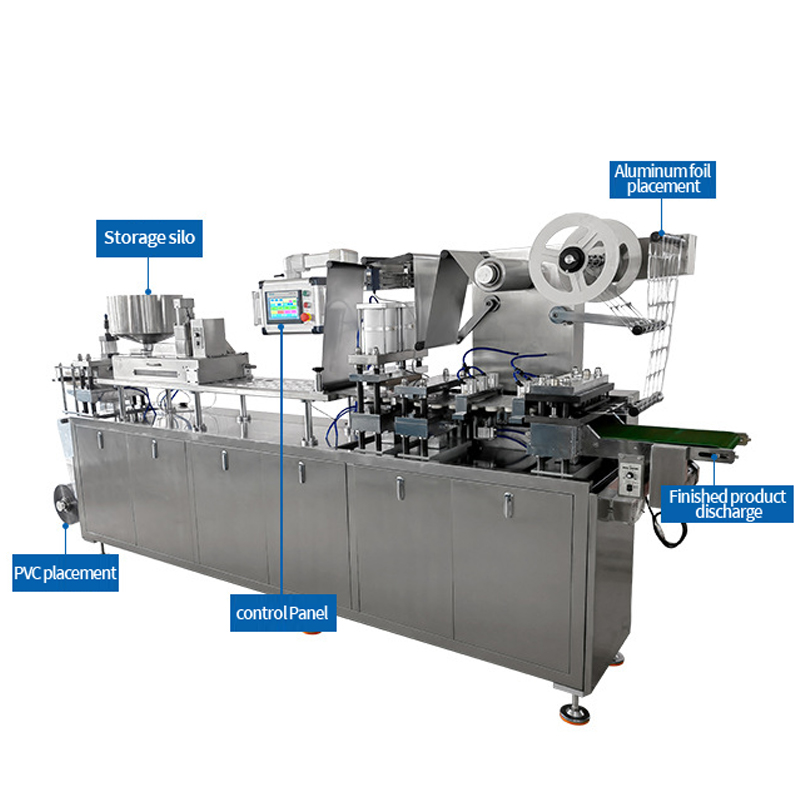

Aluminum plastic blister packaging machine

1. Precise forming and sealing: Through precise mechanical structure and control system, the forming and heat sealing process of aluminum-plastic materials can be precisely controlled to ensure the consistent size and shape of each blister.

2. Good barrier properties: Aluminum-plastic composite materials themselves have excellent barrier properties, which can block external water vapor, oxygen, light, etc., and better protect the quality and stability of the product.

3. High degree of automation: The use of advanced automation technology realizes a fully automated production process from material conveying, blister forming, product filling, sealing to finished product output.

4. High-speed and stable operation: With a high packaging speed, hundreds or even thousands of blister packages can be completed per minute, which can meet the needs of large-scale production.

5. Continuous operation: Bubble suction, filling, reticulated heat sealing, batch number printing, plate punching and other processes can be carried out continuously without frequent shutdown and start-up.

