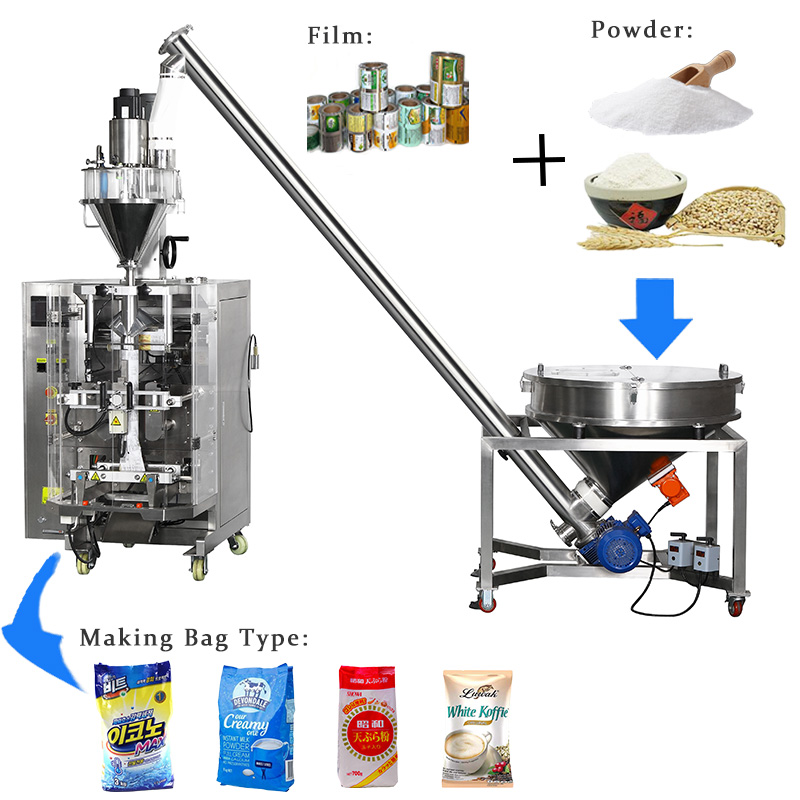

Washing powder filling production line

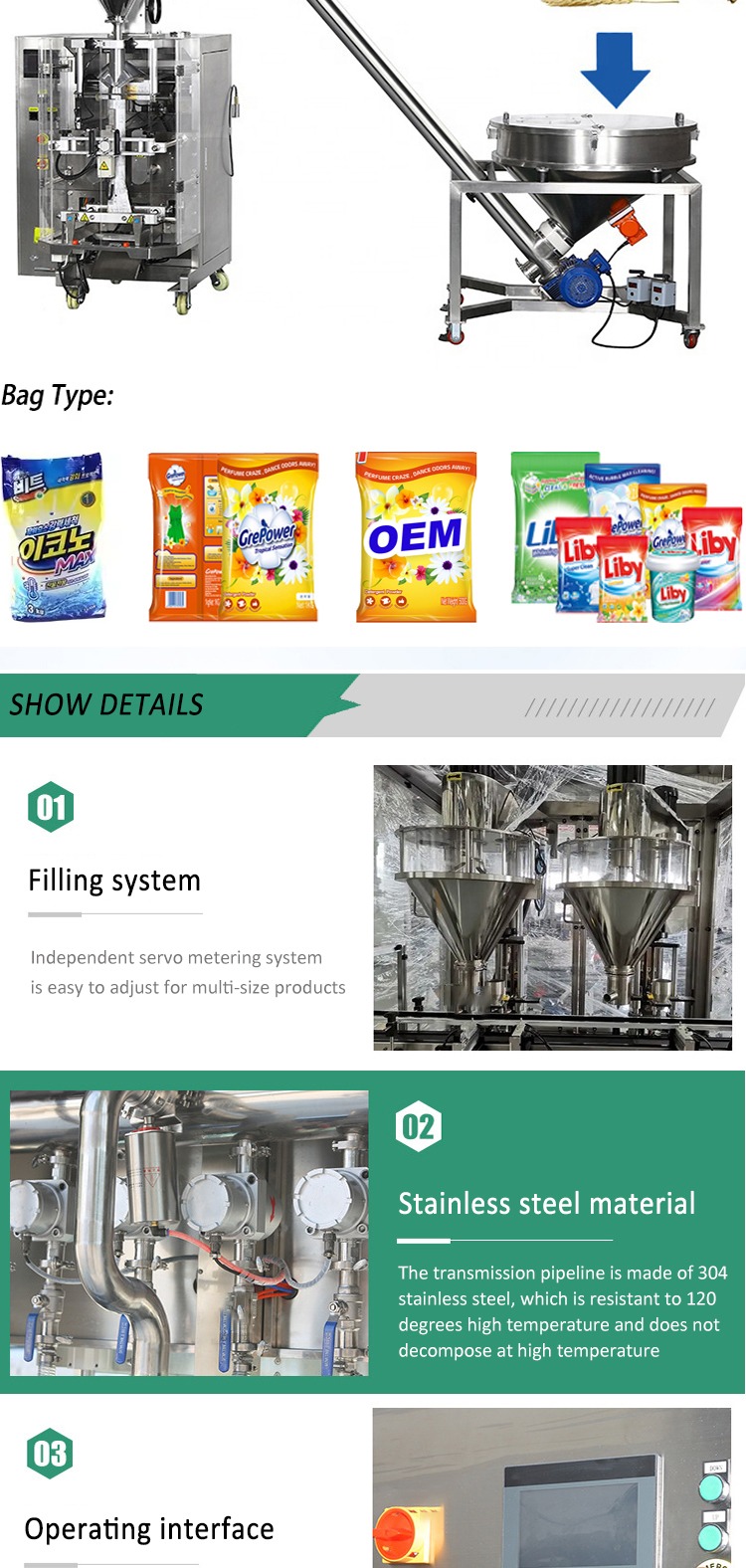

1. The use of advanced filling technology and automated control systems can achieve high-speed continuous filling, and can complete the filling task of dozens of bags per minute.

2. The equipment operates stably and reliably, and has complete fault self-diagnosis and early warning functions, which can detect and solve potential problems in a timely manner.

3. Equipped with a high-precision metering system, it can accurately control the filling amount of washing powder with a very small error range.

4. The metering device has an automatic calibration function, which can perform self-calibration regularly or when necessary to ensure the accuracy of measurement.

5. The filling volume and packaging specifications can be easily adjusted according to market demand and customer requirements.

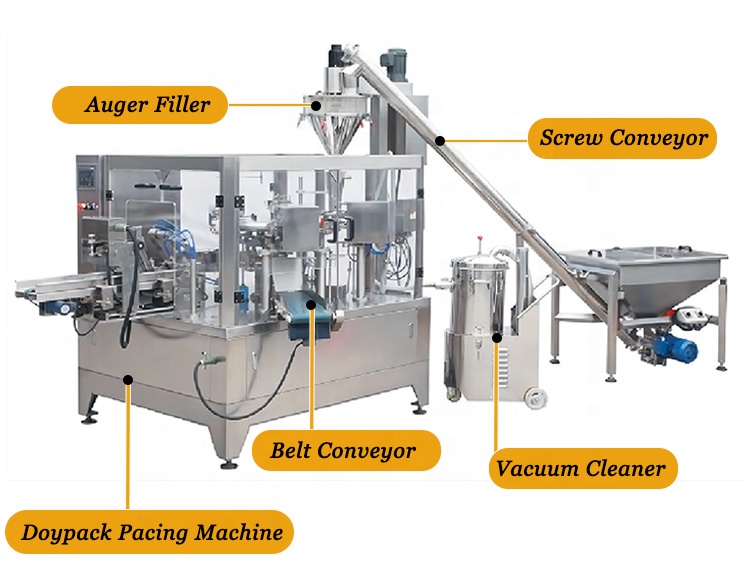

A vacuum loader or pneumatic conveying device is used to quickly and stably convey the detergent powder from the storage tank to the hopper of the filling machine.

The core component of the filling system is a high-precision filling machine. Depending on the characteristics of the washing powder and the filling requirements, screw, volumetric or weighing filling methods can be selected.

For bagged laundry detergent, heat sealing or ultrasonic sealing technology is used to ensure that the packaging bag is tightly sealed to prevent leakage of the laundry detergent; for boxed or bottled laundry detergent, an automatic capping machine or capping machine is equipped to complete the installation and tightening of the lid.

The conveying system consists of conveyor belts, elevators, turning machines, etc., and is responsible for transporting empty bags (bottles), semi-finished products after filling, and finished products to each production link in an orderly manner.

The control system uses an advanced PLC control system, and operators can easily set parameters such as filling volume, filling speed, and sealing temperature through the human-machine interface.

It is widely used in various types of washing powder production enterprises, whether it is a large daily chemical group or a small and medium-sized washing powder manufacturer, they can use this production line to improve production efficiency and product quality.