Fresh-keeping sealing packaging machine

1. Isolation from air: It can effectively isolate the product in the package from the outside air, prevent oxidation, moisture, mildew and other problems, and greatly extend the shelf life of the product.

2. Inhibit microbial growth: Reduce the conditions for microbial growth and reduce the risk of product contamination and deterioration.

3. Good sealing performance: Through advanced sealing technology and high-quality sealing materials, the sealing of the package is ensured.

4. Firm seal: The seal is firm and neat, not easy to crack, and can withstand certain external forces and pressures.

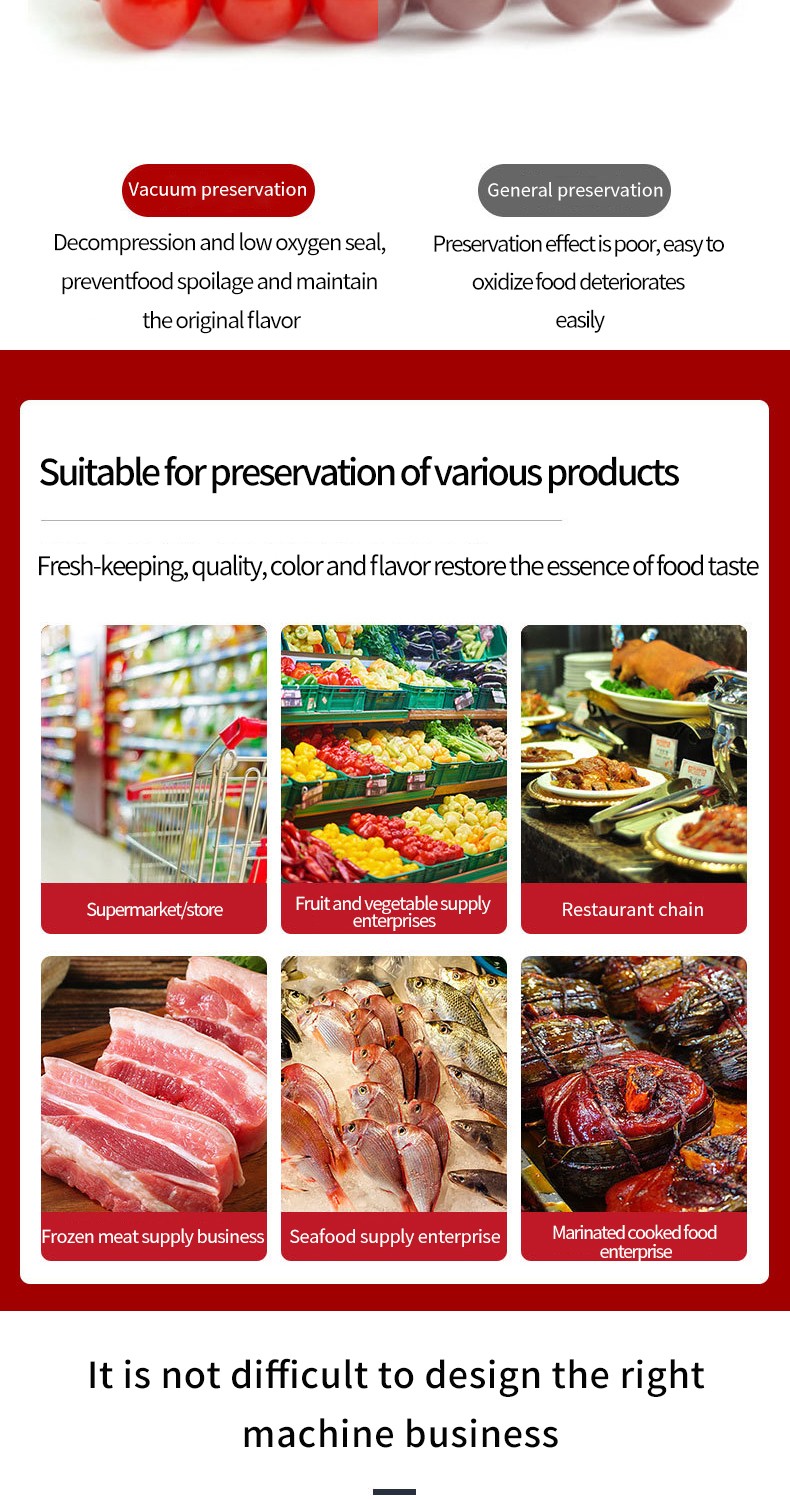

5. Many product types: It can be used for various types of product packaging, including food, medicine, cosmetics, etc.

6. Diverse packaging materials: Compatible with a variety of common packaging materials, such as plastic film, aluminum foil, composite materials, etc. Users can choose the appropriate packaging material according to the characteristics and needs of the product.

Fresh-keeping sealing packaging machine adopts advanced vacuum extraction and heat sealing integrated system, which can quickly extract the air in the package, create a low-oxygen or anaerobic environment, inhibit the reproduction of aerobic microorganisms, enzymatic reactions and oxidation processes, and maximize the shelf life of the product.

It has flexible and diverse packaging modes to meet the needs of various products. From conventional three-side seals and four-side seals for flat products to three-dimensional pillow seals and special-shaped seals for packaging irregular items.

