Fully automatic Valve port packaging machine

1. Easy operation: a series of operations from bag delivery, bagging, metering and filling to sealing and bag transportation can be completed automatically, reducing manual intervention.

2. Intelligent control: the use of advanced control systems such as PLC programmable controllers can achieve precise control and automatic management of the entire packaging process.

3. Advanced metering system: equipped with high-precision weighing sensors, intelligent instruments and other metering devices, which can accurately control the filling volume of materials.

4. Multiple metering methods: according to the characteristics and packaging requirements of different materials, multiple metering methods such as weight measurement can be used.

5. Valve port design advantages: filling and sealing through the valve port can effectively prevent material leakage and dust flying.

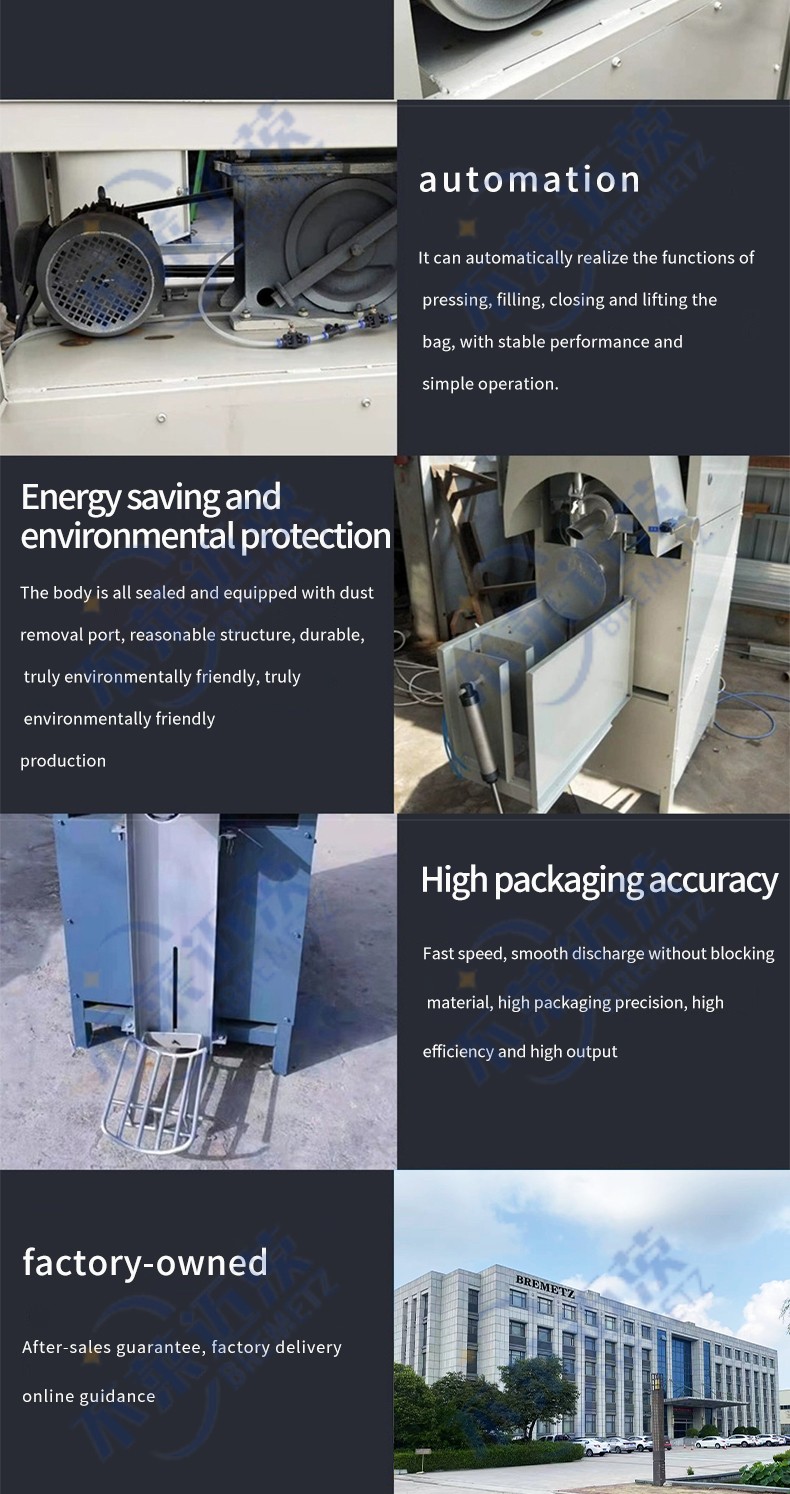

6. Overall sealing structure: the machine body usually adopts a fully enclosed dustproof structure and is equipped with a dust removal port to further reduce dust leakage.

The fully automatic valve-mouth packaging machine accurately puts the valve bag on the filling port through automatic bag feeding, bag suction and bag covering devices, and then uses accurate measurement methods such as weight measurement. The weighing sensor outputs signals to control the feeding speed, accurately fill the material into the bag, stop filling when the preset weight is reached, and then perform sealing and other operations to complete the entire packaging process.

High degree of automation: a series of operations from bag delivery, bagging, metering and filling to sealing and bag transportation can be completed automatically, which greatly reduces the intensity of manual labor, improves production efficiency and reduces production costs.

High-precision metering: the advanced metering system can accurately control the filling volume of materials with high metering accuracy, which can effectively avoid material waste and ensure product quality.

Good sealing and environmental protection: The valve port design and overall sealing structure can effectively prevent material leakage and dust flying, improve the working environment, and meet environmental protection requirements.

Wide applicability: Not only suitable for a variety of materials, but also compatible with different types of valve bag packaging materials, such as kraft paper bags, coated woven bags, plastic bags, PE bags, aluminum foil bags, etc.

Stable and reliable performance: key components are made of high-quality products, with reasonable structural design, stable and reliable operation, few failures, and long service life, which can effectively ensure the continuity of production.

Strong scalability: functional modules can be added or expanded according to user needs, such as automatic bag unloading mechanism, dust removal fan, coding device, metal inspection device, conveying and stacking equipment, etc. It is also easy to integrate with other production equipment to achieve a more efficient automated production process.

Scope of application:

Material type: It can be widely used in the packaging of various powders, ultrafine powders, fine granular materials and other chemical raw materials, as well as flour, milk powder, coffee powder and other food raw materials.

Packaging specifications: The common packaging specifications are 10kg-50kg, but some models can also meet the needs of smaller or larger packaging volumes.

Industry fields: It has important applications in many industries such as chemicals, building materials, medicine, food, feed, etc., and can meet the requirements of different industries for efficient, accurate and environmentally friendly material packaging.