Automated palletizing upgrade for logistics companies

Kuaijie Logistics Co., Ltd. is a large logistics company that faces tremendous work pressure in the loading and unloading and warehousing of goods. The traditional manual palletizing method is not only inefficient, but also prone to problems such as uneven placement of goods and incorrect palletizing, which affects the utilization rate of storage space and the efficiency of goods in and out of the warehouse. In addition, with the continuous growth of logistics business volume, labor costs are also rising. Enterprises urgently need an efficient and automated palletizing solution to improve operational efficiency and reduce costs.

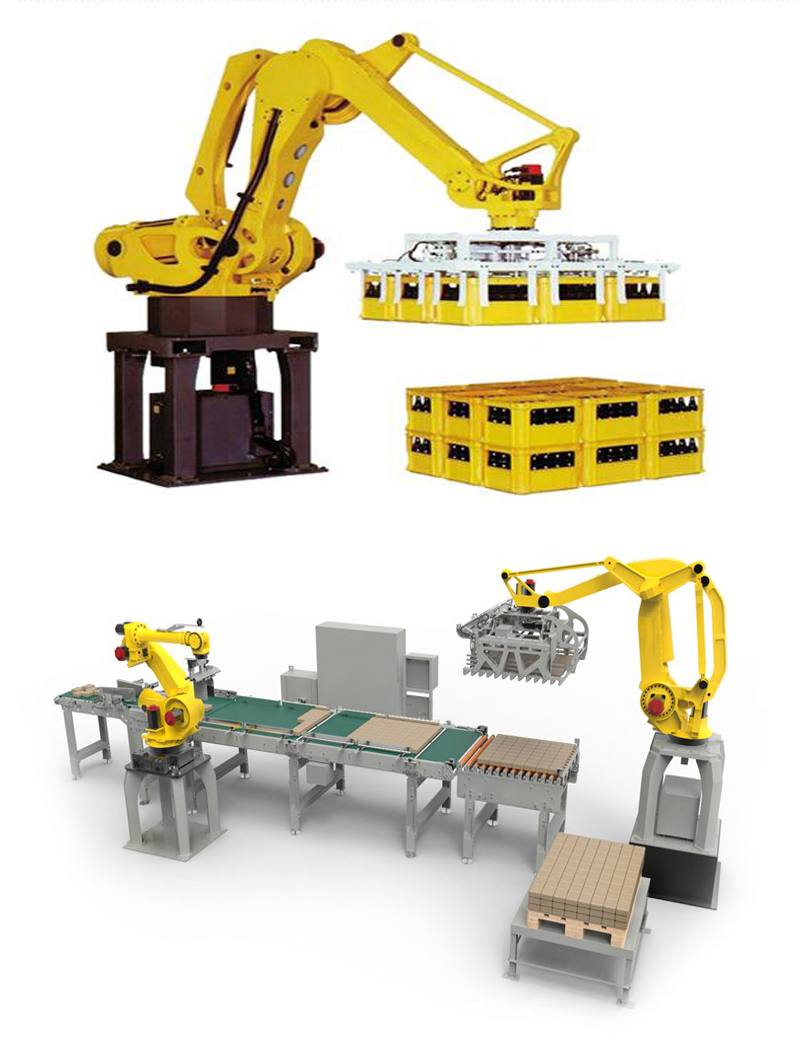

We provide Kuaijie Logistics Co., Ltd. with a set of intelligent collaborative palletizing robot systems. The system consists of multiple palletizing robots that work together through wireless networks. The robot can seamlessly connect with logistics conveyor lines, sorting equipment, etc. to realize automatic grabbing, handling and palletizing of goods. At the same time, the system is equipped with intelligent warehouse management software, which can monitor the working status of the robot and the storage inventory in real time, and automatically optimize the palletizing strategy and warehouse layout according to the type, weight, size and other information of the goods.