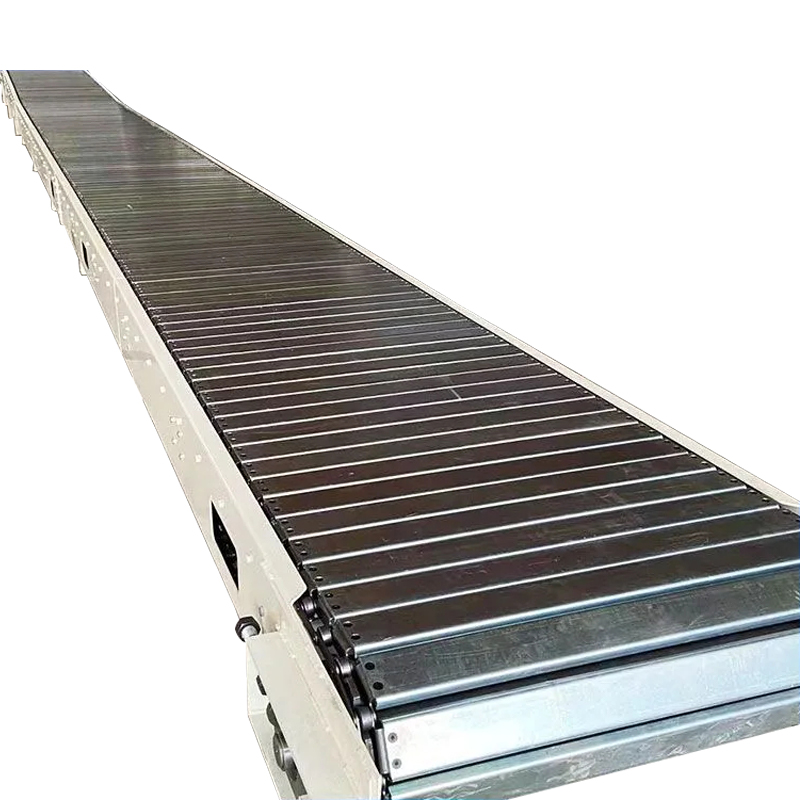

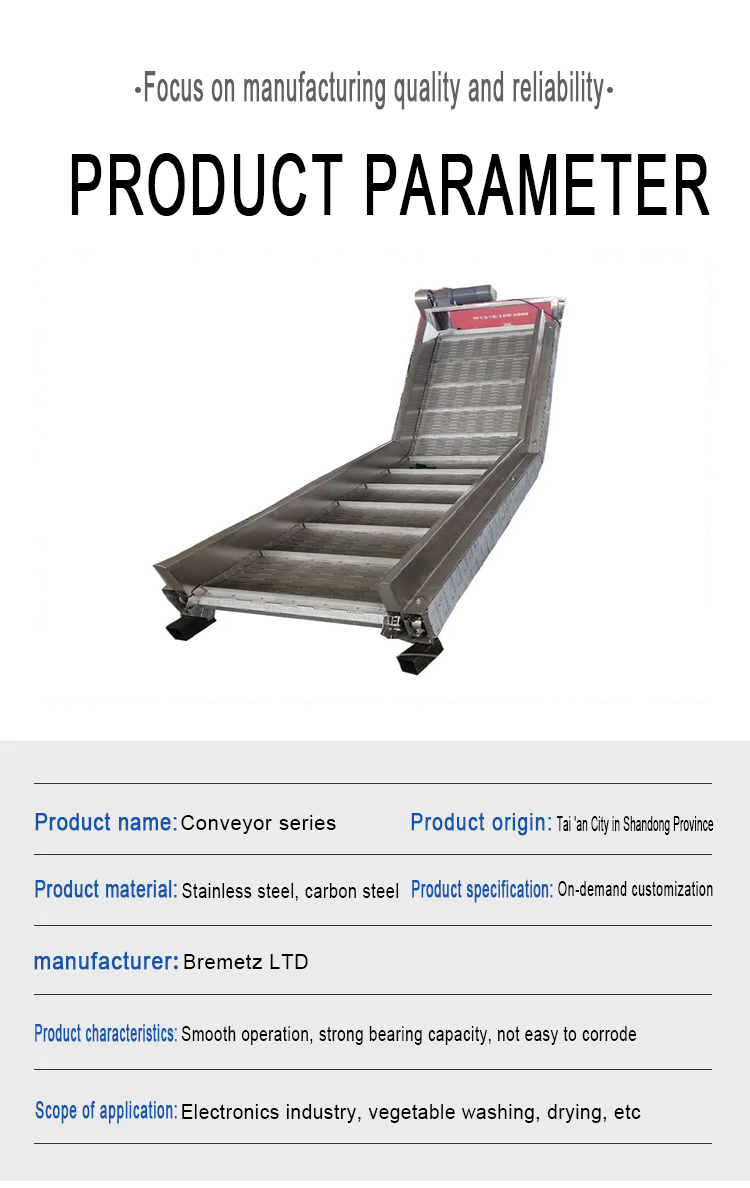

Pallet Chain Roller Conveyor Turntable Conveyor Motorized Roller Conveyor

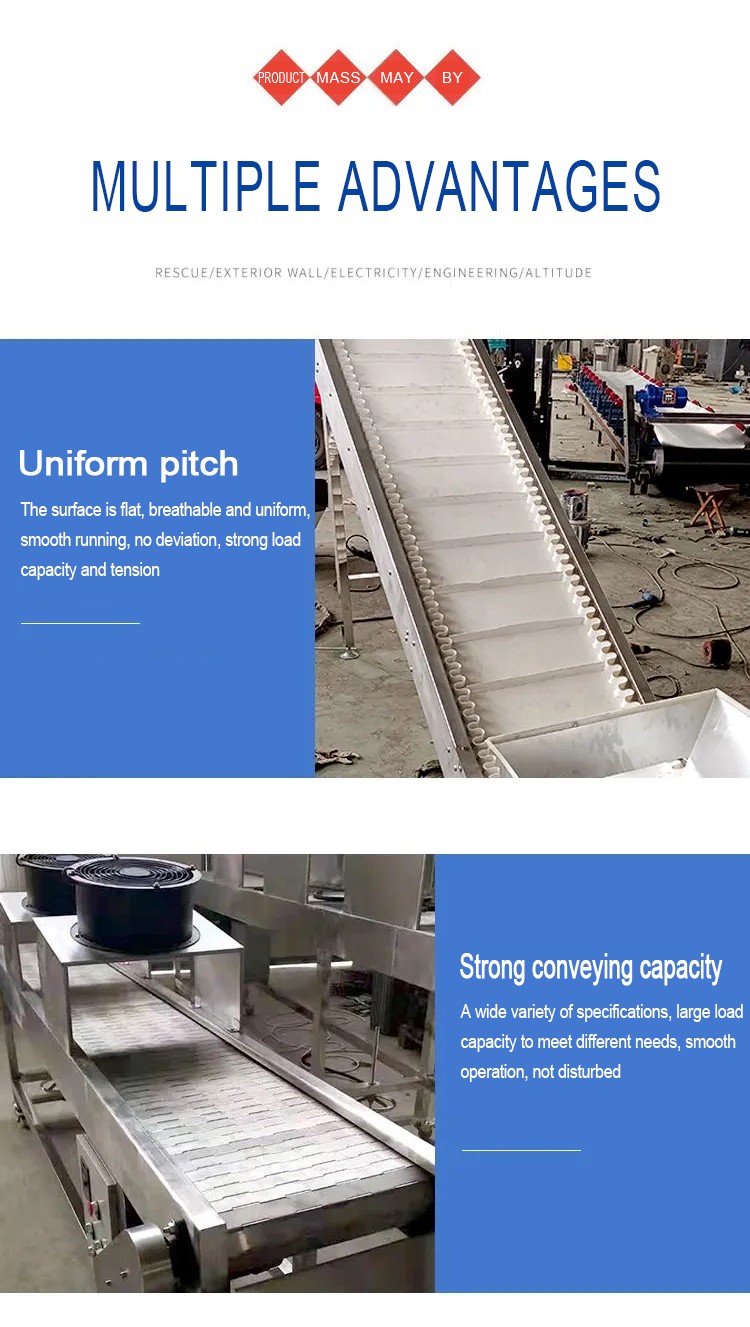

1. Large conveying capacity, efficient conveyors allow large amounts of materials to be transported in a small space.

2. Low energy consumption, with the help of the internal friction of the material, the material is changed to pull, so that it saves 50% of electricity compared with the screw conveyor.

