Energy-efficient strapping machine

1. The use of advanced energy-saving technology and optimized circuit design can significantly reduce energy consumption compared to traditional strapping machines.

2. Equipped with an intelligent control system, it can automatically adjust the power according to the actual needs of the strapping task.

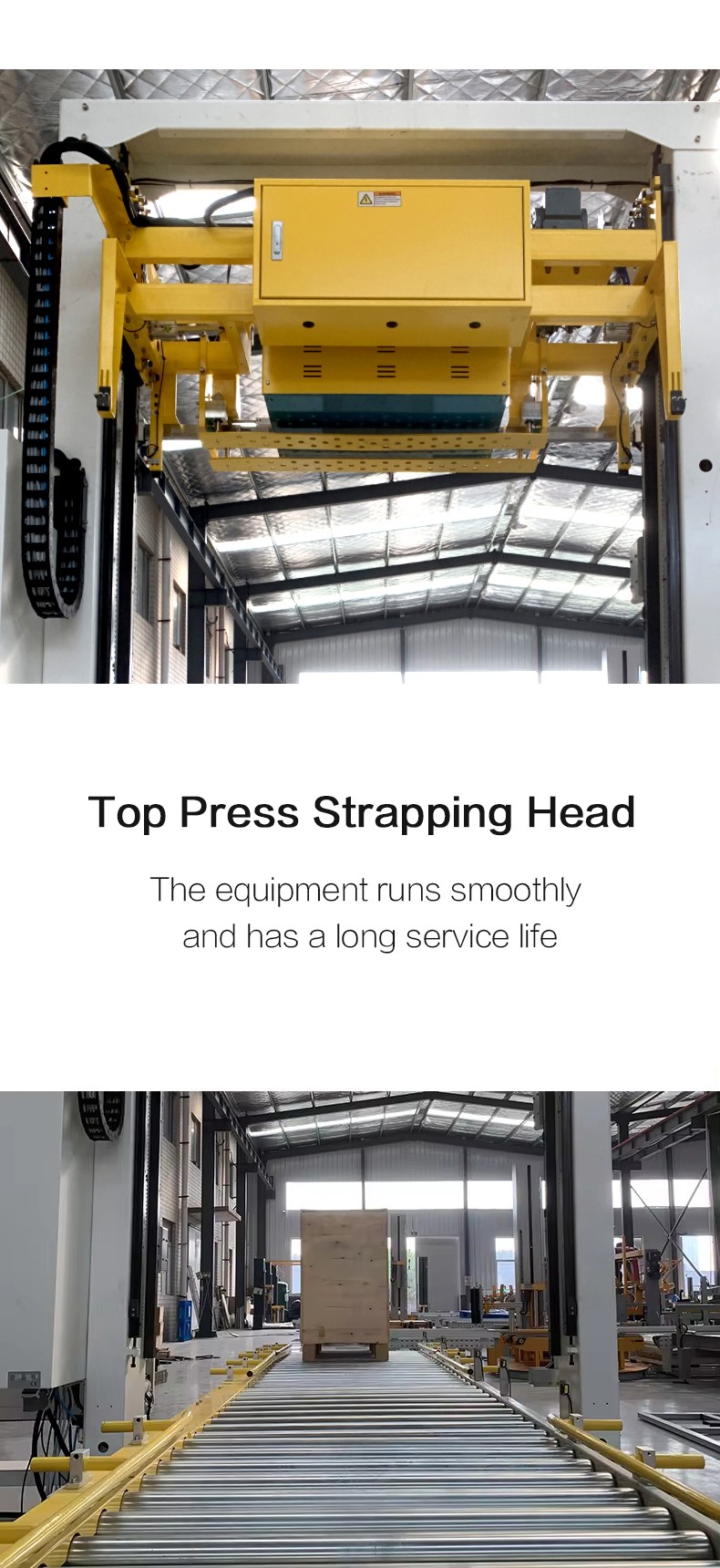

3. The use of high-quality components and advanced manufacturing technology has a low failure rate of the equipment.

4. Equipped with a user-friendly operation interface, it is easy to use. The staff can operate it proficiently after simple training, and the strapping parameters can be easily set.

5. Equipped with multiple safety protection devices, such as photoelectric sensors, emergency stop buttons, etc., the equipment can be stopped in time when an abnormal situation occurs.

The motor drives the transmission device to drive the tightening wheel or tightening mechanism to tighten the strapping belt around the object. Some advanced models use torque control technology to accurately control the tightening force to ensure that the object is tied tightly without damaging it.

Common ones are hot melt connection and mechanical buckle connection. Hot melt connection uses a heating element to instantly melt and stick the two ends of the strapping tape together; mechanical buckle connection uses metal or plastic buckles to fix the two ends of the strapping tape.

