Fully automatic boxing and packaging machine

1. Improve production efficiency: It can realize high-speed continuous packaging operations, complete a large number of packaging tasks in a short time, and greatly improve the overall production efficiency.

2. Accurate product quantity and arrangement: The use of advanced sensors and control systems can accurately control the number of products and the arrangement of products in the box to ensure that the number of products in each box is consistent and neatly arranged.

3. Strong specification adaptability: The size of the box can be automatically adjusted to meet the packaging needs of products of different specifications.

4. Stable operation: The use of high-quality materials and advanced manufacturing processes has a solid equipment structure and stable performance.

5. Good packaging consistency: Through precise measurement and control systems, ensure that the product weight, volume and other indicators of each packaging unit meet the standard requirements.

6. Production data recording: It can record various data in the packaging process in real time, such as production quantity, packaging specifications, fault information, etc.

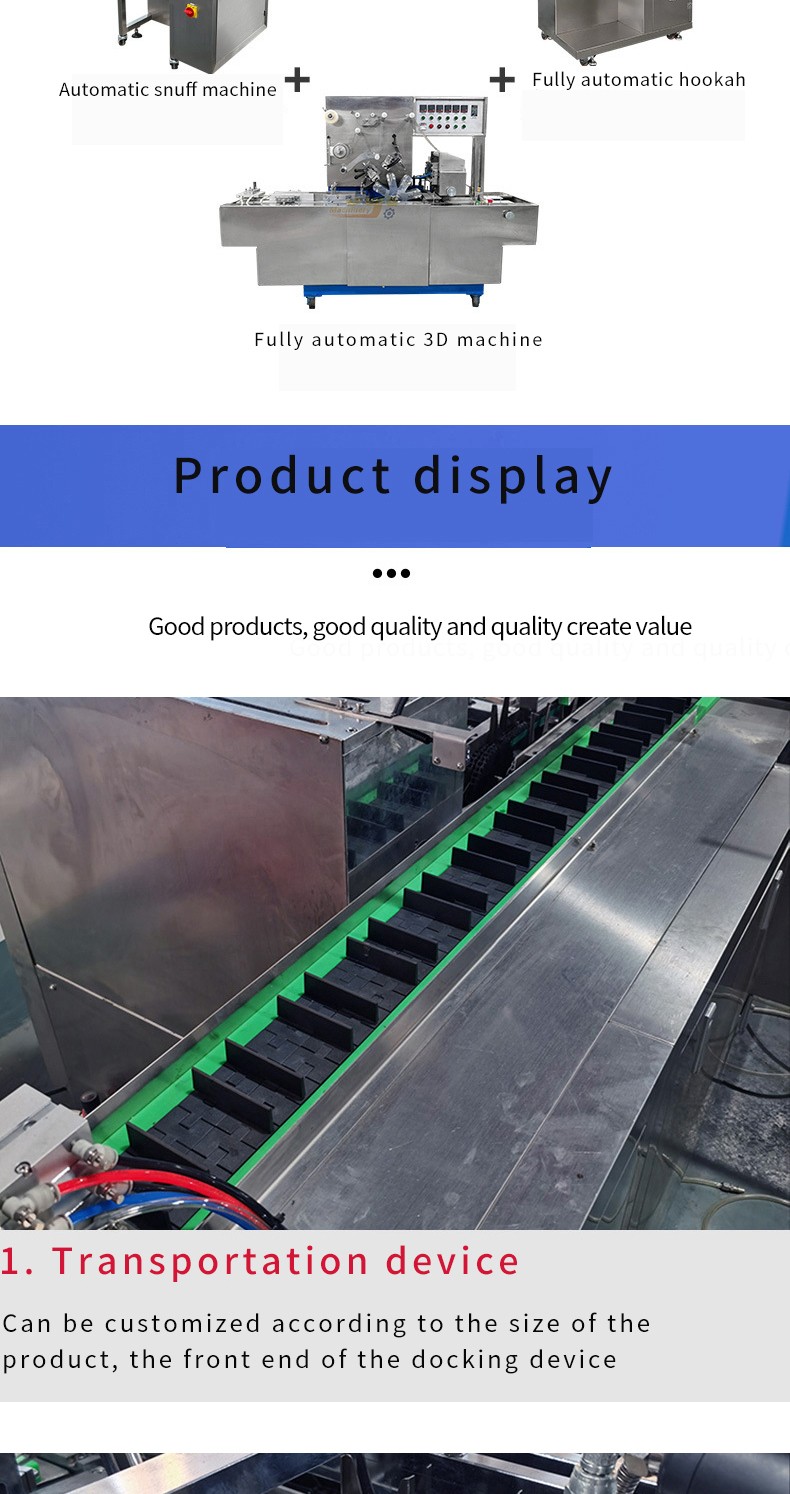

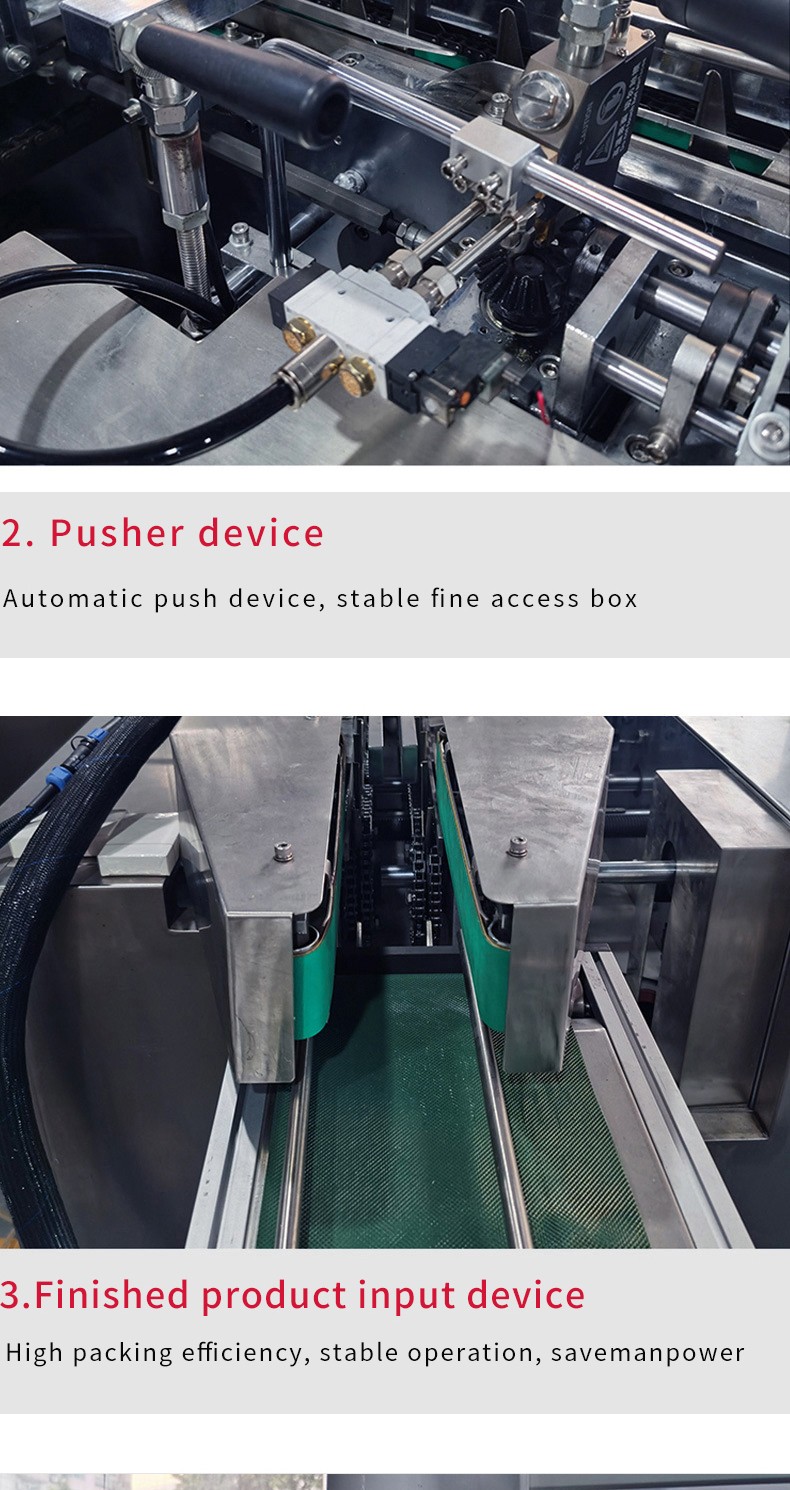

The fully automatic boxing and packaging machine integrates a full set of processes including material transportation, sorting and arrangement, precise boxing, sealing and bundling, to achieve a seamless and continuous operation from product input to finished packaged product output.

Accurate packing: Relying on high-precision visual recognition and positioning systems, combined with fine-tuning of the mechanical structure, after in-depth "learning" of product size and shape, ensure that the products are neatly arranged in the carton and the quantity is accurate.

