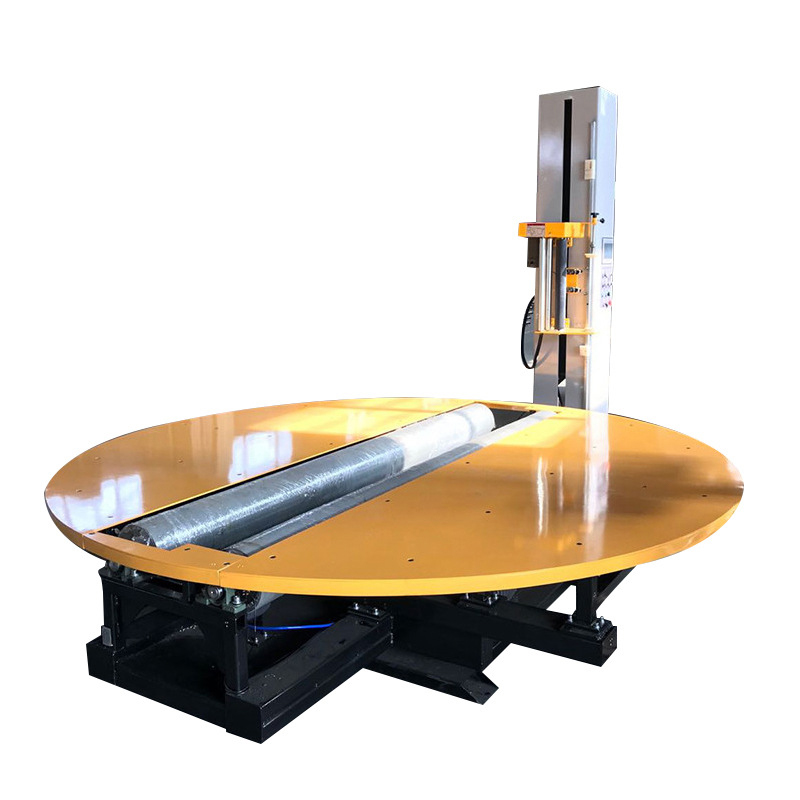

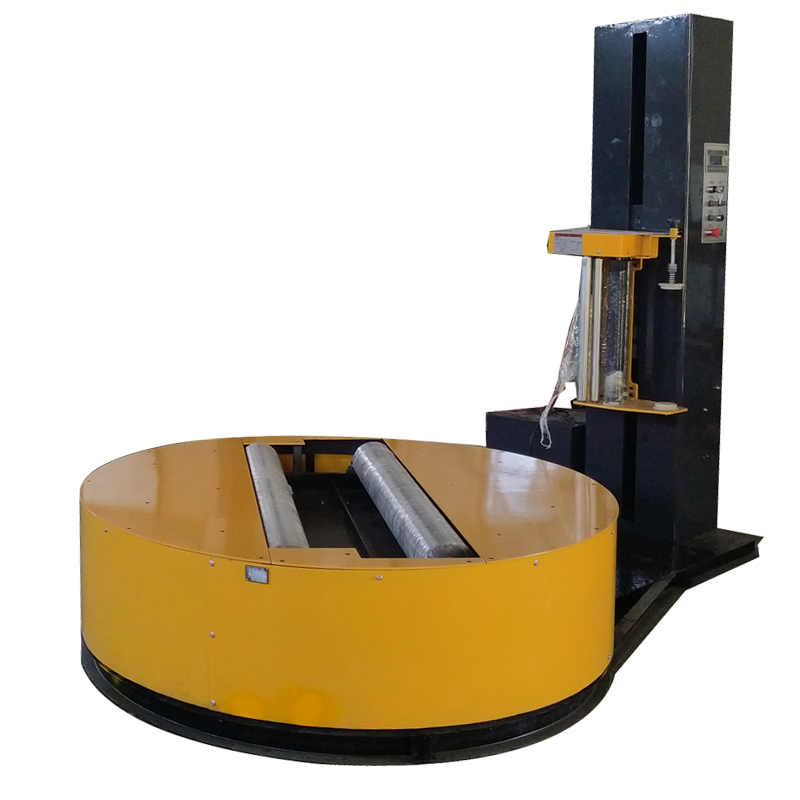

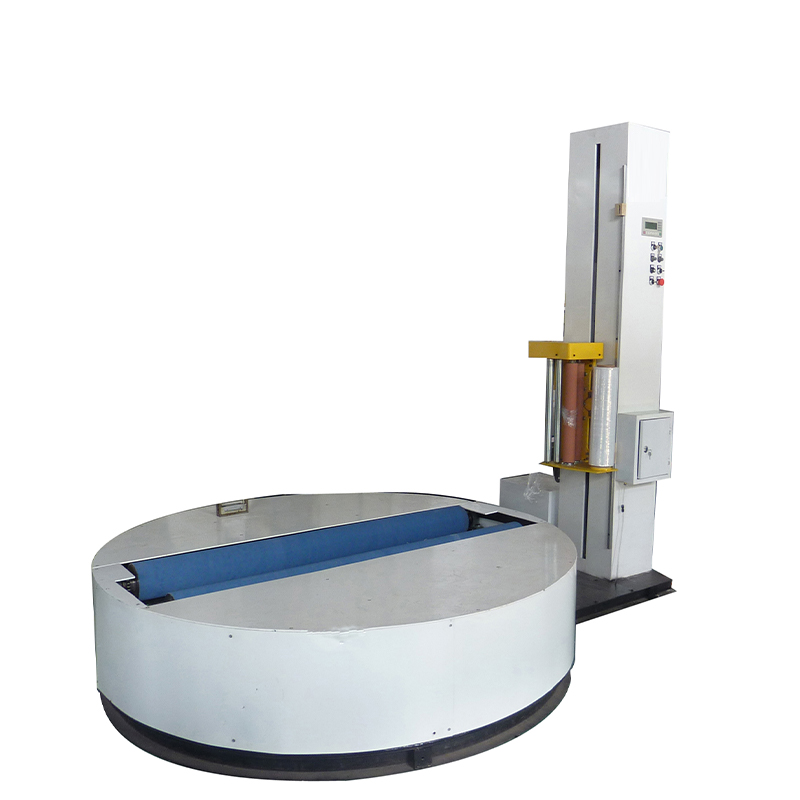

Round barrel stretch film packaging machine

1. Tight fit: The stretch film can be tightly wrapped around the surface of the barrel to form a uniform and tight protective film.

2. Moisture-proof and dust-proof: The stretch film has good moisture-proof and dust-proof properties, and can isolate moisture, dust and other impurities in the external environment.

3. Enhanced stability: Through spiral or ring winding, the center of gravity of the barrel is more stable and not easy to tip over.

4. Diverse packaging objects: It can package barrels of various sizes and materials, including plastic barrels, metal barrels, wooden barrels, etc.

