Paint filling machine

1. High-precision metering system: Equipped with advanced metering devices, such as high-precision flow meters or weighing sensors, the filling amount of the paint can be accurately controlled. For different types and viscosities of paint, the filling error can be guaranteed to be within a very small range.

2. Multiple metering modes to adapt to different paint characteristics: Support multiple metering modes, which can be adjusted according to the density, viscosity and other physical properties of the paint. For thin water-based paints and viscous oil-based paints, suitable metering methods can be found

3. High-speed filling design: Adopting optimized filling structure and efficient power system, it has the ability of fast filling. Some filling machines also have the function of multi-station simultaneous filling, and multiple filling heads can work at the same time.

4. Continuous and stable operation: The mechanical structure and control system have been carefully designed to ensure long-term continuous and stable operation.

5. Applicable to different packaging containers: It can adapt to a variety of packaging containers, such as barrels, cans, bags and other containers of different shapes and specifications. For common metal barrels, plastic barrels, metal cans, and plastic cans, the filling machine can achieve accurate filling by adjusting the filling head, positioning device and other components.

6. Uniform filling ensures paint quality: It can achieve uniform filling to ensure that the paint is evenly distributed in the container. Whether it is a large container or a small container, the paint can be filled with a stable flow rate and pressure.

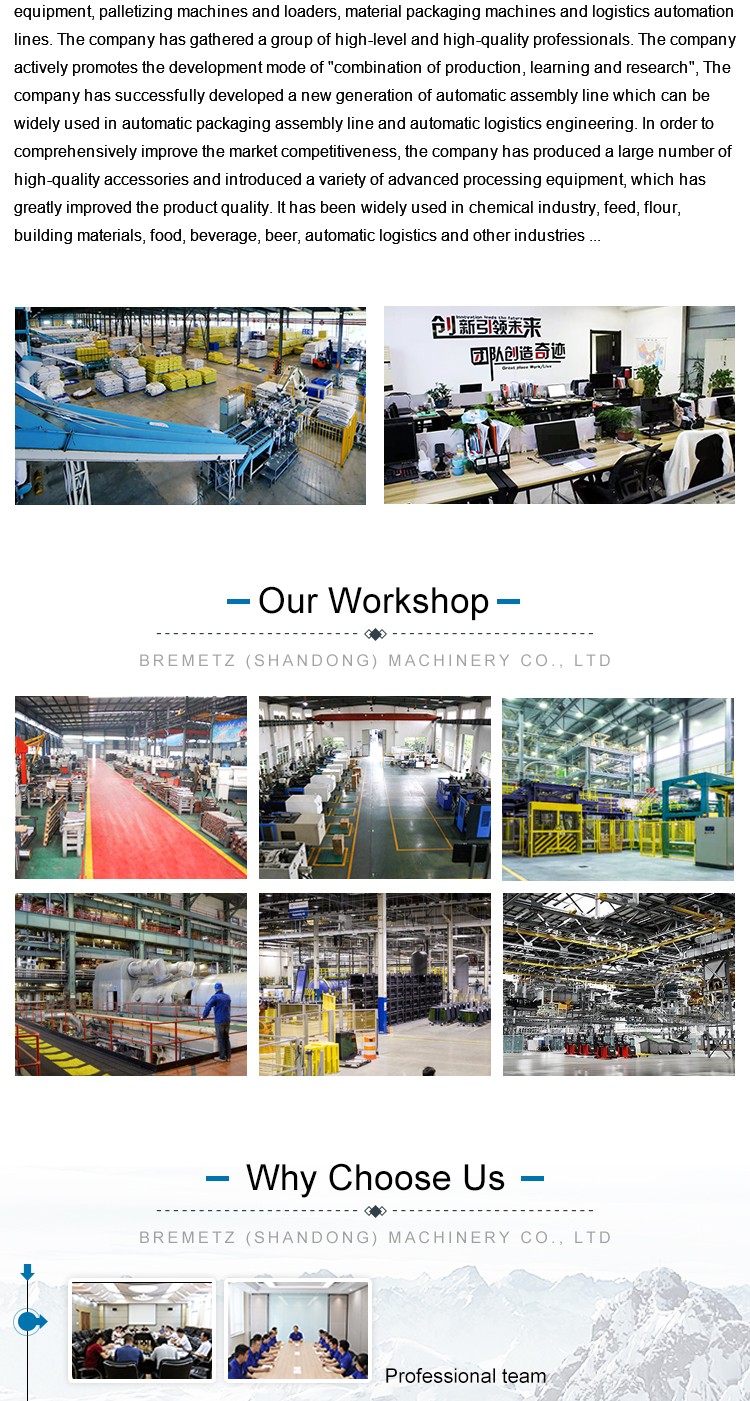

7. Safety protection measures: For oily paints containing organic solvents, the filling machine is equipped with complete safety protection devices, such as explosion-proof motors, anti-static devices, overload protection, etc.

