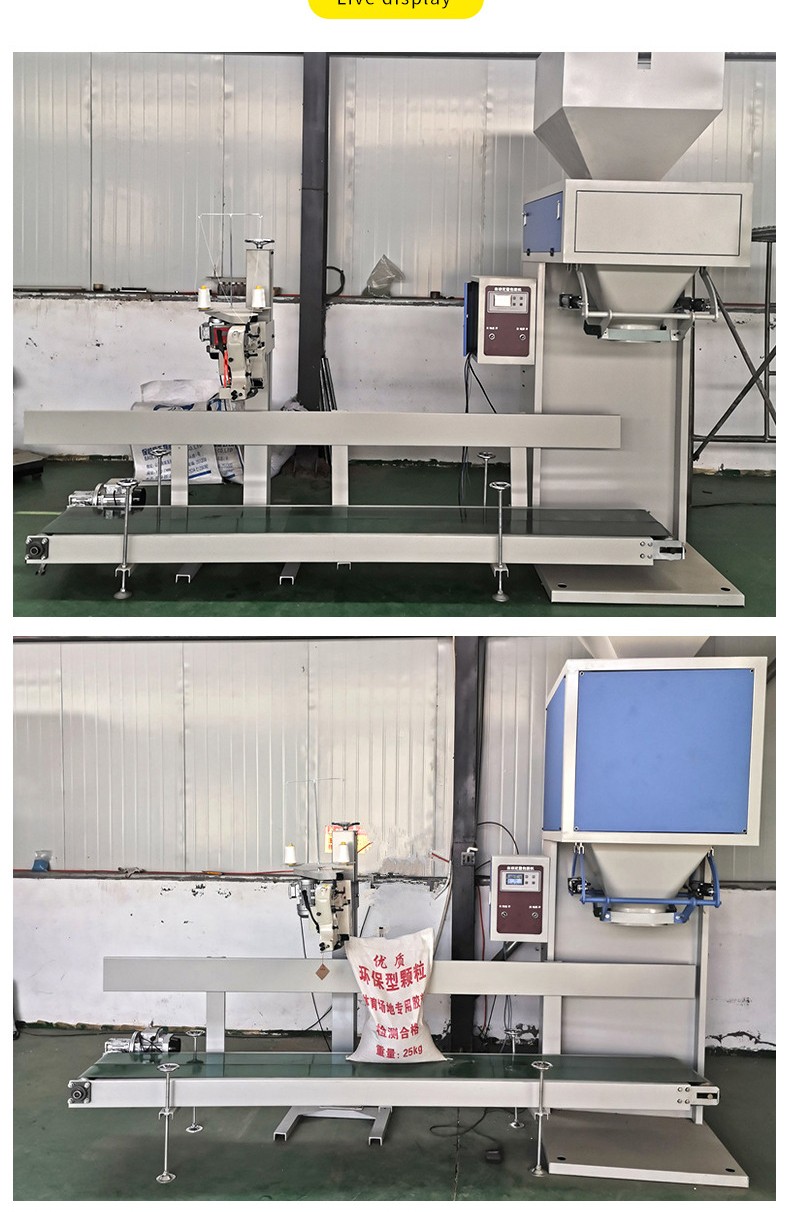

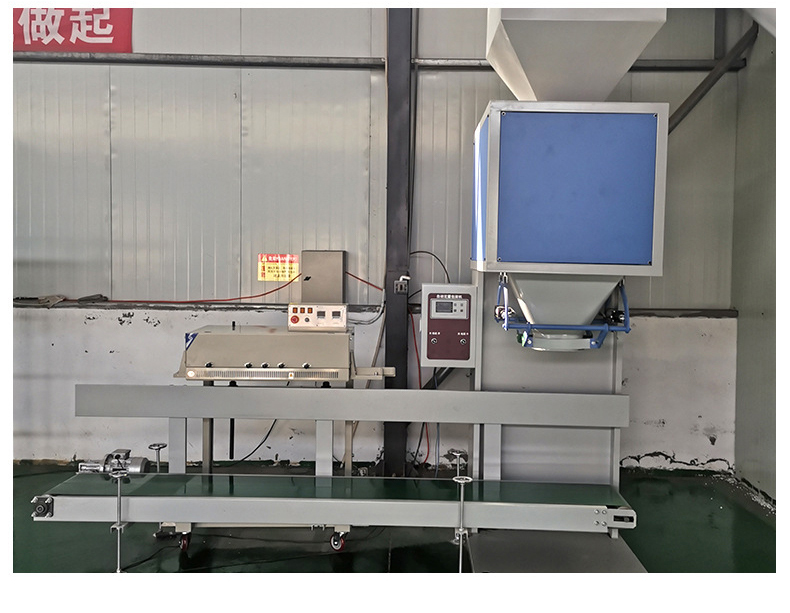

Weighing packaging machine

1. High-precision measurement: relying on advanced sensor technology, it can accurately weigh all kinds of materials, and the error range can be accurately controlled within a very small range.

