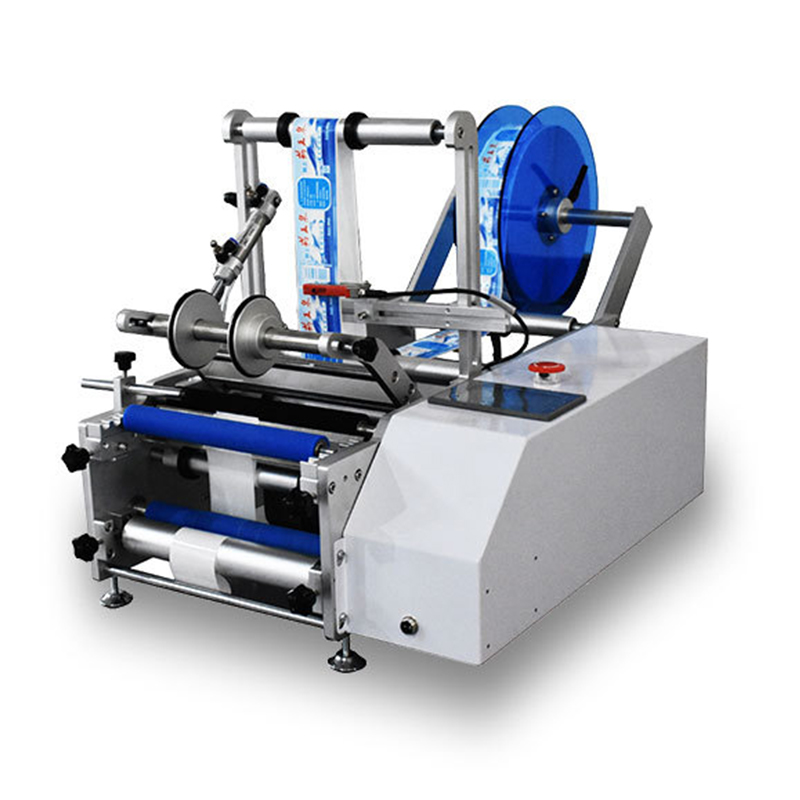

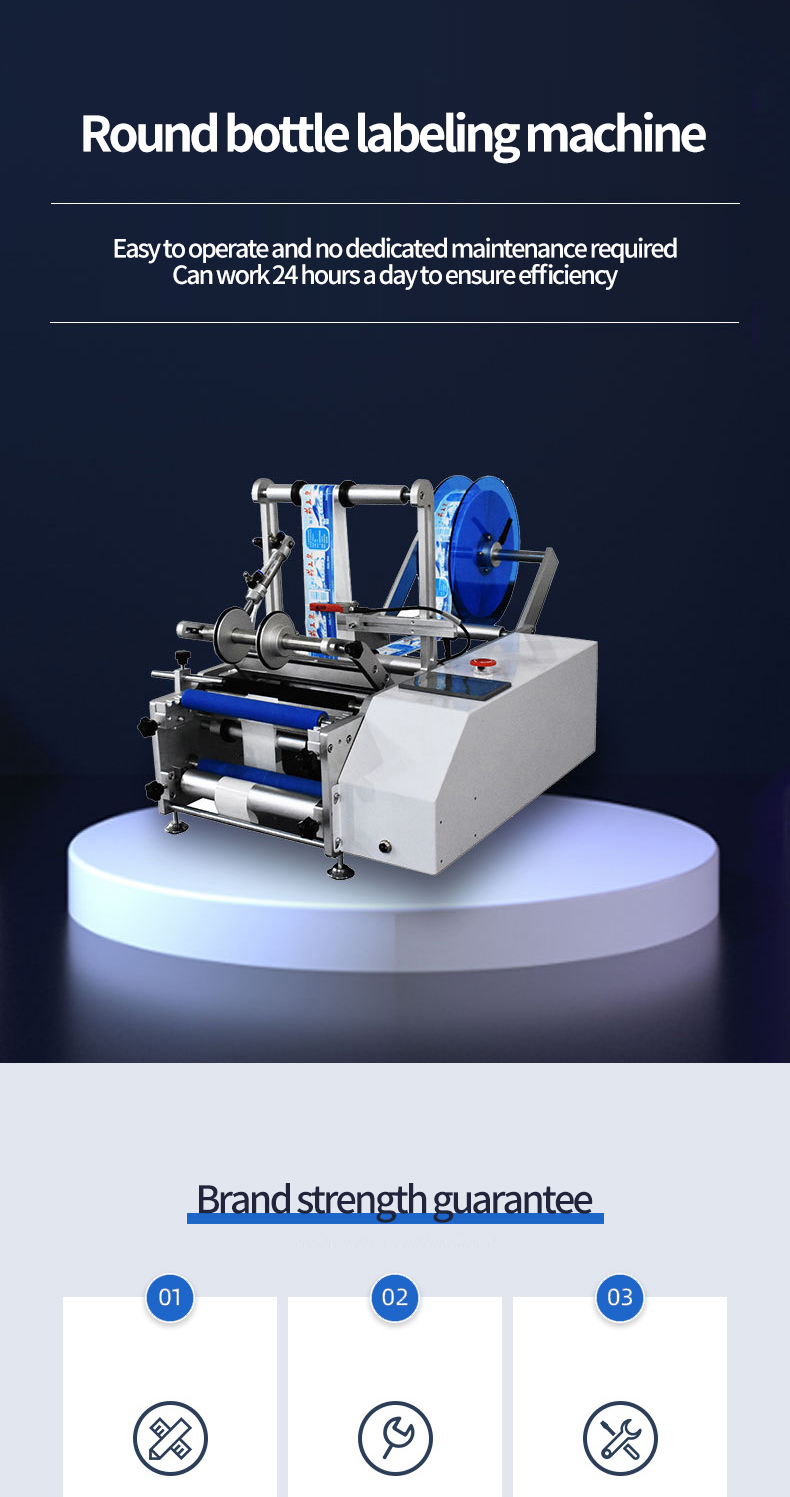

New high speed round bottle labeling machine

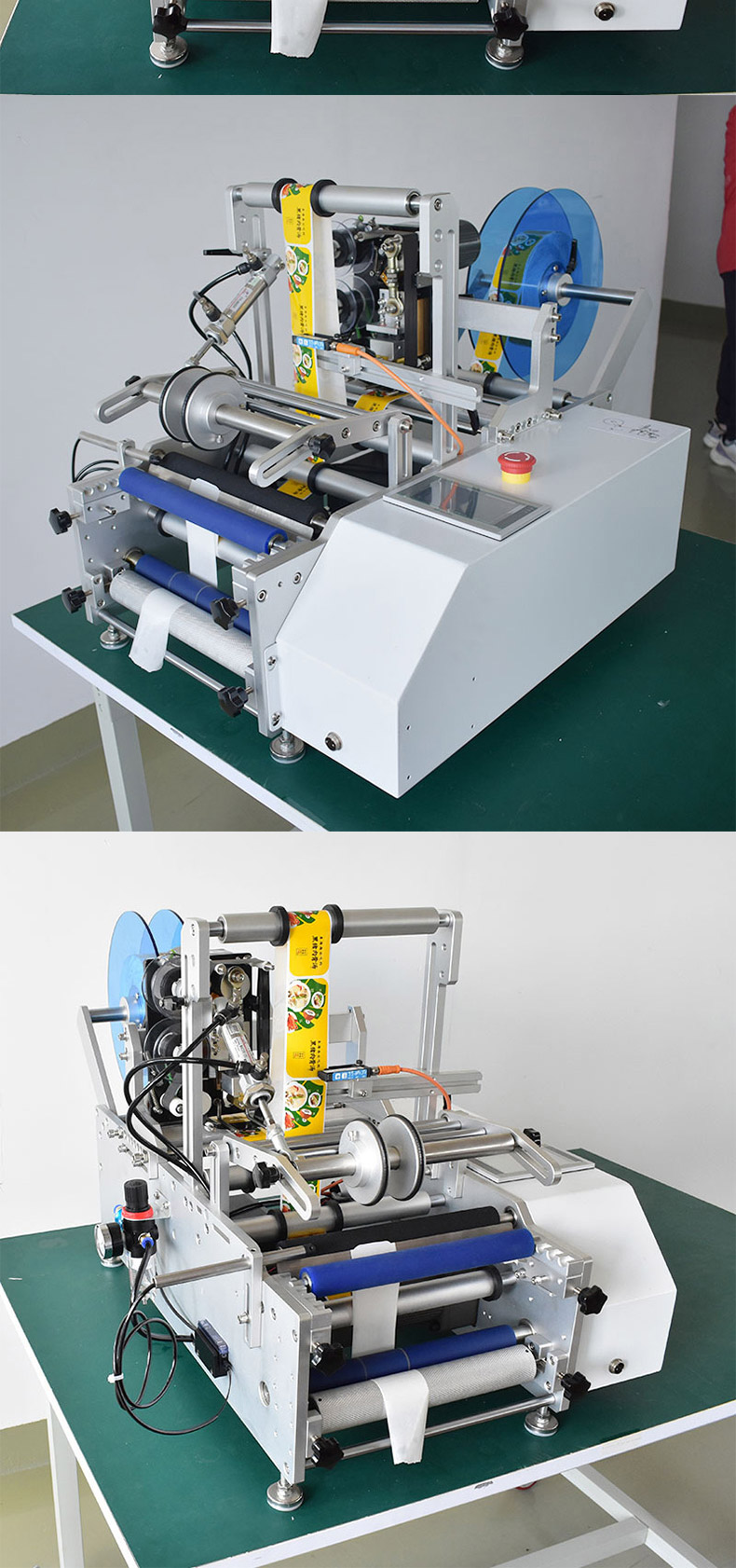

1. While running at high speed, it can also ensure continuous and stable operation, reducing the equipment's downtime and label change time, etc.

