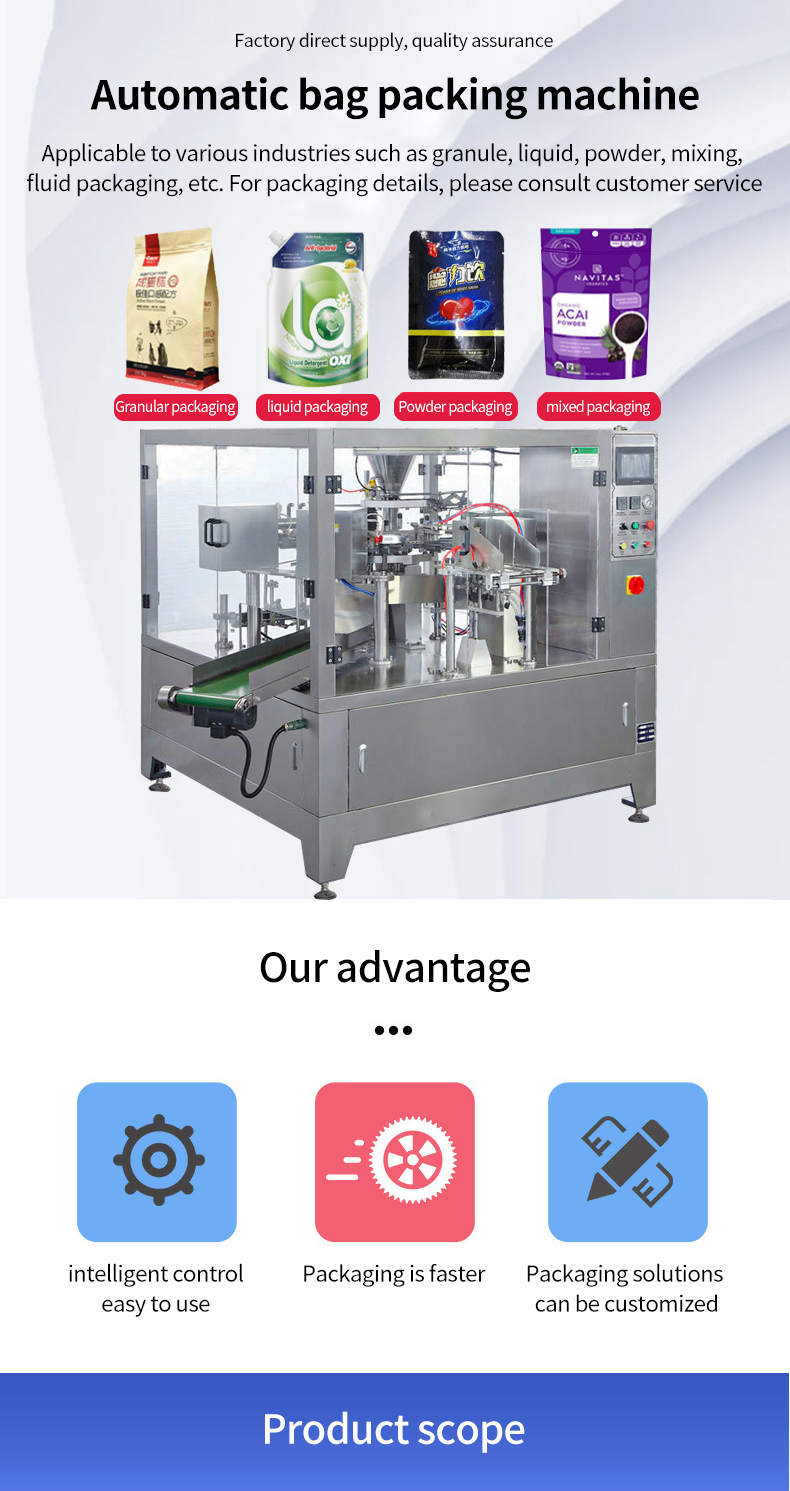

Automatic smart bag packing machine

1. High degree of automation: It can automatically complete a series of packaging processes such as material conveying, metering, bag making, filling, and sealing, which greatly reduces manual operations and improves packaging speed.

2. Accurate metering system: Equipped with high-precision sensors and metering devices, it can accurately control the filling amount of materials to ensure that the weight or volume of the product in each packaging bag meets the set requirements.

