Multifunctional horizontal winding machine

1. It can realize wrapping of products of different shapes, sizes and types, and can also be equipped with various auxiliary packaging functions such as labeling, coding, metering, etc. according to needs.

2. It is suitable for a variety of packaging materials, such as stretch film, wrapping tape, etc., and users can flexibly choose according to product characteristics and packaging requirements.

3. Equipped with advanced control systems and sensors, it can automatically complete packaging processes such as material conveying, wrapping, and cutting.

4. It is designed with a fast mold change device, which can complete mold replacement and equipment debugging in a short time to adapt to packaging switching of different products.

5. It adopts CNC technology or precise mechanical transmission system to accurately control parameters such as winding speed, tension, number of layers, etc.

6. The equipment has a solid structure, and key components are made of high-quality materials and advanced manufacturing processes, and the operation is stable and reliable.

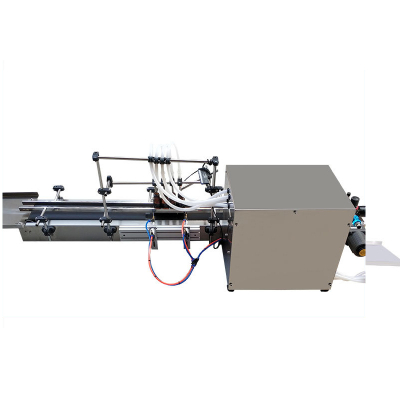

The multifunctional horizontal wrapping machine is a high-performance equipment that integrates a variety of advanced packaging technologies. It is designed to meet the diverse and efficient packaging needs of modern industry. It wraps various products accurately and stably in the horizontal direction.

The frame is made of high-strength carbon steel or stainless steel, and undergoes precision welding and processing technology to ensure that the overall structure is strong and stable, has good anti-deformation ability, and can withstand various forces generated during the operation of the equipment.

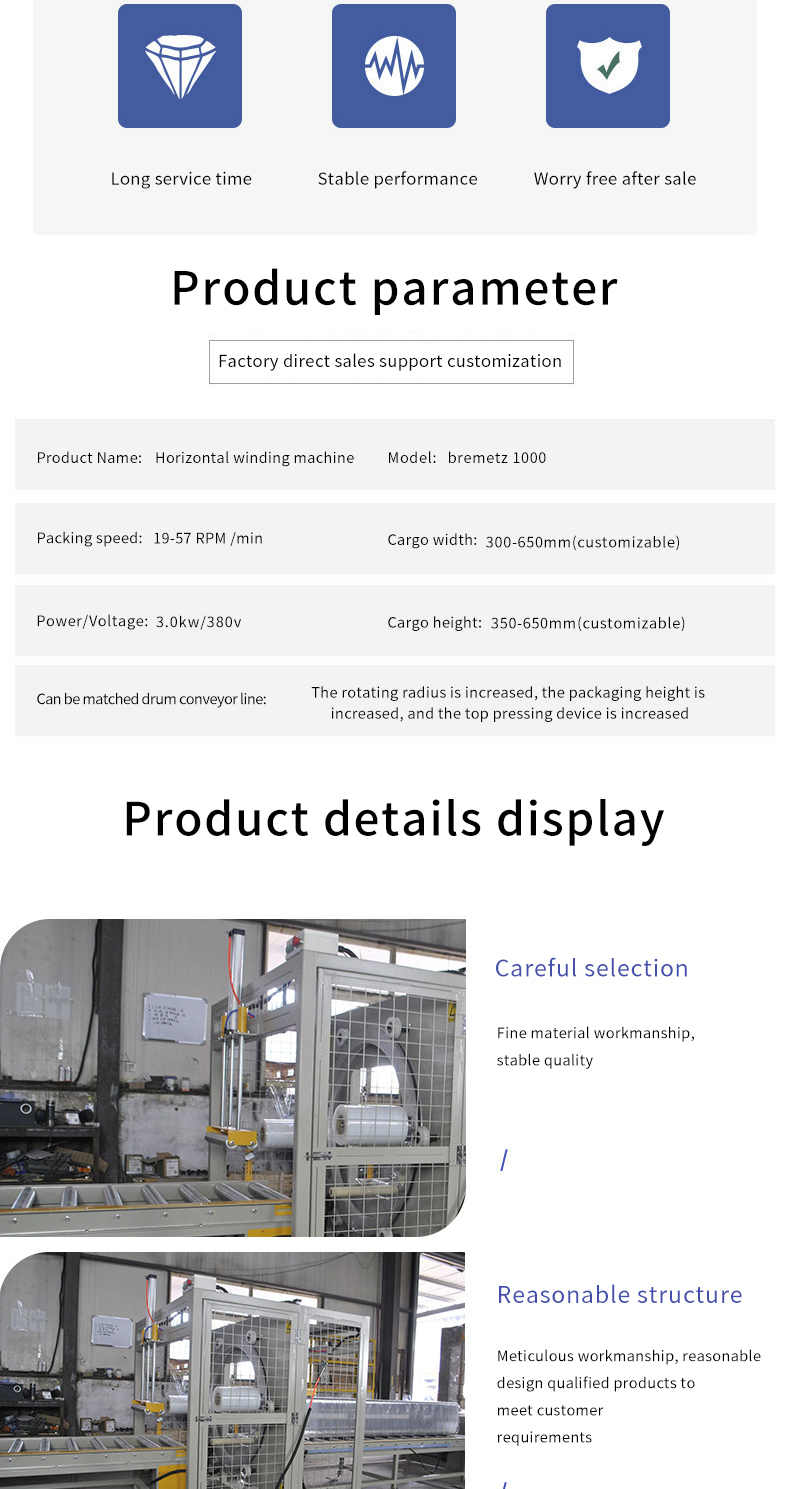

Product Name: Horizontal winding machine

Model: bremetz 1000

Packing speed: 19-57 RPM/min

Cargo width: 300-650mm (customizable)

Power/Voltage: 3.0kw/380v

Cargo height: 350-650mm (customizable)

Can be matched drum conveyor line:The rotating radius is increased, the packaging height is increased, and the top pressing device is increased

It integrates multiple functions such as wrapping, labeling, coding, and metering, and can complete multiple packaging processes of products on one device, reducing the equipment footprint and investment costs, and improving production efficiency and the integration of the packaging production line.

By replacing different fixtures, molds and adjusting equipment parameters, it is easy to package various products in cylindrical, square, conical, irregular shapes, such as products in food, beverage, medicine, chemical, building materials, electronics and other industries.

The human-machine interface is simple and intuitive. Operators only need to make simple parameter settings and input operating instructions on the touch screen to easily start and control the equipment.

The mechanical structure is strong and durable, and can withstand high-intensity workloads; the electrical system has strong anti-interference ability and stable operation; at the same time, the perfect safety protection device ensures the personal safety of operators and the normal operation of equipment.