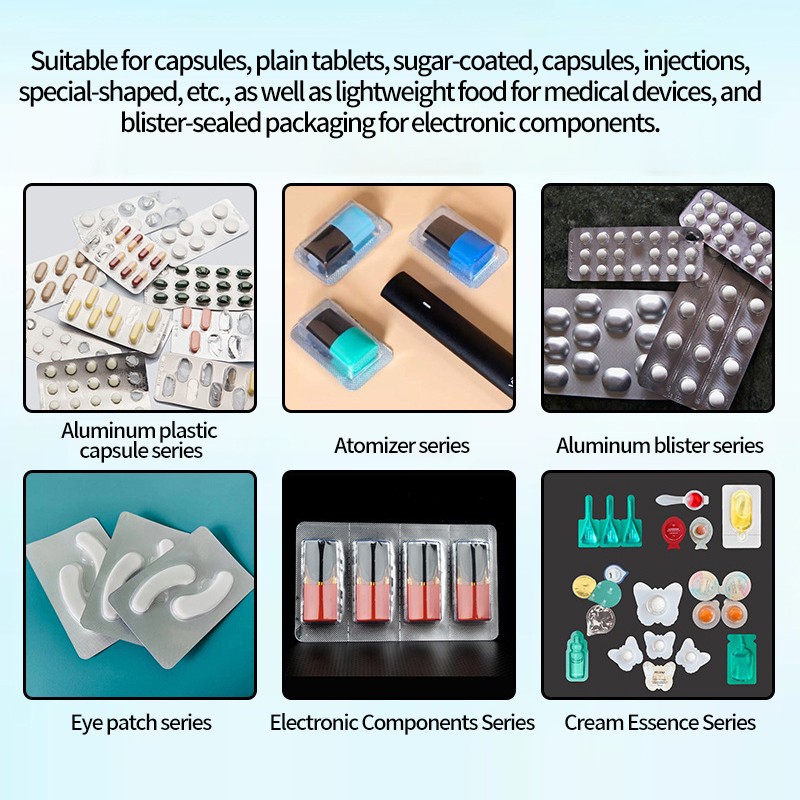

Aluminum plastic blister packaging machine is an advanced equipment specially used for aluminum plastic blister packaging, which is widely used in many industries such as medicine, food, health care products, electronic components, etc. It encapsulates the product in a blister composed of aluminum foil and plastic, providing good protection, display and storage functions for the product.