3. Stable sealing technology: Through precise temperature control, pressure regulation and sealing time setting, the packaging bag can be firmly sealed to prevent material leakage.

4. Reduce costs and reduce dependence on manual packaging, reduce the manpower requirements of enterprises, and thus save a lot of labor costs.

5. Reduce material waste: It can accurately control the amount of packaging materials used, avoid excessive packaging, and reduce the loss of packaging materials.

6. Convenient product switching: When the enterprise needs to change the packaging product, it only needs to make corresponding parameter settings and simple adjustments in the equipment control system to quickly switch between different products.

Automatic smart bag packing machine is a packaging equipment that integrates advanced automation technology and intelligent control system. It is designed for bag packaging of various products and is widely used in many industries such as food, medicine, daily chemicals, and chemicals, providing enterprises with efficient, accurate and reliable packaging solutions.

The entire process from material delivery to packaging is fully automatic, reducing manual intervention, labor intensity and human errors. The intelligent control system can automatically adjust the packaging speed and metering accuracy according to the preset parameters. It also has automatic diagnosis and alarm functions, which can detect abnormal conditions of the equipment in real time, such as insufficient materials, film deviation, metering deviation, etc., and issue alarms in time to ensure smooth production.

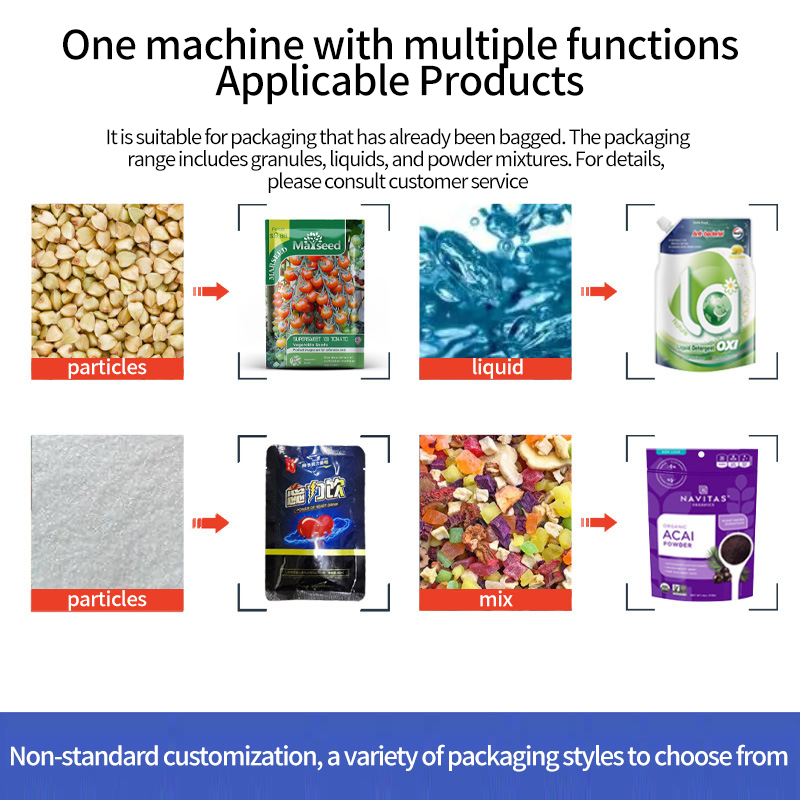

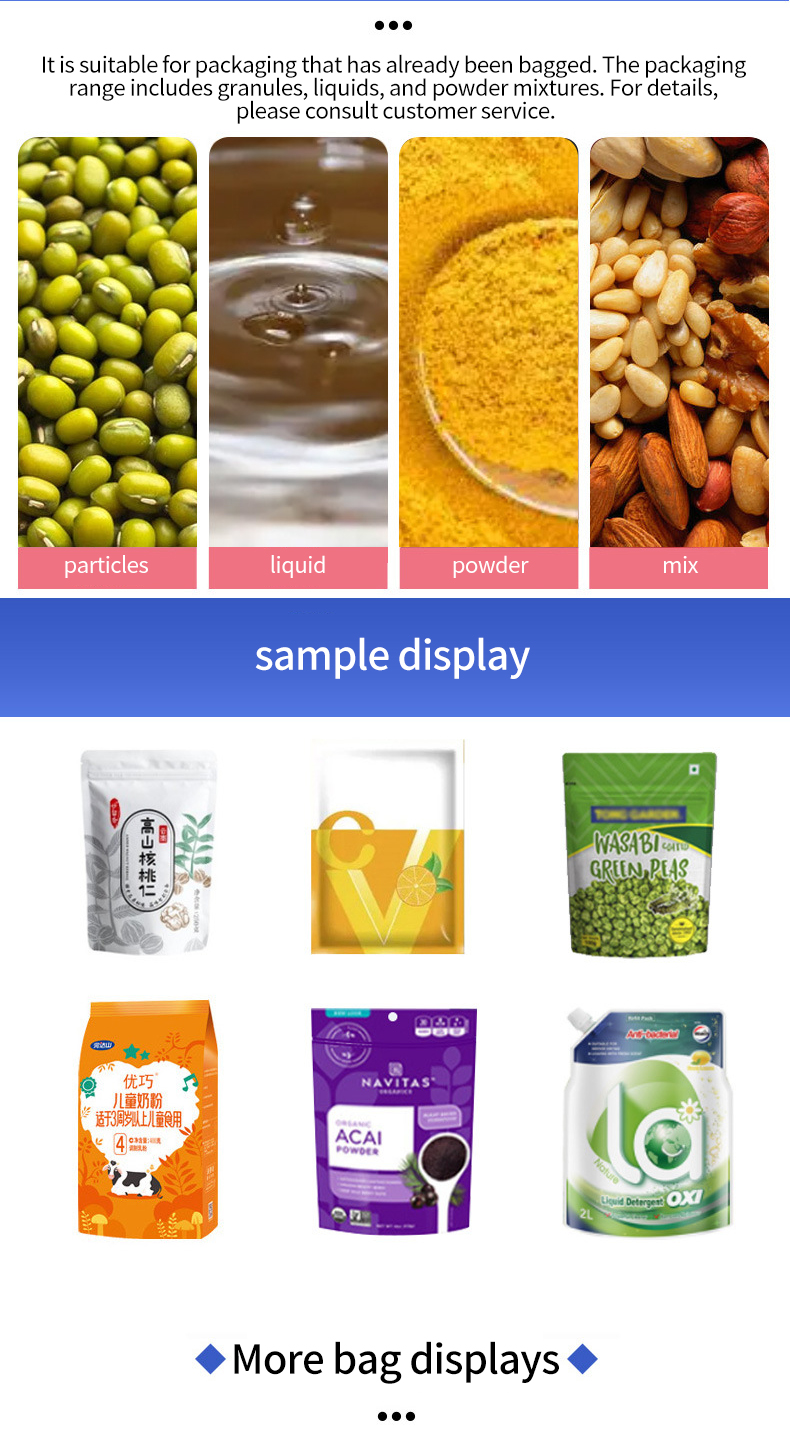

Applicable industries and products: Food industry, suitable for packaging all kinds of food, such as snack food, powdered food, liquid food and frozen food.Pharmaceutical industry, can be used to package pharmaceutical granules, powders, capsules, etc., strictly comply with the requirements of pharmaceutical production quality management standards.Daily chemical industry, used to package cosmetics, cleaning products and other products, to meet the requirements of daily chemical products for packaging beauty and quality.Chemical industry, can package chemical raw materials, can adapt to materials of different chemical properties, by selecting appropriate packaging materials and protective measures, to ensure the safety and stability of the packaging process.