2. Multi-range adaptation: with a wide range of choices, from milligrams to tens of kilograms, it can match the appropriate weighing and packaging machine model.

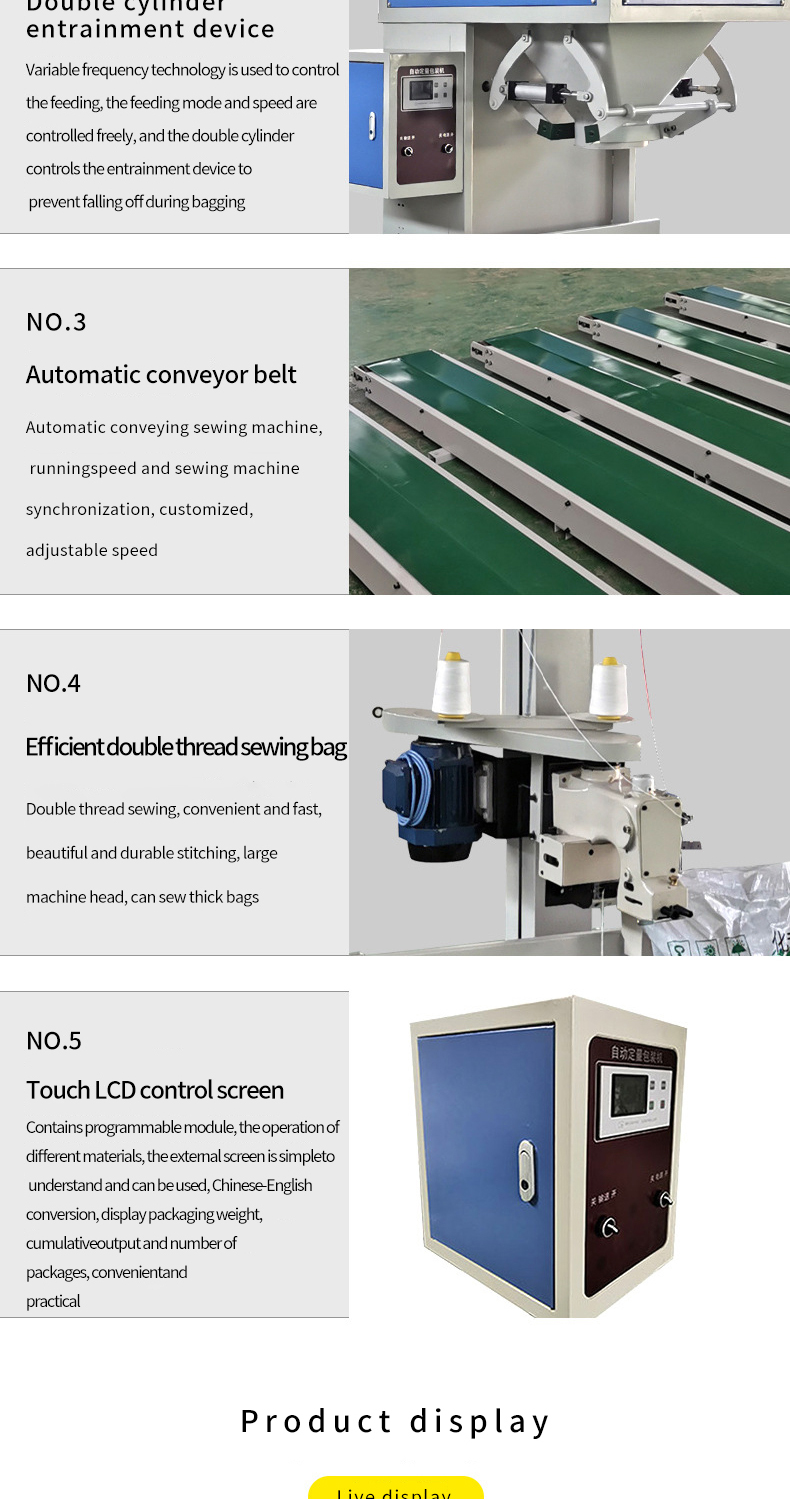

3. Fast packaging process: integrating automated feeding, weighing, filling, sealing and other coherent processes, running smoothly and fast.

