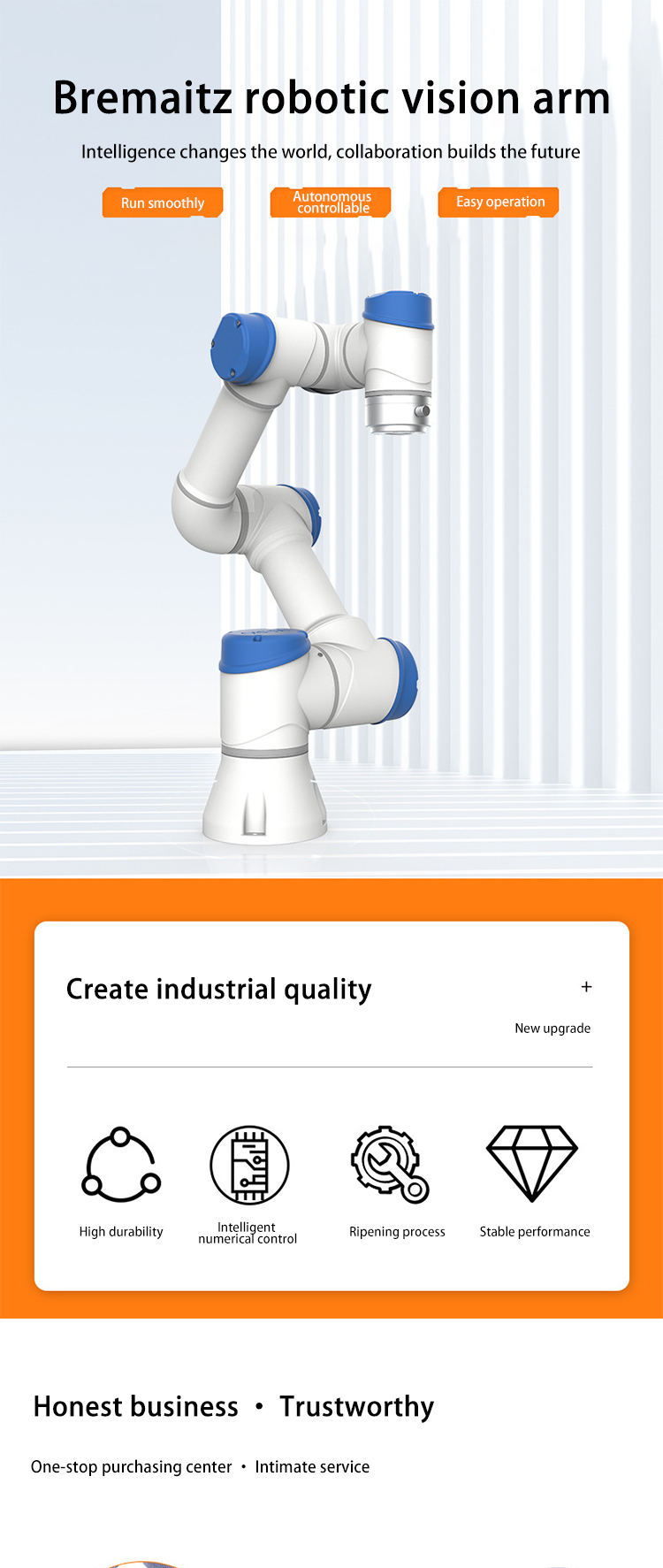

Precision operation collaborative robot arm

1. It can achieve high-precision positioning in three-dimensional space, and its repeated positioning accuracy can reach millimeter level or even higher.

2. It has excellent stability and can always maintain high-precision working state during long-term continuous operation.

3. Through advanced sensor technology and control algorithms, it can sense human movements and positions in real time and adjust its own movement trajectory and speed accordingly.

4. It has sensitive force feedback characteristics. When the robot contacts external objects, it can accurately sense the size and direction of the contact force.

5. It has high movement speed and acceleration, and can complete a large number of repetitive operation tasks in a short time.

6. It has low power consumption and basically does not require complex maintenance work. The energy consumption and maintenance costs during operation are effectively controlled.

The precision operation collaborative robot arm is an innovative industrial equipment that integrates advanced mechanical engineering, precision sensing technology, intelligent control algorithms and the concept of human-machine collaboration. It is designed for production tasks with extremely high precision requirements and can be used in multiple industries.

