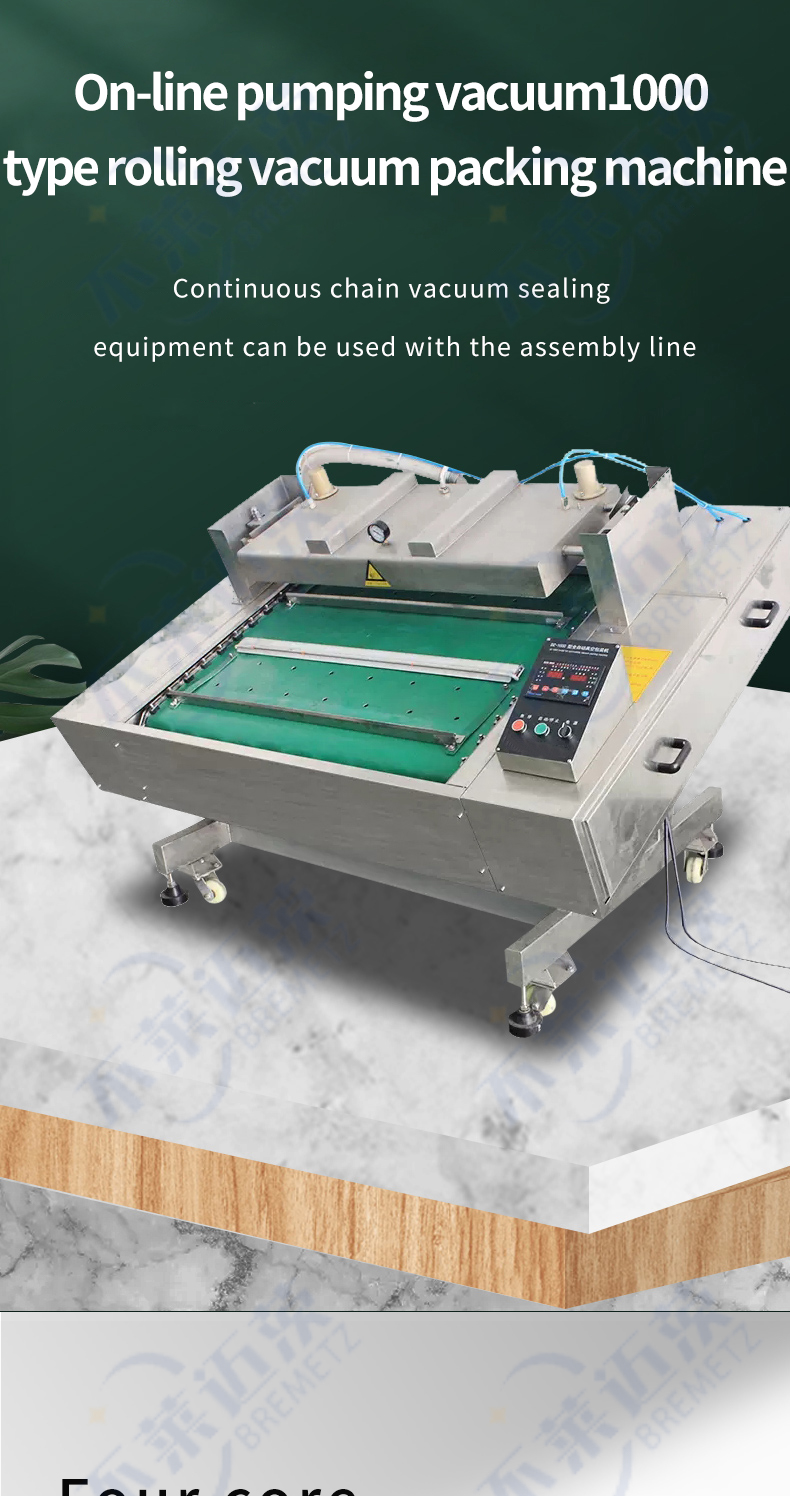

Rolling vacuum packaging machine

1. The continuous rolling working mode can perform vacuum packaging operations uninterruptedly, greatly improving production efficiency.

2. The equipment runs fast, the sealing line is long, and multiple packaging bags can be vacuumed and sealed at the same time.

