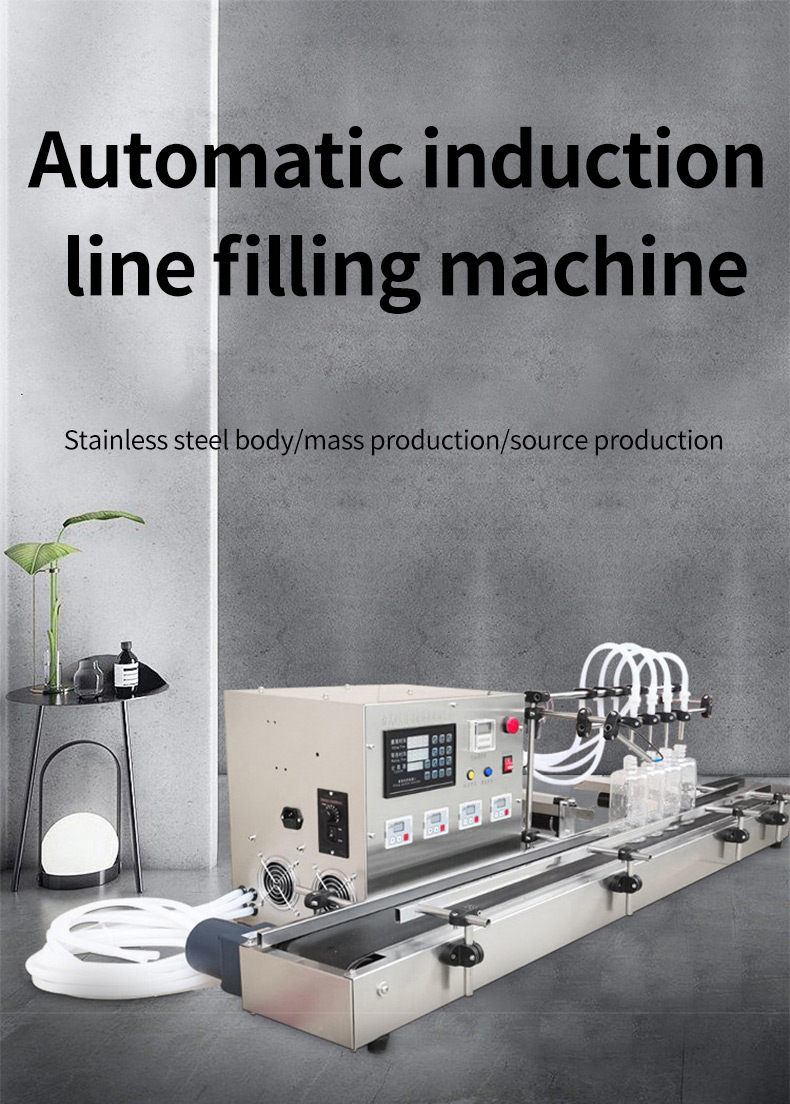

Multifunctional liquid filling machine

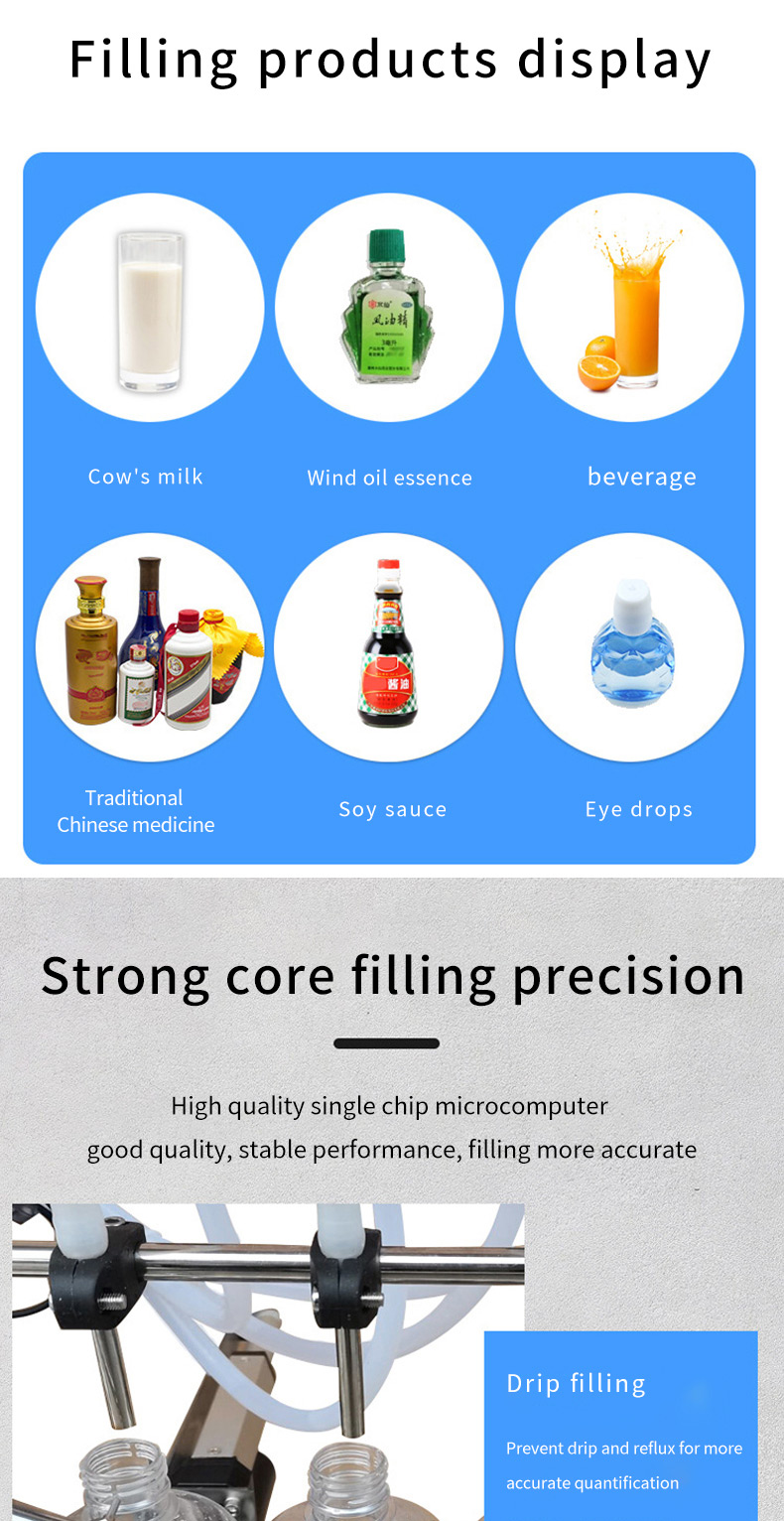

1. Can adapt to liquids of different properties and viscosity, from low viscosity water, alcohol to medium viscosity syrup, fruit juice, and high viscosity sauce, honey, etc. can be accurately filled.

2. The principles of various irrigation such as constant pressure irrigation, pressure irrigation, vacuum filling, and vacuum filling. A multi -functional device can meet a variety of production needs.