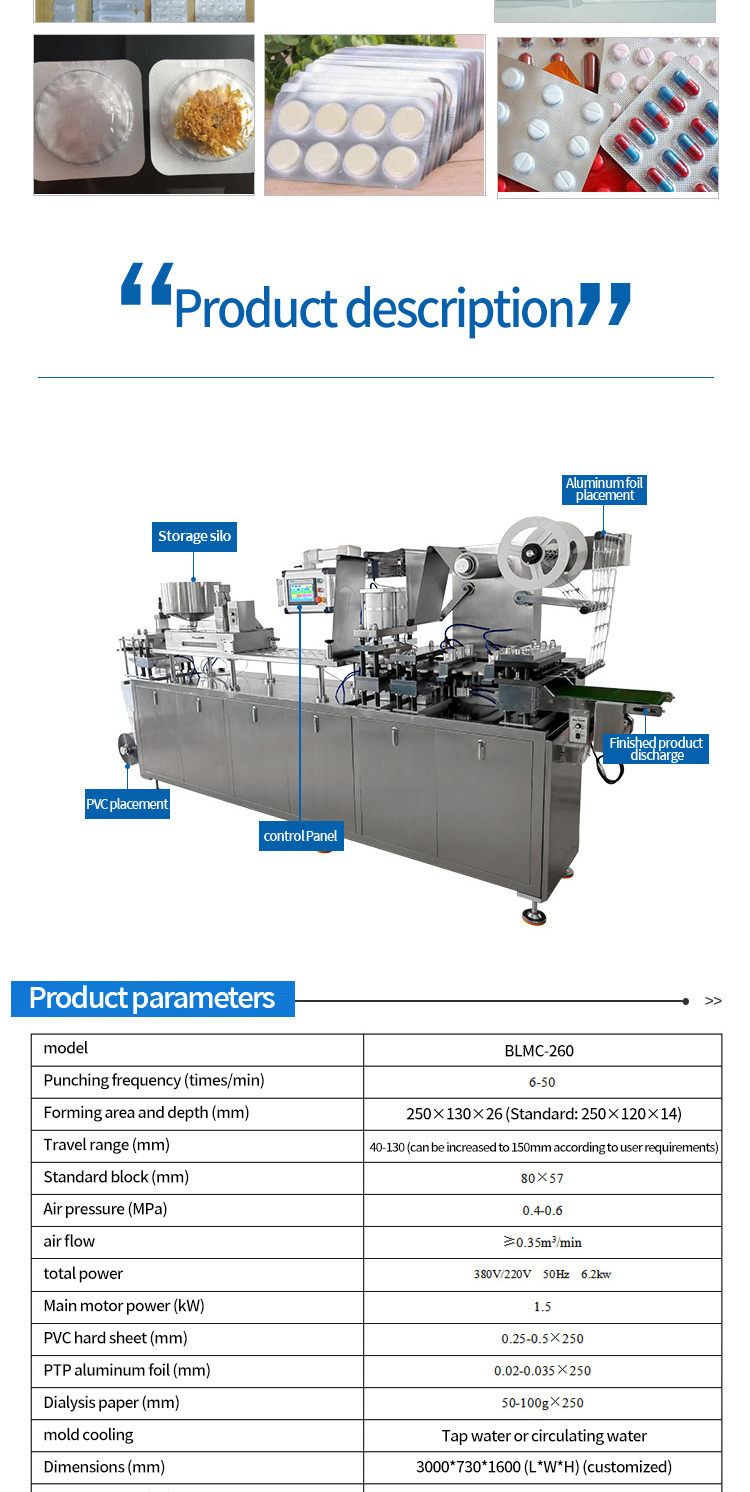

Product parameters:

model:BLMC-260

Punching frequency (times/min):6-50

Forming area and depth (mm):250×130×26 (Standard: 250×120×14)

Travel range (mm):40-130 (can be increased to 150mm according to user requirements)

Standard block (mm):80×57

Air pressure (MPa):0.4-0.6

air flow:≥0.35m³/min

total power:380V/220V 50Hz 6.2kw

Main motor power (kW):1.5

PVC hard sheet (mm):0.25-0.5×250

PTP aluminum foil (mm):0.02-0.035×250

Dialysis paper (mm):50-100g×250

mold cooling:Tap water or circulating water

Dimensions (mm):3000*730*1600 (L*W*H) (customized)