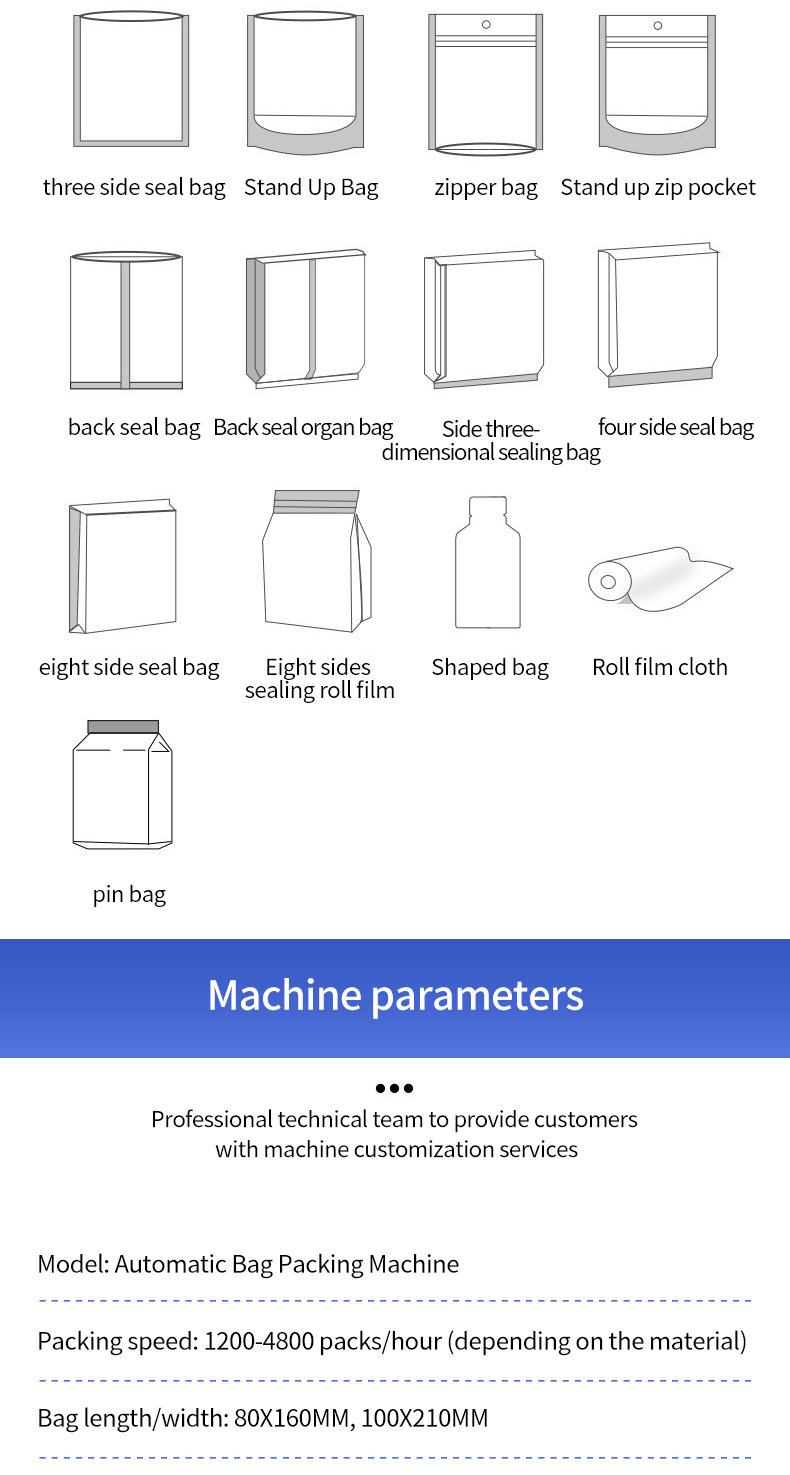

Machine parameters:

Model: Automatic Bag Packing Machine

Packing speed: 1200-4800 packs/hour (depending on the material)