4. Continuous and stable operation: the mechanical structure of the equipment is reasonably designed, the transmission system is precise and reliable, and it cooperates with the fault monitoring and early warning function of the intelligent control system.

5. Strong material compatibility: whether it is powder, granular, block or liquid material, it can be smoothly packaged by adjusting the equipment parameters.

6. Data traceability management: the intelligent control system can record detailed information such as the parameters of each batch of product packaging, which is convenient for enterprises to trace and query.

Weighing Packaging Machine is a modern industrial equipment that integrates precise weighing and efficient packaging functions. It aims to solve the quantitative packaging and packaging problems of materials in many industries, and ensure the high quality and high efficiency of product packaging with automated and intelligent processes.

Precision first: relying on top sensors and precise algorithms, the weighing error is small in the whole range, and the milligram-level deviation is strictly observed in the packaging of medicines and high-end foods to maintain product quality and regulatory compliance.

Efficient output: under continuous and stable operation, the packaging volume per hour can easily exceed 100, and large-scale equipment can reach more than 1,000 pieces in simple packaging scenarios (such as grain bagging), helping enterprises to seize the market and increase production capacity.

Universal adaptability: Whether the material is loose powder, rounded particles, irregular blocks, or flowing liquid, it can be processed accurately; with rich packaging forms and materials, it can meet the "fantasy" of various product packaging.

Stable and durable: The mechanical structure is solid and sturdy, the high-quality components have been rigorously tested, and it is equipped with intelligent electrical protection and heat dissipation, anti-interference, low fault, long equipment life, and low operation and maintenance costs.

Smart and convenient: The operation is simple and intuitive, and novices can master it after a short training; remote monitoring and data traceability functions allow production management to "strategize", optimize processes and control quality.

Strict hygiene: The material contact area follows food-grade and pharmaceutical-grade standards for material selection and production, combined with dust-proof, insect-proof and pollution-proof designs, to build a solid "line of defense" for hygiene and safety and protect sensitive products.

