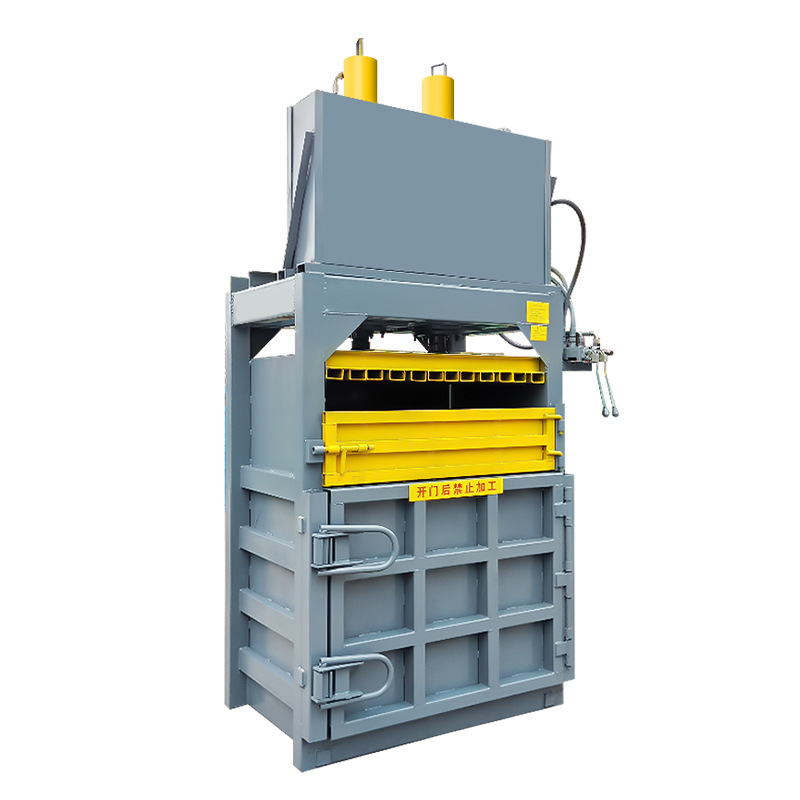

Multifunctional vertical hydraulic baling machine

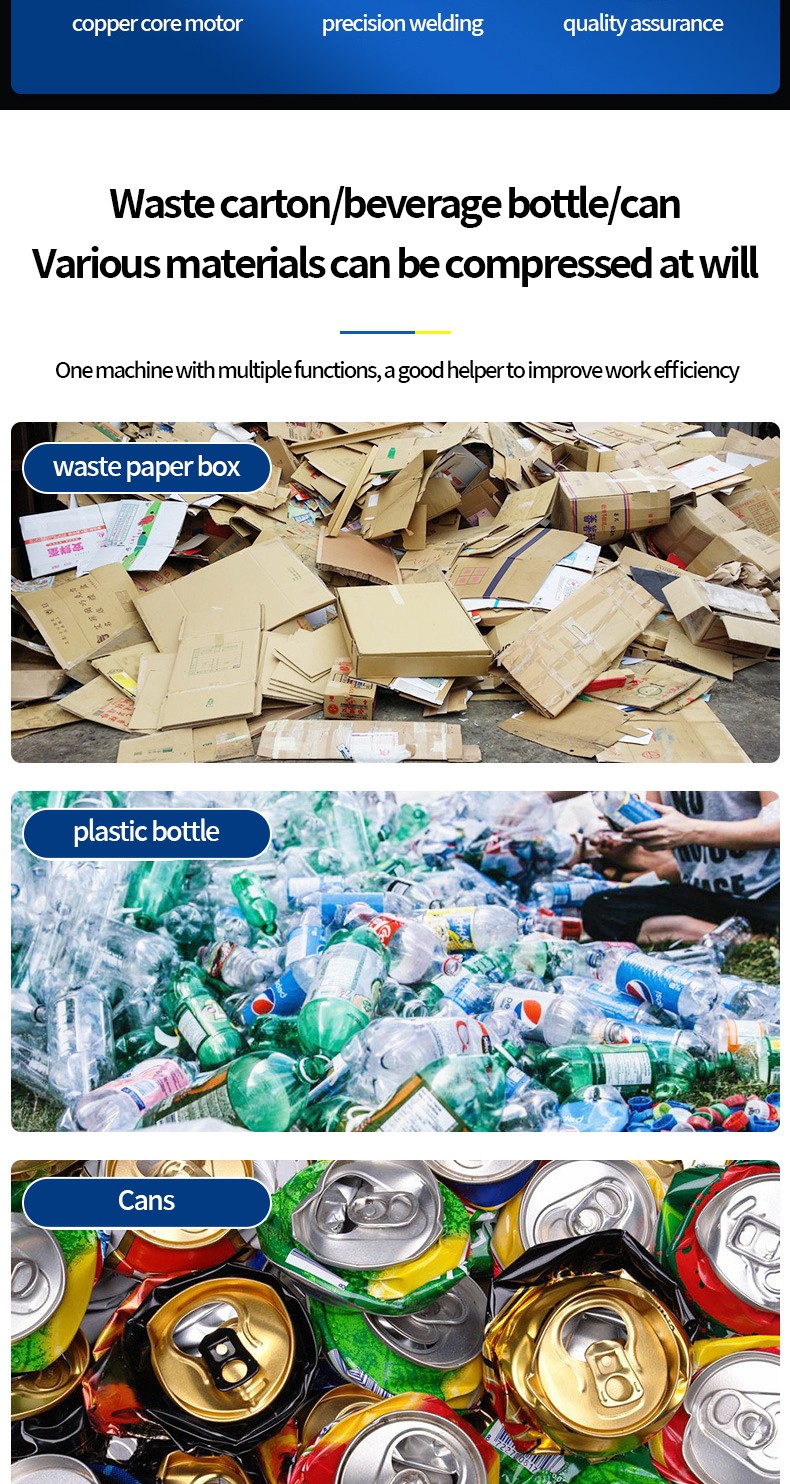

1. Multifunctional application: It can be applied to the packaging of various types of materials, such as waste paper, waste metal, straw, etc., to meet the diverse needs of different industries and enterprises.

2. Various packaging sizes: The size of the compression chamber and the size of the bale can be customized according to customer requirements, and can flexibly produce packaging products that meet different transportation, storage and sales requirements.

3. Efficient compression: The hydraulic drive system provides strong and stable pressure, so that the material can be tightly compressed, and the waste compaction ratio can reach 5:1.

4. Fast packaging: With a high packaging speed, a large amount of materials can be packaged in a short time, improving production efficiency.

5. Maintaining material properties: During the packaging process, the physical properties of the material can be completely maintained, and the material will not be damaged or its original properties will not be changed.

6. Convenient maintenance: The structural design is reasonable and easy to clean, maintain and repair on a daily basis.

Multifunctional vertical hydraulic baling machine is an advanced material compression and baling equipment, which is widely used in various industrial, commercial and recycling industries. Through the hydraulic power system, it can efficiently compress and pack a variety of materials of different properties, converting loose materials into compact blocks, which are convenient for storage, transportation and subsequent processing, and effectively improve the efficiency and economy of material management.

Body frame: It is welded with high-strength high-quality steel, has good rigidity and stability, and can withstand strong hydraulic pressure without deformation. The frame structure is carefully designed to ensure safety and reliability during long-term use, providing solid support for the entire packaging process.

Hydraulic system: This is the core power part of the equipment, including key components such as hydraulic pumps, hydraulic cylinders, and hydraulic valves. As a power source, the hydraulic pump provides a stable flow and pressure of hydraulic oil for the entire system. The hydraulic cylinder generates a strong compression force through the movement of the piston to compact the material. The hydraulic valve is used to control the flow direction and pressure of the hydraulic oil, to achieve pressure regulation and motion control at different stages of the packaging process, such as fast mold closing, slow pressurization, etc., to ensure packaging quality and efficiency.