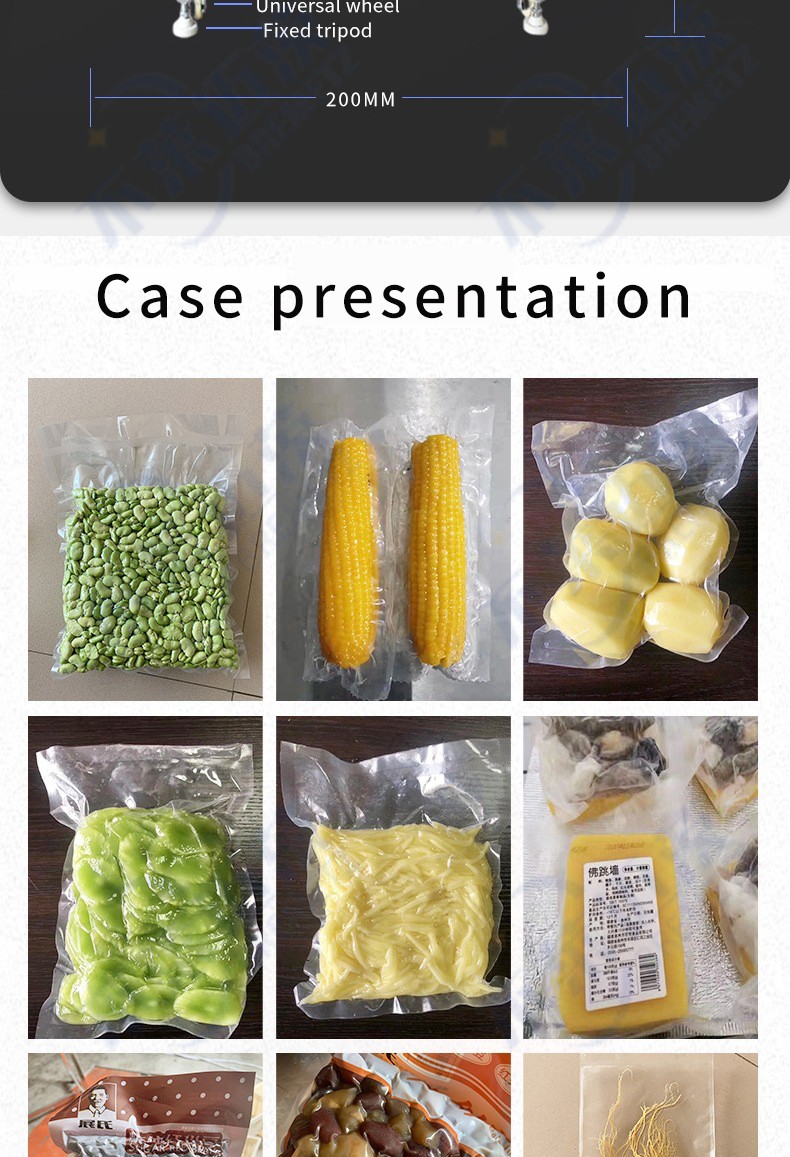

3. By extracting the air in the packaging bag, a low-oxygen or anaerobic environment is created to effectively inhibit the growth and reproduction of aerobic microorganisms.

4. Vacuum packaging can isolate external moisture and pests, and play a good role in moisture and insect prevention.

5. It is suitable for various plastic composite film bags, aluminum foil composite film bags and other packaging materials, and can meet the barrier properties, flexibility, transparency and other requirements of different products for packaging materials.

