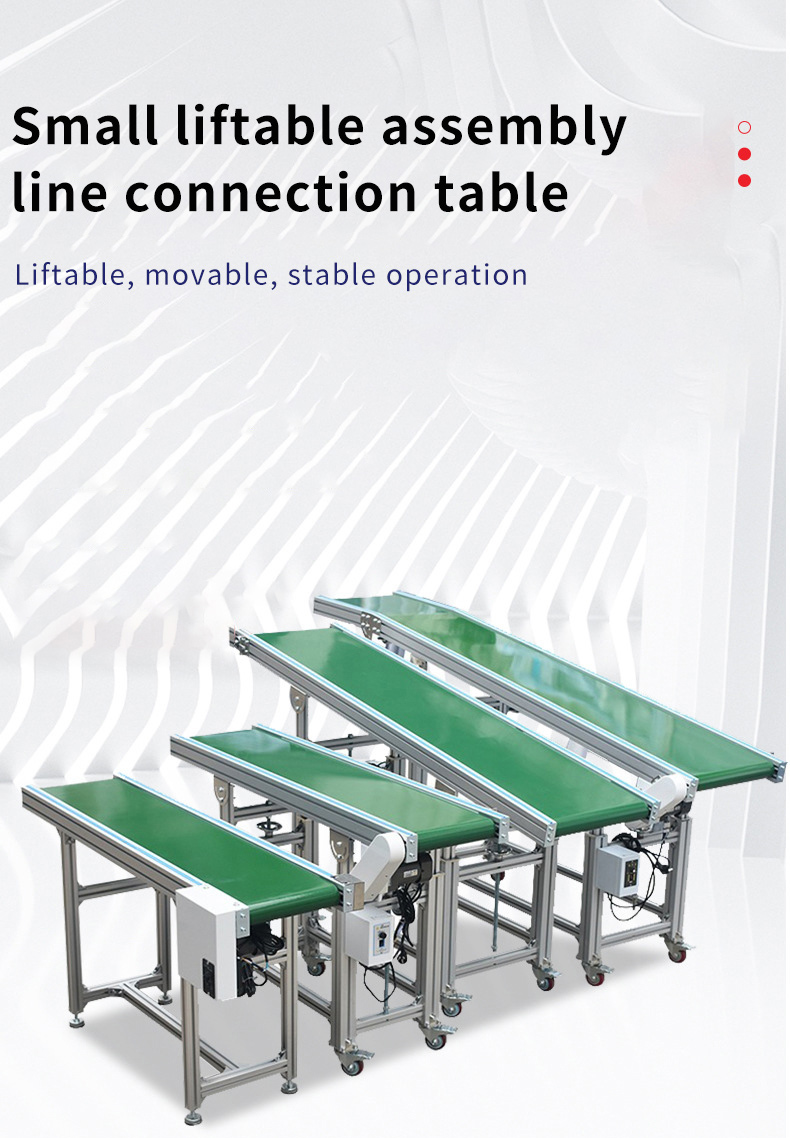

Fully automatic belt conveyor

1. No need for a lot of manual material handling, the material conveying task can be completed automatically.

2. Equipped with advanced control system, it can accurately control parameters such as conveying speed, start and stop time.

3. It can carry and convey a large amount of materials. According to different specifications and models, its conveying capacity can meet the needs of various production scales.

4. It has a fast running speed and can transport materials from one location to another in a short time, greatly shortening the transportation time of materials.

5. It adopts high-quality materials and advanced manufacturing technology, with a sturdy and durable structure, which can remain stable during long-term operation.

Fully automatic belt conveyor is a kind of equipment that relies on the continuous movement of the conveyor belt to realize the automatic transportation of materials. It integrates advanced mechanical manufacturing technology and automatic control technology, and can accurately and efficiently complete the transportation tasks of various materials.

