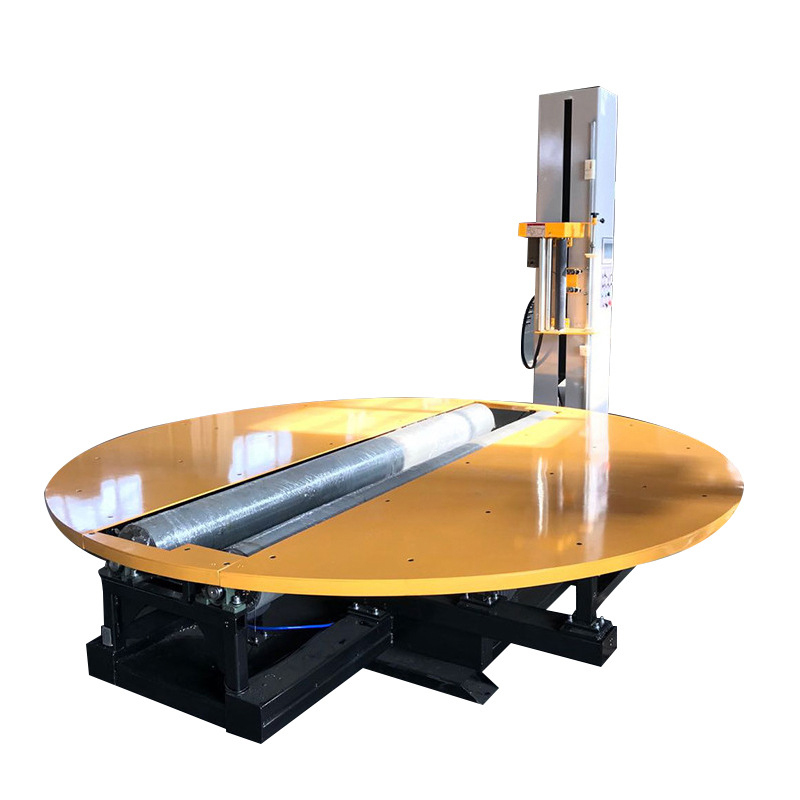

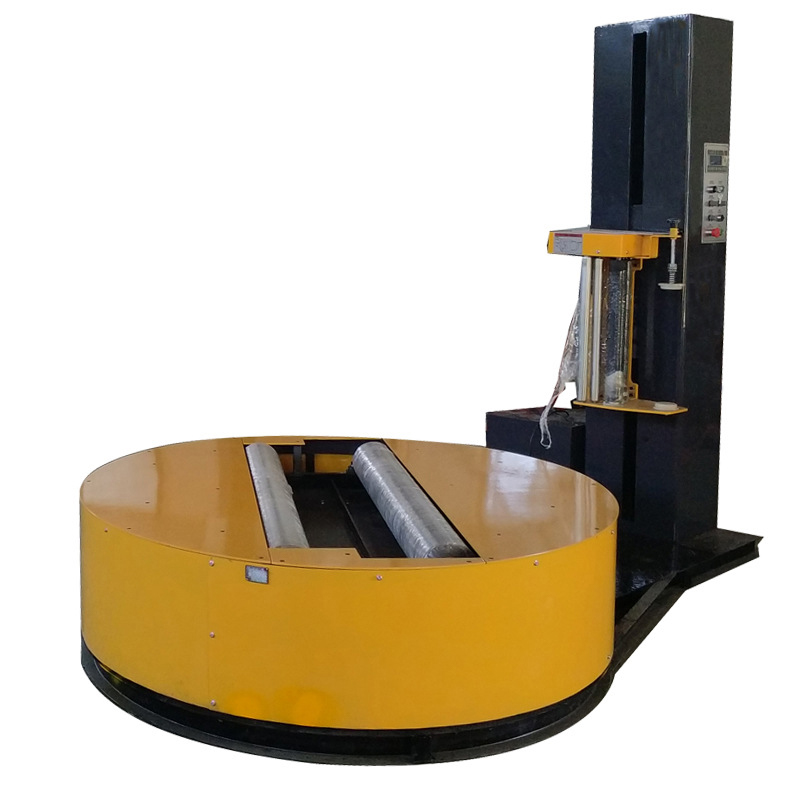

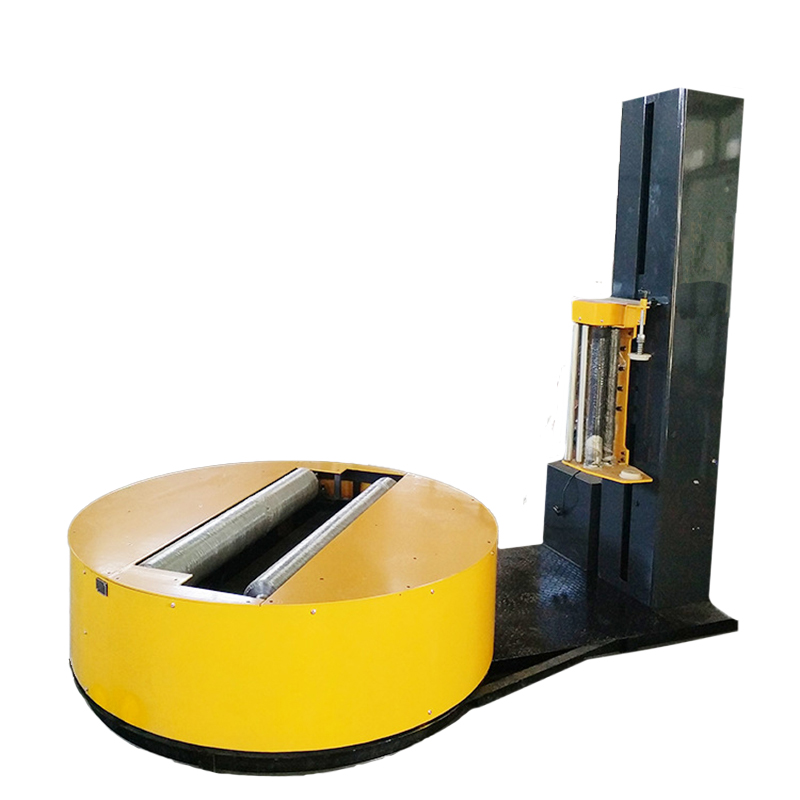

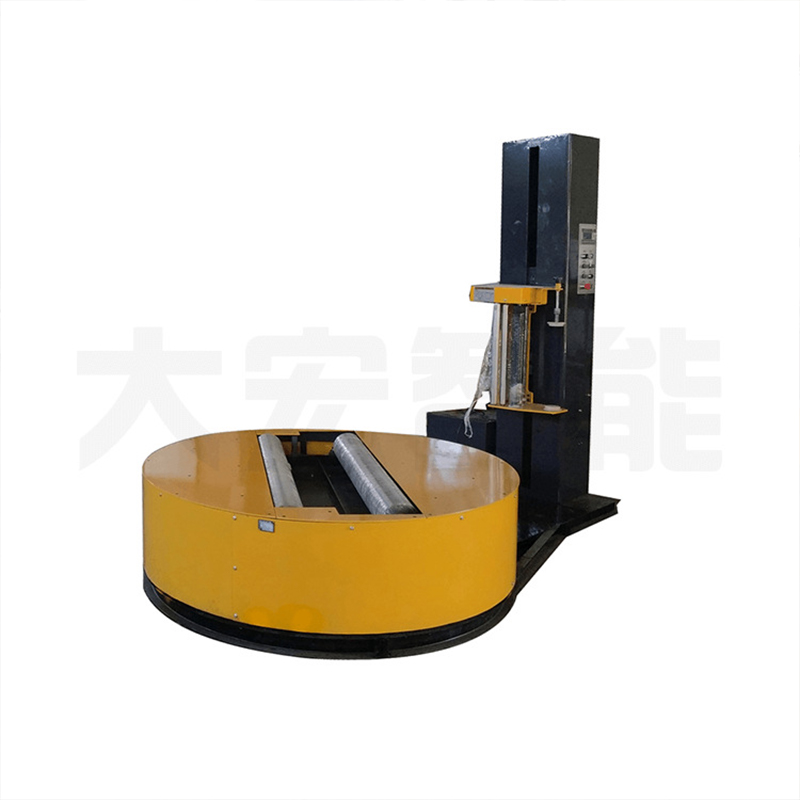

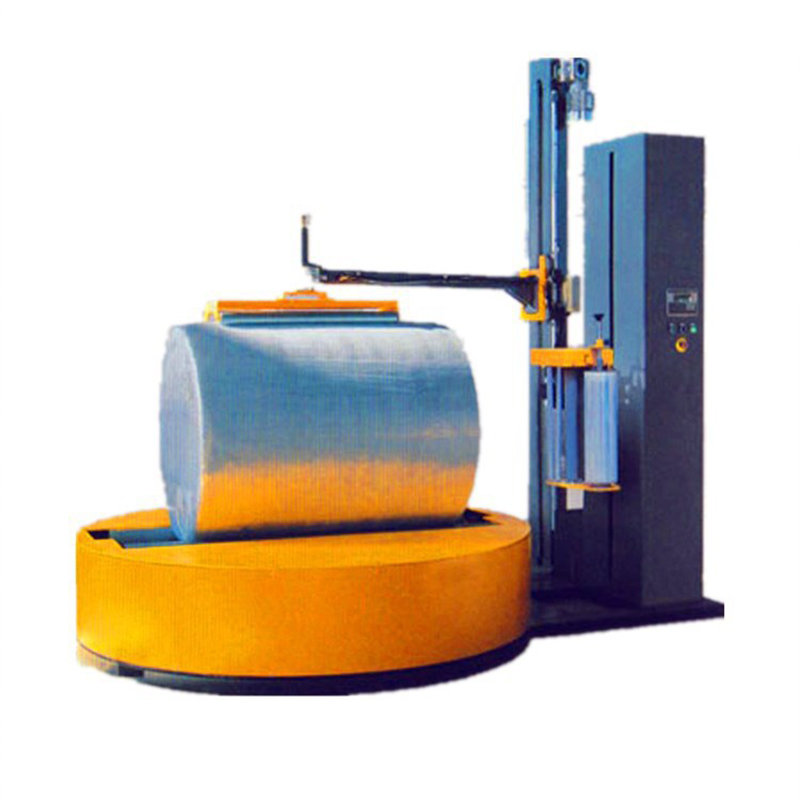

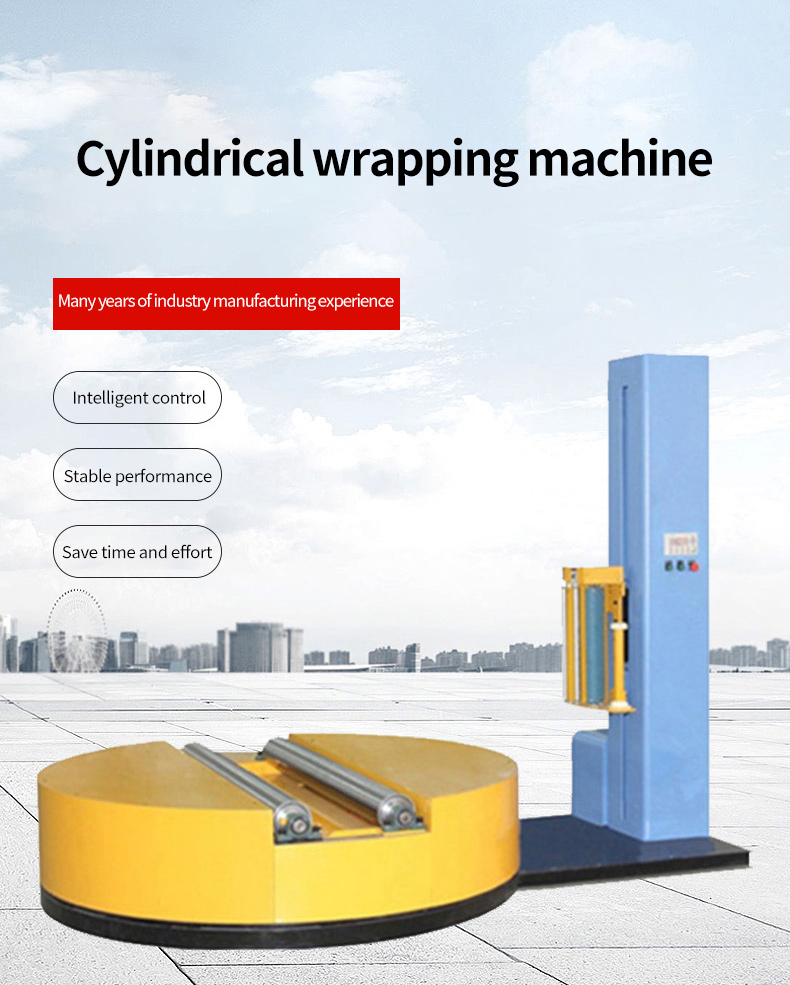

Horizontal cylindrical wrapping machine

1. Its structure is reasonably designed, and it adopts advanced transmission system and motor, which can run stably for a long time and improve production efficiency.

2. It has a high packaging speed and can complete the packaging task of a large number of cylindrical products in a short time.

3. Through precise tension control and packaging material conveying system, it can ensure that the packaging material is tightly wrapped around the surface of the cylindrical object.