Paint filling machine is an advanced filling equipment specially used in the paint industry, which is designed to accurately, efficiently and safely fill various types of paint into different packaging containers. It integrates modern mechanical design, high-precision metering technology, automatic control system and environmental protection and safety concepts, providing a one-stop filling solution for paint manufacturers and meeting the diverse filling needs of paint products.

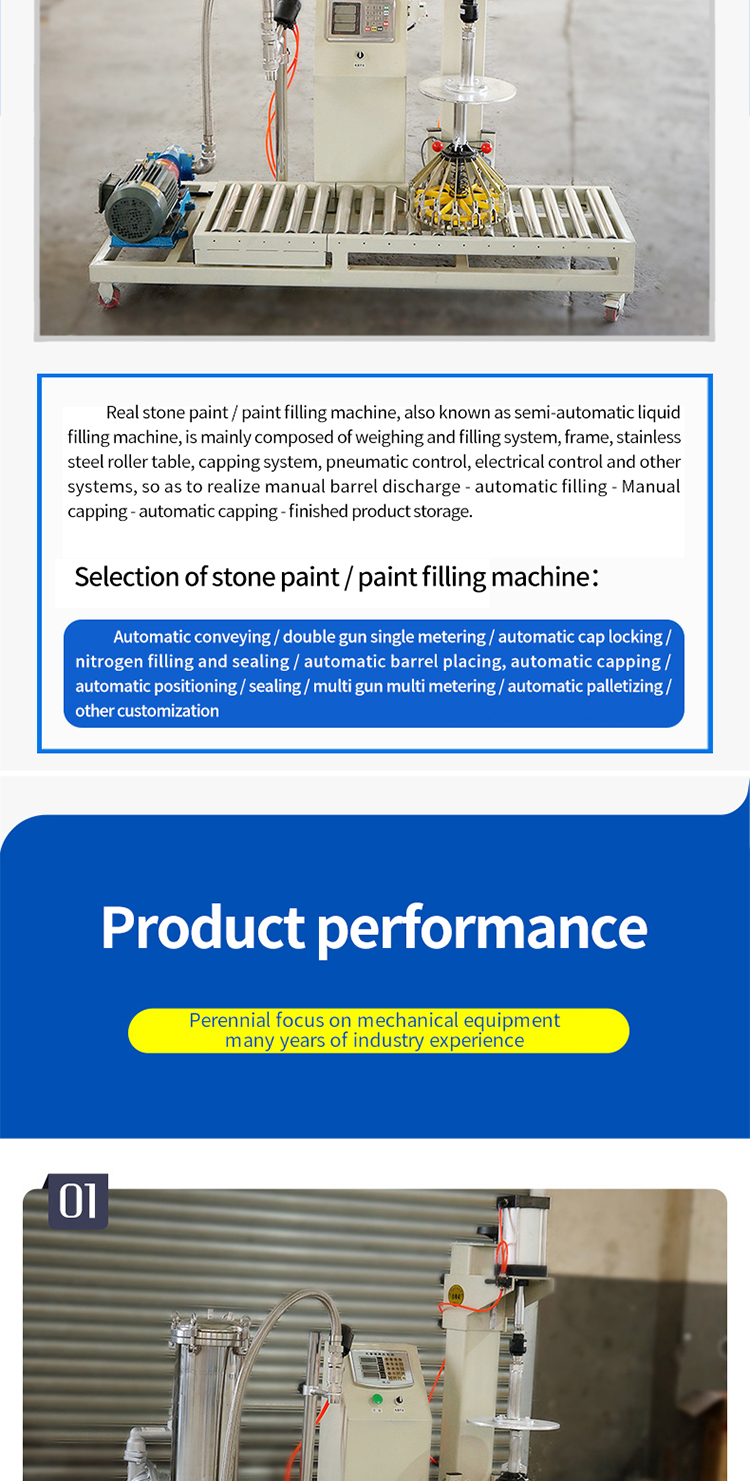

Paint filling machine, also known as semi-automatic liquid filling machine, is mainly composed of weighing filling system, frame, stainless steel roller, capping system, pneumatic control, electrical control and other systems, realizing manual barrel discharge - automatic filling - manual capping - automatic capping - finished product storage.

Selection of paint filling machine:

Automatic conveying/double gun single metering/automatic capping/nitrogen filling capping/automatic barrel placement, automatic capping/automatic positioning/sealing/multi-gun multi-metering/automatic stacking/other customization.