Bag length/width: 80X160MM, 100X210MM

Machine voltage: 220V/380V

Machine size: 1700×1050×1100

Machine weight: 600KG

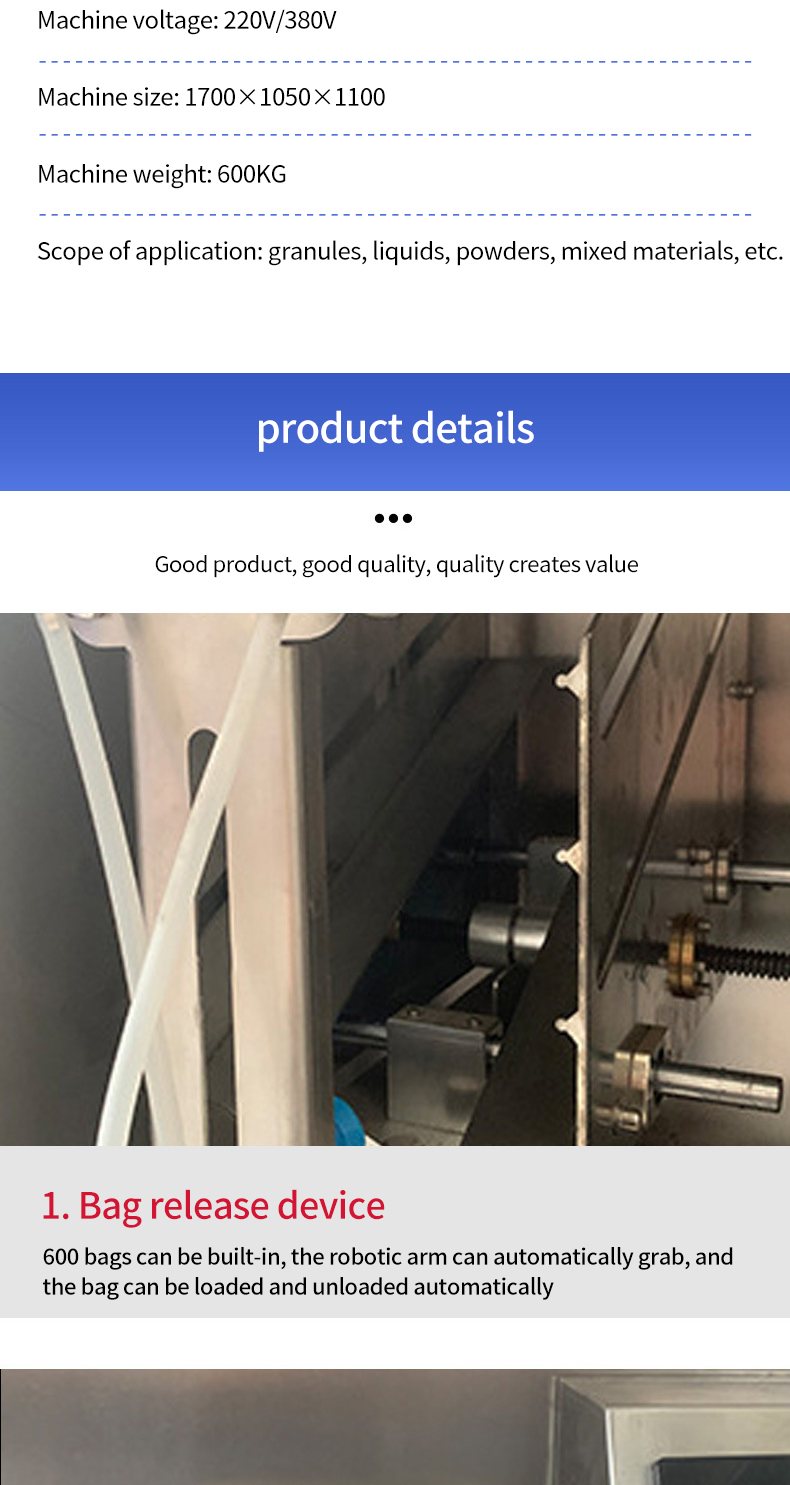

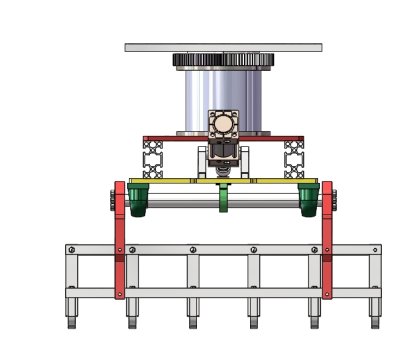

Bag release device,600 bags can be built-in, the robotic arm can automatically grab, and the bag can be loaded and unloaded automatically.