We have developed a unique ultra-high precision motion control algorithm that can achieve ultra-fine motion control of the robot arm joints. The motor speed, torque and position are accurately controlled and adjusted in real time at the micro-step level.

It has high-precision intelligent force control technology, which can accurately sense, control and adjust the force between the end effector of the robot arm and the operating object.

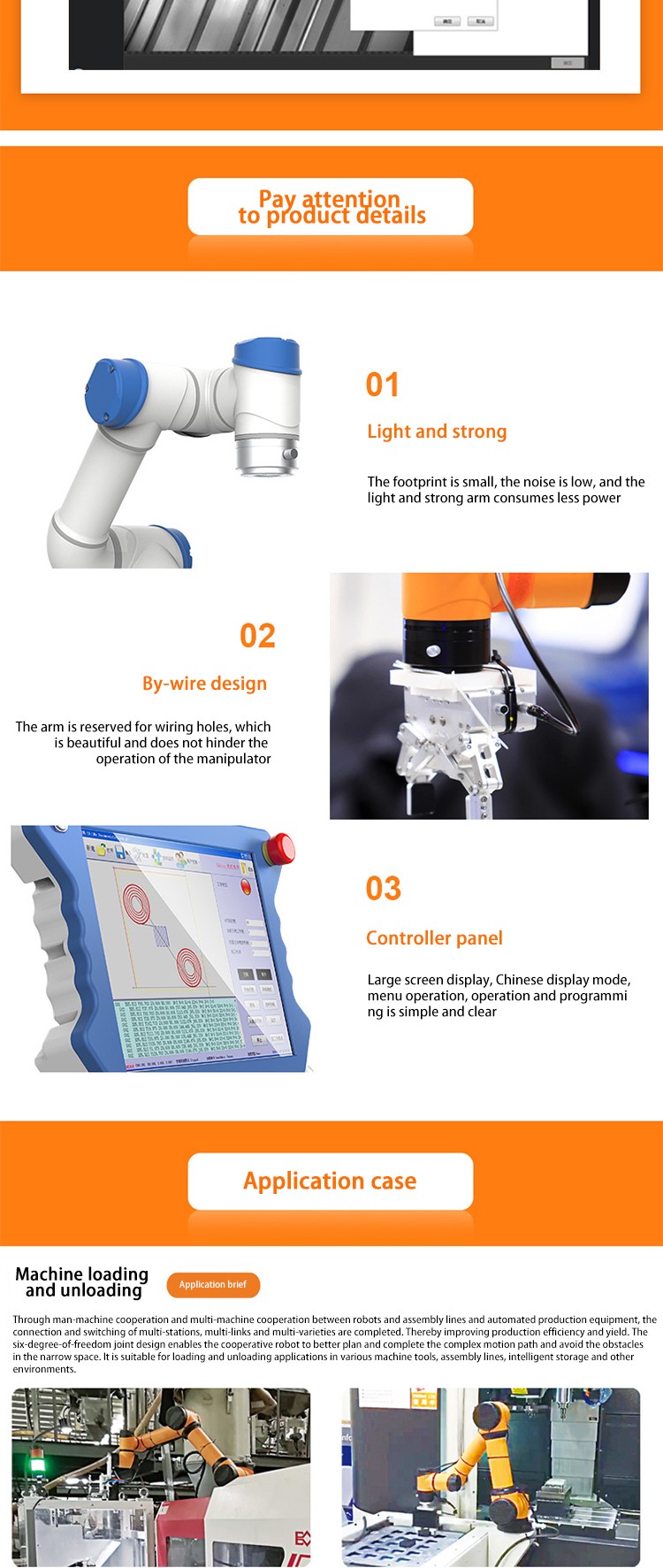

With its excellent high-precision motion control and intelligent force control technology, it is able to complete various ultra-precision tasks at the micro scale.We focus on safety performance in the process of human-machine collaboration, and through a variety of safety technologies and design measures, we achieve safe and efficient collaborative work between humans and robots in the same workspace.

It can be widely used in different production links of multiple industries, such as electronic manufacturing, precision machining, optical instrument manufacturing and other industries, and can adapt to various types of work tasks and production environment requirements.

It has good scalability and compatibility, and can be easily integrated and connected with other automation equipment, production line control systems and enterprise information management systems.