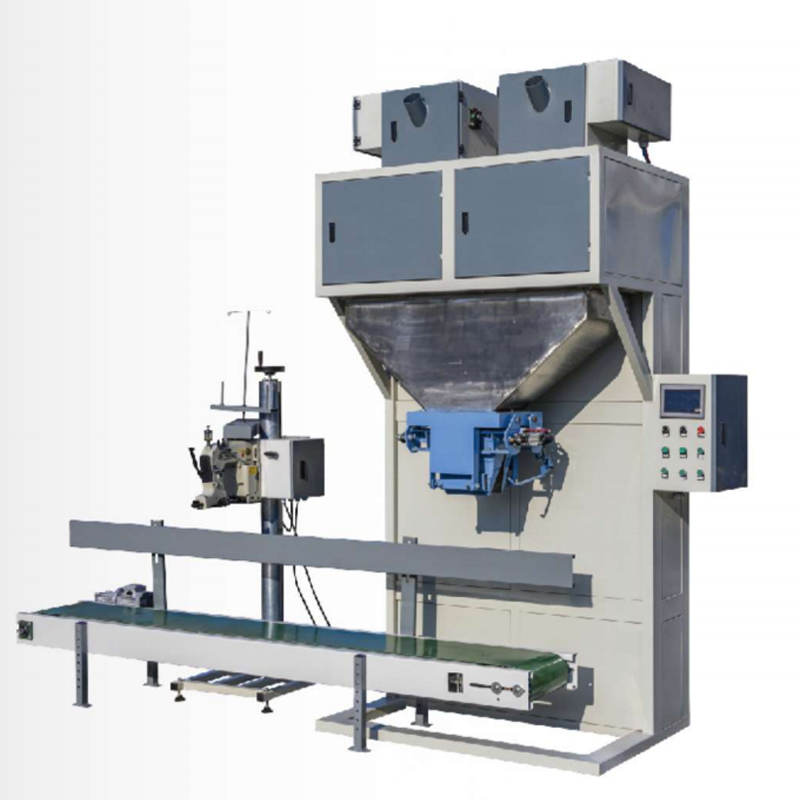

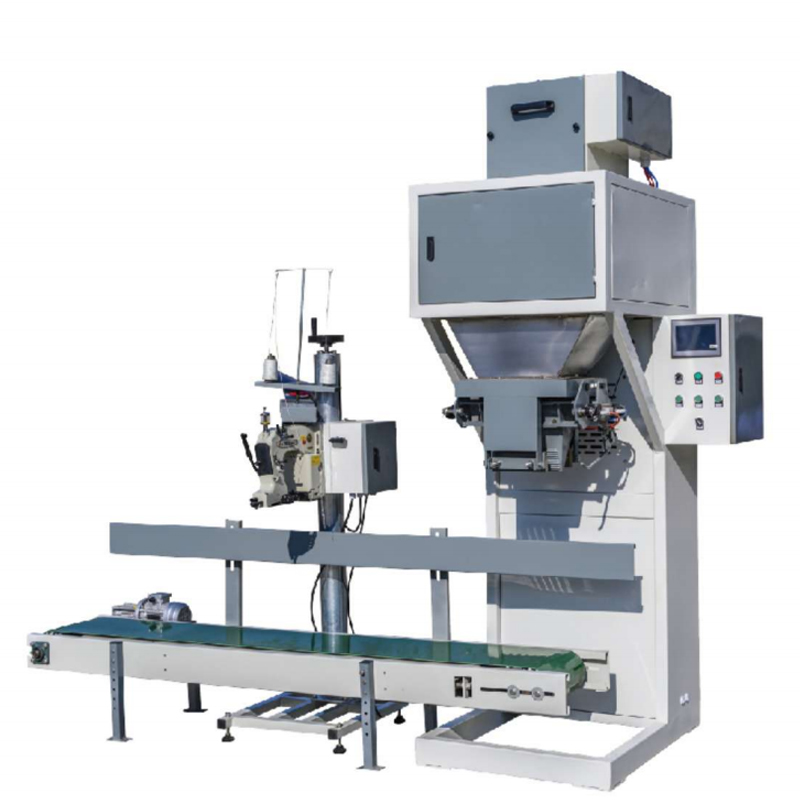

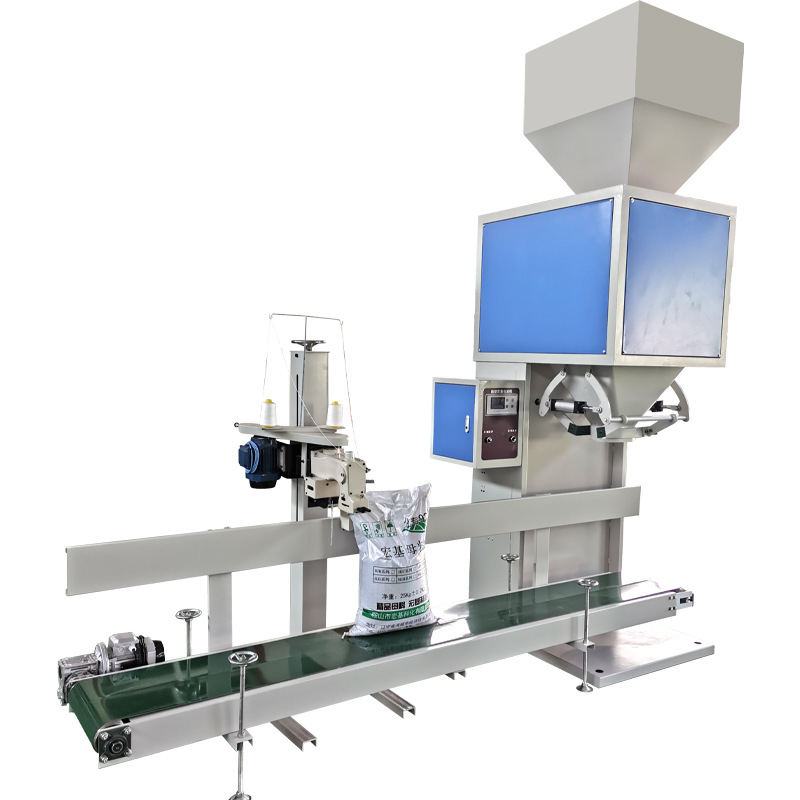