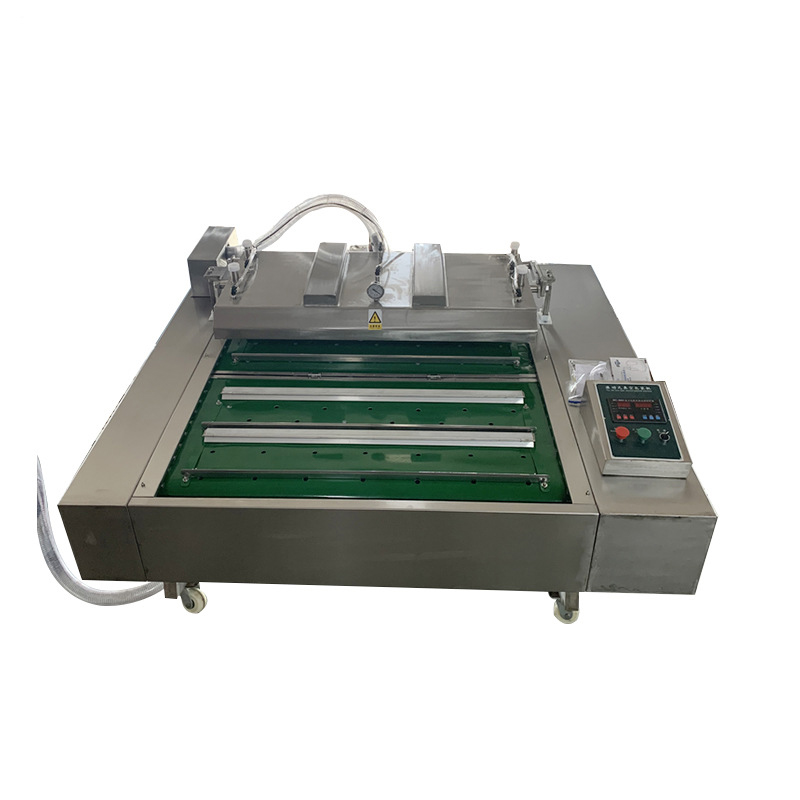

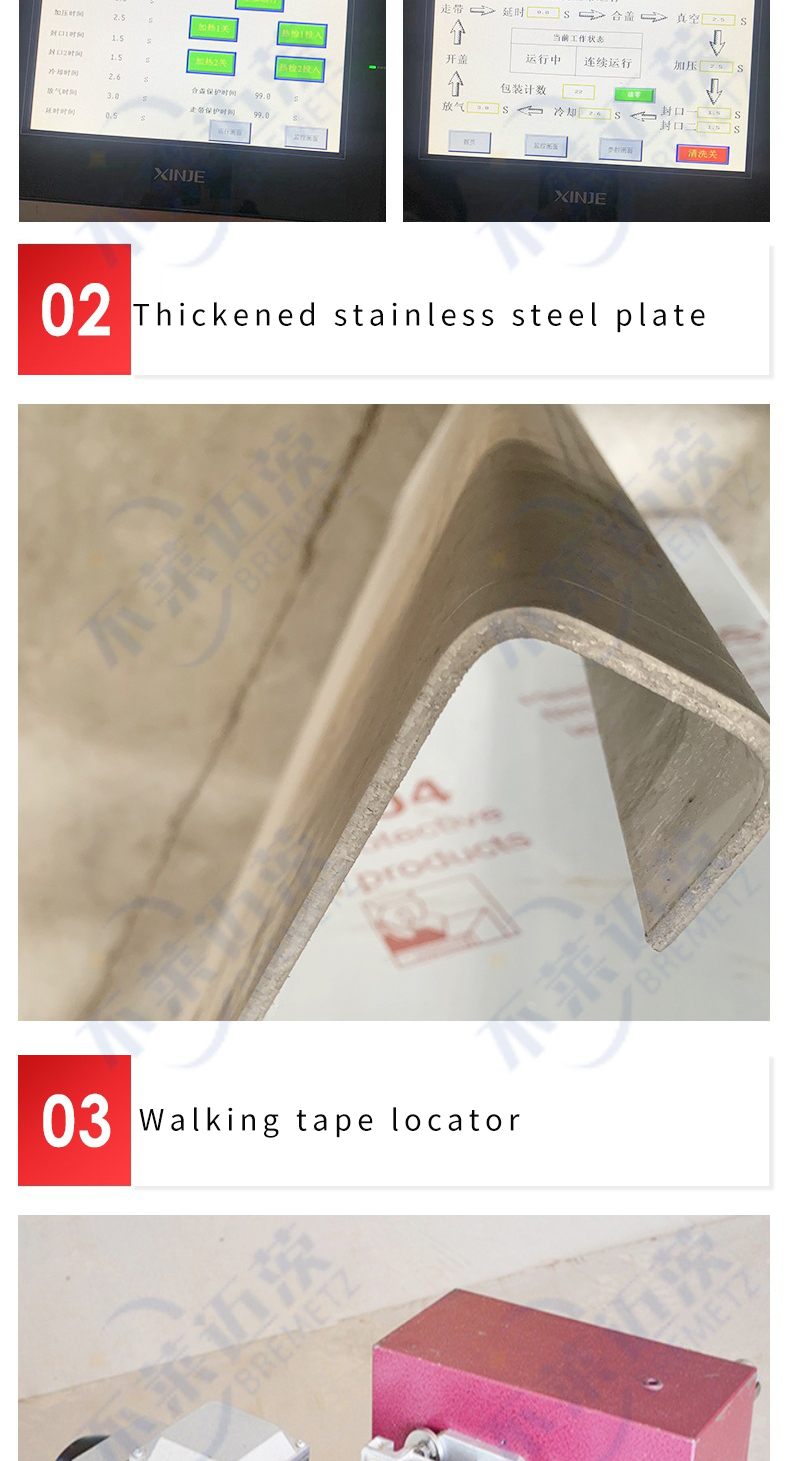

The overall structure of the rolling vacuum packaging machine is compact and reasonably designed. It is mainly composed of a frame, a vacuum system, a sealing system, a transmission system, a control system, and a packaging studio.

