Professional collaborative welding machine

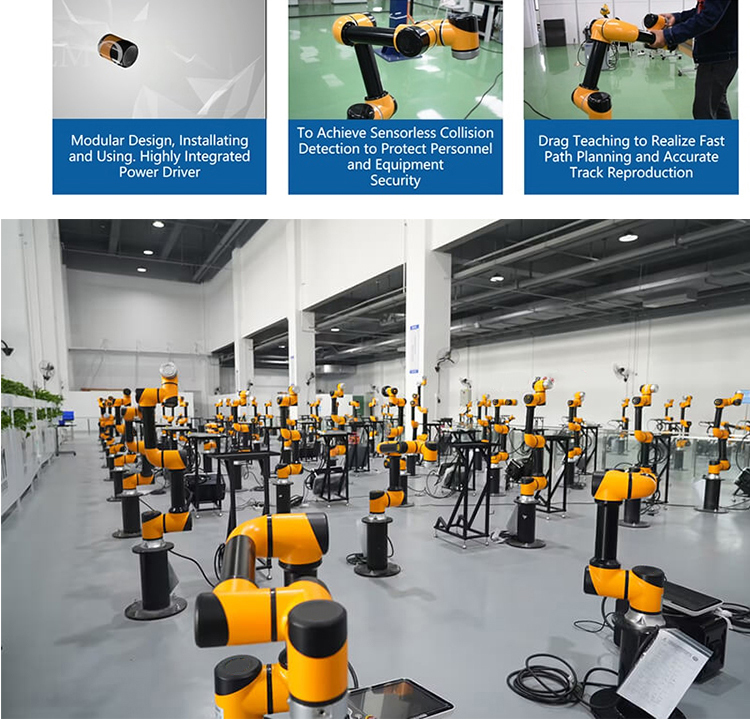

1. With advanced collision detection technology, it can respond and stop welding within milliseconds, effectively avoiding collisions between the robot and the operator or surrounding objects.

2. Built-in multiple safety modes and intelligent welding instruction inspection functions ensure safe and reliable operation.

3. Intuitive drag operation can be used to complete teaching programming without professional programming knowledge and complex code writing.

4. Equipped with advanced algorithms and control systems, it can ensure high accuracy of welds and meet the industrial production needs with strict requirements on welding quality.

5. It can accurately control parameters such as welding current, voltage, speed, etc. to ensure the stability of the welding process and reduce the occurrence of welding defects.

This is a professional collaborative welding robot that integrates cutting-edge technology, designed to provide efficient, accurate, safe and flexible solutions for the industrial welding field. It integrates advanced robotics technology, precision welding technology and intelligent control systems, and can work seamlessly with human operators.

The body is made of aviation-grade aluminum alloy or high-strength carbon fiber, which not only ensures the structure is strong and stable, but also effectively reduces the weight of the robot itself, making it have higher movement speed and flexibility.

The servo motors and drivers of each joint have high torque output, fast response and precise control capabilities, which can achieve high-speed and high-precision movement of the robotic arm.

Based on the advanced Robot Operating System (ROS) or dedicated welding robot control software platform, it adopts high-performance processors and complex motion control algorithms to achieve real-time and precise control of the robot.

Equipped with a full range of safety sensors, including lidar, visual cameras, force sensors and collision detection sensors, the robot's surrounding environment and contact with people and objects are monitored in real time.

It supports teaching programming. The operator can guide the robot to complete a welding operation by manually dragging the robotic arm or using a teach pendant. The robot will automatically record information such as motion trajectory, welding parameters and action sequence, and can automatically repeat the welding task later.