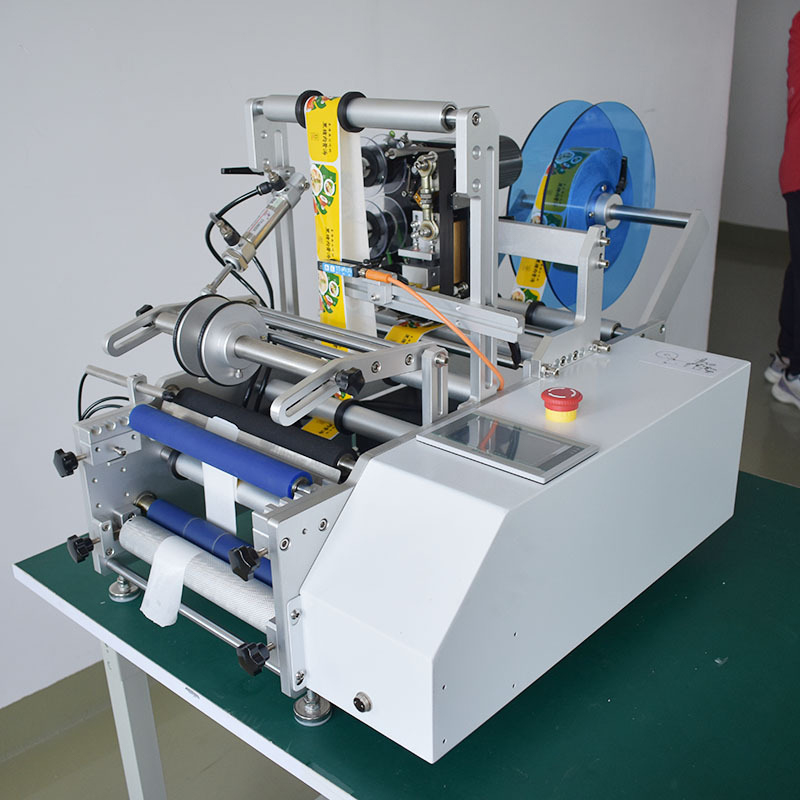

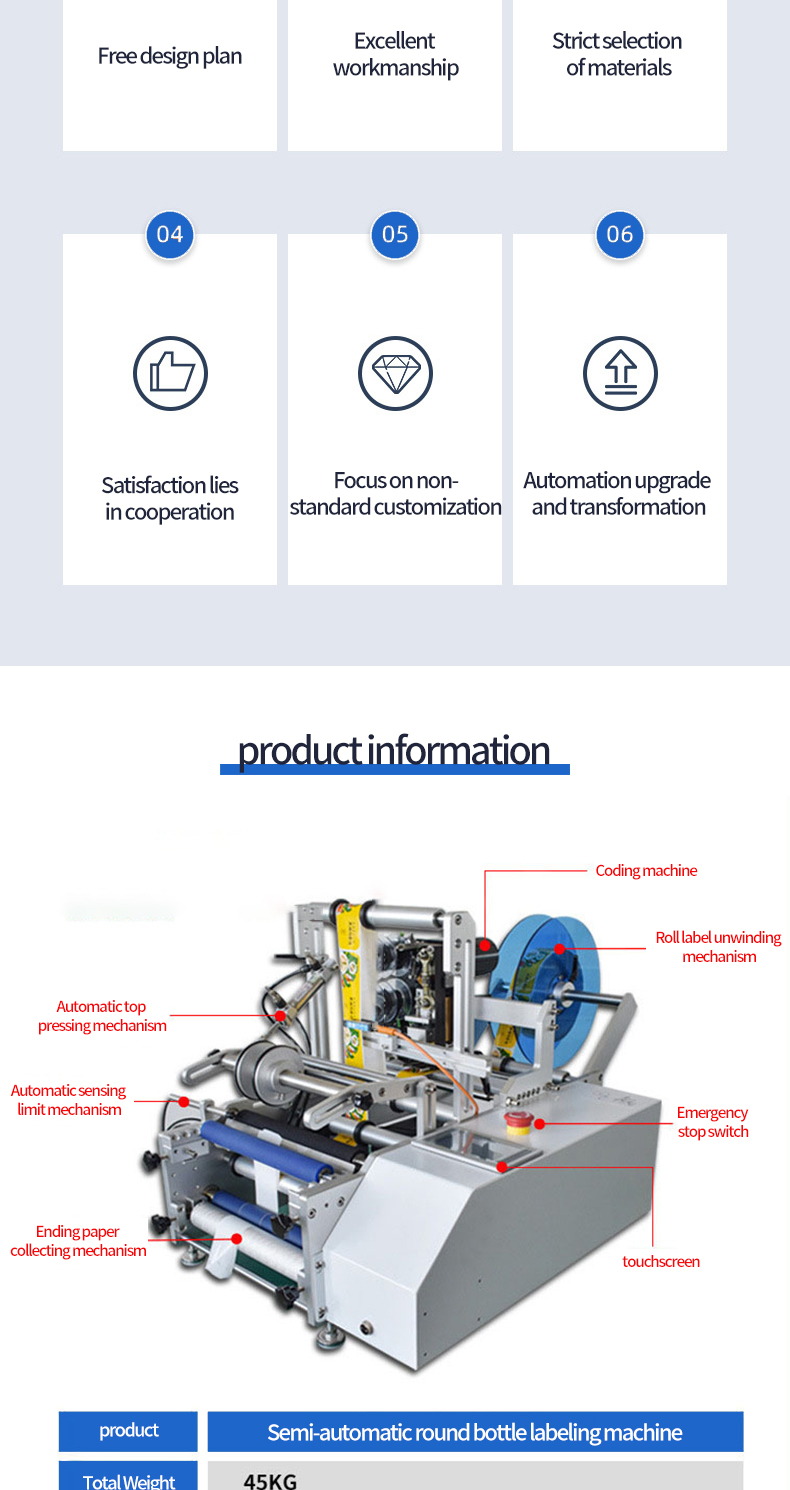

2. Equipped with a high-precision sensor system and advanced visual recognition technology, it can accurately identify the position of the bottle and the alignment of the label.

