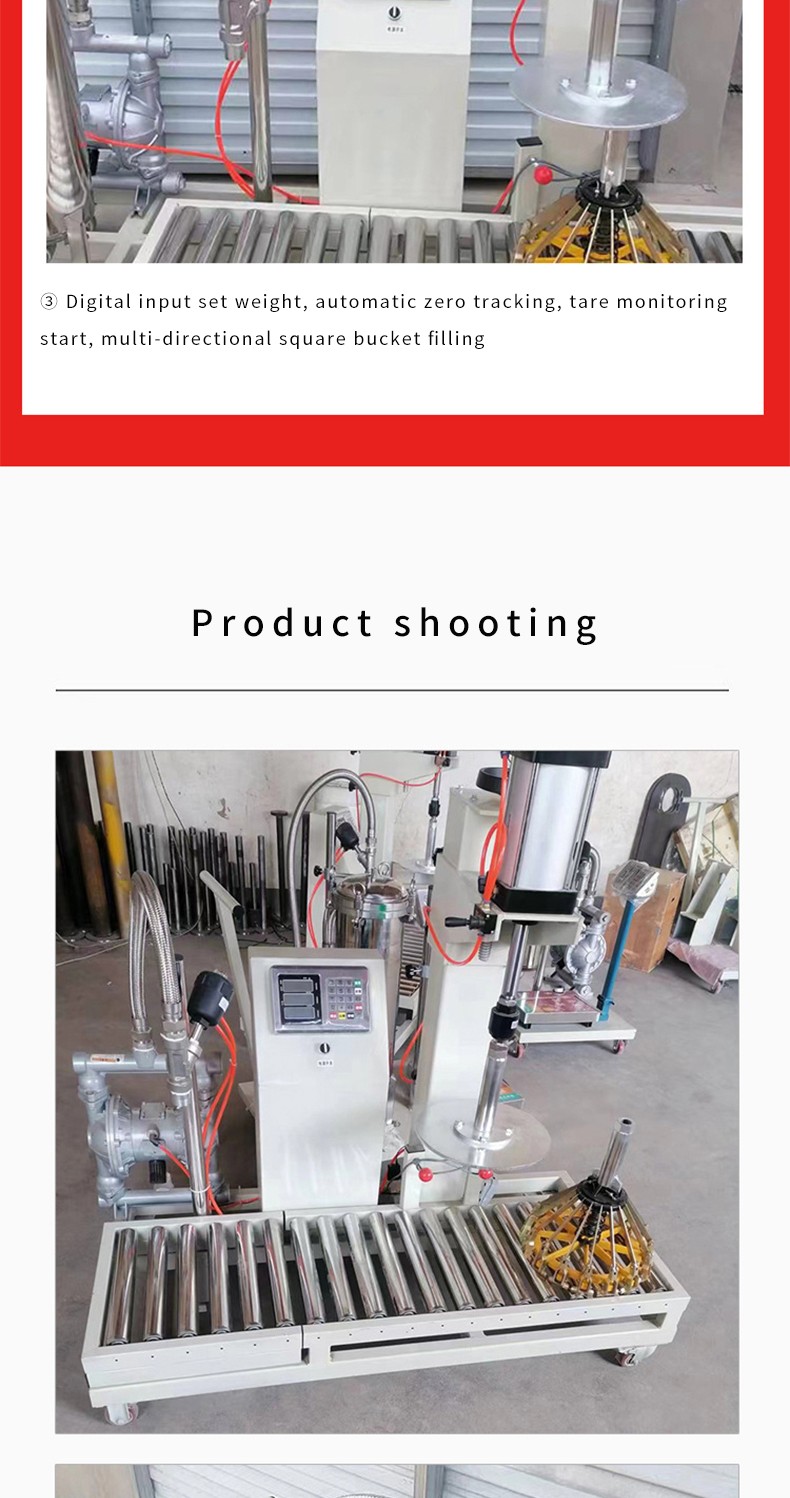

Automatic weighing filling machine

1. The use of advanced weighing sensors and precise metering algorithms can achieve extremely accurate weighing and metering of various materials. Whether it is a small dose or a large batch of filling, the error can be controlled within a very small range.

2. It has fast filling capabilities and can greatly improve production efficiency. Its automated workflow reduces manual operation links and can complete the filling tasks of a large number of products in a short time.

3. The design is ingenious and can handle a variety of materials of different types, properties and forms. Whether it is a liquid with good fluidity, a fine powder, or a granular material of various shapes, stable and accurate filling can be achieved on this machine.

4. The fully automated operation mode greatly reduces manpower input, reduces labor costs and labor intensity.

5. It is composed of high-quality mechanical components and advanced electronic control systems. The overall structure is sturdy and durable, and the operation stability is extremely high.

Automatic weighing and filling machine is an advanced packaging equipment that integrates mechanical, electronic, automatic control and other multi-field technologies. It is mainly used to accurately weigh various powdered, granular, liquid and other materials and fill them into designated containers. It is widely used in many industries such as food, beverage, medicine, chemical, daily chemical, etc.

With advanced weighing sensors and precise control algorithms, extremely high weighing accuracy can be achieved and the filling error can be controlled within a very small range, meeting the strict requirements of different industries for product packaging weight accuracy.

It can be applied to materials of various types, properties and forms, including powder, granular, liquid, etc. Through targeted design and adjustment, such as replacing different filling heads and adjusting material conveying parameters, it can easily meet the filling requirements of various materials.

Product name:Automatic weighing heavy pressure cap filter filling machine

Product use:Filling liquid

Packaging type:barrel

Product principle:normal pressure

Scope of application:Chemical food, etc.

Filling volume:50-1000ML

The use of high-quality mechanical parts and advanced electronic components, after strict quality inspection and debugging, ensures that the equipment always maintains stable and reliable performance during long-term continuous operation. The reasonable structural design of the equipment and the close coordination between the various components reduce the probability of mechanical failure.

For industries with extremely high hygiene requirements such as food and medicine, the equipment uses stainless steel that meets hygiene standards to manufacture parts that come into contact with the materials, and the entire filling process is carried out in a relatively closed environment, effectively preventing material contamination and cross infection.

It can be customized according to the special needs and production process requirements of different customers. Whether it is the shape, size, material of the filling container, or the size, production capacity, degree of automation of the equipment, etc., it can be customized and modified.