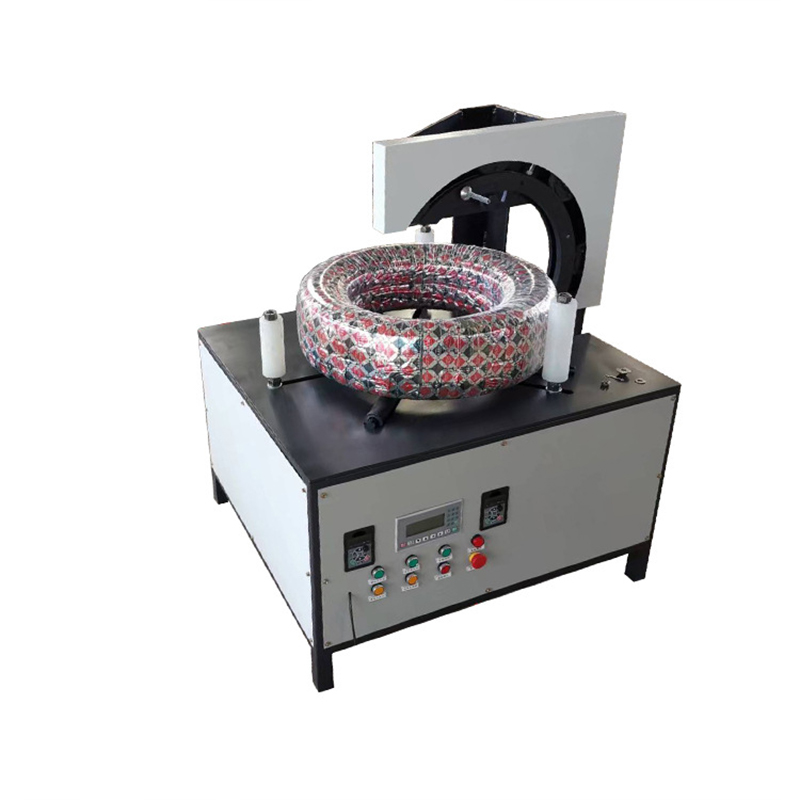

New upgrade entangle packing machine

1. High-speed packaging capability: The new upgraded wrapping packaging machine adopts advanced motor and transmission system, which can achieve higher packaging speed.

