Collaborative palletizing robots help companies significantly improve production efficiency

Recently, a machinery company has successfully introduced advanced palletizing robots, bringing revolutionary changes to its production process. The company is facing increasing demand for product palletizing in multiple production areas. The traditional manual palletizing method is not only inefficient, but also difficult to ensure the accuracy and stability of palletizing.

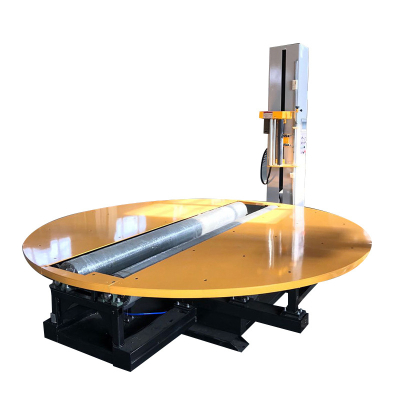

In order to solve this problem, after in-depth research and screening, a palletizing robot with highly intelligent and efficient performance was finally selected. This robot uses an advanced visual recognition system and precise motion control technology to quickly identify products of different shapes and sizes and accurately place them on the pallet.

Since the palletizing robot was put into use, production efficiency has been significantly improved. According to statistics, compared with traditional manual palletizing, the robot's palletizing speed is increased by more than 55%, and it can achieve 24-hour uninterrupted work, greatly shortening the production cycle. At the same time, due to the robot's high palletizing accuracy, the damage rate of products has also been greatly reduced, saving the company a lot of costs.