Laundry Detergent Filling Production Line

1. With advanced filling technology, the equipment runs fast and can fill dozens of bottles or even more per minute.

2. Through high-precision metering devices, the filling amount of laundry detergent can be accurately controlled with minimal error.

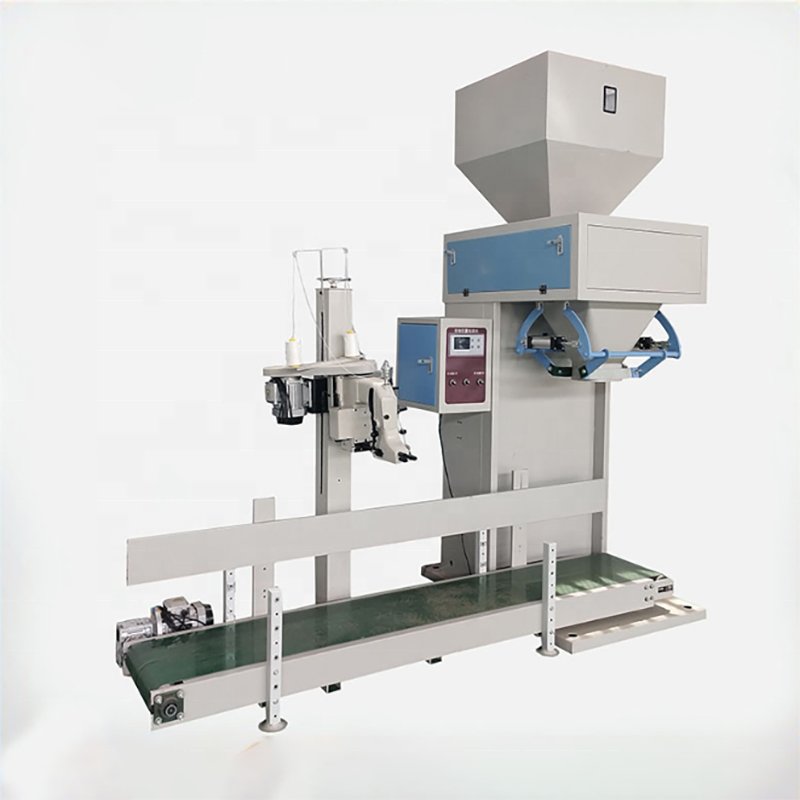

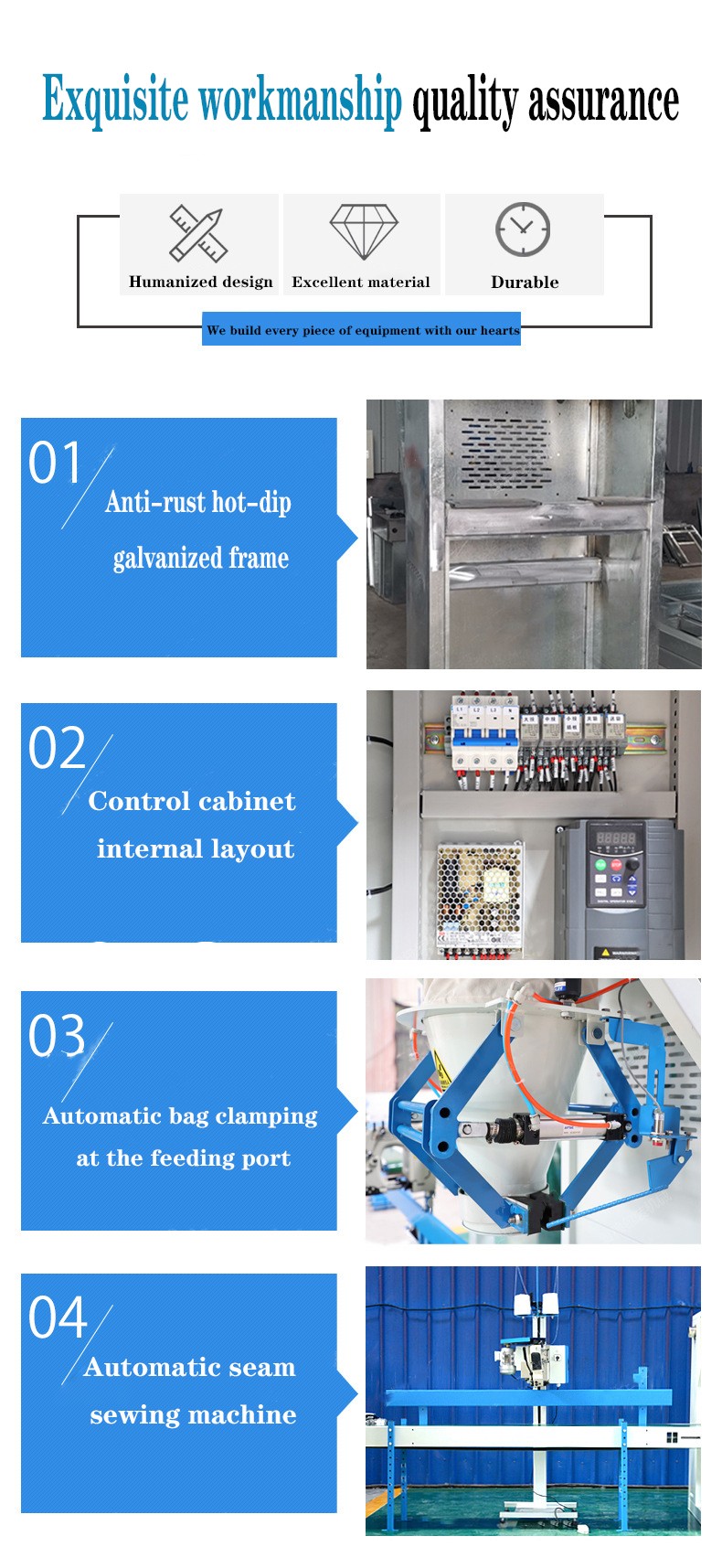

3. With a high degree of automation, most of the links from laundry detergent delivery, filling to capping can be completed automatically by the equipment.

4. With high-quality materials and advanced manufacturing technology, the equipment is stable and reliable during long-term operation.

5. With good flexibility, it can quickly adjust the filling volume and adapt to packaging bottles of different specifications according to market demand and enterprise production plans.

The production line runs fast and has high filling efficiency. It can complete the filling task of 10 bottles per minute, which greatly improves the production capacity and meets the company's large-scale production needs.

Using advanced metering technology and control systems, the filling error can be controlled within ±2 ml, ensuring that the filling amount of each bottle of laundry detergent is consistent and meets strict quality standards.

The highly automated production process reduces the number of manual operations, allowing companies to significantly reduce labor costs while also reducing product quality problems caused by manual errors.

The filling volume and equipment parameters can be quickly adjusted according to different laundry detergent packaging specifications and production process requirements, with strong flexibility and versatility.

Through the PLC control system and HMI operation panel, the production line can be monitored and managed in real time. Production data can be recorded and stored in real time, which is convenient for enterprises to analyze production data and trace quality, and optimize production processes.