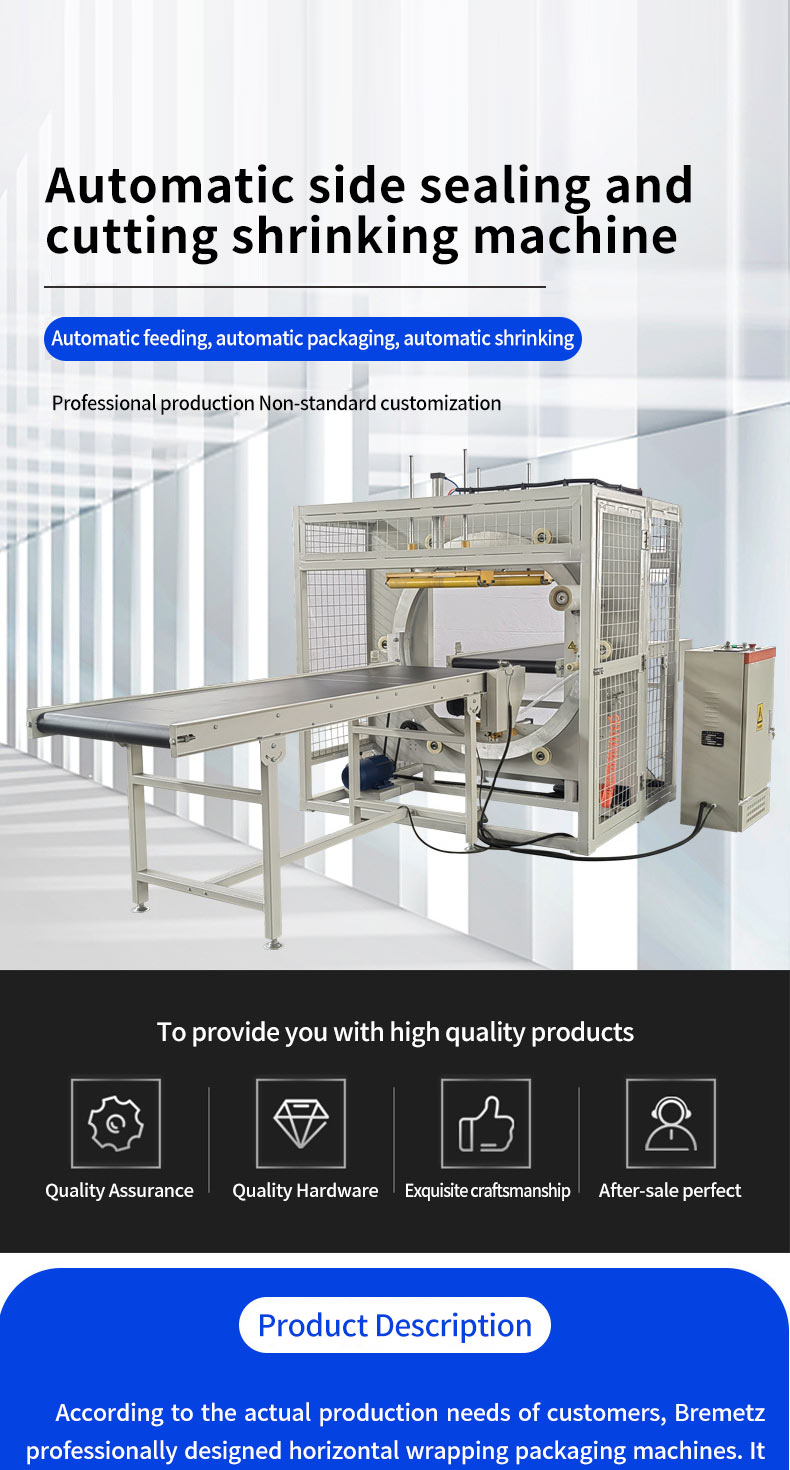

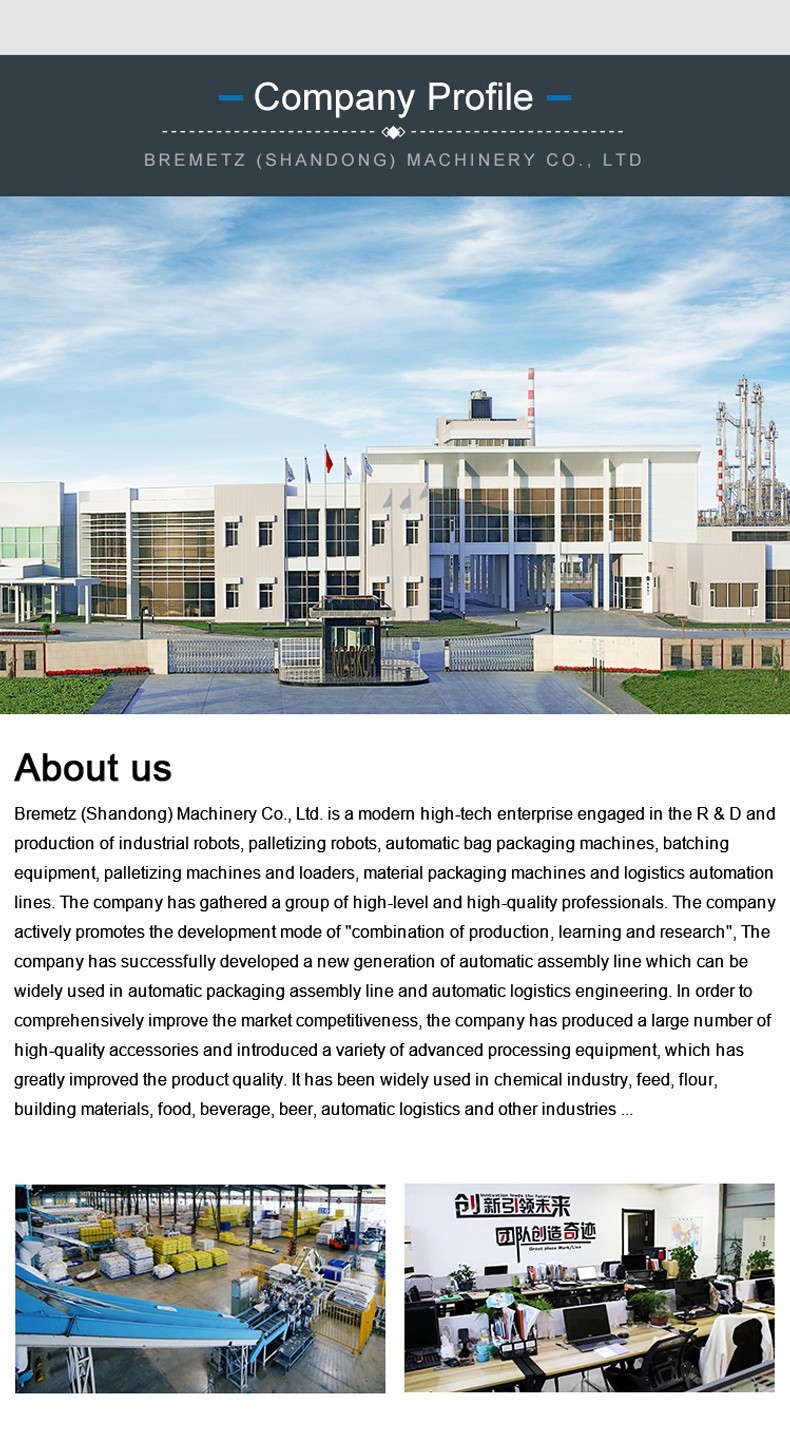

Fully automatic horizontal wrapping machine

1. It can automatically complete the packaging process of material conveying, winding, cutting and clamping without excessive human intervention.