3. Sealed and safe, the fully sealed casing makes the dust seamless and drillable, safe operation and reliable operation.

4. Long service life, the transport chain made of alloy steel processed by advanced heat treatment means has a normal life of >5 years, and the life of the roller on the chain (according to different materials) ≥2~3 years.

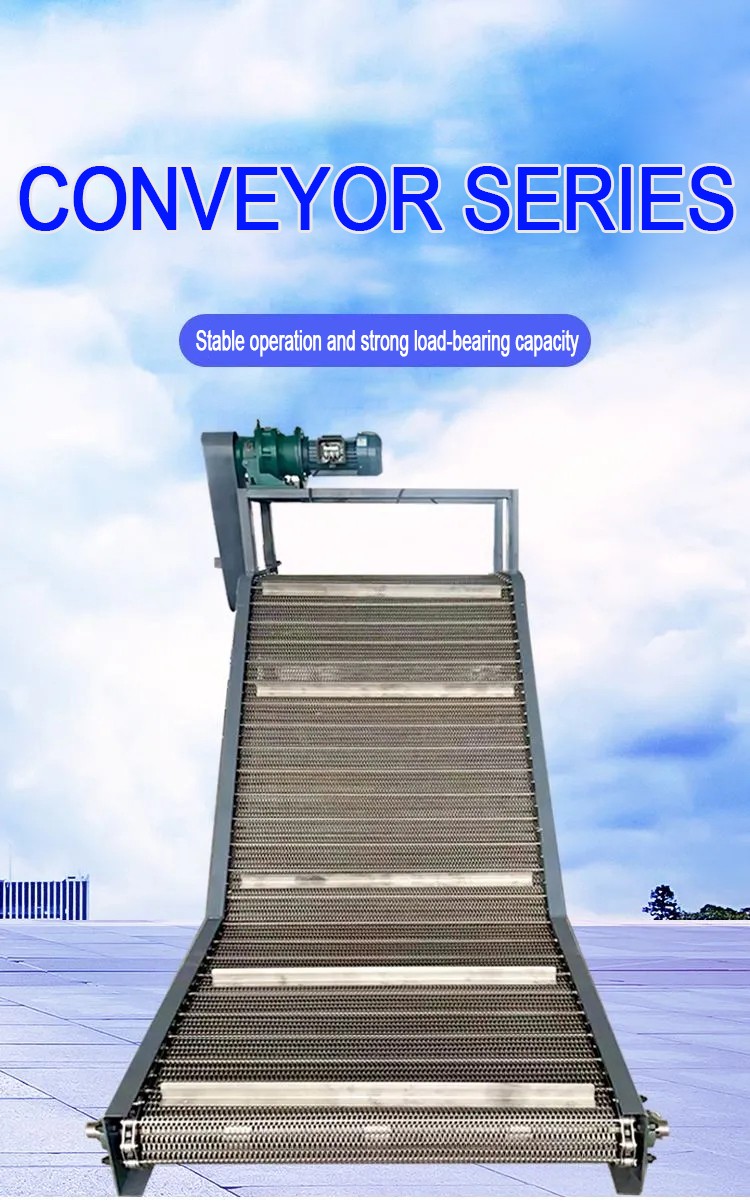

5. Flexible process layout, can be elevated, ground or pit layout, can be installed horizontally or uphill (≤15°), can also be installed horizontally and uphill with the same machine, can be multi-point in and out of materials.

6. Low cost of use, power saving and durable, less maintenance, low cost (about 1/10 of the screw machine), to ensure the normal operation of the host, in order to increase output, reduce consumption, improve efficiency.

Chain plate conveyor can meet the requirements of beverage labeling, filling, cleaning and other equipment for single column transportation, but also can make a single column into multiple columns and walk slowly, thereby generating storage capacity, to meet the requirements of sterilization machine, bottle storage table, cold bottle machine for a large number of materials, we can make the head and tail of the two chain plate conveyor into a overlapping mixed chain, The bottle (tank) body is in a dynamic and excessive state, so that the bottle is not stranded on the conveying line, and the pressure and non-pressure conveying of empty and solid bottles can be met.