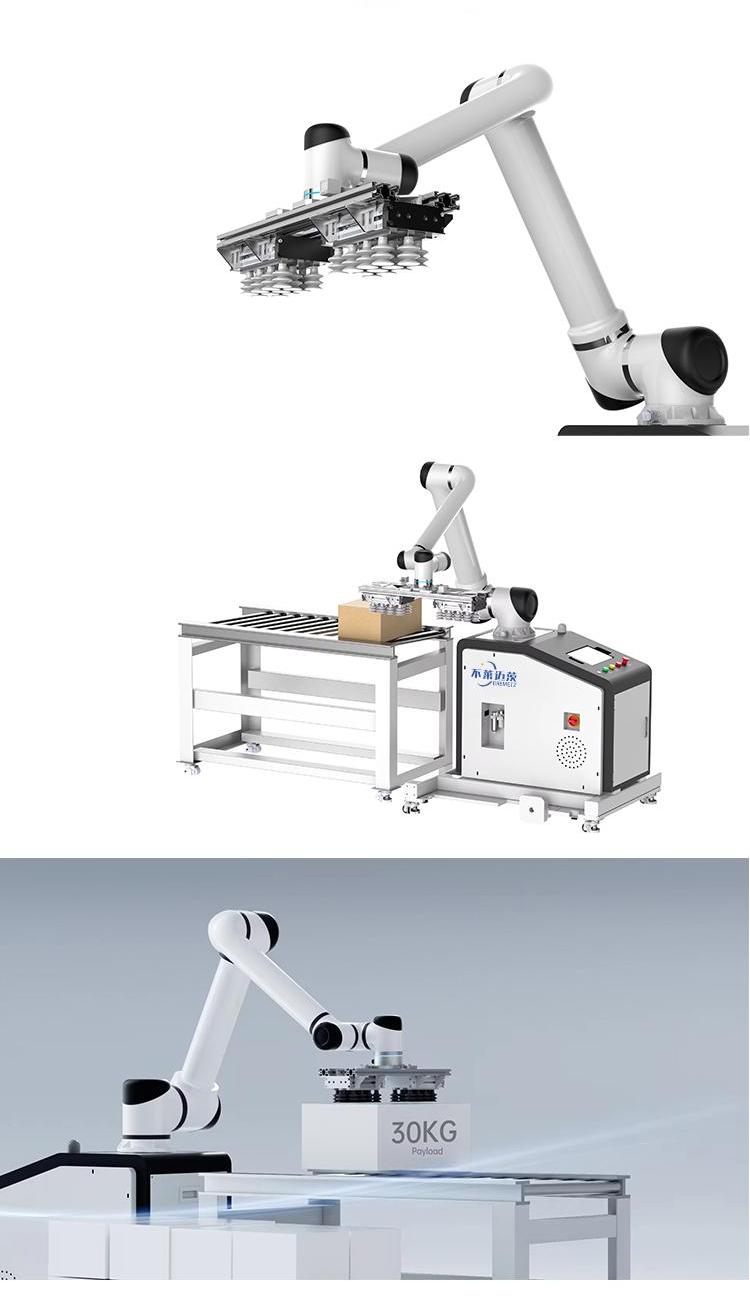

Collaborative handling and palletizing robot

1. It can run continuously for a long time and is not affected by fatigue, rest and other factors, which can significantly improve the overall production efficiency.

2. With precise control and optimized action paths, it can complete the stacking of large quantities of goods in a short time.

3. It can replace part of the manual labor for repetitive and heavy handling and palletizing work, reducing the company's dependence on manpower.

4. It has precise positioning and grabbing capabilities, and can accurately grab goods and place them in designated locations.

5. Different end effectors can be quickly replaced or the program adjusted to accommodate products of various shapes, sizes, weights and different types of packaging.

The collaborative handling and palletizing robot is an intelligent device that integrates advanced technologies and is designed to solve the efficiency, accuracy and safety issues in material handling and palletizing in industrial production. It has the ability to work closely with human operators.

The motors of each joint of the robot have high speed and high torque output capabilities. Combined with the optimized motion control algorithm, it can achieve fast material handling and palletizing actions.

With precise visual positioning and precise control of the control system, materials can be stacked strictly according to the preset stacking mode to ensure that each layer of materials is arranged neatly and the stacking height is consistent.

It can handle materials of various shapes, sizes and weights, from small electronic components to large industrial parts, from regular rectangular and cylindrical packaging boxes to special-shaped plastic and metal products, etc.

Equipped with a large touch screen operation interface, the display is clear and the operation is simple and intuitive. Users can easily perform operations such as robot parameter setting, task selection, operation status monitoring, fault diagnosis and alarm information viewing through the touch screen.

The structural design fully considers the convenience of maintenance. The key components of the robot are reasonably arranged and easy to disassemble and replace. The modular design concept is adopted. When a component fails, the module can be quickly replaced.