Equipped with high-performance vacuum pumps, such as rotary vane vacuum pumps or German imported vacuum pumps, which have strong vacuuming capabilities and can quickly extract the air in the packaging studio to achieve a high vacuum level.

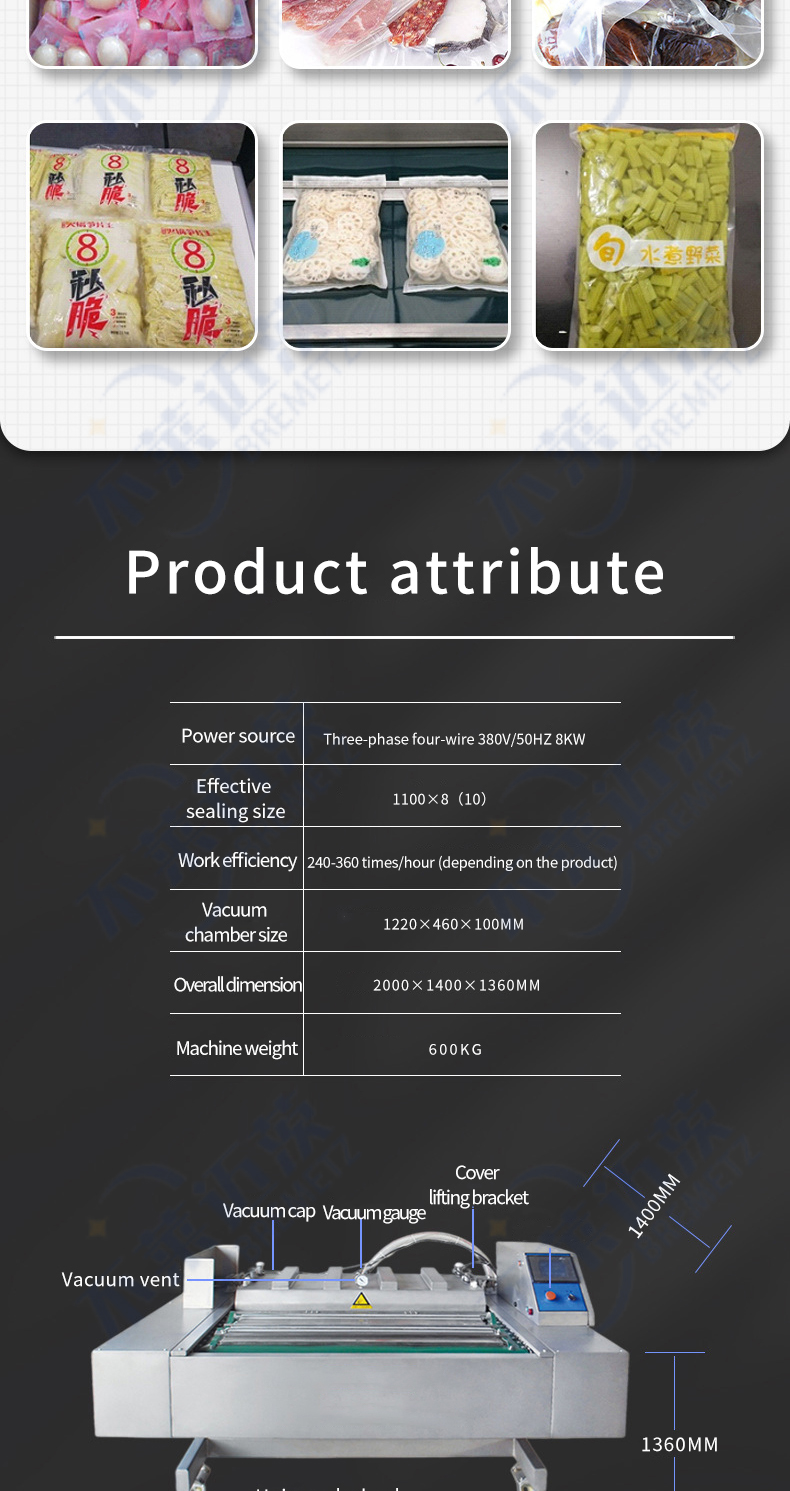

Power source:Three-phase four-wire 380V/50HZ 8KW

Effective sealing size:1100×8 (10)

Work efficiency;240-360 times/hour (depending on the product)

Vacuum chamber size:1220×460×100MM

Overall dimension:2000×1400×1360MM

Machine weight:600KG

Using advanced heat sealing technology, the sealing heating element is made of high-quality alloy material, which can quickly heat up to the set sealing temperature, usually in the range of 180 - 220℃ and can be precisely adjusted.