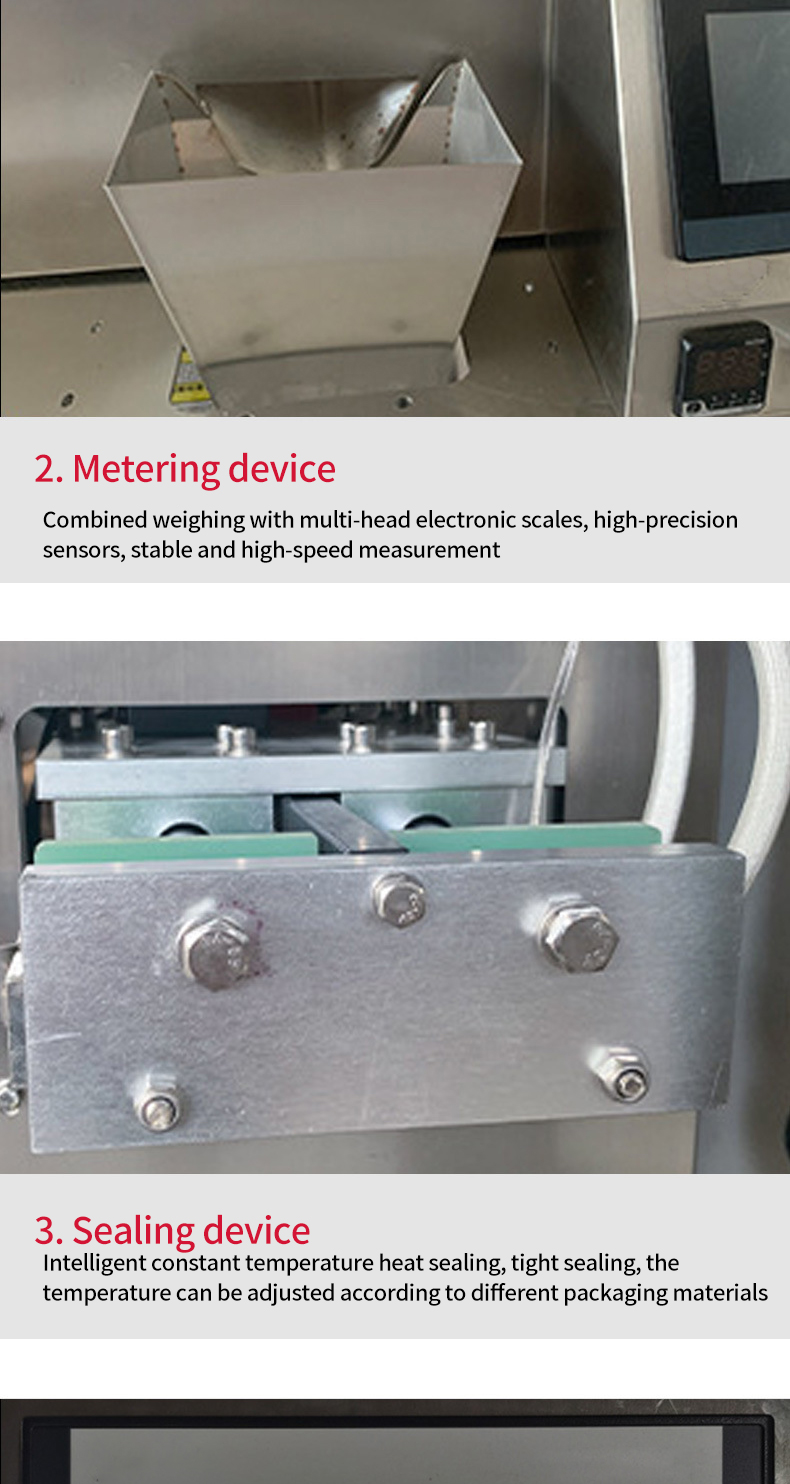

Metering device,Combined weighing with multi-head electronic scales, high-precision sensors, stable and high-speed measurement.

Sealing device,Intelligent constant temperature heat sealing, tight sealing, the temperature can be adjusted according to different packaging materials.

