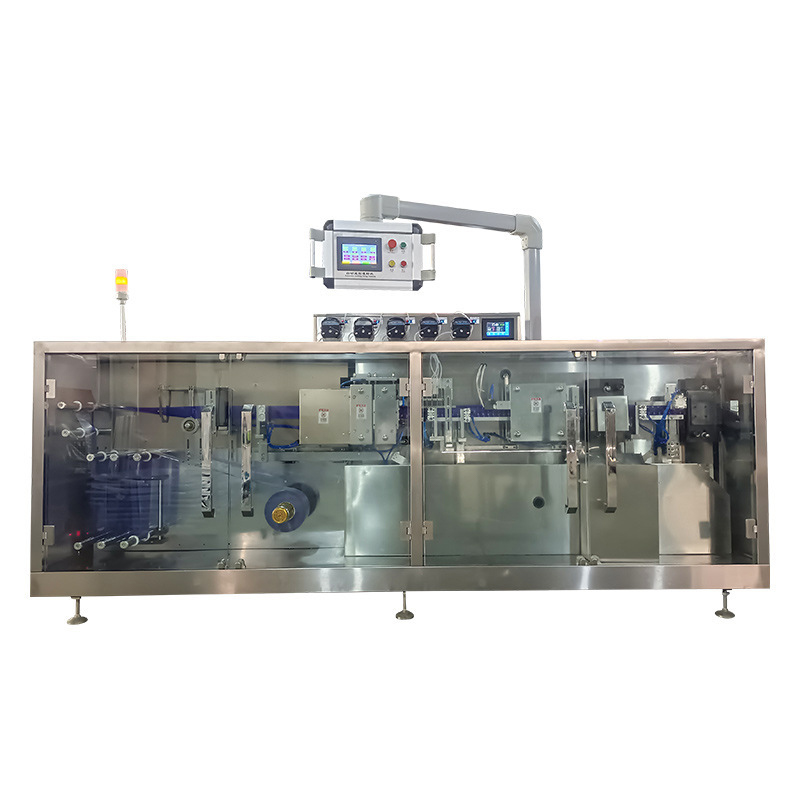

Fully automatic oral liquid filling machine

1. It can realize a series of operations such as automatic bottle feeding, automatic filling, and automatic bottle discharging without excessive human intervention, and can run continuously and stably.

2. It reduces the links of manual operation, frees operators from heavy repetitive labor, and reduces labor intensity

3. It adopts advanced metering technology, such as precision metering pumps, flow meters or weight sensors, etc., which can accurately control the filling volume of each bottle of oral liquid.

4. The high-precision filling system can ensure that the filling volume of each bottle of oral liquid is highly consistent, thereby ensuring the quality stability and consistency of the product.

5. It can fill liquids of different viscosities, whether it is water, oil, or relatively viscous syrups, honey and other oral liquids.

6. The filling head and conveying system of the equipment usually have a certain degree of versatility and adjustability, and can adapt to oral liquid bottles of various specifications and shapes.

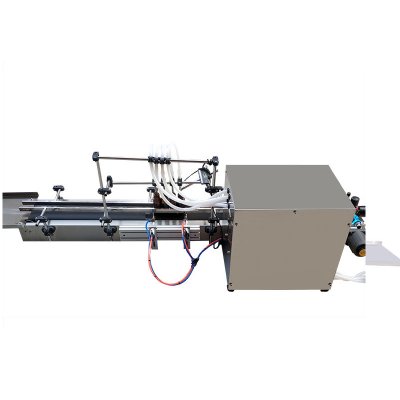

The fully automatic oral liquid filling machine is mainly composed of bottle feeding device, filling system, capping device, capping device, bottle discharging device, control system, frame and auxiliary devices. Its overall design concept revolves around completing the oral liquid filling, capping and other packaging processes efficiently, accurately, hygienically and automatically.

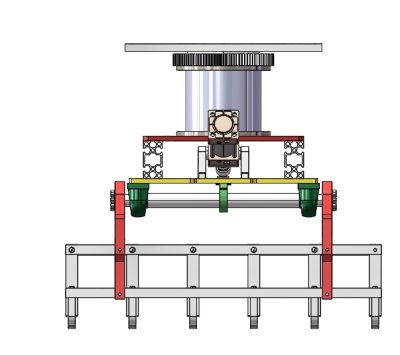

Imported high-precision plunger metering pumps or peristaltic pumps are used, which have excellent metering accuracy and stability. The plunger metering pump achieves accurate liquid delivery by precisely controlling the plunger stroke, and its metering error can be controlled within ±0.5%.