Feeding device: For some application scenarios that require continuous feeding, the equipment is equipped with a feeding device. The feeding device can be in the form of a conveyor belt, a screw propeller, etc., which can automatically and evenly transport the material into the compression chamber, further improving the automation and work efficiency of the equipment.

Pressure range: Depending on the model, the maximum pressure that the hydraulic system can generate is generally between 10 and 100 tons, which can meet the compression and packaging needs of light to heavy materials. For example, for some loose materials such as waste paper and plastic film, lower pressure can achieve good compression effect; while for materials with higher density and higher hardness such as metal waste, higher pressure is required.

Standard-8T horizontal bar:

Engine (kW):4

Packing size(mm):600*400*600

Overall Dimensions (mm):1250*650*2150

oil pump:306 gear pump

Oil cylinder outer diameter(mm):95

Standard-10T horizontal bar:

Engine (kW):7.5

Packing size(mm):800*400*800

Overall Dimensions (mm):1450*650*2600

oil pump:320 gear pump

Oil cylinder outer diameter(mm):110

Standard-20T horizontal bar:

Engine (kW):7.5

Packing size(mm):0*400*800

Overall Dimensions (mm):1450*650*2700

oil pump:325gear pump

Oil cylinder outer diameter(mm):140

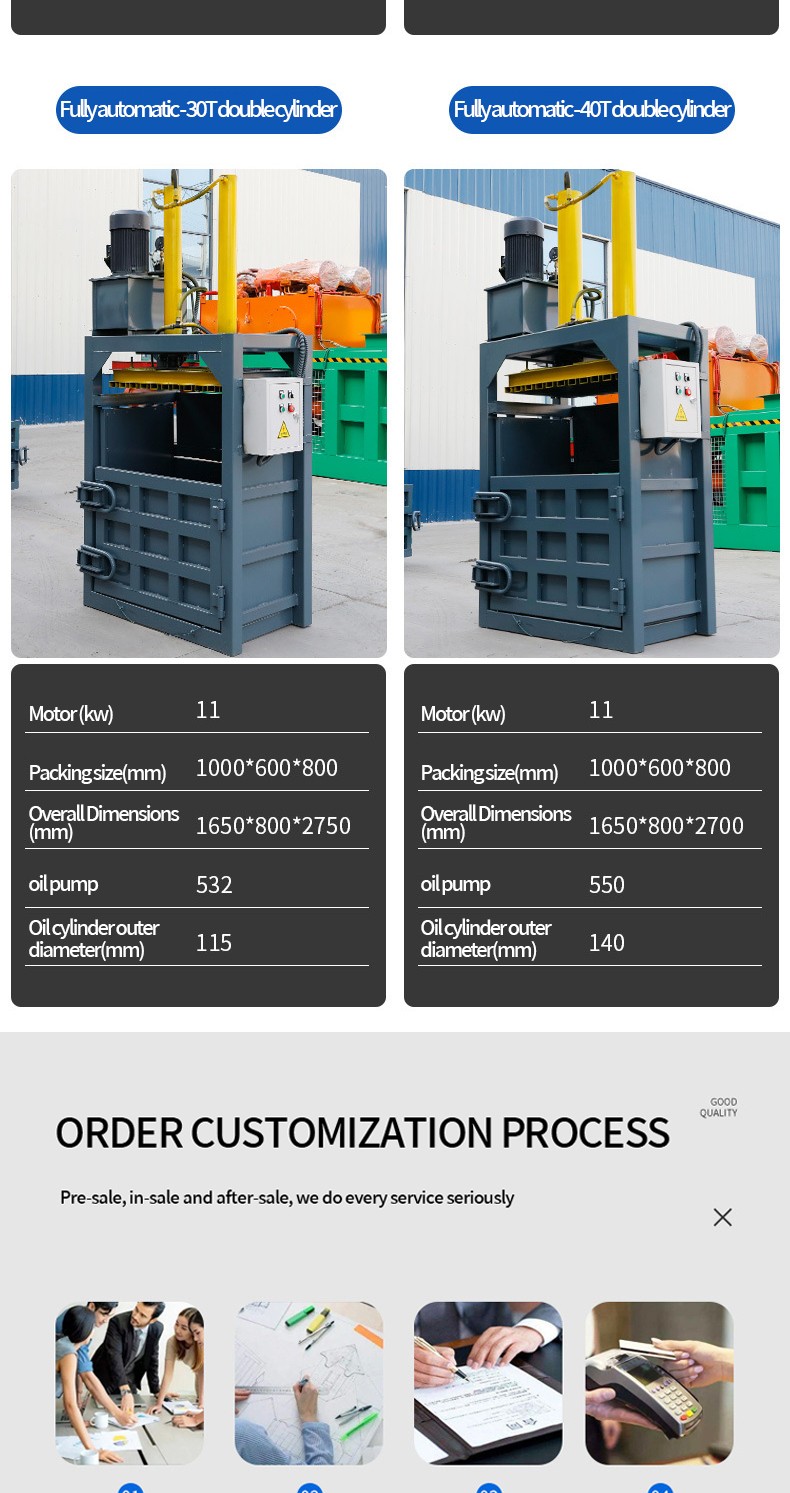

Standard-30T horizontal bar:

Engine (kW):11

Packing size(mm):1000*600*800

Overall Dimensions (mm):1650*850*2750

oil pump:550gear pump

Oil cylinder outer diameter(mm):160

Standard-30T parallel bars:

Engine (kW):11

Packingsize(mm):1000*600*800

Overall Dimensions (mm):1650*850*2750

oil pump:550 gear pump

Oil cylinder outer diameter(mm):110

Standard-40T parallel bars:

Engine (kW):11

Packingsize(mm):1000*600*800

Overall Dimensions (mm):1650*850*2750

oil pump:550 gear pump

Oil cylinder outer diameter(mm):140

Standard-60T parallel bars

Engine (kW):15

Packing size(mm):1100*750*950

Overall Dimensions (mm):1850*2000*3100

oil pump:563 gear pump

Oil cylinder outer diameter(mm):160

Standard-80T parallel bars

Engine (kW):18.5

Packing size(mm):1100*750*950

Overall Dimensions (mm):1850*2000*3100

oil pump:563 gear pump