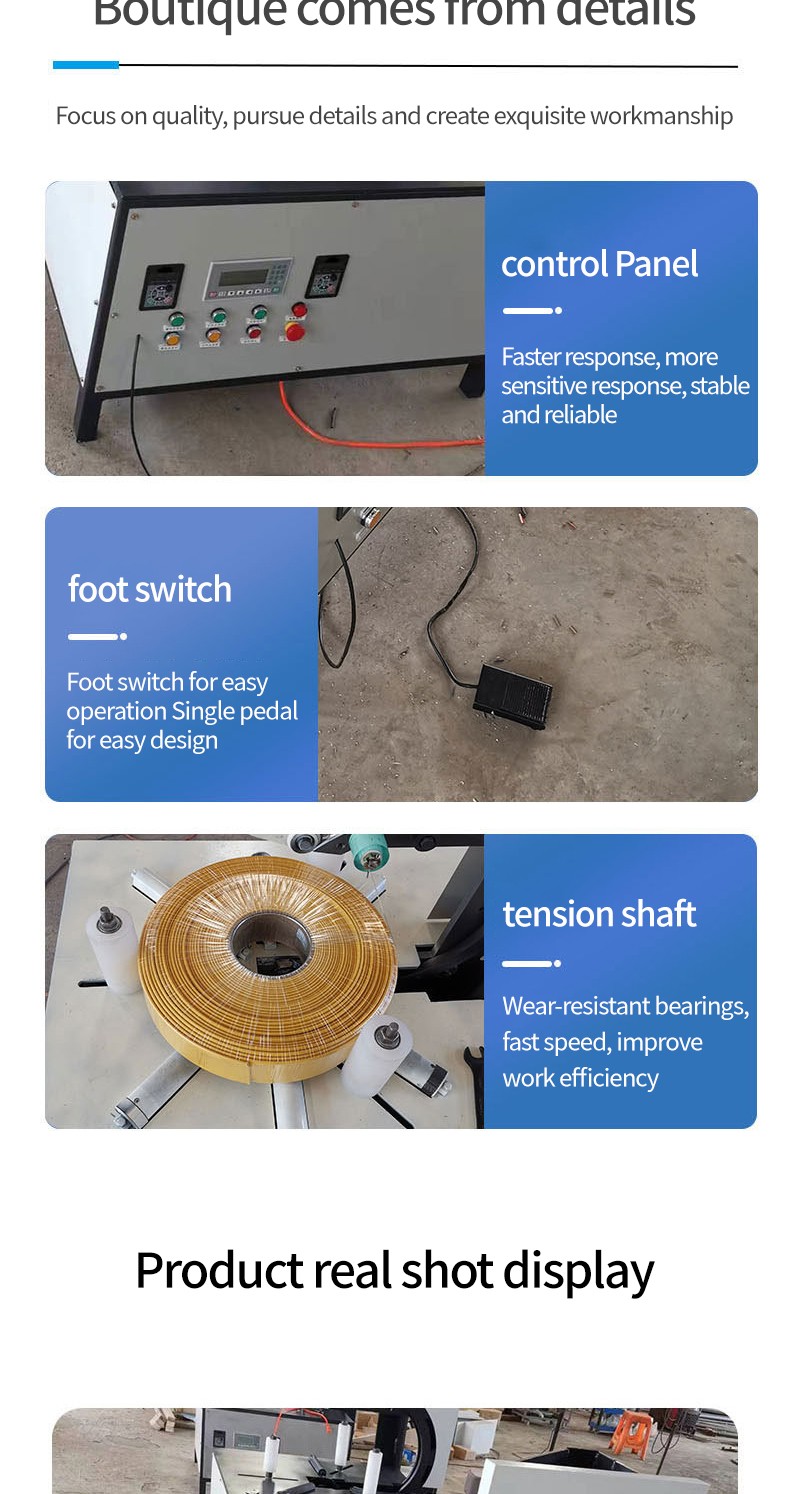

2. Tight and uniform wrapping: Through precise control system and high-quality wrapping materials, it can ensure that the packaging film is tightly and evenly wrapped on the product surface.

3. Beautiful packaging appearance: Flexible packaging settings can be made according to different product shapes and sizes, as well as the personalized needs of customers.

4. Multiple packaging modes: Support multiple packaging modes and parameter settings, such as different wrapping layers, wrapping tension, packaging height, etc., which can meet the packaging requirements of various types and specifications of products.