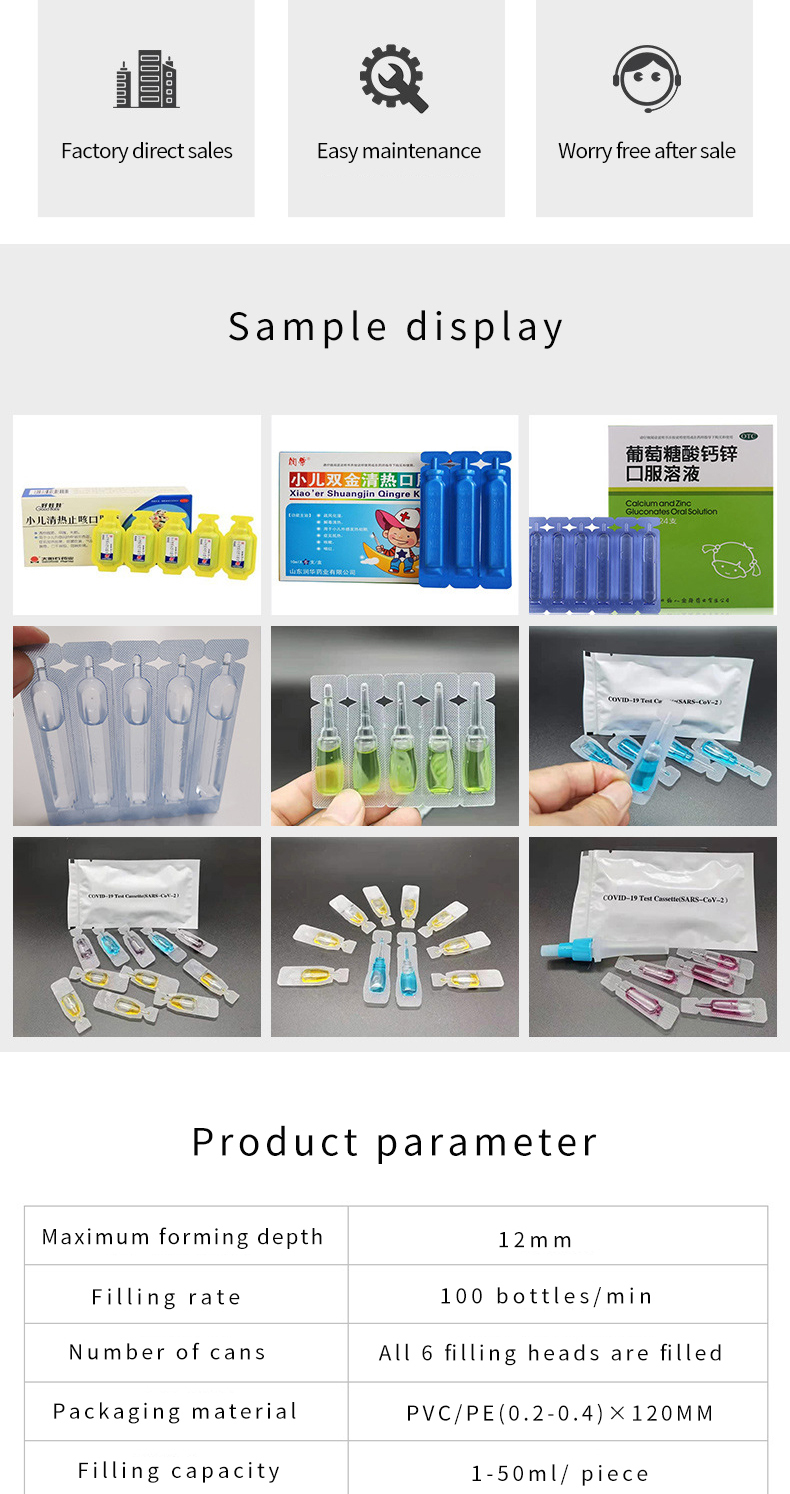

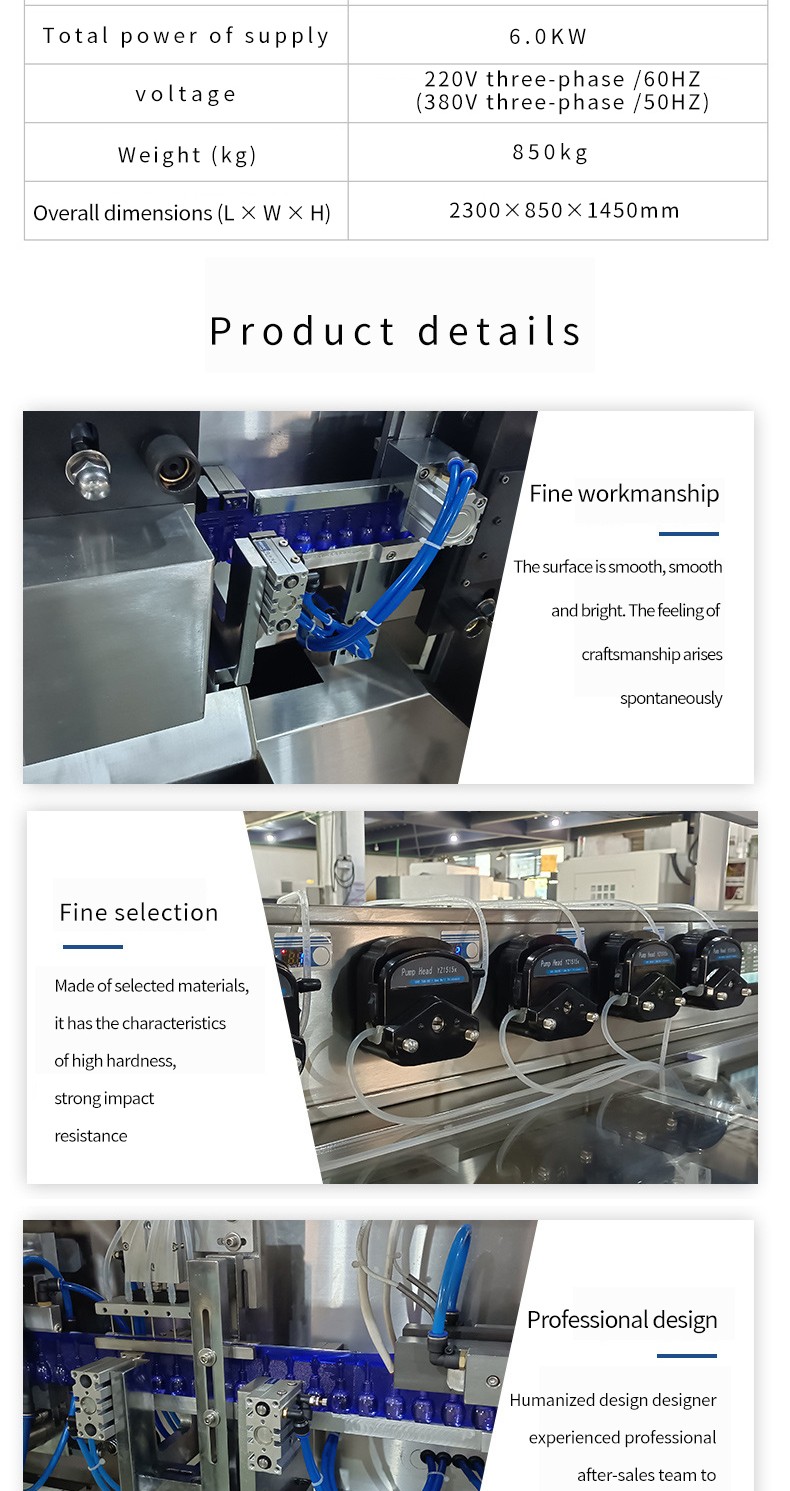

Product parameter

Maximum forming depth:12 mm

Filling rate:100 bottles/min

Number of cans:All 6 filling heads are filled

Packaging material:PVC/PE(0.2-0.4) × 120MM

Filling capacity:1-50ml/piece

Total power of supply:6.0KW

voltage:220V three-phase /60HZ (380V three-phase/50HZ)

Weight (kg):850kg

Overall dimensions (L × W × H);2300×850×1450mm

The filling needle is made of stainless steel, with a smooth inner wall and fine processing technology, ensuring that the liquid can flow out smoothly during the filling process, and no liquid will remain inside the needle, avoiding dripping and contamination.

The filling pipeline adopts food grade stainless steel pipe or plastic pipe that meets pharmaceutical standards to ensure the quality safety of materials during transportation and the service life of the pipeline.

Scope of application:

Pharmaceutical industry: It can accurately control the dosage of drugs, meet the strict requirements of the drug production quality management specifications for drug measurement accuracy and hygiene standards, and ensure the stable quality of each bottle of drugs.

Health care products industry: Whether it is oral liquid with nutrients such as vitamins and minerals, or oral liquid with specific health functions, it can be efficiently and accurately filled by the fully automatic oral liquid filling machine

Food and beverage industry: Some food and beverage liquid products can also be filled by fully automatic oral liquid filling machines, such as high-end fruit juice drinks, functional drinks, concentrated syrups, etc.