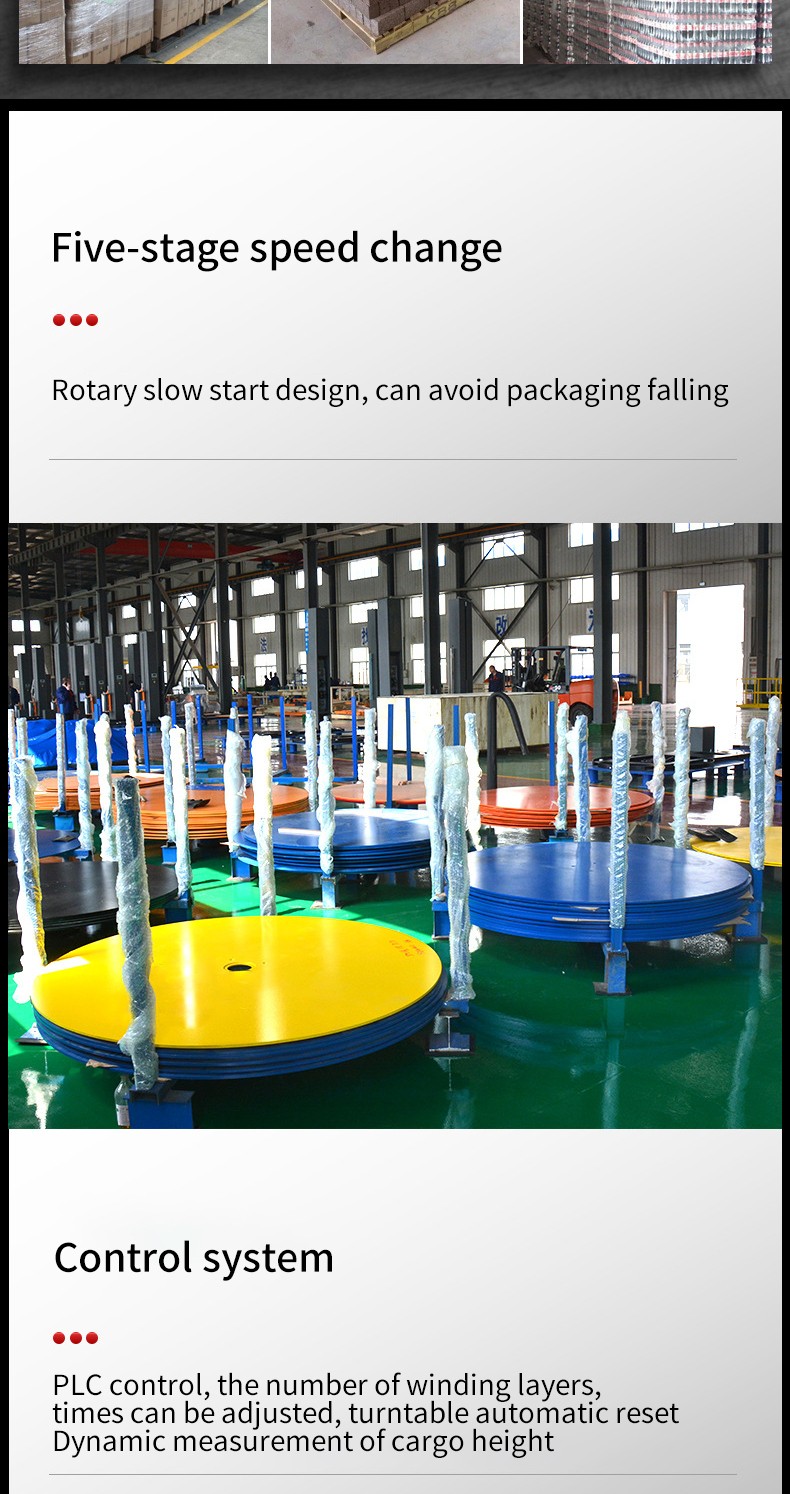

5. Stable and reliable: It adopts high-quality mechanical structure and advanced control system, and the operation is stable and reliable with low failure rate.

Round barrel stretch film packaging machine stretches the stretch film through a mechanical device and wraps it tightly around the surface of the barrel to form a protective film, thereby protecting the items in the barrel and preventing them from being damaged during transportation and storage.

High packaging efficiency: It can complete the packaging task of a large number of drums in a short time, improve production efficiency, and is suitable for large-scale production enterprises. For example, some advanced models can pack dozens or even hundreds of drums per hour.