Oil cylinder outer diameter(mm):180

All steel model-200T:

Engine (kW):22

Packingsize(mm):1500*1100*1000

Overall Dimensions (mm):Innerheight 1700

oil pump:Silent vane pump type 80+562

Oil cylinder outer diameter(mm):230

All steel model-260T:

Engine (kW):22

Packingsize(mm):2000*1100*1000

Overall Dimensions (mm):Innerheight 1700

oil pump:Silent vane pump type 100+532

Oil cylinder outer diameter(mm):230

Versatility: It can handle a variety of materials and meet the material packaging needs of different companies without changing the equipment. For example, in a waste recycling plant, it can package different types of waste such as waste paper, plastic bottles, and metal cans in turn, greatly improving the use value and versatility of the equipment.

High efficiency and energy saving: The advanced hydraulic technology and energy-saving motor are adopted to optimize the hydraulic circuit design, so that the equipment has low energy consumption during operation. While ensuring strong compression force, reasonable pressure regulation and motion control can avoid unnecessary energy waste and reduce the company's operating costs.

Customizability: In addition to basic technical parameters and functions, the equipment can be customized according to the user's special needs. For example, for packaging certain materials with high hygiene requirements (such as food processing waste), the compression chamber and related components made of stainless steel can be customized; or according to the space limitations of a specific production site, the equipment of appropriate size can be customized to better meet the user's personalized needs.

Installation and commissioning guidance: After the equipment is delivered, the manufacturer will arrange professional technicians to go to the customer site for installation and commissioning guidance to ensure that the equipment can operate normally, and train the operators to make them familiar with the operation methods and precautions of the equipment.

Service attitude: Have a good service attitude, be able to patiently listen to customers' needs and problems, and provide customers with warm and thoughtful after-sales service until the customers are satisfied.