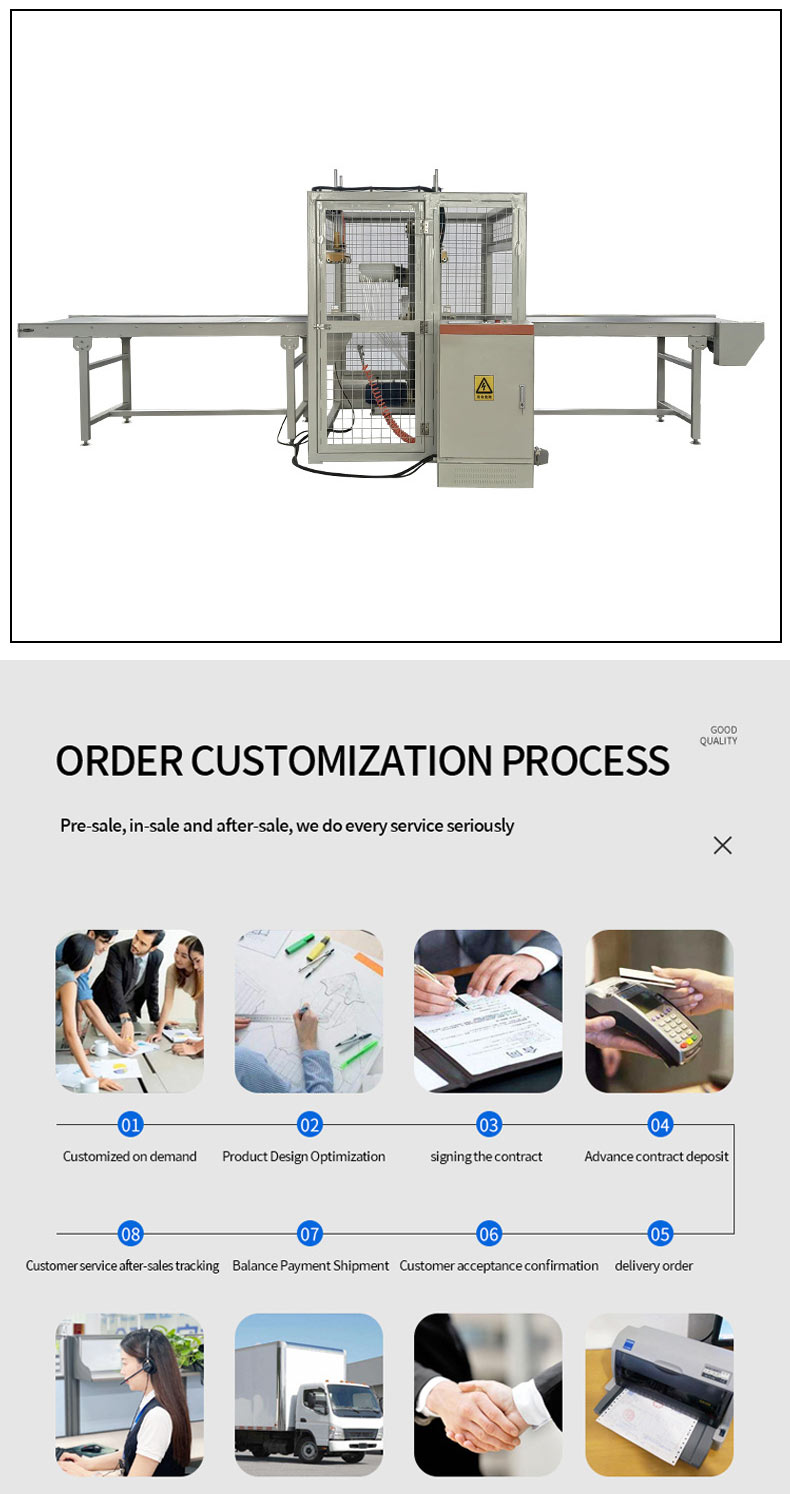

2. With precise control system and stable mechanical structure, it can ensure the high consistency of packaging effect of each product.

3. It has high working efficiency and can complete the packaging task of a large number of products in a short time.

4. It can be used to package products of various shapes, sizes and types, such as pallet goods, long pipes, columnar objects, etc.

5. Through tight and uniform winding packaging, it can effectively prevent the product from being affected by dust, moisture, collision and other factors during transportation and storage.

6. It can fix multiple products or products with pallets, etc. together to prevent the product from displacement and scattering during transportation.

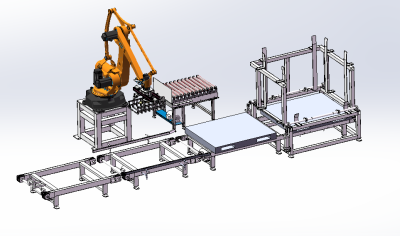

The fully automatic horizontal wrapping machine is a mechanical device specially used for efficient and automatic wrapping of various goods. Its main function is to wrap the packaging material evenly on the surface of the goods according to the preset procedures and parameters, so as to protect the goods and fix the position of the goods.

