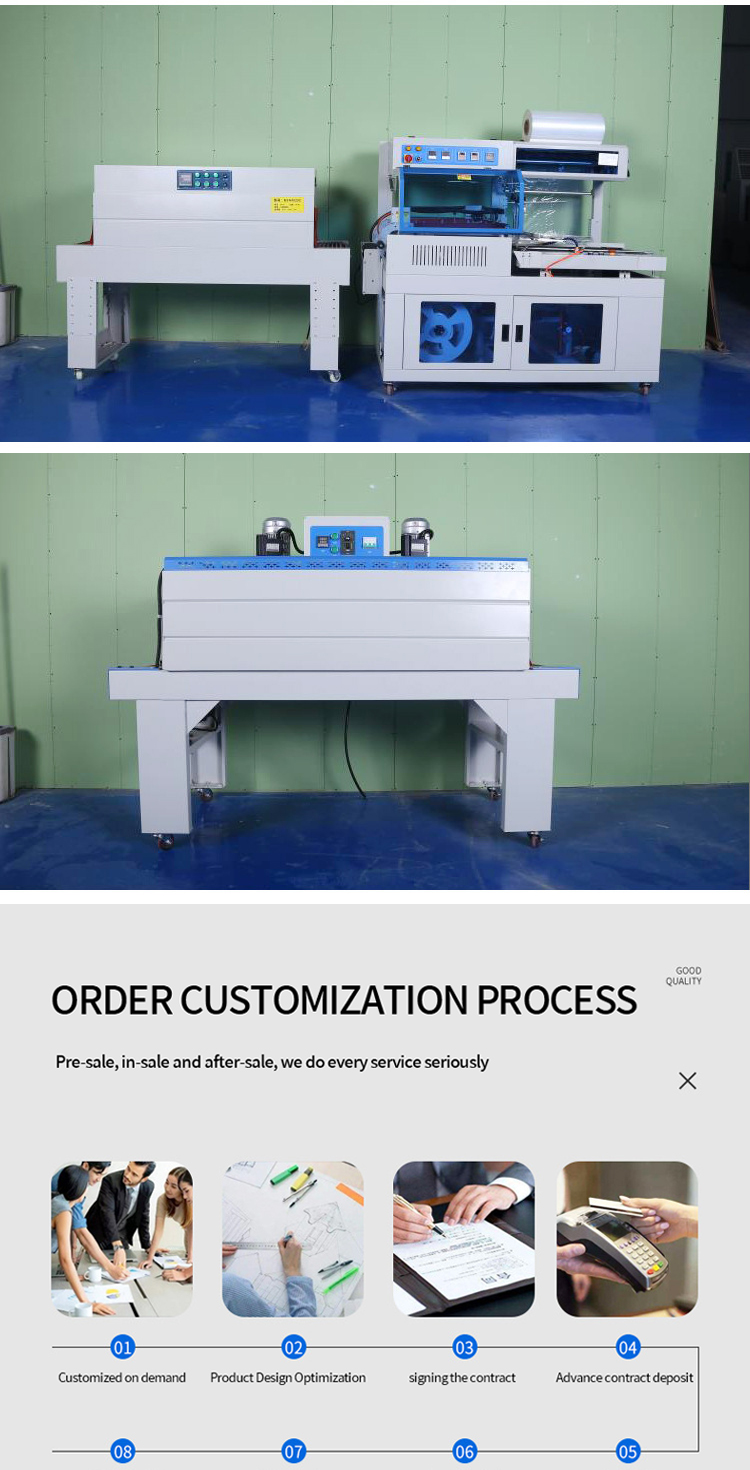

Sealing and cutting machineheat shrink packaging machine

1. Efficient and automated operation: Sealing and cutting machines are usually highly automated and can realize functions such as automatic film feeding, perforation, film sealing and cutting, and automatic waste winding.

2. Good sealing quality: Carton sealing is done by sticky tape and other methods, which is economical, fast and easy to adjust. The upper and lower sealing actions can be completed at one time, and printed tape can also be used.