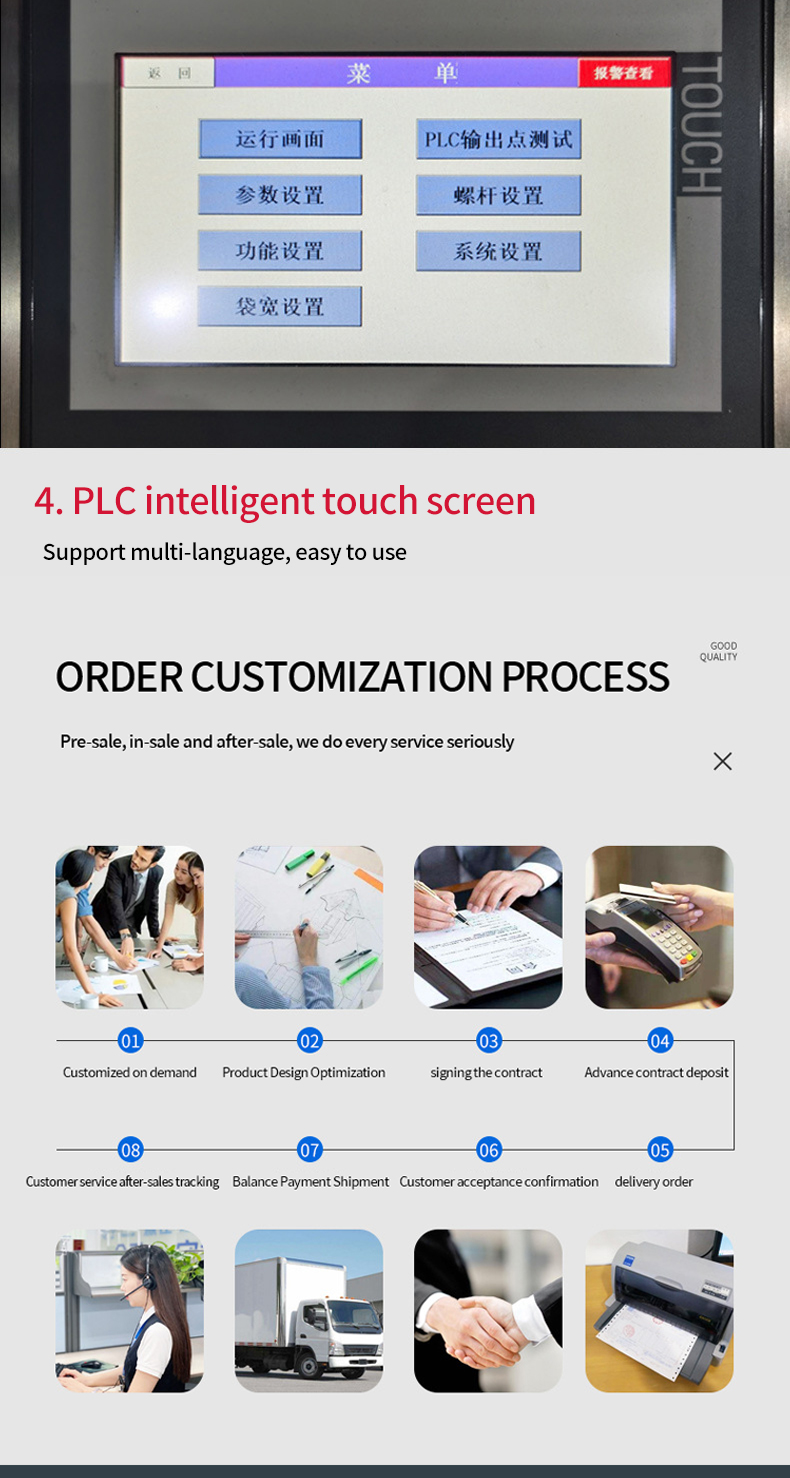

PLC intelligent touch screen,Support multi-language, easy to use.

The friendly human-machine interface allows operators to operate without complex training. The structural design of the equipment is convenient for daily maintenance and upkeep, and key components are easy to disassemble and replace. Regular maintenance work is simple, such as cleaning the material conveying channel, checking the metering device, replacing the heat sealing element, etc., which can effectively reduce the failure rate and maintenance cost of the equipment.

The company has a professional installation team with rich experience and expertise to ensure that the packaging machine is installed accurately at the location specified by the user. The installation process is strictly carried out in accordance with the equipment's installation instructions and safety regulations to ensure that all parts of the equipment are installed correctly and firmly, and the electrical connections are safe and reliable.

After installation, the technicians will conduct a comprehensive commissioning of the equipment. According to the user's material characteristics and conveying requirements, the appropriate operating parameters, such as lifting speed, unloading method, etc., will be carefully set to ensure that the equipment can operate normally and achieve the best conveying effect.

Provide remote training services. Provide users with follow-up technical support and training through online video conferencing and other means, and answer questions users encounter during use.

We handle and solve user feedback in a timely manner. At the same time, we carefully collect suggestions and opinions from users and use them as an important basis for improving products and services. We continuously improve the after-sales service system, enhance service quality and user experience, and establish long-term and stable cooperative relationships with users.