Multifunctional Industrial Collaborative Robot

1. Safety guarantee: With advanced sensing technology and collision detection functions, it can sense the surrounding environment and the approach of people in real time.

2. Convenient operation: The design is more user-friendly, the operation interface is simple and easy to understand, and it can be quickly operated after simple training, which is convenient for workers to work closely with robots to complete complex tasks.

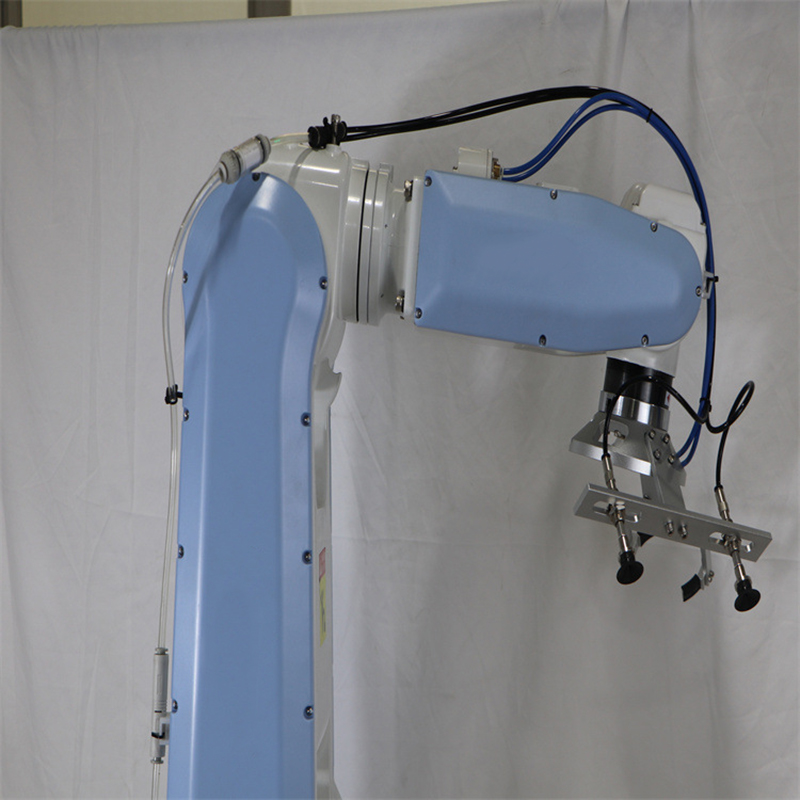

3. Multi-degree-of-freedom movement: It usually has multiple degrees of freedom, flexible joints, and can move in multiple angles and directions in complex spaces, which can adapt to various different work scenarios and task requirements.