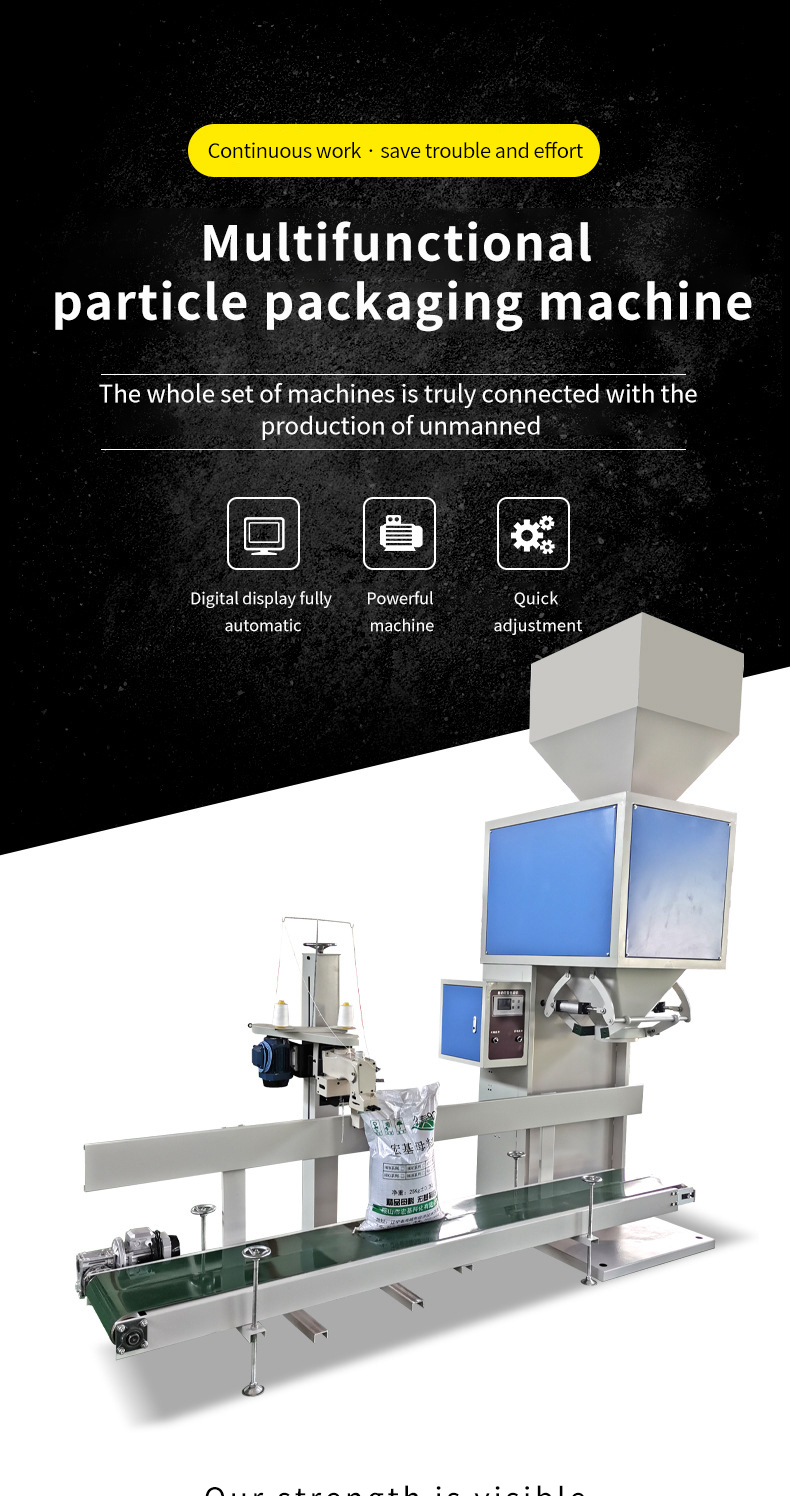

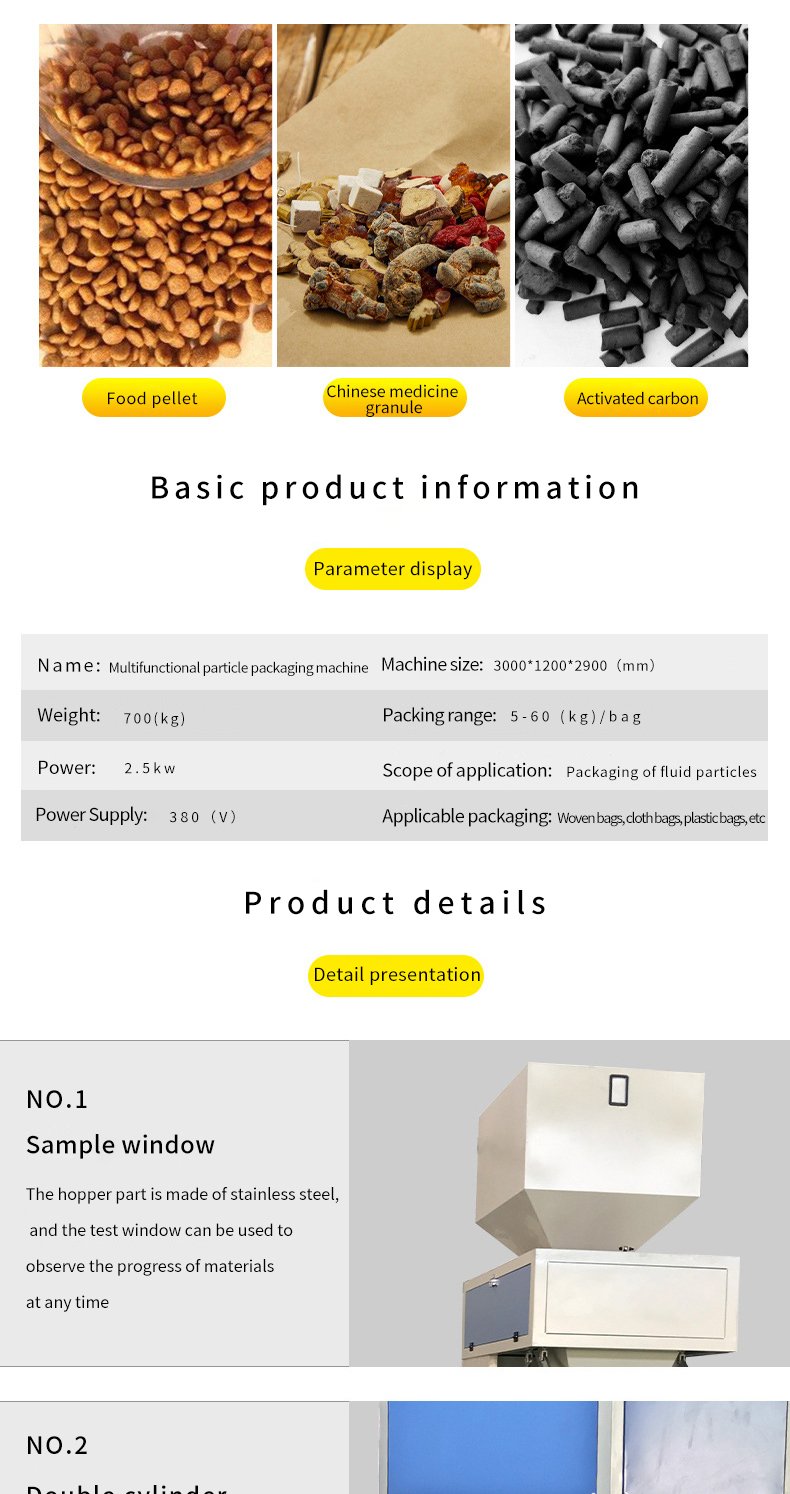

Name: Multifunctional particle packaging machine

Machine size: 3000*1200*2900 (mm)

Weight: 700(kg)

Packing range: 5-60 (kg)/bag

Power:2.5kw

Scope of application: Packaging of fluid particles

Power Supply: 380 (V)