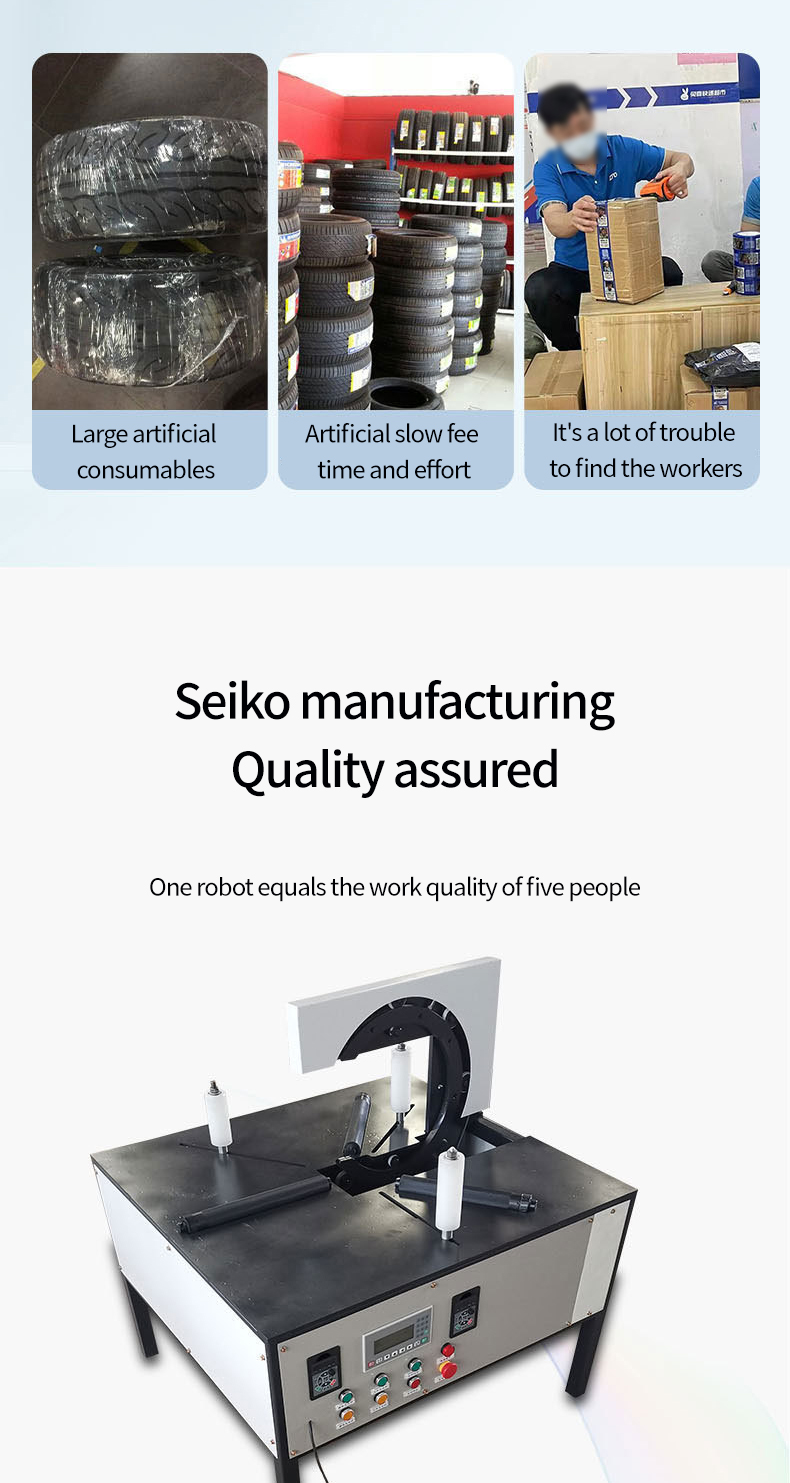

5. Reduce packaging costs: Efficient packaging speed and automated operation reduce labor costs and packaging time.

6. Improve production efficiency: Due to its efficient and stable packaging performance, it can enable enterprises to complete more packaging tasks in the same time and increase product output and shipments.

New upgraded entangle packing machine adopts a new winding method and control system. Compared with traditional packaging machines, it can wrap the packaging material more tightly and evenly on the product surface, effectively improve the stability and protection performance of the packaging, and reduce the risk of damage to the product during transportation and storage.

With the ability to run at high speed, its optimized mechanical structure and powerful power system can greatly increase the packaging speed, which is more than 50% more efficient than traditional packaging machines. At the same time, the equipment has a high degree of automation and can achieve continuous and uninterrupted packaging operations, greatly reducing manual intervention and improving overall production efficiency.

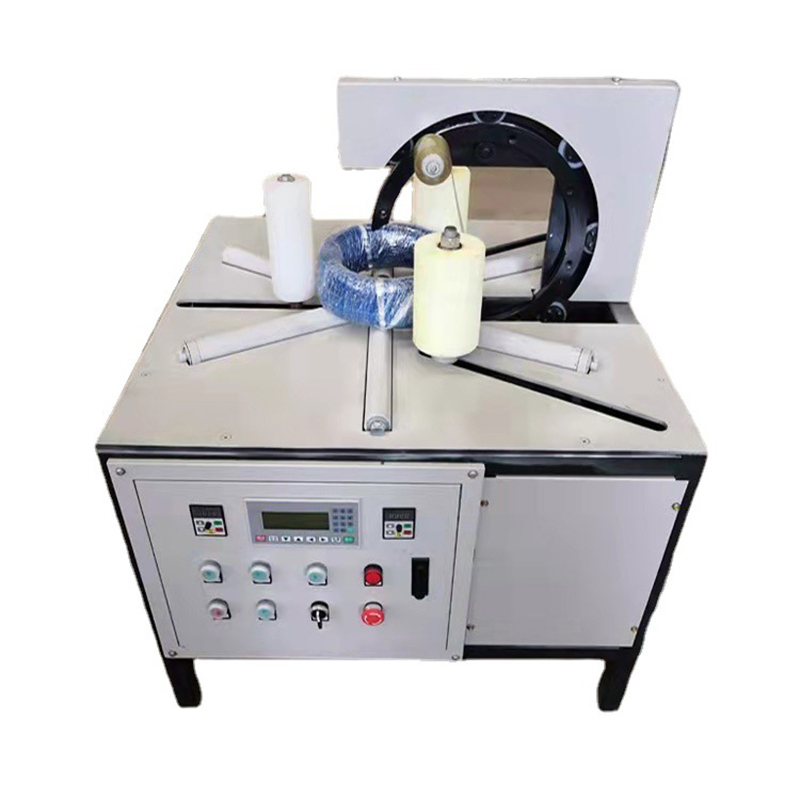

Equipped with a variety of packaging modes and adjustable parameter settings, you can flexibly select the appropriate winding method, number of layers, tension and other parameters according to the shape, size, weight and packaging requirements of different products. For example, for fragile products, you can increase the number of winding layers to enhance protection, and for products with regular shapes, you can choose a tighter winding method to save packaging materials.