When the strapping tape is tightened and connected, the excess strapping tape is cut off by a cutting device, which usually uses a blade or hot cutting method.

It is mostly made of high-strength aluminum alloy or stainless steel. The body is sturdy, durable, corrosion-resistant, light in weight, and easy to move and install.

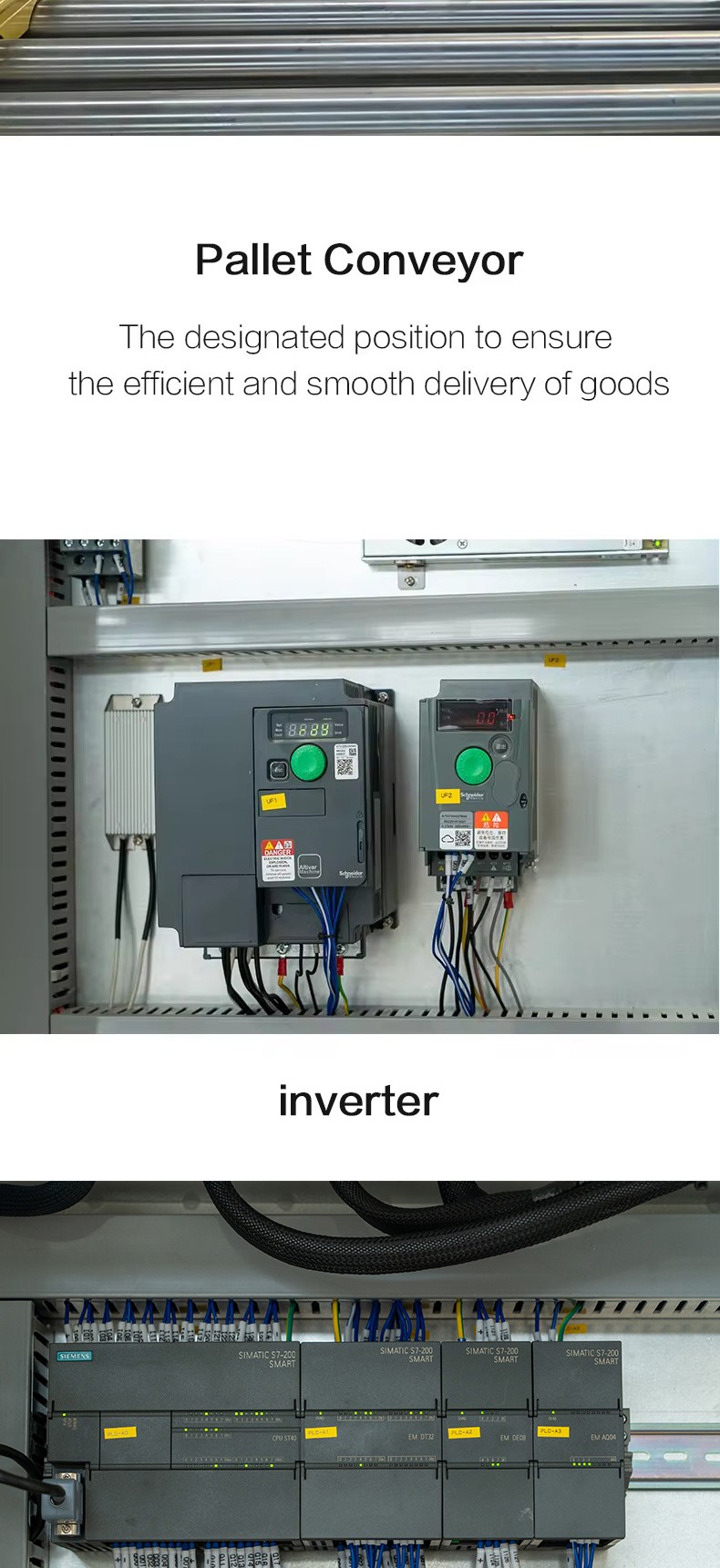

The motor uses energy-saving and high-efficiency motors, matched with high-quality reducers and transmission chains to ensure stable and efficient power transmission. The control system uses advanced PLC controllers, with touch screen operation interface, easy to operate and precise control.

It uses energy-saving motors and optimized circuit control systems, which can automatically adjust power according to actual workload.

It is equipped with multiple safety protection devices, such as photoelectric sensing devices. When objects or human bodies enter the dangerous area, the equipment will automatically stop running.

A variety of interfaces are reserved, which can be connected with other packaging equipment such as automatic feeders, conveyors, labeling machines, etc. to form an automated packaging production line.