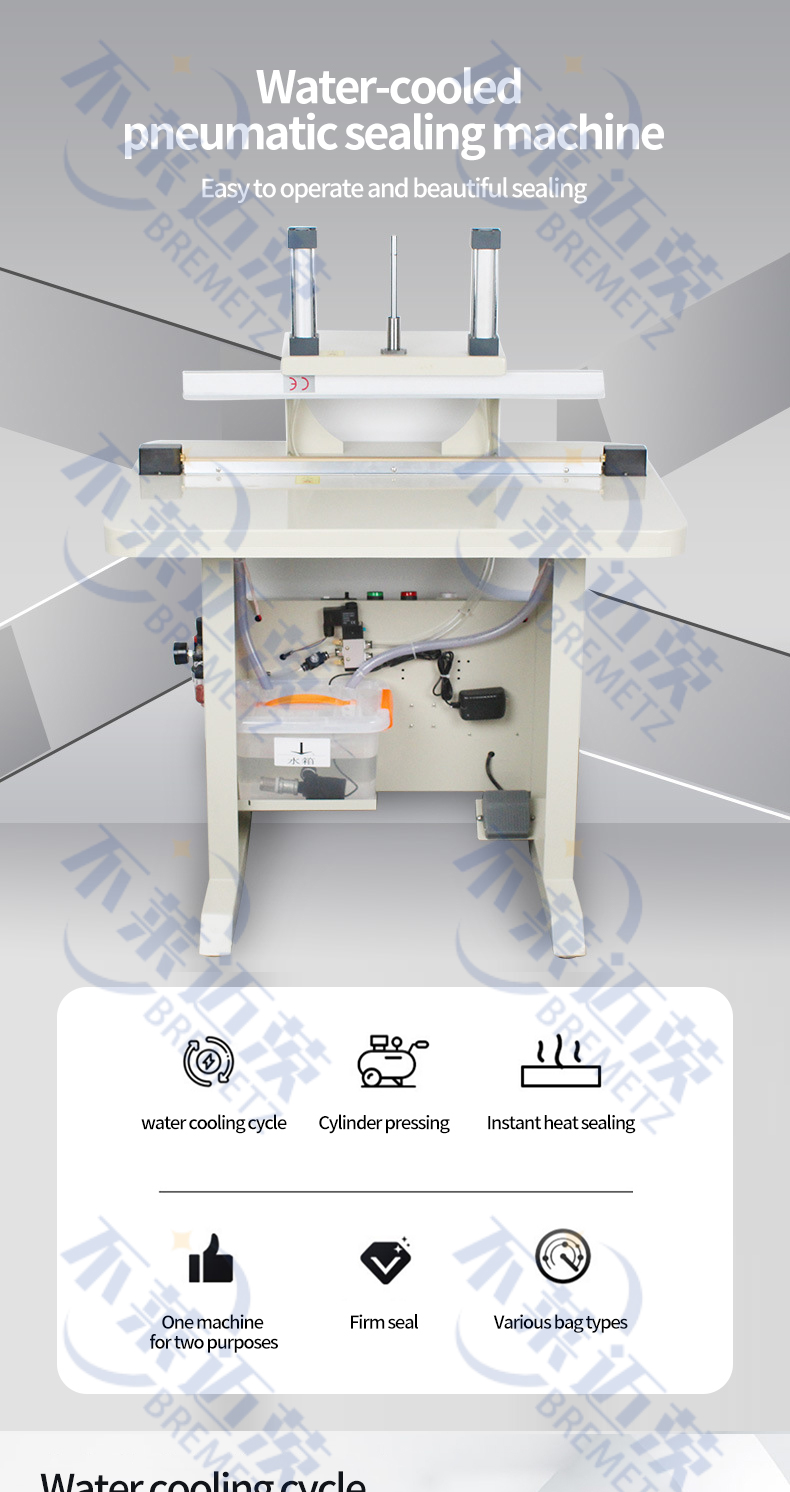

Water-cooled pneumatic sealing machine

1. Rapid cooling and sealing: A large amount of heat will be generated during the sealing process. The water cooling system can quickly take away this heat. Compared with sealing machines without cooling systems or air cooling systems, the cooling time can be greatly shortened.

2. Stable sealing effect: Stable cooling can prevent deformation and burning of the sealing part due to overheating, ensuring that the quality of each sealing is stable and reliable.

3. High sealing quality: Pneumatic control is adopted, and the pressure provided by the cylinder is uniform and stable, which can make the sealing material fit tightly and the sealing is firm and tight. And the sealing pressure can be adjusted according to different packaging materials and thicknesses to meet the sealing needs of various types of products.

4. Smooth and beautiful sealing: The pneumatic vertical downward pressure method makes the sealing process more stable, the sealing part is flat and smooth, and there will be no wrinkles, skewness, etc., which improves the packaging appearance quality of the product.

5. High degree of automation: The pressing time can be preset, and the machine automatically completes the pressing, sealing, and popping up actions. The operator only needs to place the items to be sealed in the appropriate position and start the switch.

6. Can handle items of different sizes: Whether it is a small packaging bag or a larger package, it can be effectively sealed. For some special shapes or sizes of packaging, it can also be adapted by adjusting the relevant parts of the machine.

The water-cooled pneumatic sealing machine is an advanced packaging and sealing equipment that combines water-cooling technology and pneumatic principles. It is widely used in packaging and sealing operations of various products. It can complete the sealing task efficiently and stably, ensure the sealing and integrity of the packaging, and meet the strict requirements of different industries for product packaging quality.