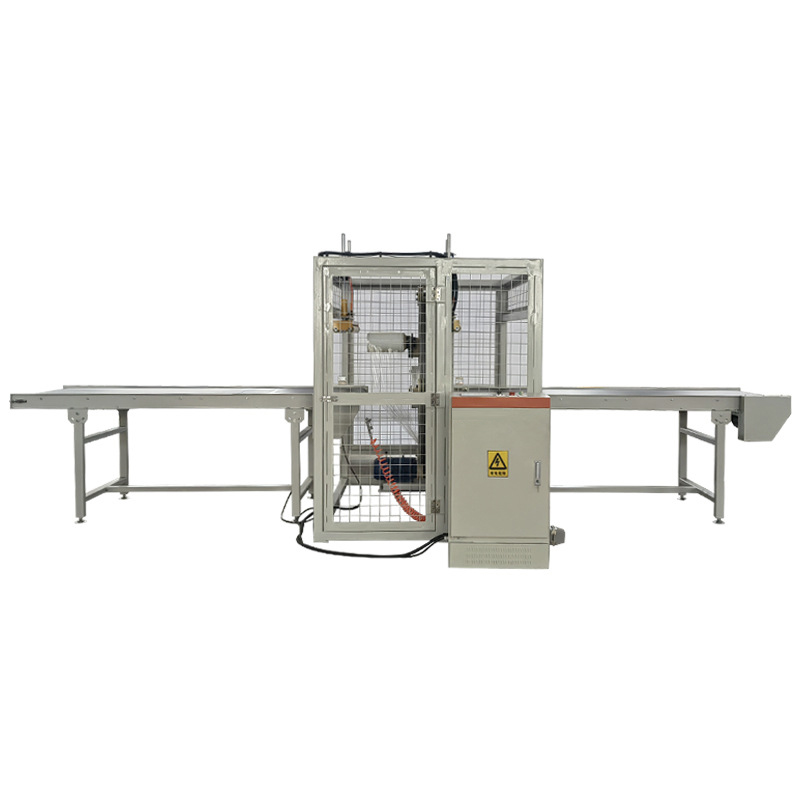

It adopts a solid metal structure, usually welded from high-quality steel, which has sufficient strength and stability to support the operation of the entire packaging machine and withstand the various forces during the packaging process.

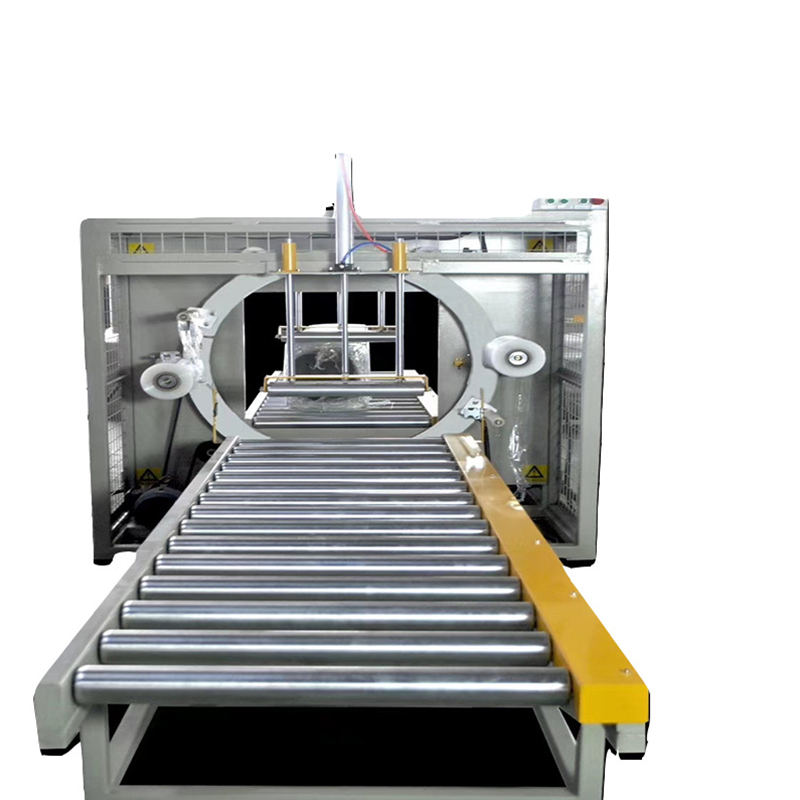

The conveying system includes components such as powered rollers, conveyor belts or chains, which are used to smoothly transport the goods to be packaged to the packaging location and output them after packaging is completed.