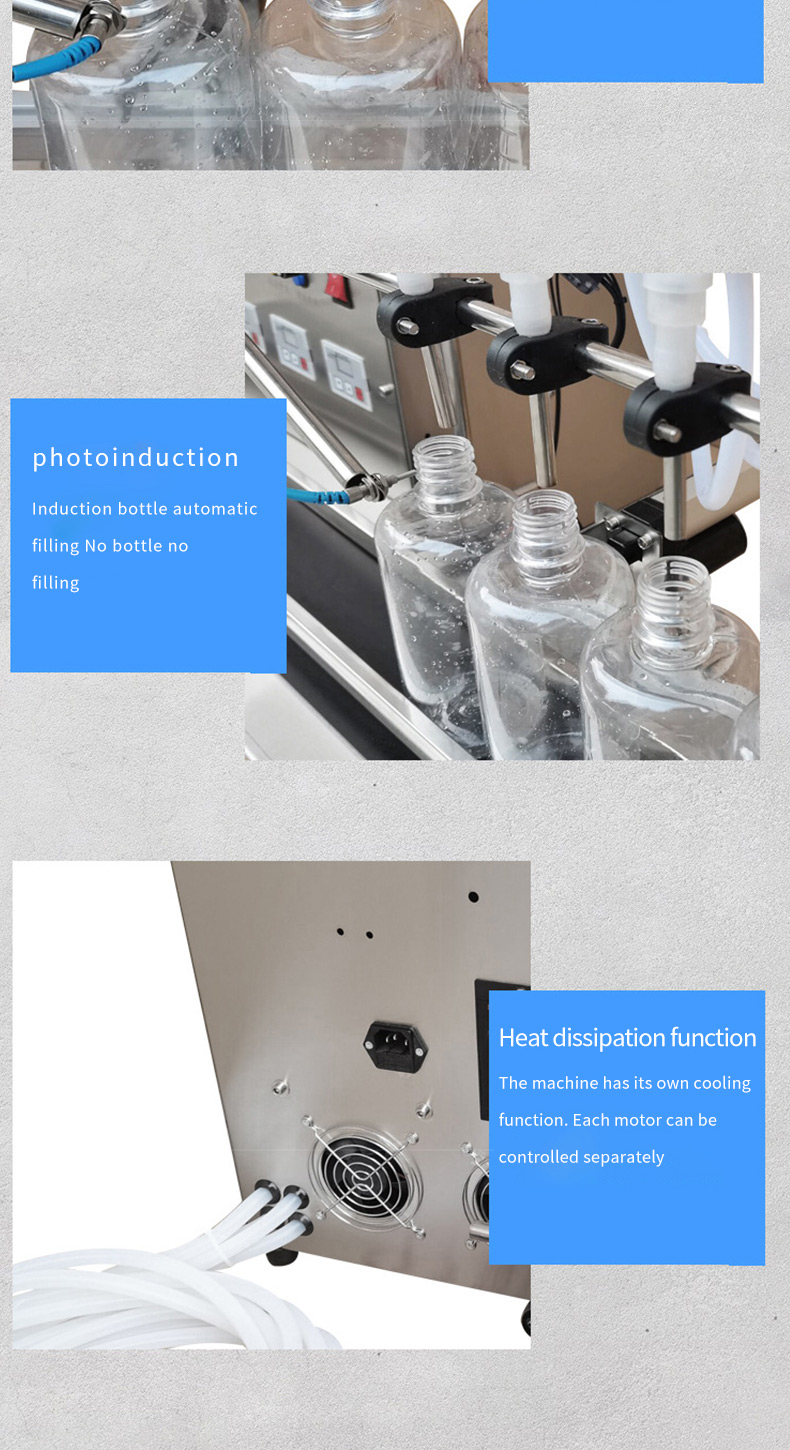

3. It has additional functions such as stirring, heating, cooling, etc. It may need to heat the liquid to maintain good fluidity; when the liquid containing the precipitated ingredient is installed.

4. Using high -precision measuring pumps, flow meters or weight sensors and other metering devices, it can accurately control the amount of perfusion each time.

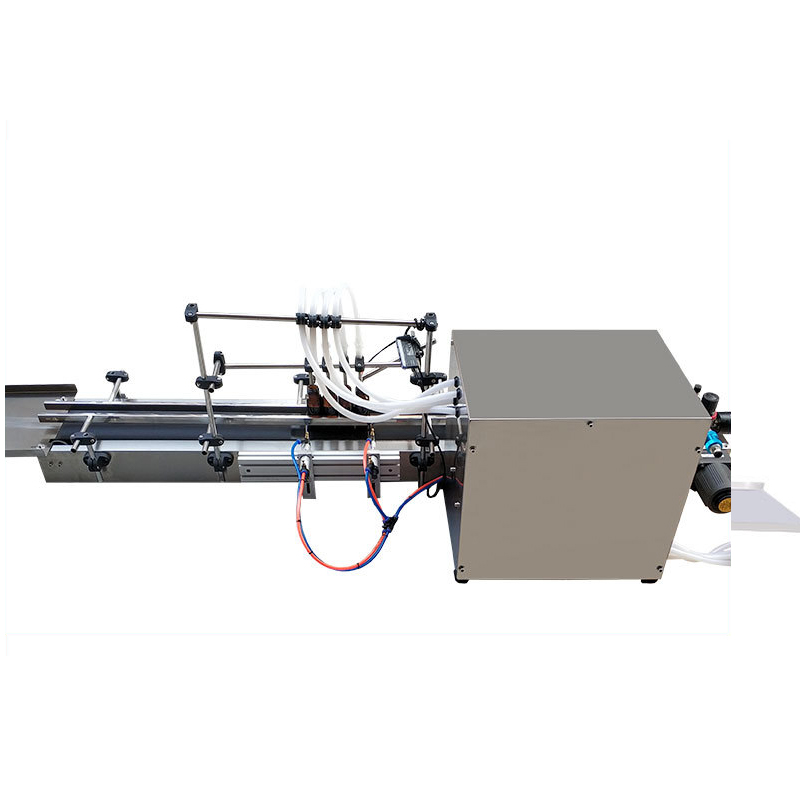

5. Design a reasonable mechanical structure and efficient transmission system make the filling speed greatly improved. Dozens or even hundreds of irrigation operations can be completed per minute.

In today's diversified production environment, the performance and adaptability of liquid filling equipment have become the focus of attention of many companies. Our multifunctional liquid filling machine, with excellent design and advanced technology, provides efficient, accurate and flexible liquid filling solutions for food, medicine, daily chemicals, chemical industry and other industries.

The optimized mechanical structure and high -speed transmission system gives the equipment excellent irrigation speed. Dozens or even hundreds of irrigation operations can be performed per minute, which greatly shortens the production cycle and improves production efficiency.