Applicable packaging: Woven bags, cloth bags, plastic bags, etc

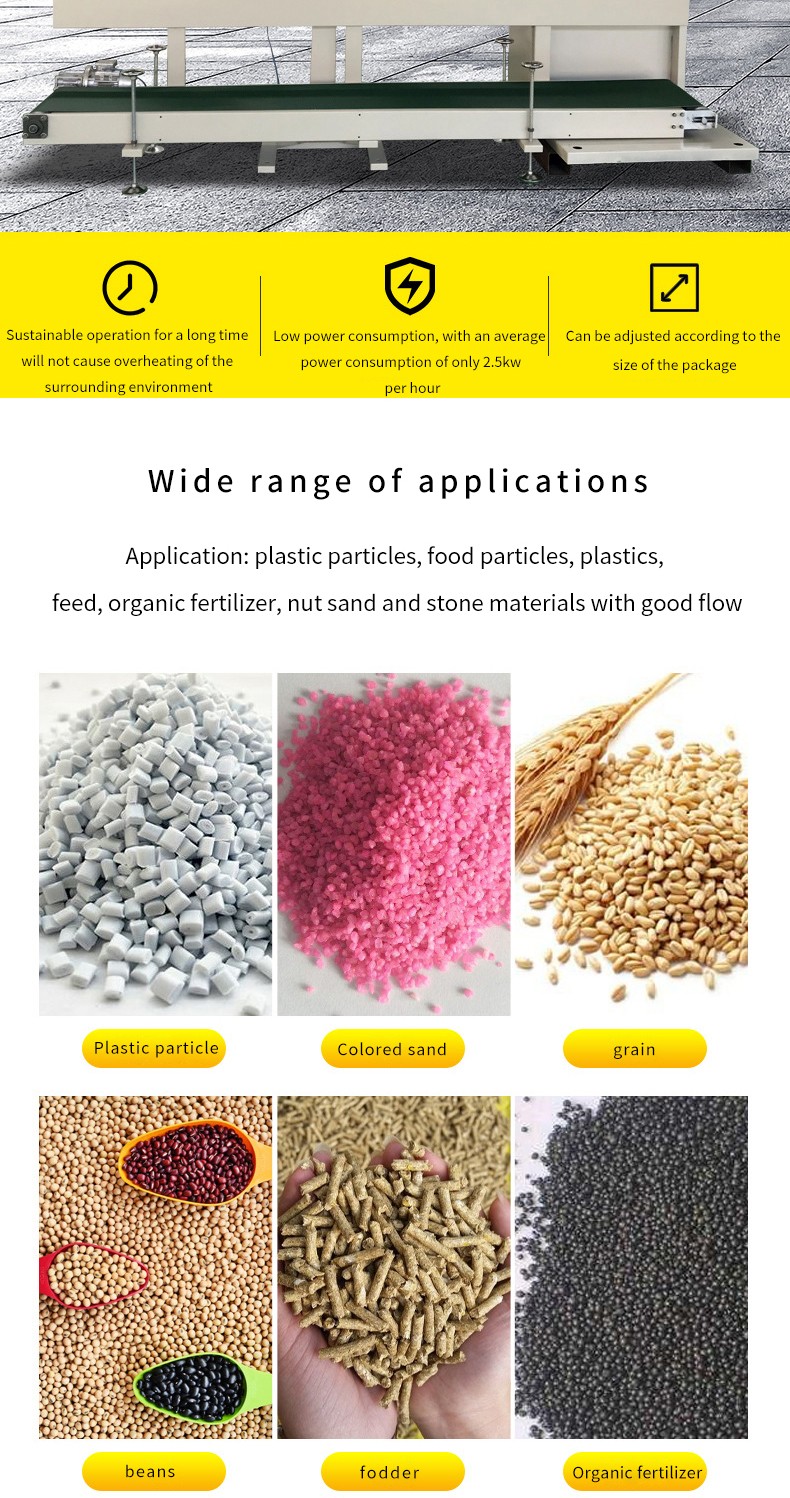

Applicable to a wide range of scenarios:

Food processing: the entire chain of food processing, from snacks, condiments to staple grains, precise packaging ensures accurate measurement of deliciousness and long-lasting freshness.

Health escort: pharmaceutical and health product production lines, strictly adhere to accurate dosage, and anti-pollution mechanism ensures safe use of drugs.

Chemical matrix: chemical raw materials, finished product packaging, precise proportioning and packaging, convenient transportation and storage.

Agricultural foundation: seeds, fertilizers, pesticide packaging, to help agricultural scientific planting, fertilization and medication.

Daily chemical world: cosmetics, detergent packaging, with exquisite appearance and precise measurement.

Operation skills training: tailor-made system training courses for your front-line operators, covering theoretical explanations and practical exercises. In the theoretical part, the working principle, structural composition, and control panel function operation logic of the equipment are explained in simple terms.

We have set up a professional after-sales service hotline, which is open 24 hours a day, 7 days a week. Once we receive a report of equipment failure, we promise to respond within 48 hours and conduct preliminary investigations through remote guidance via phone or video.