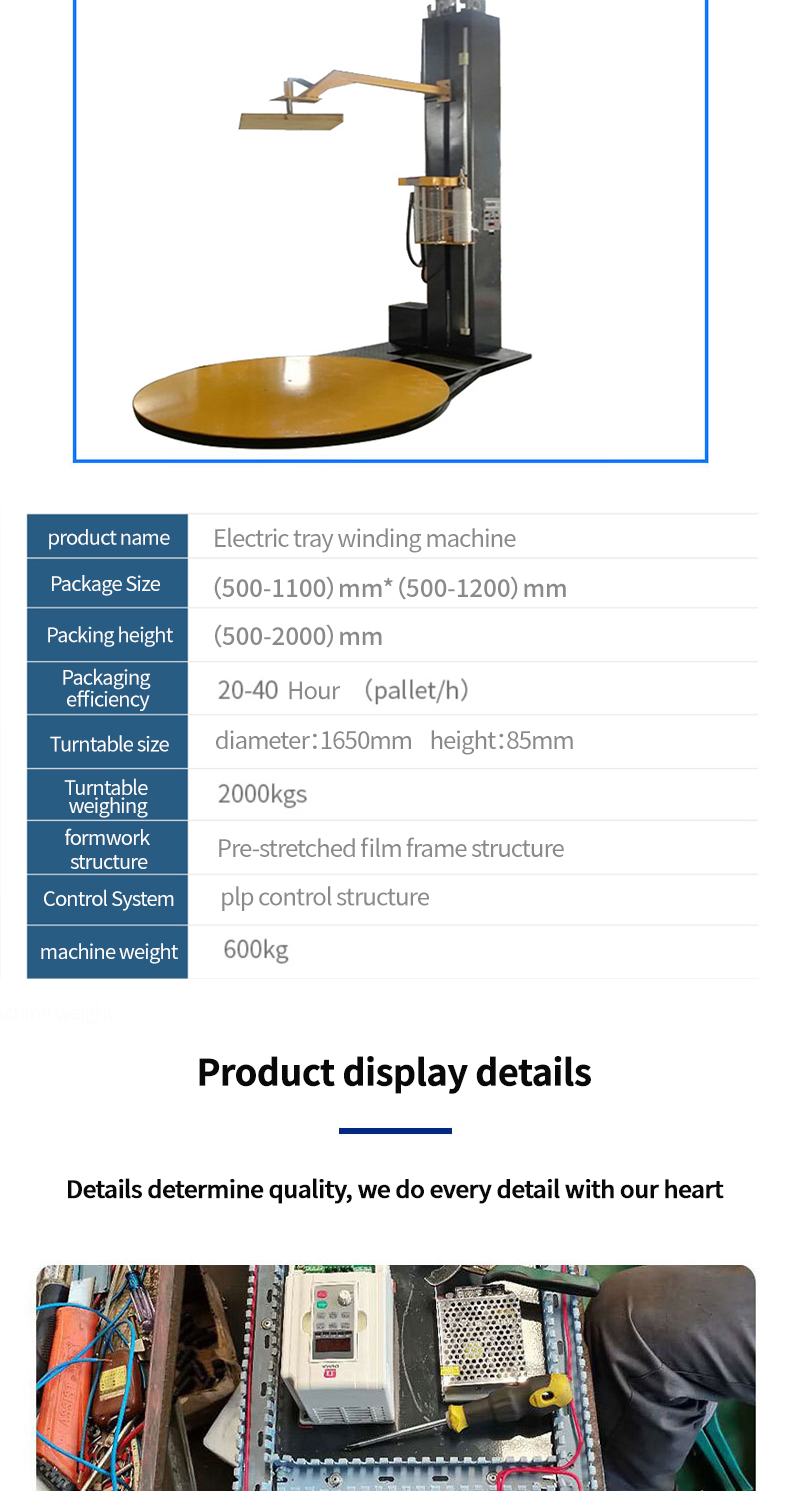

product name:Electric tray winding machine

Package Size:(500-1100) mm* (500-1200) mm

Packing height:(500-2000) mm

Packaging efficiency:20-40 Hour (pallet/h)

Turntable size:diameter: 1650mm height:85mm

Turntable weighing:2000kgs

formwork structure:Pre-stretched film frame structure

Control System:plp control structure

machine weight:600kg

The winding shaft has been dynamically balanced and rotates smoothly with high concentricity. It is equipped with a high-precision screw-type wire arrangement mechanism, which can achieve uniform winding of the wire in an orderly manner according to preset parameters such as wire diameter, number of turns, and wire arrangement spacing. The wire arrangement error is controlled within a very small range, which meets the requirements of electronic components for coil consistency.

It is applicable to a wide range of scenarios: in the field of electronic manufacturing, it is used for winding various types of inductors and transformer coils inside electronic products such as mobile phones and computers; in the electrical equipment industry, it assists in the production of small motors, relays, mutual inductors and other products; in the laboratories of scientific research institutes, it meets the high-precision winding requirements of new electromagnetic device sample trial production.

The after-sales team regularly visits customers, collects usage feedback, provides customers with equipment software upgrade services, optimizes control algorithms, and expands functional modules. In order to solve complex technical problems, the team organizes expert teams to conduct special seminars to help customers innovate their production processes.