3. The label can be evenly and flatly attached to the bottle to avoid problems such as skew, bubbling, and wrinkles.

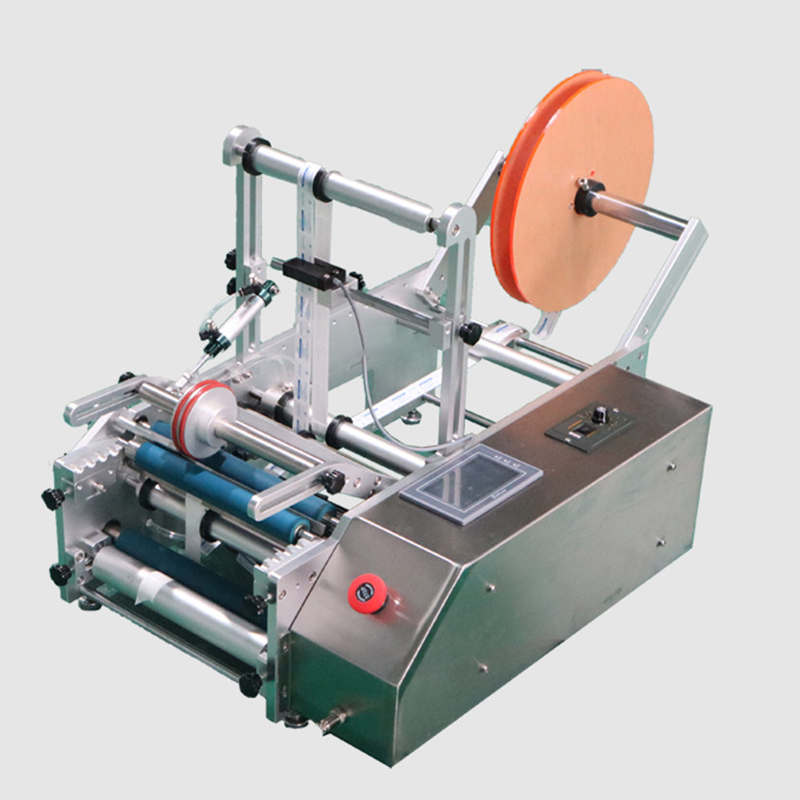

4. Through simple adjustments, it can be applied to round bottles of different diameters and heights, and can also label products of different shapes.

5. The use of advanced PLC control systems and intelligent sensors, combined with high-precision transmission devices, makes the equipment run smoothly.

Mainly made of stainless steel and high-grade aluminum alloy, it meets the hygiene standards of the food, medicine and other industries and is corrosion-resistant.

The components are made by CNC machining center with high precision. The electrical appliances imported from Europe and Japan are used to ensure long service life.

Equipped with advanced PLC control system and intelligent sensor, automatic photoelectric tracking, it has the functions of no-object labeling, no-label automatic correction and label automatic detection, which can avoid wasting labels and missing labels.

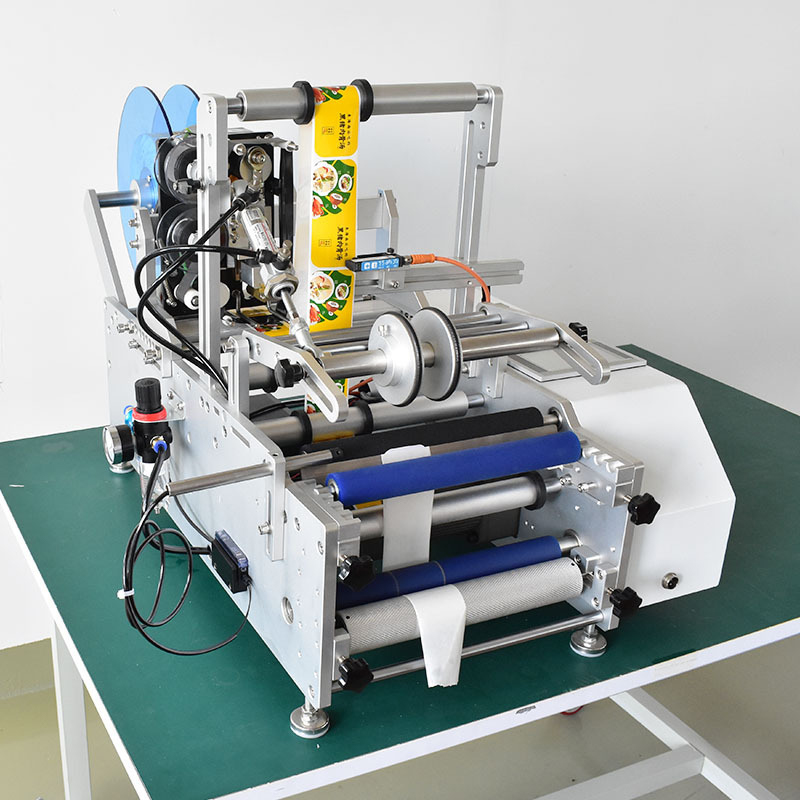

It can be connected online or operated as a single machine. The front and rear sections can be connected to the production line, and the rear section can be equipped with a material receiving platform or a material receiving turntable.

The touch screen operation interface has friendly human-computer interaction, operation teaching function, intuitive parameter modification and simple function switching.

It is widely used in food, daily chemical, chemical, pharmaceutical and other industries, and is suitable for labeling various round products with relatively stable standing, such as glass bottles, plastic bottles, cans, etc.