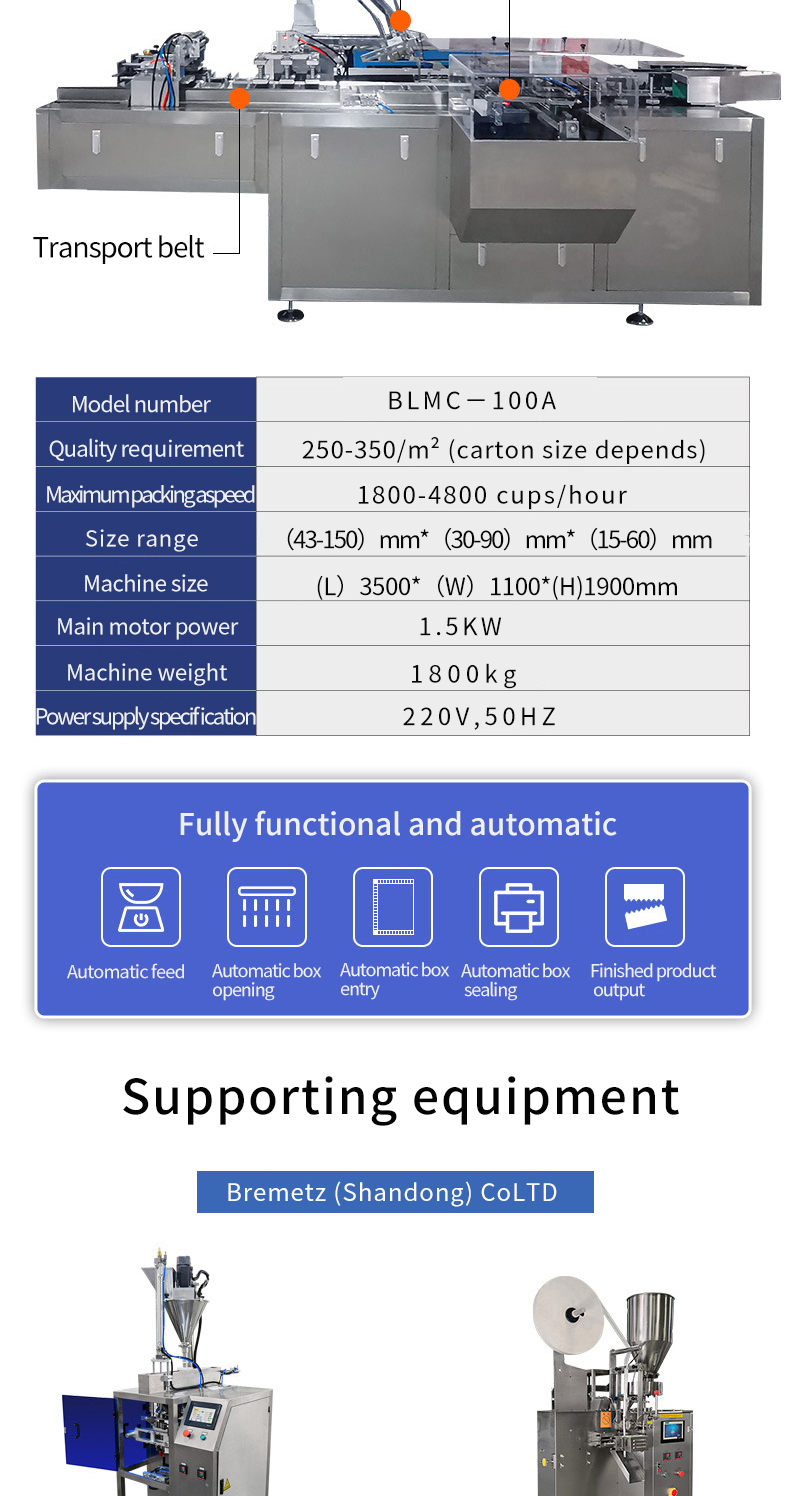

Model number:BLMC-100A

Quality requirement:250-350/m² (carton size depends)

Maximum packing aspeed:1800-4800 cups/hour

Size range:(43-150) mm* (30-90) mm* (15-60) mm

Machine size:(L) 3500* (W) 1100*(H)1900mm

Main motor power:1.5KW

Machine weight:1800kg

Power supply specification:220V,50HZ

Firm and beautiful sealing: Using multiple sealing technologies such as constant temperature heat sealing and tape pasting, the sealing strength and temperature are intelligently controlled according to the material and size of the carton. In the corrugated carton packaging commonly used in e-commerce logistics, the sealing tape is pasted tightly and smoothly, and the folded edges are tightly closed.

Stable mechanical structure: The machine body is made of high-quality stainless steel and high-strength aluminum alloy, and is formed by precision welding and CNC processing. The key transmission parts are specially treated by quenching and grinding, which are wear-resistant and damage-resistant.

Fault redundancy protection: Built-in multiple fault self-checking and early warning modules can immediately detect abnormalities such as electrical system short circuit, insufficient air pressure, and mechanical jam. Some key components are equipped with redundant backup, such as dual power supplies and spare conveyor belt motors. In case of sudden faults, seamless switching can be achieved to maintain the operation of the production line and ensure production continuity.

Wide product universality: from light daily chemical items, food and snacks to medium-sized electronic appliances and heavier industrial parts, we flexibly configure suction cups, grippers, push plates and other gripping and conveying components according to the physical characteristics of the products, and change the packaging strategy. For example, toy building blocks are gently transported and packed with suction cups, while automotive parts are firmly positioned and packaged with robotic arms.

Maintenance is hassle-free and labor-saving: The modular design makes it easy to disassemble and replace parts. The equipment has reserved cleaning and maintenance windows, and prompts for replacement of wearing parts, lubrication and maintenance on a periodic basis. The manufacturer also provides 24/7 after-sales response throughout the year, covering remote assistance and on-site repairs to ensure stable operation of the equipment throughout its life cycle.