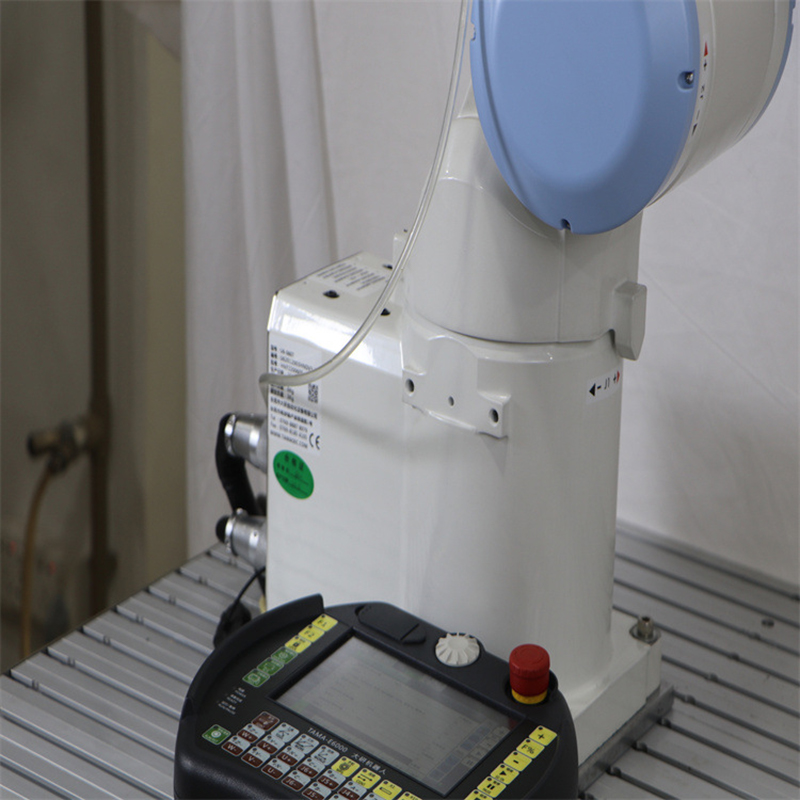

4. Easy to program and debug: The programming method is simple and intuitive, and can be carried out through teaching programming, offline programming and other methods. The programming process is fast and efficient. Moreover, it can quickly adjust the program according to the changes in production tasks, realize rapid switching of production tasks, and improve the adaptability and flexibility of production.

5. Mobility: Some multifunctional industrial collaborative robots have movable functions, can move freely in the workplace, are not restricted by fixed positions, and can reach different work locations at any time according to work needs, further improving the flexibility and efficiency of work.

6. High-precision operation: It can accurately perform various tasks, with high repeated positioning accuracy, which can ensure the quality and consistency of products. When performing precision assembly, welding, spraying and other work with high precision requirements, it can stably exert excellent performance and improve the product qualification rate.

7. Can be integrated with other equipment: It can be seamlessly integrated with other equipment on the production line, such as conveyor belts, CNC machine tools, sensors, etc., to achieve collaborative work of automated production processes and improve the automation level and production efficiency of the entire production line.

The multifunctional industrial collaborative robot is an innovative industrial equipment that integrates advanced technologies and is designed for modern industrial production environments. It integrates multiple functions into one, has excellent collaborative capabilities, and can work with humans or other equipment in multiple links such as industrial manufacturing, processing, and assembly.

Safety protection mechanism: Equipped with a high-precision sensor system, these sensors monitor the environment around the robot in real time, and can respond instantly when a risk of contact with people or other objects is detected. The design complies with international safety standards and adopts a variety of safety measures such as safety light curtains and emergency stop buttons. Convenient human-computer interaction: It has a simple and intuitive operation interface and supports a variety of interaction methods, such as teaching programming and touch screen operation. In the teaching programming mode, the operator can manually guide the robot to complete a series of actions, and the robot can automatically record and generate the corresponding operation program without complex programming knowledge. Touch screen operation makes it convenient for users to set the robot's parameters and schedule tasks, making the operation more convenient and efficient.

Model: BS6-0608, Movement radius: 849.7 mm, Repeatability: ±0.02 mm,

Motor power consumption: 2450 watts, Bulk mass: 50 kg, Power interface: 220 V 50 Hz, Installation method: Floor-standing/ceiling-mounted, Protection level: IP54, Rated load: 3 kg, Installation humidity: 20%~75% relative humidity, Communication interface: MODBUS-485 MODBUS-232 MODBUS-TCP TCP/IP I/0 Analog, Maximum load: 6 kg, Installation temperature: 0℃~45℃

Motion range, maximum speed: J1 axis, ±170.5°, J2 axis, -144.5 inches + 69 inches, J1 axis, 297.5°/south, J2 axis, 138.5°/south, J3 axis, -50°-+203.5”, J3 axis, 166 /S,J4 axis,±180°,J4 axis,367.5°/South,J5 axis,-127°-+135°,J5 axis,187.5°/South,J6 axis,±360,J6 axis,600/second,

Standard configuration: flange, power cord, network interface, 2X2 interface.

High-precision and long-life harmonic reducer, high-quality harmonic reducer, high precision, good reliability, long life and low noise.

High-precision and long-life harmonic reducer, high-quality harmonic reducer, high precision, good reliability, long life, low noise. Robot AC servo motor, the engine that controls the operation of the robot is stable and jitter-free at low speed, fast response at high speed, and the encoder has strong anti-interference ability.The robot arm is flexible and free, all joints are connected with high-quality bearings, the robot arm is flexible and free, and the motion trajectory is smooth.

Scope of application:

Applicable to welding, stamping, injection molding, polishing, loading and unloading, process transfer, handling, palletizing, spraying, screw locking, testing, packaging and other applications, suitable for all process automation.

Robot welding, handling and palletizing, painting, loading and unloading integration, application assembly, cutting and grinding.