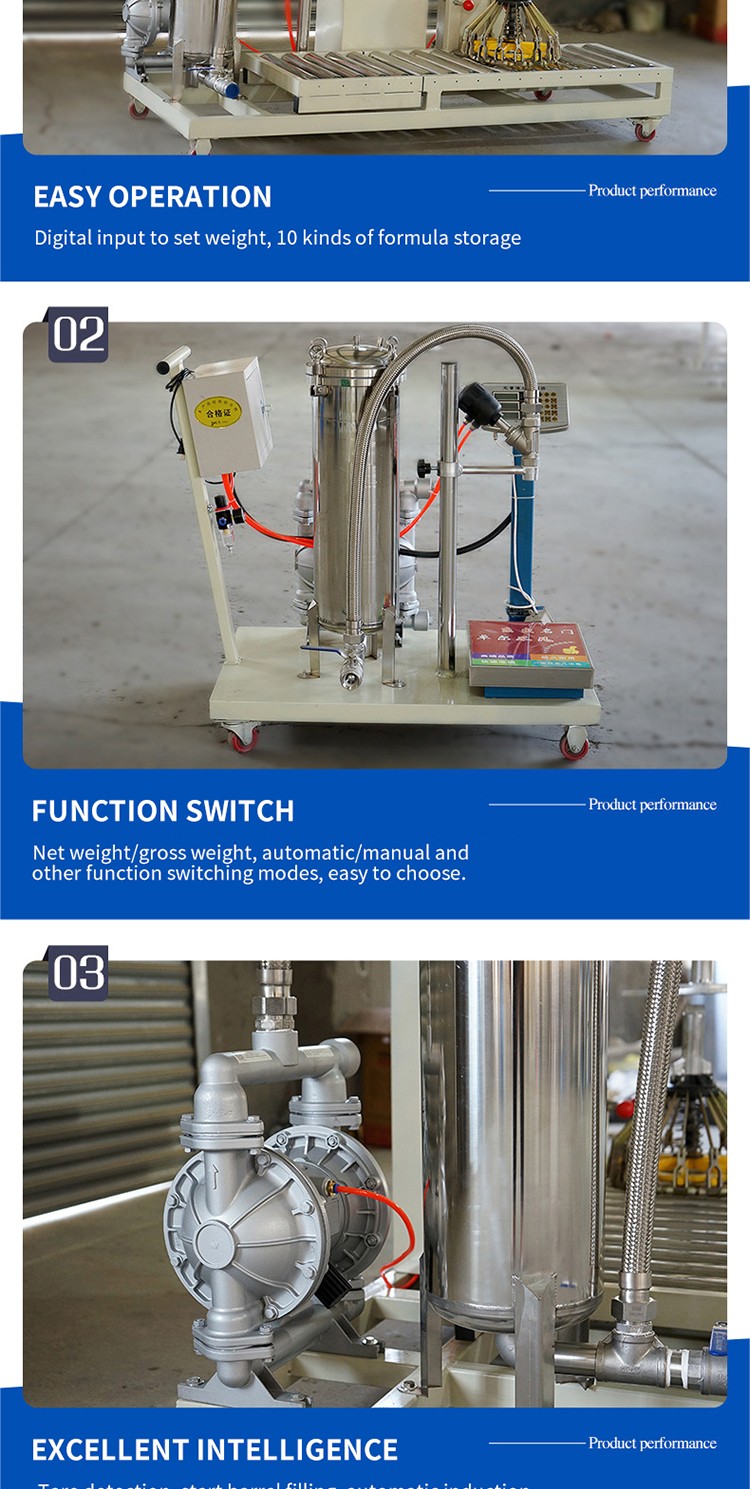

Easy to operate, digital input to set weight, 10 recipes to store

Function switch, net weight/gross weight, automatic/manual and other function switching modes, easy to choose.

Tare weight detection, start filling, automatic sensing.

Original Swiss Mettler-Toledo high-quality digital instrument, Japanese Omron relay, Taiwan Weilun touch screen, Taiwan original AirTac actuator, cylinder, the overall performance of the packaging equipment is stable and sturdy.

Wide range of applications: products are used in many fields, coatings, inks, furniture paints. Applicable to various paints, inks, automotive paints, furniture paints, adhesives (glue), resins, chemical solvents, curing agents, lubricants, shoe glue, spray glue and other fluid fields. Years of independent research and development experience provide you with professional and mature technical services.

Advanced anti-drip technology: After filling is completed, the equipment can quickly and effectively cut off the flow of paint to prevent the paint from dripping outside the container. This is achieved through a specially designed filling head valve and control system to ensure that the paint channel is closed at the moment of filling to avoid wasting paint and polluting the working environment.

The company provides a professional installation team to install the paint filling machine to the location specified by the user and conduct comprehensive commissioning. During the installation process, ensure that all parts of the equipment are installed correctly and firmly, and the pipeline connections are.