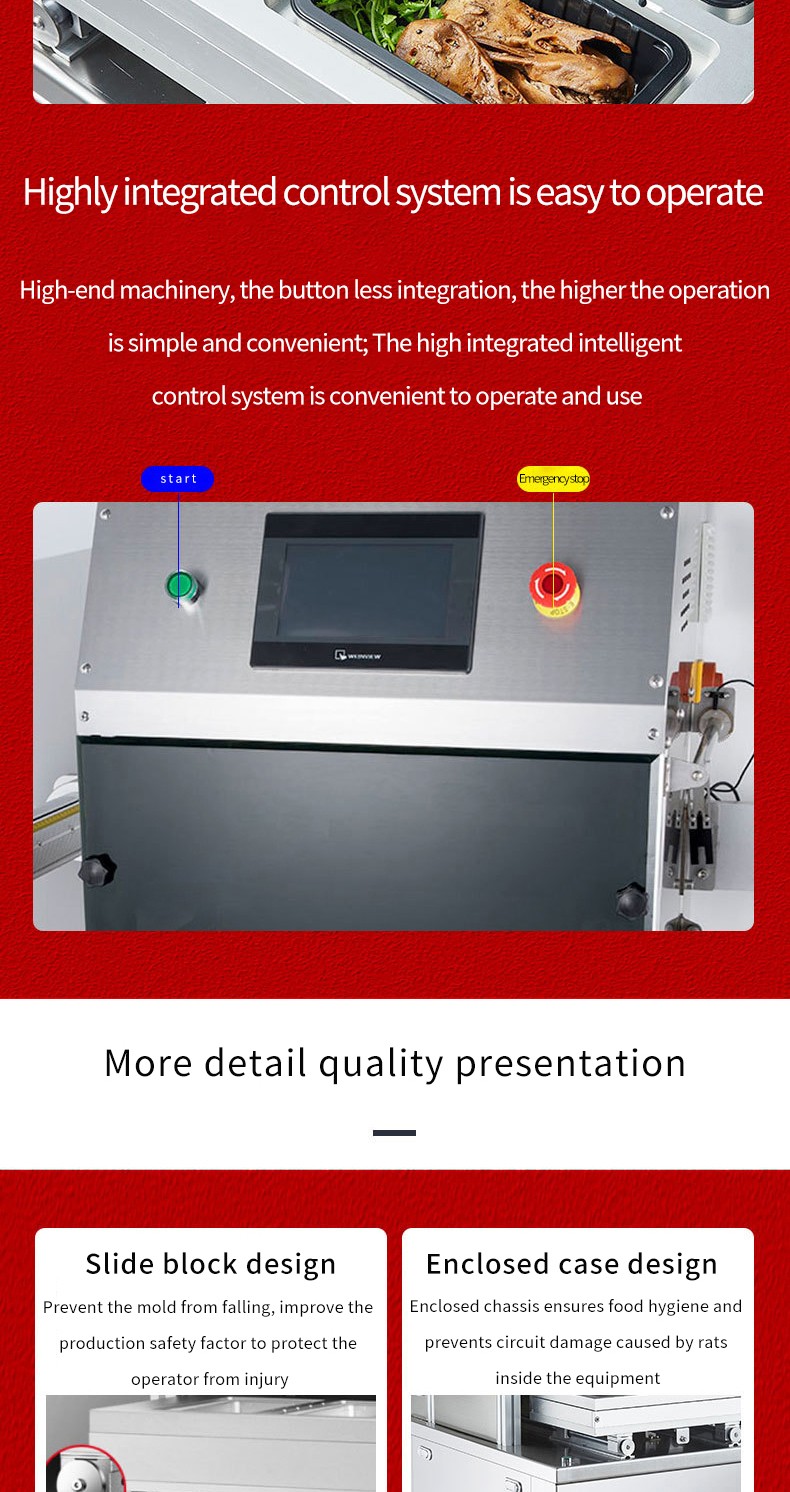

Built-in high-sensitivity sensor monitors key parameters such as air pressure, temperature, material position, etc. in real time, and automatically provides feedback to adjust the machine's operating status.

Depending on the complexity of the packaging specifications, the packaging volume can reach 300-800 packages per hour. When processing small single-specification products, it can easily exceed 800/hour under continuous and efficient operation; when dealing with large products that require fine-tuning packaging, it can also maintain a stable 400 packages/hour.

