Fully automatic electromagnetic induction aluminum foil sealing machine

1. Fast and reliable sealing: The electromagnetic induction principle is used to generate heat instantly, so that the aluminum foil and the container mouth can be quickly sealed.

2. Wide applicability: Compatible with a variety of containers and materials: The aluminum foil can be sealed on containers of different shapes and materials by simply adjusting the equipment parameters.

3. Accurate parameter control: Equipped with an advanced control system, it can accurately adjust the power, time, temperature and other parameters of electromagnetic induction.

4. Automatic detection and feedback: The built-in intelligent detection system can monitor the sealing quality in real time, such as the integrity and sealing of the aluminum foil seal.

5. Easy maintenance: The structural design is reasonable, and each component is easy to disassemble, clean and replace.

6. Environmental protection and energy-saving design: Low energy consumption during the working process, in line with the modern environmental protection and energy-saving production concept.

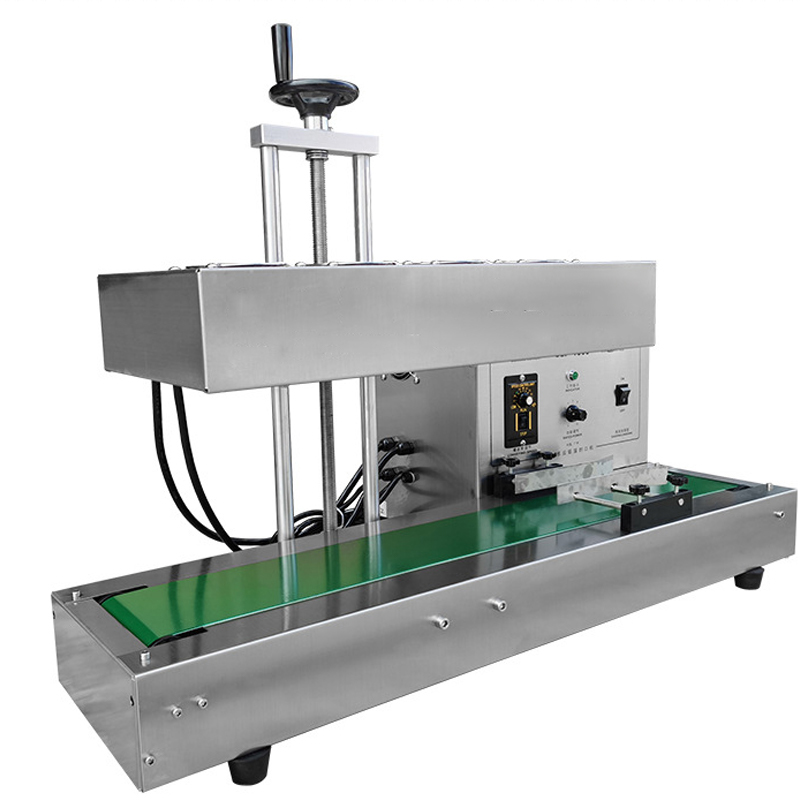

The fully automatic electromagnetic induction aluminum foil sealing machine adopts a compact and reasonable structural design, a scientific overall layout, and smooth coordination of various components to achieve efficient and stable sealing operations. Its outer shell is usually made of sturdy and durable metal materials, which can not only effectively protect the internal precision components, but also has good heat dissipation performance.

Efficient and automated production: It realizes fully automated and continuous operation from container conveying, aluminum foil supply to sealing and cooling, with fast sealing speed and high efficiency, which greatly reduces labor costs and labor intensity, and improves the production efficiency and economic benefits of the enterprise.

Precise sealing quality control: With precise electromagnetic induction system and advanced control system, key parameters such as sealing temperature, time and pressure can be precisely controlled to ensure uniform sealing quality between aluminum foil and container mouth. It can effectively prevent product leakage, oxidation and contamination, and ensure the stability and reliability of product quality.

Product name:Electromagnetic induction sealing machine

Sealing diameter:15-60/35-85/50-120(mm)

Sealing speed:20-50 bottles/min

Sealing height;20-280mm

Product material:Stainless steel body

Conveying speed:0–12.5 m/min

Motor power:P220V/2200W

Overall dimension:90*45-50cm

Wide applicability and flexibility: It can adapt to a variety of container shapes, materials and aluminum foil specifications, and can achieve sealing operations for different products through simple parameter adjustments. Whether it is round, square or special-shaped containers, plastic, glass or ceramic materials, and aluminum foils of different thicknesses and widths, good sealing effects can be achieved on this equipment.

We have established a complete rapid response maintenance mechanism. Once your equipment fails, just call our after-sales service hotline, the customer service staff will record the failure information in detail and feedback the situation to the professional maintenance engineer as soon as possible.

With the continuous advancement of science and technology, we will continue to pay attention to the development of industry technology and upgrade the technology of the fully automatic electromagnetic induction aluminum foil sealing machine.