3. Low maintenance cost: The structure of the sealing and cutting machine is relatively simple, the performance of the main components such as the drive motor is stable, and daily maintenance work is relatively easy.

4. Excellent packaging effect: The heat shrink packaging machine can make the packaging film fit tightly on the surface of the product, forming a transparent, flat and beautiful packaging layer that can effectively protect the product from external factors such as dust and moisture.

5. High efficiency and energy saving: The use of advanced heating technology, such as far-infrared heating, can quickly shrink the film and improve packaging efficiency.

6. Flexible and diverse packaging forms: The packaging form and parameters can be flexibly adjusted according to the shape, size and packaging requirements of different products to achieve a variety of packaging methods.

Sealing and cutting machines are widely used in the packaging field. They are mainly used to seal products and cut packaging materials to wrap the products. They are one of the key equipment for primary packaging of products. They are often used in conjunction with other packaging equipment and are widely used in product packaging in many industries such as food, daily necessities, and industrial parts.

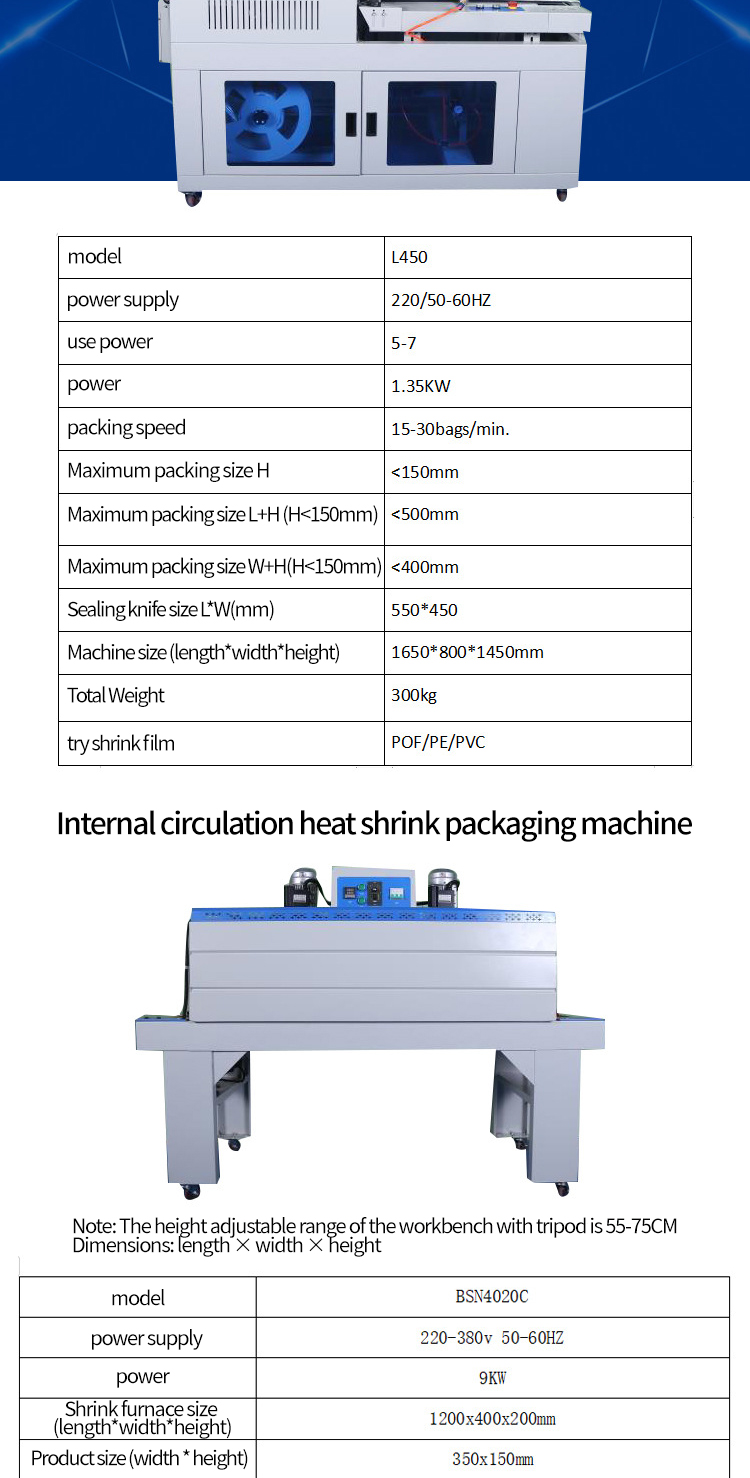

model:L450

power supply:220/50-60HZ

use power:5-7

power:1.35KW

packing speed:15-30 bags/min

Maximum packing size H:<150mm

Maximum packing size L+H (H<150mm):<500mm

Maximum packing size W+H(H<150mm):<400mm

Sealing knife size L*W(mm):550*450

Machine size (length*width*height):1650*800*1450mm

Total Weight:300kg

try shrink film:POF/PE/PVC

model:BSN4020C

power supply:220-380v 50-60HZ

power:9KW

Shrink furnace size (length*width*height):1200x400x200mm

Product size (width* height):350x150mm

transfer speed:0-15m/min

Transport material:Mesh belt, chain roller, Teflon

Transport load:20kg max

Machine size (length*width*height):1600x560x660mm

Total Weight:80 kg

use shrink film:POF. PVC

Efficiency: The sealing and cutting speed is fast, and it can complete the packaging of a large number of products in a short time, improving production efficiency and reducing production costs. Compared with traditional manual packaging, the packaging speed can be significantly improved to meet the needs of mass production.

Accuracy: Through advanced positioning and sealing and cutting technology, the quality of sealing and the accuracy of packaging dimensions are ensured. The seal is firm, which can effectively prevent product leakage and external contamination, while ensuring the neat and beautiful appearance of the packaging and improving the overall quality of the product.