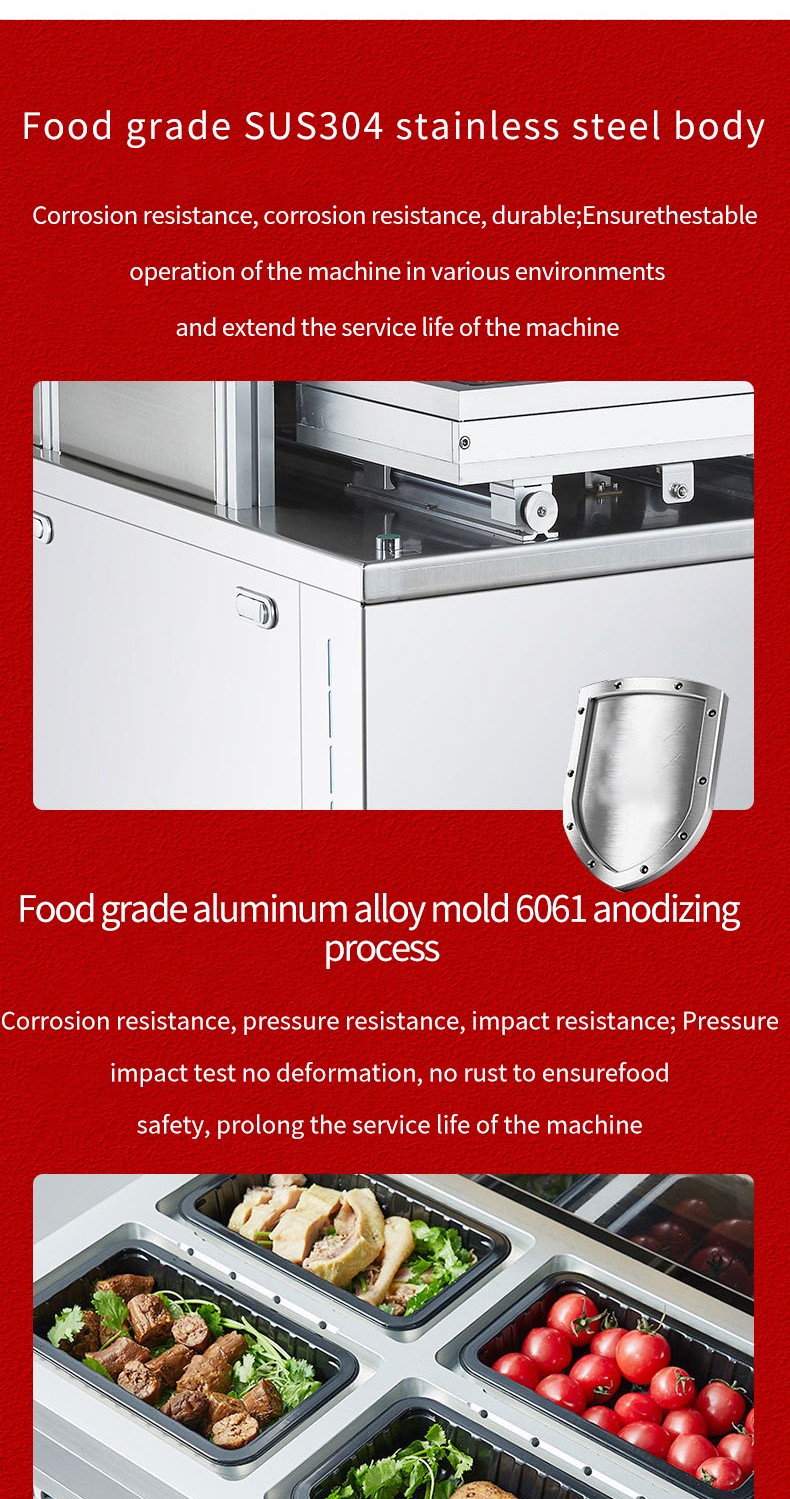

The power and heating system design is optimized, and the energy consumption of the whole machine is reduced by about 25% compared with traditional models. Energy-saving motors and high-efficiency thermal insulation materials are used, and the operating cost is economical. The key mechanical structure is strengthened and balanced, and with high-quality electrical components, the average trouble-free operation time exceeds 10,000 hours, and it can withstand long-term continuous operation.

It is suitable for a variety of packaging materials, ranging from common PE, PP, PET plastic films to high-end aluminum foil and composite materials, and automatically optimizes sealing parameters according to material characteristics. It comes with a precise electronic metering module to control the error within a very small range when packaging by weight and quantity.