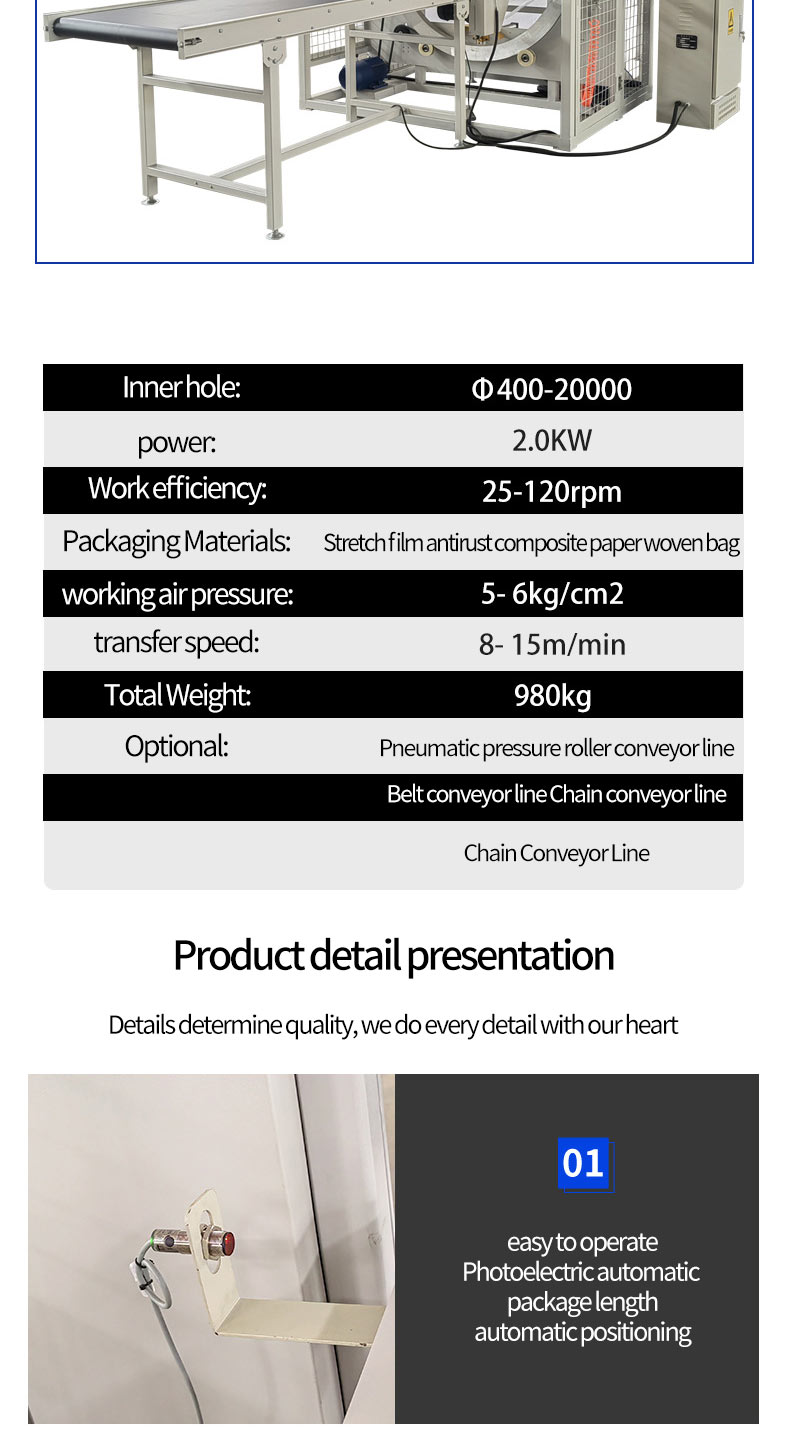

Inner hole:Φ400-20000

power:2.0KW

Work efficiency:25-120rpm

Packaging Materials:Stretch film antirust composite paper woven bag

working air pressure:5-6kg/cm2

transfer speed:8-15m/min

Total Weight:980 kg

Optional:Pneumatic pressure roller conveyor line,Belt conveyor line ,Chain conveyor line