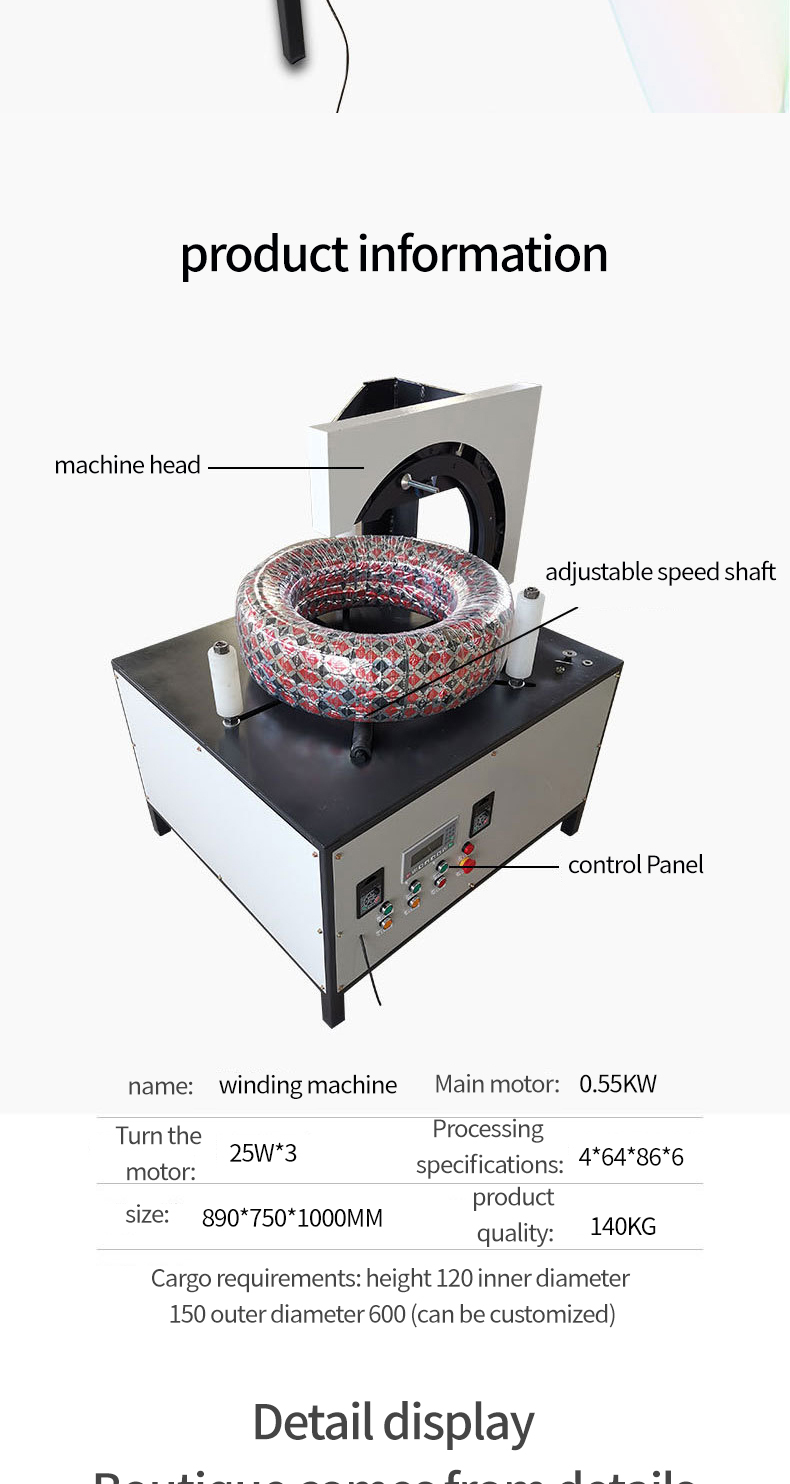

name: winding machine

Main motor: 0.55KW

Turn the motor:25W*3

Processing specifications: 4*64*86*6

product quality: 140KG

size: 890*750*1000MM

Cargo requirements: height 120 inner diameter 150 outer diameter 600 (can be customized)

Equipped with a variety of packaging modes and adjustable parameter settings, you can flexibly select the appropriate winding method, number of layers, tension and other parameters according to the shape, size, weight and packaging requirements of different products. For example, for fragile products, you can increase the number of winding layers to enhance protection, and for products with regular shapes, you can choose a tighter winding method to save packaging materials.

Standardized interfaces and communication protocols are designed to enable seamless connection with other packaging equipment or production lines, such as labeling machines, inkjet printers, metering devices, etc., to achieve full automation and integration of the packaging process. This compatibility and scalability helps companies build intelligent and efficient production workshops and improve the overall level of production management.

Provide customers with long-term technical support services, including telephone consultation, online answers, remote assistance and other methods. If customers encounter any technical problems during use, they can get professional technical advice and solutions in time to help customers better use and maintain the equipment and ensure that the equipment always maintains a good operating condition.