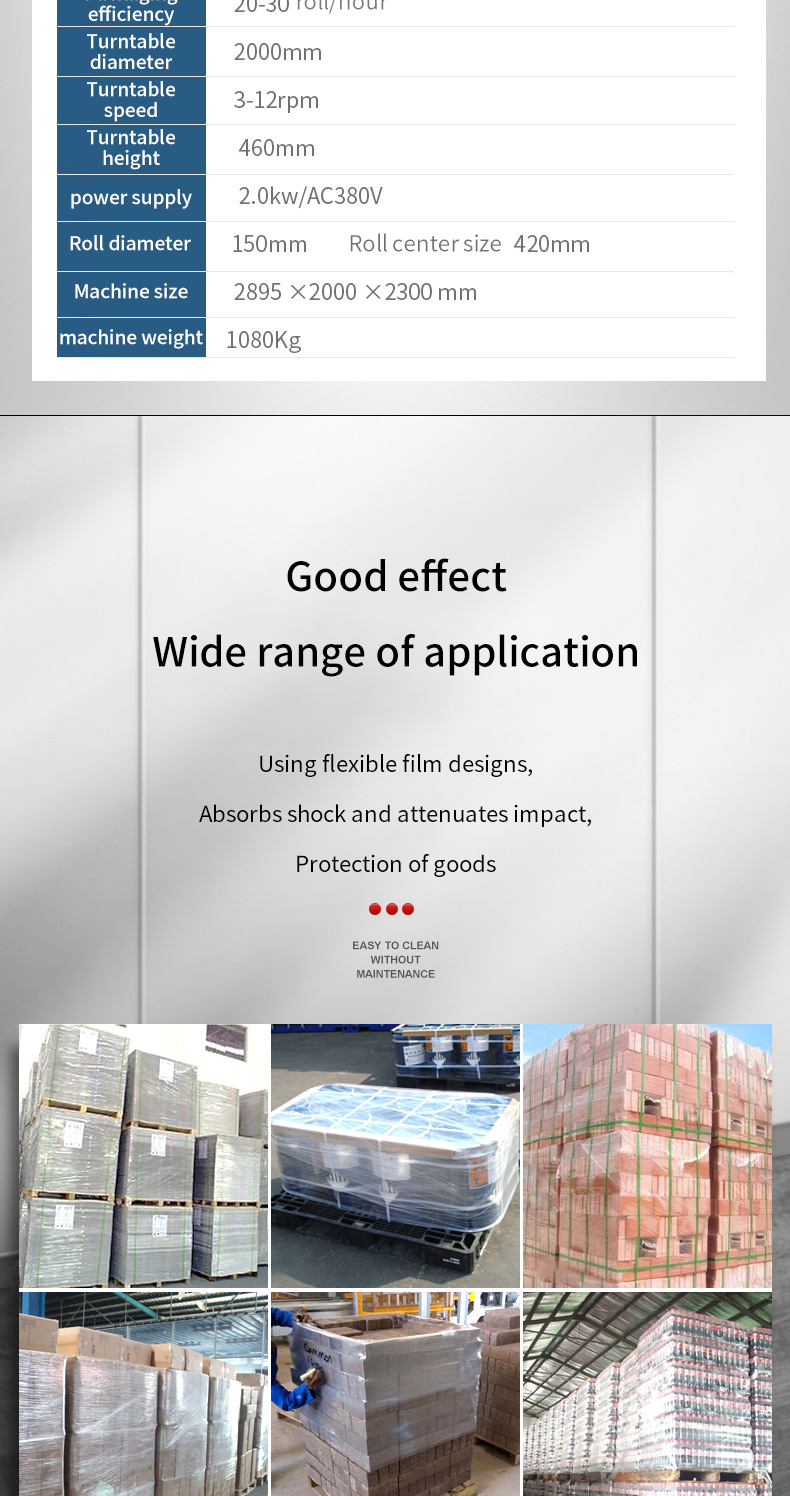

Good packaging quality: The stretch film can be tightly and evenly wrapped around the drum, making the appearance of the drum neat and beautiful after packaging. It can also effectively prevent problems such as film loosening and falling off, ensure the firmness and stability of the packaging, and provide good protection for the product.