Adapt to a variety of packaging materials: Whether it is common plastic films such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), or multi-layer composite packaging materials, they can achieve good sealing effects on water-cooled pneumatic sealing machines. This wide range of material adaptability makes it widely used in the packaging field of many industries such as food, medicine, daily chemicals, and electronics.

Can handle packages of different sizes: The design of the sealing mold and the structure of the equipment make it adaptable to the sealing needs of packaging bags or packaging containers of various sizes. It can flexibly respond to both small sample packaging and large industrial packaging products.

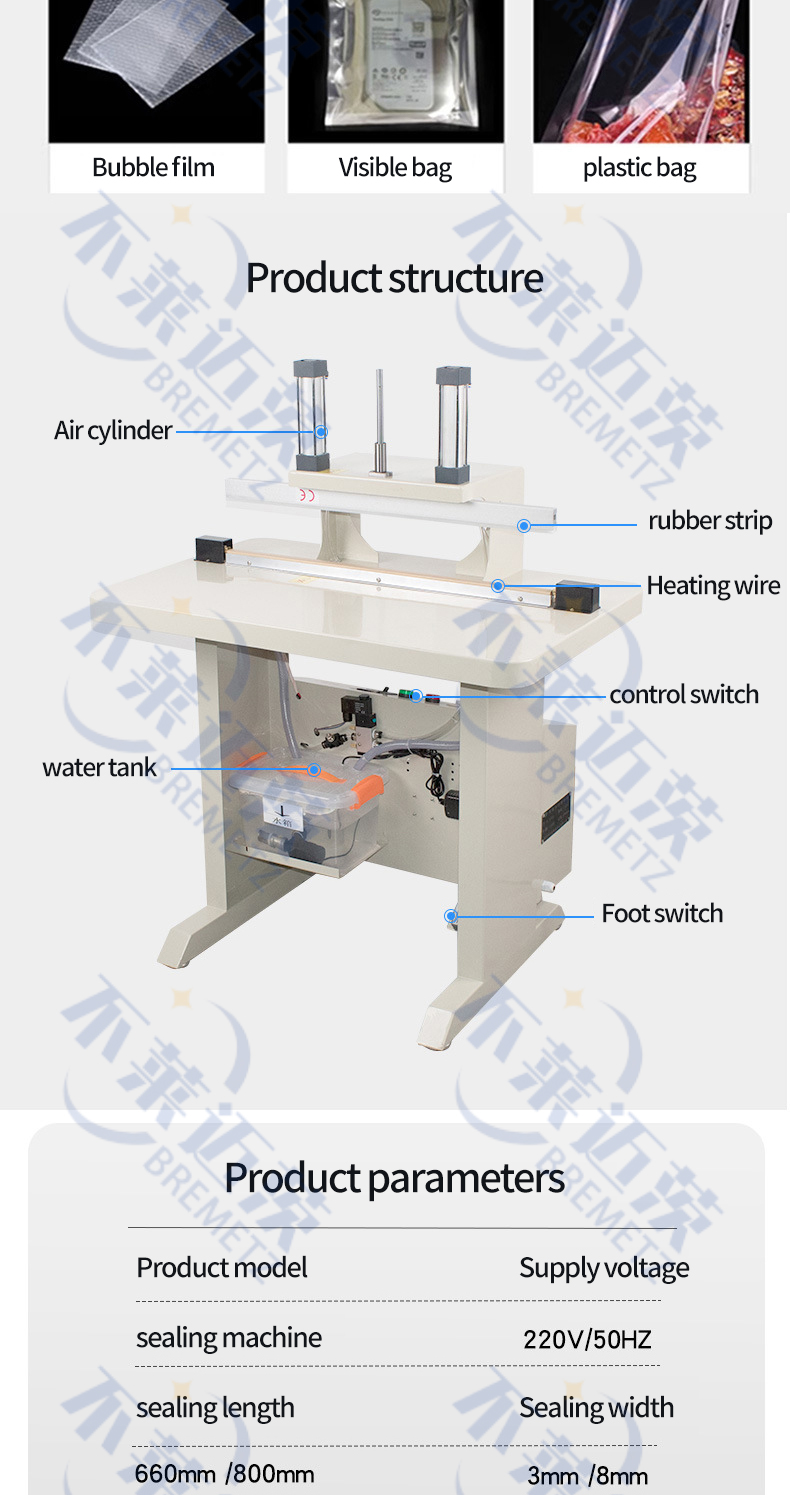

product parameters:

product model:sealing machine

Supply voltage:220V/50HZ

sealing length:660mm/800mm

Sealing width:3mm/8mm

Voltage power:1200w/1500w

Machine weight:30kg/50kg

Wide pressure adjustment range: The pneumatic system allows users to flexibly adjust the sealing pressure within a wide range according to different packaging materials and packaging thicknesses. This adjustability ensures the best sealing effect under various packaging conditions.

Precise temperature control: The heating element is equipped with an advanced temperature control system, which can accurately set and control the sealing temperature. The temperature sensor monitors the temperature changes in real time and feeds back to the control system, so that the sealing temperature is always kept near the set value, avoiding the influence of too high or too low temperature on the sealing quality.

The company provides a professional installation team to install the water-cooled pneumatic sealing machine to the location specified by the user. During the installation process, strictly follow the installation instructions and safety specifications of the equipment to ensure that all parts of the equipment are installed correctly and firmly, and the electrical connections are safe and reliable.