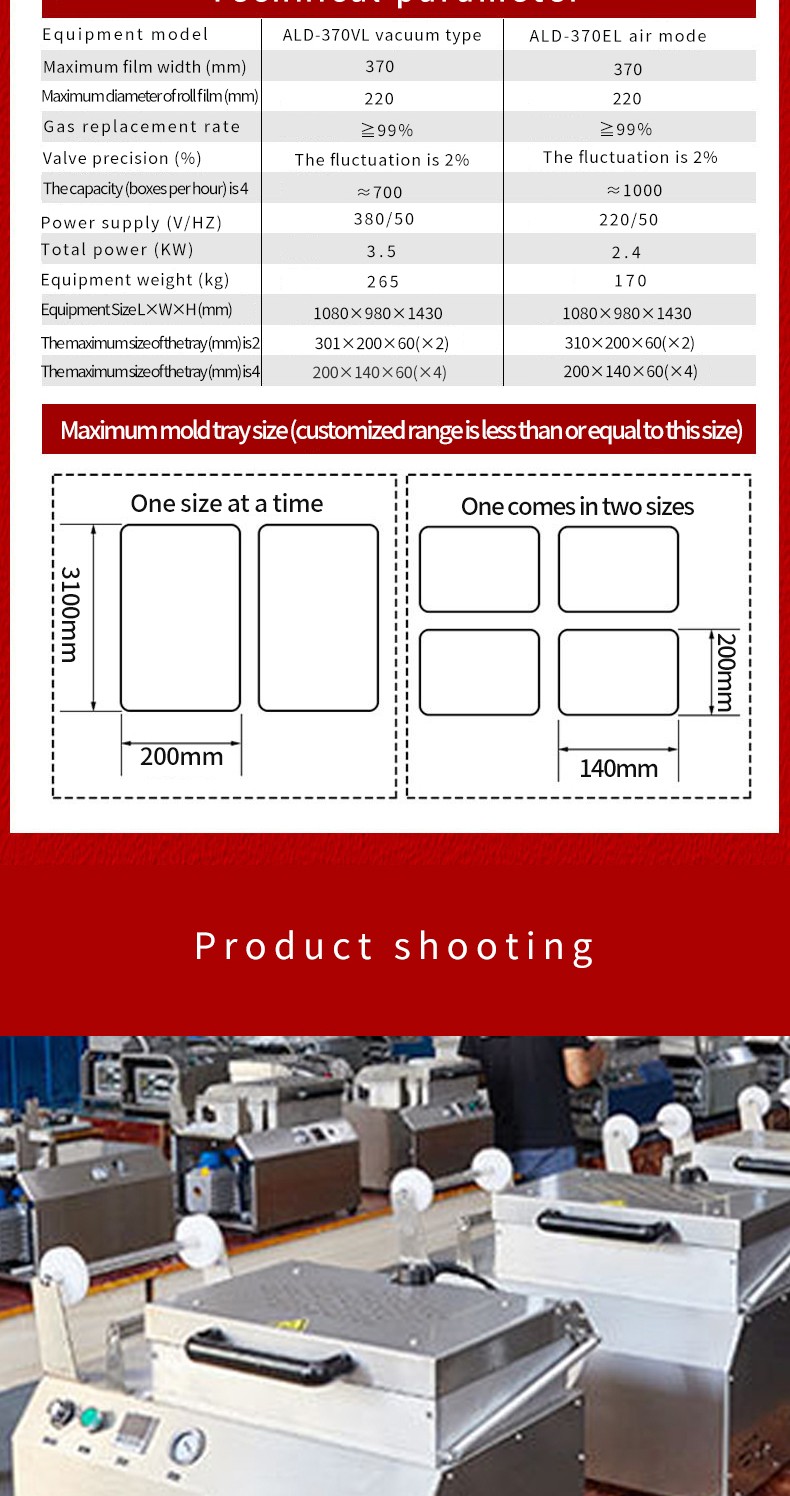

Equipment model:ALD-370VL vacuum type,ALD-370EL air mode

Maximum film width (mm):370,370

Maximum diameter of roll film (mm):220,220

Gas replacement rate:≥99%,≥99%

Valve precision (%):The fluctuation is 2%,The fluctuation is 2%

The capacity (boxes per hour) is 4:≈700,≈1000

Power supply (V/HZ):380/50,220/50

Total power (KW):3.5,2.4

Equipment weight (kg):265,170

Equipment Size L×W×H(mm):1080×980×1430,1080×980× 1430

The maximum size of the tray (mm) is2:301×200×60(×2),310×200×60(×2)

The maximum size of the tray (mm) is4:200×140×60(×4),200×140×60(×4)

The overall body structure is compact and reasonable, optimized based on ergonomics and workshop layout, and occupies about 30% less space than similar equipment. It incorporates folding and embedded components, making it easy to place in limited space, adapting to the cramped space of small and micro enterprises and facilitating flexible adjustment of production line layout.

Convenient maintenance features: Adopting the modular assembly concept, each functional module is independently packaged and easy to disassemble, which is convenient for daily cleaning and regular maintenance. Ordinary maintenance can be completed efficiently by one person within 2-3 hours to ensure the long-term and stable operation of the equipment.

Multiple protection system: Build a comprehensive safety protection network, covering electrical safety, mechanical safety and operational safety. From hardware locking to software reminders, it fully protects the safety of operators and the stable operation of equipment, in line with strict industrial safety regulations.