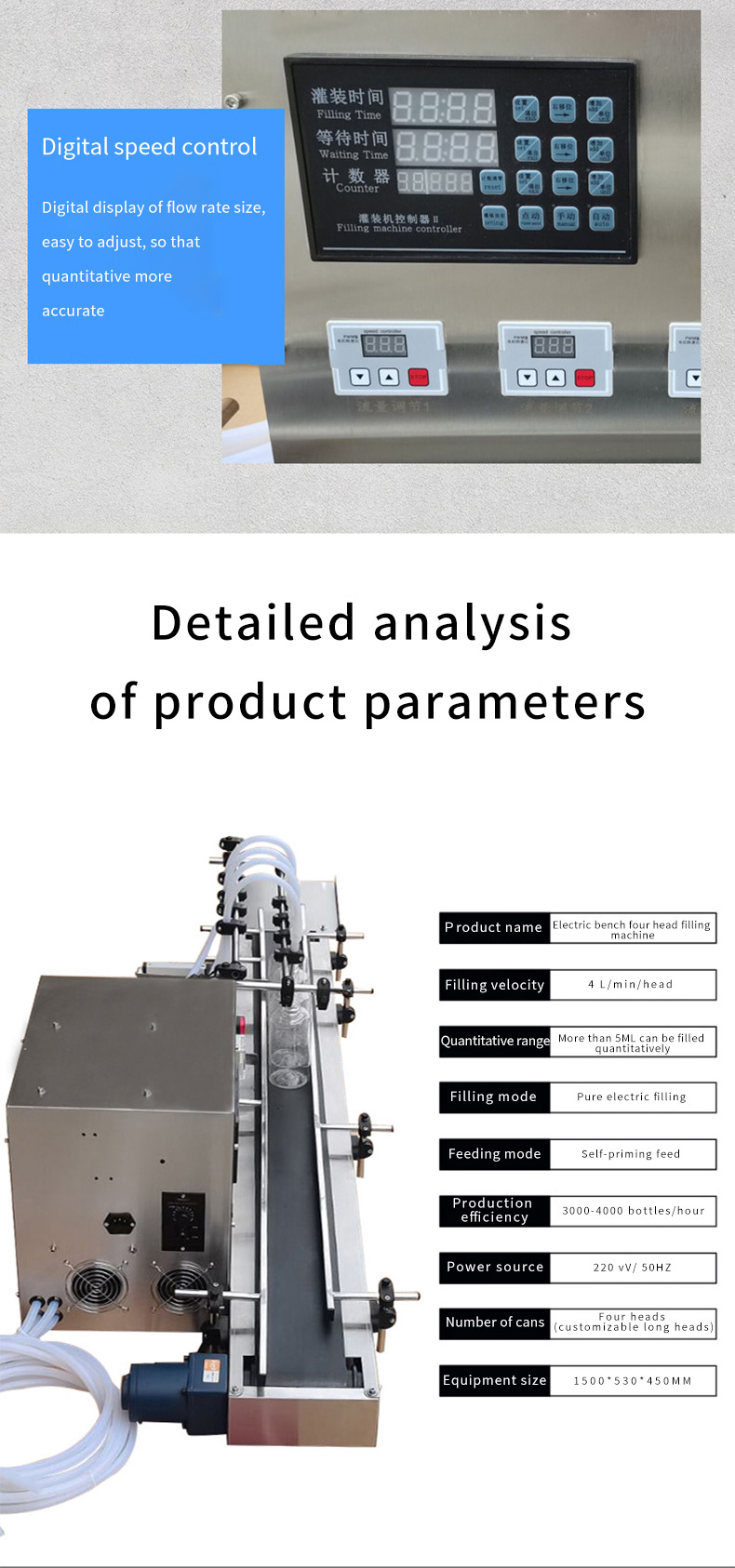

Using an intuitive touch screen operation interface, the operator only needs to easily set parameters such as filling volume, filling speed, and installation method on the screen to start the device operation.

Components in contact with liquid are made of stainless steel that meets the standards of food, medical and hygiene. The surface is smooth, easy to clean and disinfected, and effectively prevent material from cross -contamination.

The device adopts a modular design, and the various functional modules are relatively independent. When a certain part fails, the corresponding module can be replaced directly. There is no need to disassemble and repair the entire equipment, which greatly reduces the maintenance cost and time.

Whether it is a low -viscosity liquid or a high viscosity paste; whether it is glass bottle, plastic bottle, or metal tank, soft packaging bags and other materials and shapes of different materials and shapes. Replacement is adapted to show strong versatility and flexibility.