4. The use of advanced sealing technology, such as heat sealing, ultrasonic sealing, etc., can make the packaging seal firm and not easy to break or leak.

5. It can adapt to the packaging of cylindrical products of different diameters and lengths by adjusting the parameters of the packaging machine and replacing some parts.

It is usually composed of a conveyor belt or rollers, which is used to smoothly transport the cylindrical products to be packaged to the packaging position to ensure the stability and continuity of the products during the packaging process.

It can complete the packaging of a large number of cylindrical products in a short time, improve production efficiency, and meet the needs of large-scale production of enterprises. For example, some high-speed horizontal cylindrical packaging machines can package dozens of products per minute.

Through precise tension control and advanced sealing and cutting technology, it can ensure that the packaging film is tightly wrapped around the product surface, the seal is firm, the packaging appearance is neat and beautiful, and the product is effectively prevented from being damaged during transportation and storage.

It can adapt to the packaging of cylindrical products of different diameters, lengths and materials, such as plastic bottles, glass bottles, metal cans, etc.; at the same time, it has good compatibility with the material and thickness of packaging films, such as polyethylene film, polypropylene film, polyvinyl chloride film, etc. can be used normally.

The human-machine interface is friendly. Operators only need to set the corresponding parameters on the touch screen to start the equipment without complicated training. The equipment also has a fault self-diagnosis function, which can display fault information in time, making it convenient for maintenance personnel to quickly troubleshoot the fault.

Safety protection devices are installed at key parts of the equipment, such as protective doors, guardrails, emergency stop buttons, etc., to prevent operators from accidental injuries during equipment operation, in line with international and domestic safety standards.

Equipped with an adjustable film unwinding rack, it can adapt to packaging film rolls of different widths and diameters. The tension control system uses advanced sensors and controllers to monitor and adjust the film tension in real time, so that the film always maintains the appropriate tightness during the packaging process.