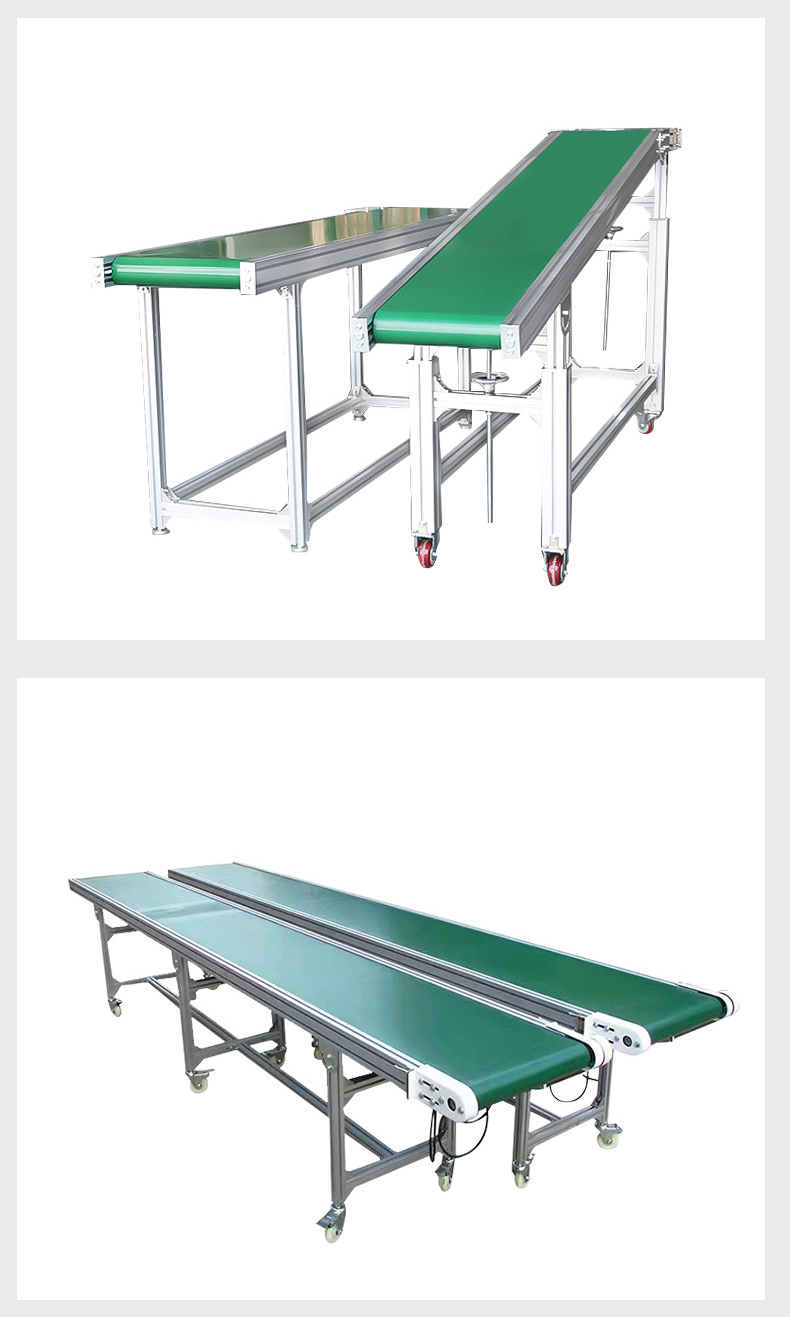

Realize automatic loading, conveying and unloading of materials, reduce manual intervention, improve production efficiency and reduce labor intensity.

The conveyor belt runs smoothly, and the materials are not easy to shake or scatter, which ensures the integrity of the materials. It is especially suitable for the transportation of fragile and vulnerable items.

It can be seamlessly connected with other production equipment, such as packaging machines, sorting machines, stacking machines, etc. to form a complete automated production line.

Adopt high-efficiency and energy-saving motors and advanced transmission technology to reduce energy consumption and meet environmental protection requirements.

It is widely used in food, medicine, chemical, electronics, logistics, building materials and other industries. In the food industry, it is used for the transportation of food raw materials and finished products; in the logistics industry, it is used for the sorting and handling of goods; in the chemical industry, it is used for the transportation of various chemical raw materials, etc.