Flexibility: It can adapt to a variety of different sizes, shapes and types of products, as well as packaging films of different materials and widths. Through simple parameter adjustment and component replacement, packaging conversion of different products can be achieved, which has strong versatility and flexibility.

Stability: The equipment adopts high-quality materials and advanced manufacturing technology, with good stability and reliability. During long-term continuous operation, it can maintain stable performance, reduce downtime, and ensure production continuity.

The operation panel is simple and clear, using high-quality electronic components, and the quality is stable.

The sealing and cutting part has a glass protective cover function to strictly protect the safety of the operator The sealing and cutting part has a glass protective cover function to strictly protect the safety of the operator.

Adjustable machine packaging height, easy to use.

The sealing and cutting knife part is coated with Teflon, and the sealing is not easy to crack and coke.

The intuitive operation panel and automated control system make it easy for operators to get started without complicated training. The structural design of the equipment is easy to maintain, key components are easy to disassemble and replace, and daily maintenance work is simple, reducing the maintenance cost and difficulty of the equipment.

We are equipped with a professional after-sales consulting team, who are familiar with the technical details and operation procedures of the equipment and can provide users with comprehensive technical support and answers. If users encounter any problems during use, such as equipment operation, parameter setting, troubleshooting, etc., they can contact the consulting team at any time by phone, email or online customer service to obtain timely and accurate suggestions and solutions.

When the equipment fails and requires repair, the user only needs to contact the after-sales service center and provide relevant information about the equipment and a description of the fault. The after-sales service team will respond quickly and arrange for maintenance personnel to come to the site for repair or instruct the user to send the equipment back to the manufacturer for repair based on the specific situation.

With the continuous development of technology and changes in market demand, manufacturers may upgrade and improve the technology of Sealing and cutting machine and Heat shrink packaging machine. The after-sales service team will provide users with relevant technical upgrade information in a timely manner, and provide users with equipment upgrade services based on user needs and the actual situation of the equipment.