It consists of a motor, a reducer, a transmission chain or a conveyor belt, etc., and is responsible for driving the rolling motion of the packaging studio and the transportation of packaging materials. The motor provides stable power output, and the reducer can adjust the speed as needed to ensure that the transmission system runs smoothly and accurately.

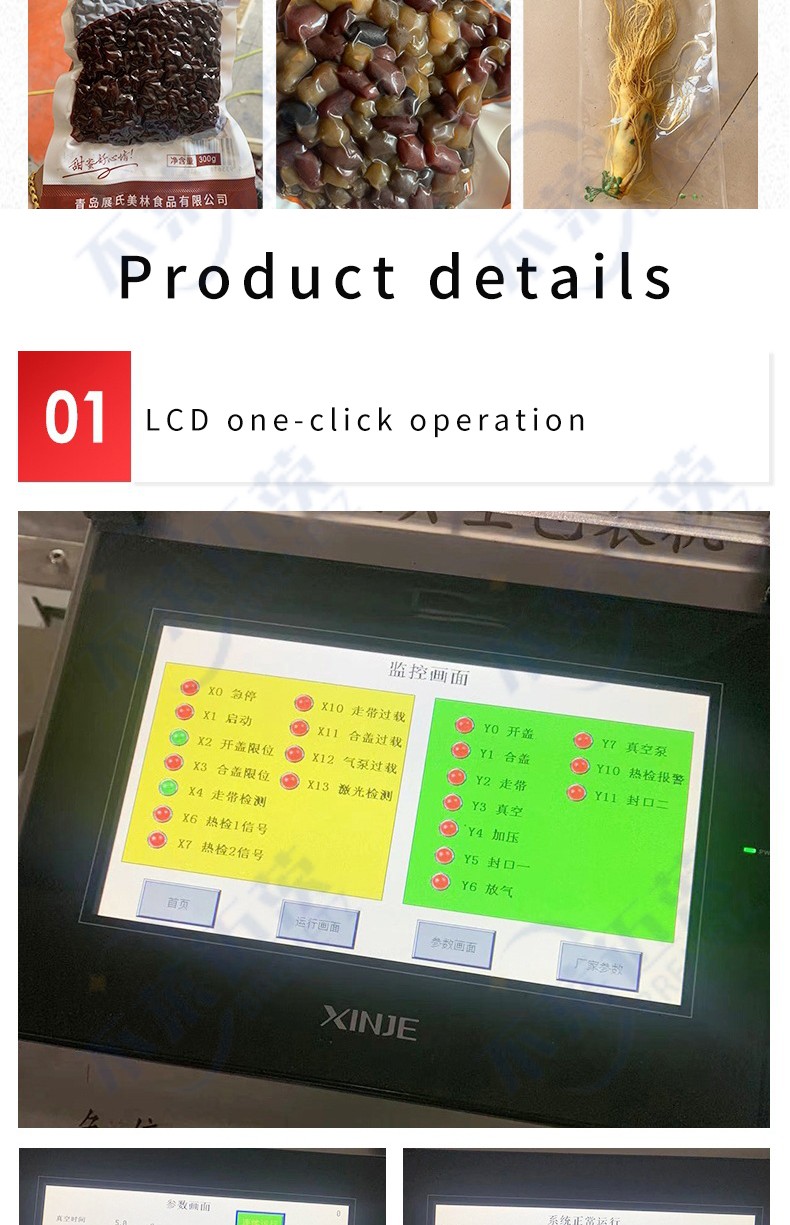

Based on the advanced programmable logic controller (PLC) and touch screen human-machine interface, intelligent equipment control and operation are realized. Operators can easily set various parameters of the equipment through the touch screen.

Through precise vacuum control, stable sealing temperature and time adjustment, and high-quality sealing molds and heating elements, the sealing performance at the seal is good, which can effectively prevent air leakage, maintain the effect of vacuum packaging, and extend the shelf life and freshness of the product.

It can adapt to the requirements of various product types, packaging materials and packaging specifications. Whether it is solid, liquid or powdery products, whether it is plastic film, aluminum foil composite film or other special packaging materials, it can be well handled on the rolling vacuum packaging machine.

While meeting the requirements of efficient production, we also focus on energy-saving and environmentally friendly design. We use energy-saving vacuum pumps and optimized electrical control systems to reduce the energy consumption of the equipment.