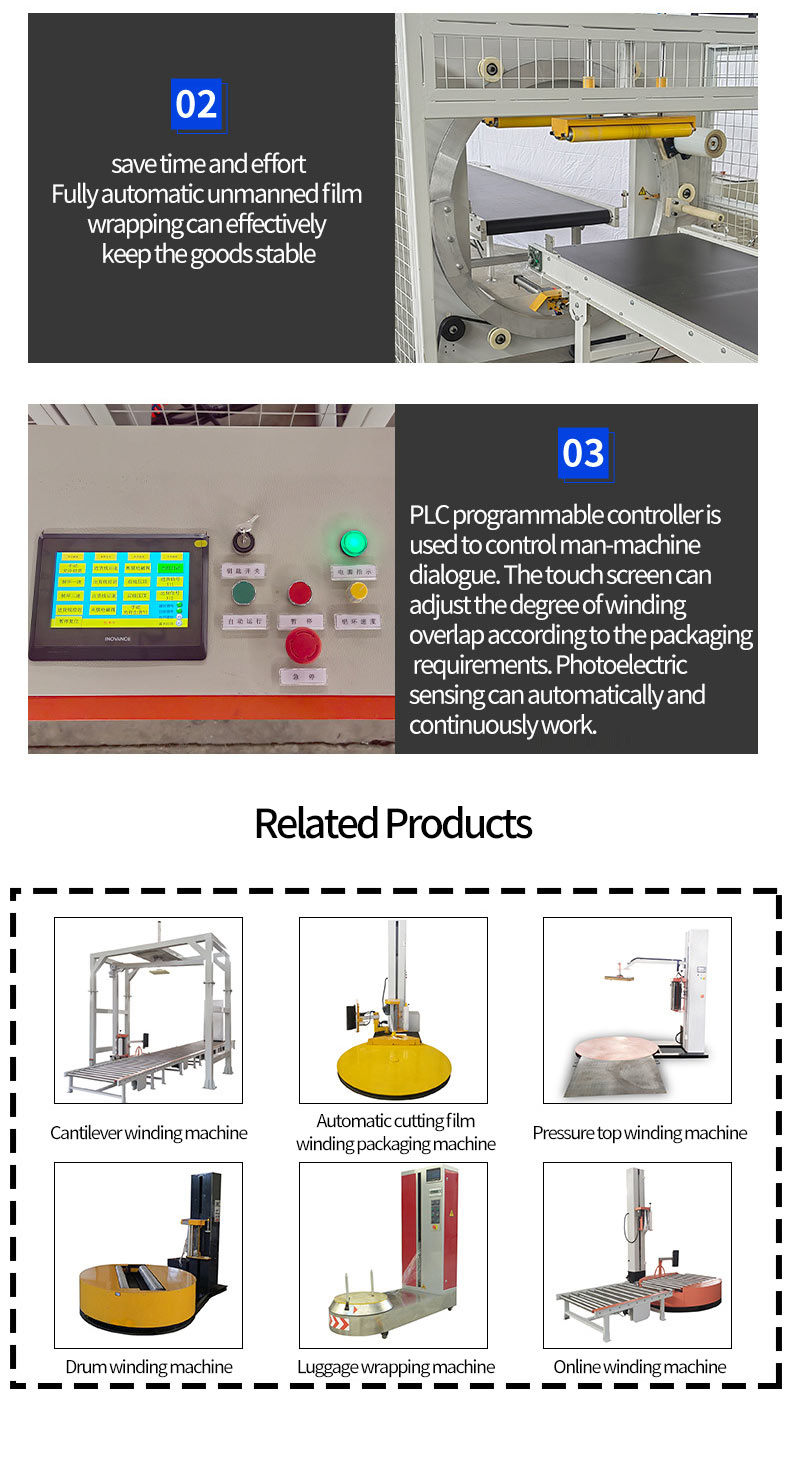

The wrapping mechanism is one of the core parts, which consists of a rotating arm, a film frame, a lifting device, etc. The rotating arm drives the film frame to make a circular motion around the goods to achieve the basic action of wrapping packaging.

Film supply system: mainly responsible for the transportation and supply of packaging film. It includes film roll installation shaft, traction roller, pre-stretching device, etc.

Scope of application

Logistics and warehousing industry: used for wrapping various cargo pallets in logistics centers and warehouses.

Manufacturing industry: widely used in machinery manufacturing, automobile manufacturing, electronic and electrical manufacturing and other industries to package produced parts and finished products.

Building materials industry: suitable for packaging various building materials products, such as cement pipes, steel, profiles, glass, etc.

Food and beverage industry: can be used for wrapping food and beverage packaging cartons or pallets to prevent product contamination.

Establish a professional after-sales maintenance team and service hotline to respond to customers' maintenance requests in a timely manner when their equipment fails.

For some simple faults or problems that customers can handle by themselves, manufacturers can also provide customers with remote technical support through telephone, video, etc.

With the continuous development of technology and changes in market demand, manufacturers may upgrade the technology and performance of fully automatic horizontal wrapping machines.

According to the special needs and production process requirements of customers, we provide customers with personalized equipment transformation services.