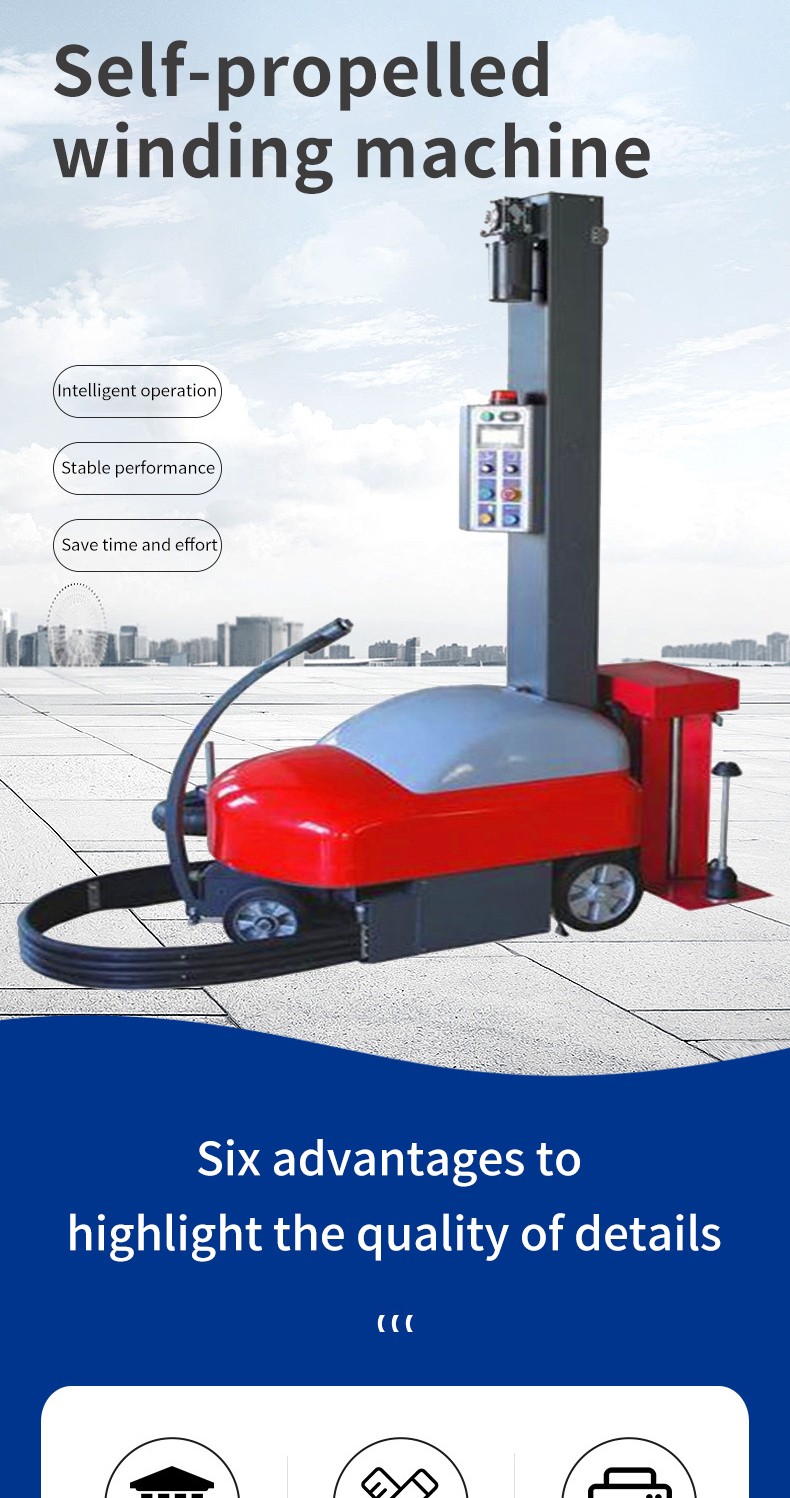

Self-propelled winding machine

1. No external traction equipment is required, it can move in the working area by itself and can quickly reach different working positions.

2. It can be easily moved to the storage area when not in use, saving valuable production space, especially suitable for production environments with limited space.

3. Equipped with an efficient power system and advanced winding mechanism, it can perform winding operations at a faster speed, greatly improving production efficiency.

4. It can run continuously for a long time without frequent shutdowns, further improving overall work efficiency

5. The advanced tension control system can accurately control the tension of the material during the winding process to ensure that the winding material is evenly and tightly distributed on the reel.

6. It has a precise position control function, which can accurately control the moving position of the winding head during the winding process to achieve precise wiring and winding layer control.

The self-propelled wrapping machine is an advanced wrapping packaging equipment. It integrates automatic control technology, mechanical transmission technology and precise sensing technology. It has the ability to move autonomously and can flexibly wrap various products or materials efficiently and accurately without external traction or track restrictions.

Product name:Self-propelled winding machine

Place of production:Shandong

Product specification:Various specifications can be customized

Product characteristics:Simple operation saves time and effort

Distribution mode:Logistics or express delivery can be selected according to the actual situation of the order

Without external traction or tracks, it can move freely in the workplace, easily cope with complex working environments and layouts, and can quickly reach different packaging stations, greatly improving the efficiency and adaptability of the equipment.

With fast winding speed and stable operation performance, it can complete the task of winding and packaging a large number of items in a short time. At the same time, its high degree of automation reduces manual intervention.

The use of advanced control systems and high-precision sensors can accurately control various parameters in the winding process, such as the tension of the winding film, the number of winding layers, the winding speed, and the moving position of the equipment, ensuring the stable and reliable quality of the winding packaging.

The human-machine interface is simple and intuitive. Operators can easily set various packaging parameters through the touch screen. The operation process of the equipment is simple and easy to understand, and can be mastered without professional technical training.

It can adapt to the wrapping and packaging needs of items of different shapes, sizes and materials. Whether it is cylindrical, square or irregular shaped items, efficient wrapping and packaging can be achieved by adjusting the parameters of the equipment and replacing some accessories.

Equipped with complete safety protection devices, such as emergency stop buttons, guardrails, light curtain sensors, etc. During the operation of the equipment, once an abnormal situation is detected or people are close to the dangerous area, the equipment can be stopped immediately to ensure the personal safety of the operator and the normal operation of the equipment.