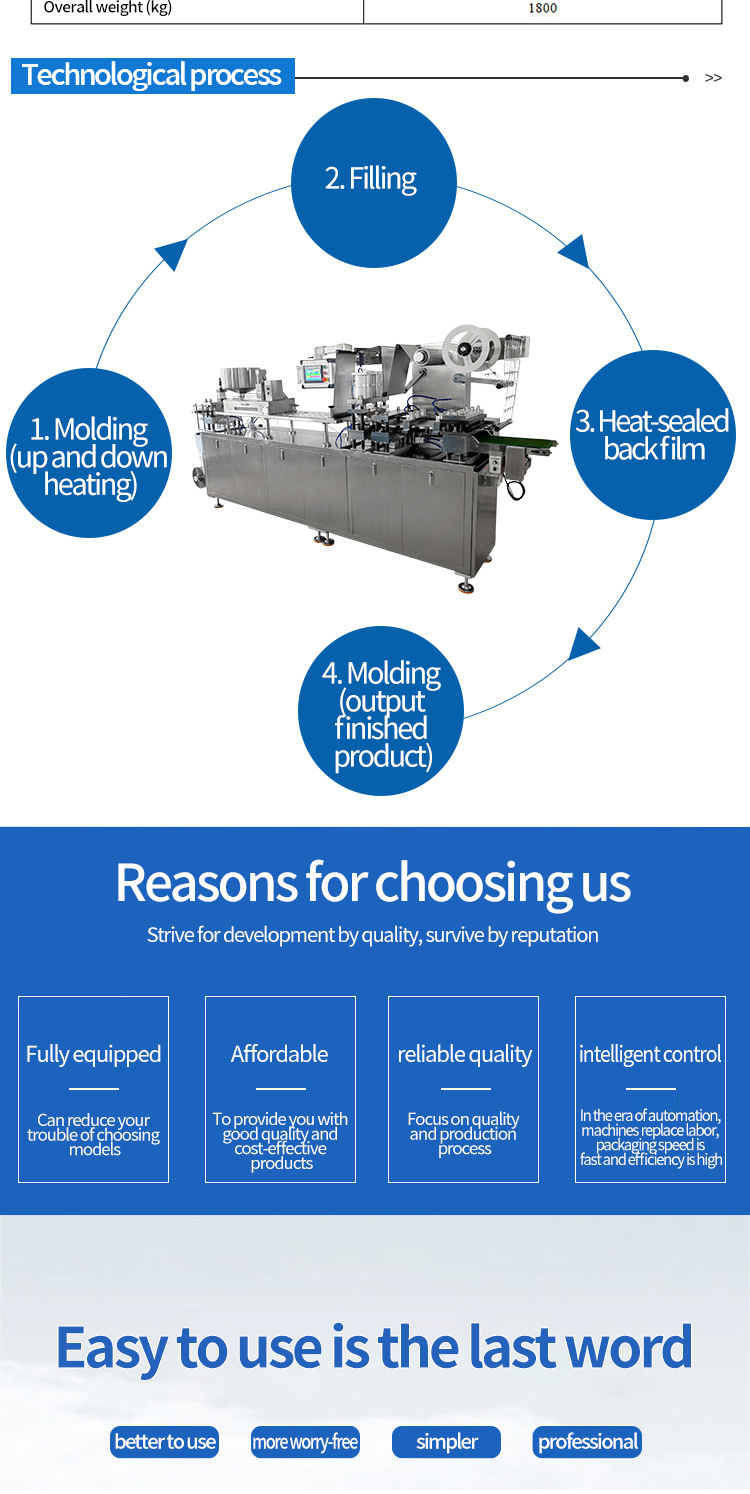

Fully equipped,

Can reduce your trouble of choosing models.

Affordable,

To provide you with good cost-effective products.

reliable quality,

Focus on quality and production process.

In the era of automation, machines replace labor, packaging.

Fully equipped,

Can reduce your trouble of choosing models.

Affordable,

To provide you with good cost-effective products.

reliable quality,

Focus on quality and production process.

intelligent control,

In the era of automation, machines replace labor, packaging.

Visual touch screen control panel,Quick reading adjustment system settings, clear interface, simple operation, easy to use.

material feeder,Design feeding boxes of different specifications for different products to adapt to the product.

Heated stamping blow molding,Design different shapes of mold cavities according to different product sizes.

Heating sealing device (point sealing, wire sealing),High temperature sealing, accurate temperature control, uniform heating, firm adhesion, beautiful and wrinkle-free.

Die cutting device,High quality just cutter durable.

High reliability: using high-quality mechanical parts and advanced manufacturing technology to ensure stable operation of the equipment under long-term, high-intensity working conditions, reduce downtime and improve production efficiency.

High-precision packaging: through precise molds and advanced control systems, high-precision packaging of products can be achieved, ensuring the accuracy of blister size, product placement and sealing quality, and improving product packaging quality and grade.

Versatility: In addition to the basic aluminum-plastic blister packaging function, some equipment can also be equipped with auxiliary functions such as coding, labeling, and anti-counterfeiting to meet the diverse needs of different customers and enhance the added value of the product.

High safety: The equipment is designed with full consideration of the safety of the operator and is equipped with safety devices such as protective doors, emergency stop buttons, and overload protection to prevent the operator from accidental injury during the operation of the equipment.

The installation of Aluminum plastic blister packaging machine is carried out by a team of experienced technical engineers. They will ensure that the equipment is installed in the right position and ensure the levelness and stability of the equipment according to the equipment installation manual and the actual situation of the customer's site, laying the foundation for the normal operation of the equipment.

We provide customers with comprehensive operation training courses, including the basic operation principle of the equipment, the function introduction of the operation panel, the setting method of each parameter, and the start, stop and emergency handling process of the equipment. The training method can be on-site training, allowing operators to learn by actual operation in front of the equipment; or it can be a combination of theoretical explanation and video demonstration to ensure that operators can be familiar with the operation skills of the equipment and avoid equipment damage or safety accidents caused by improper operation.