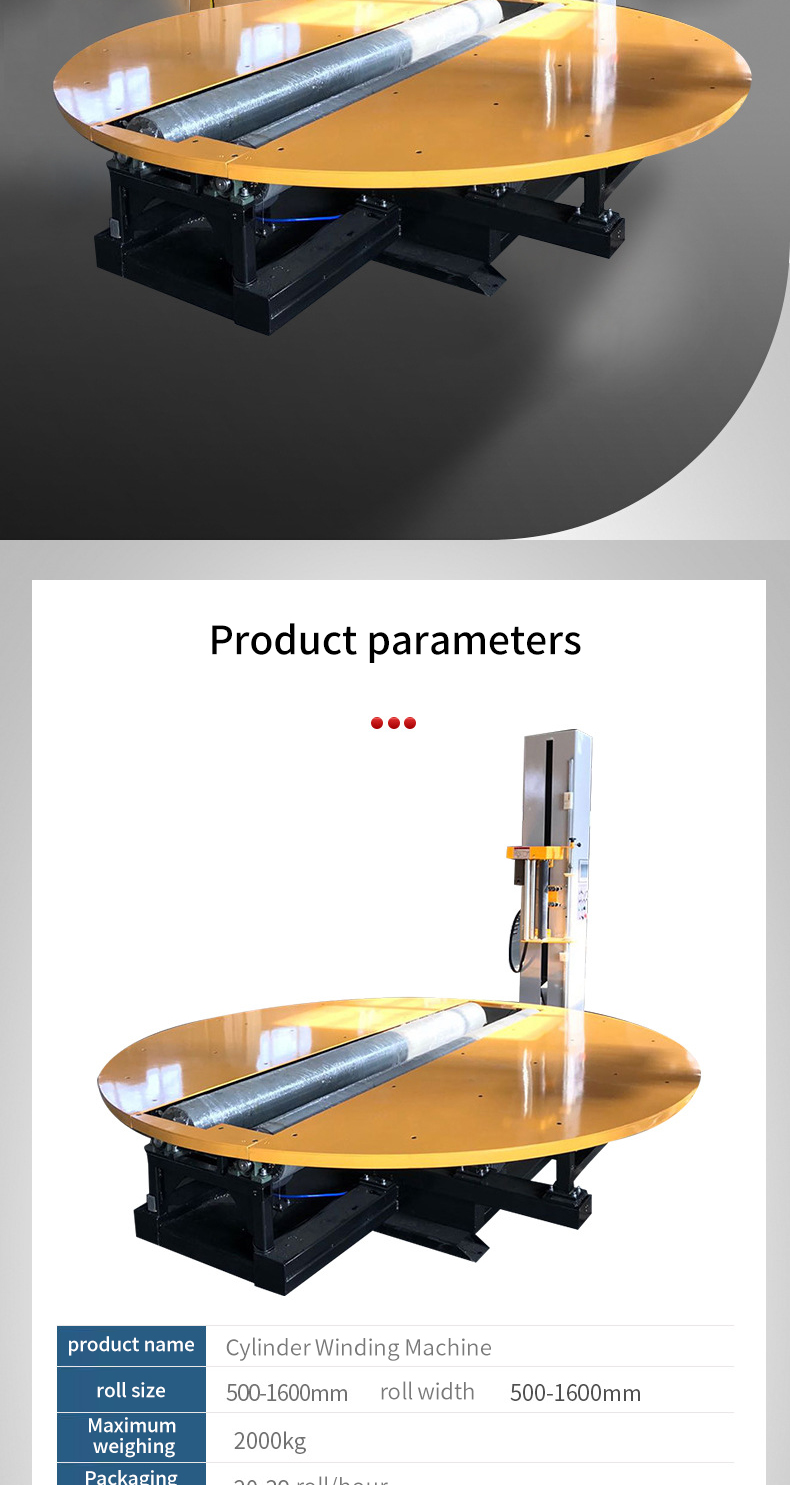

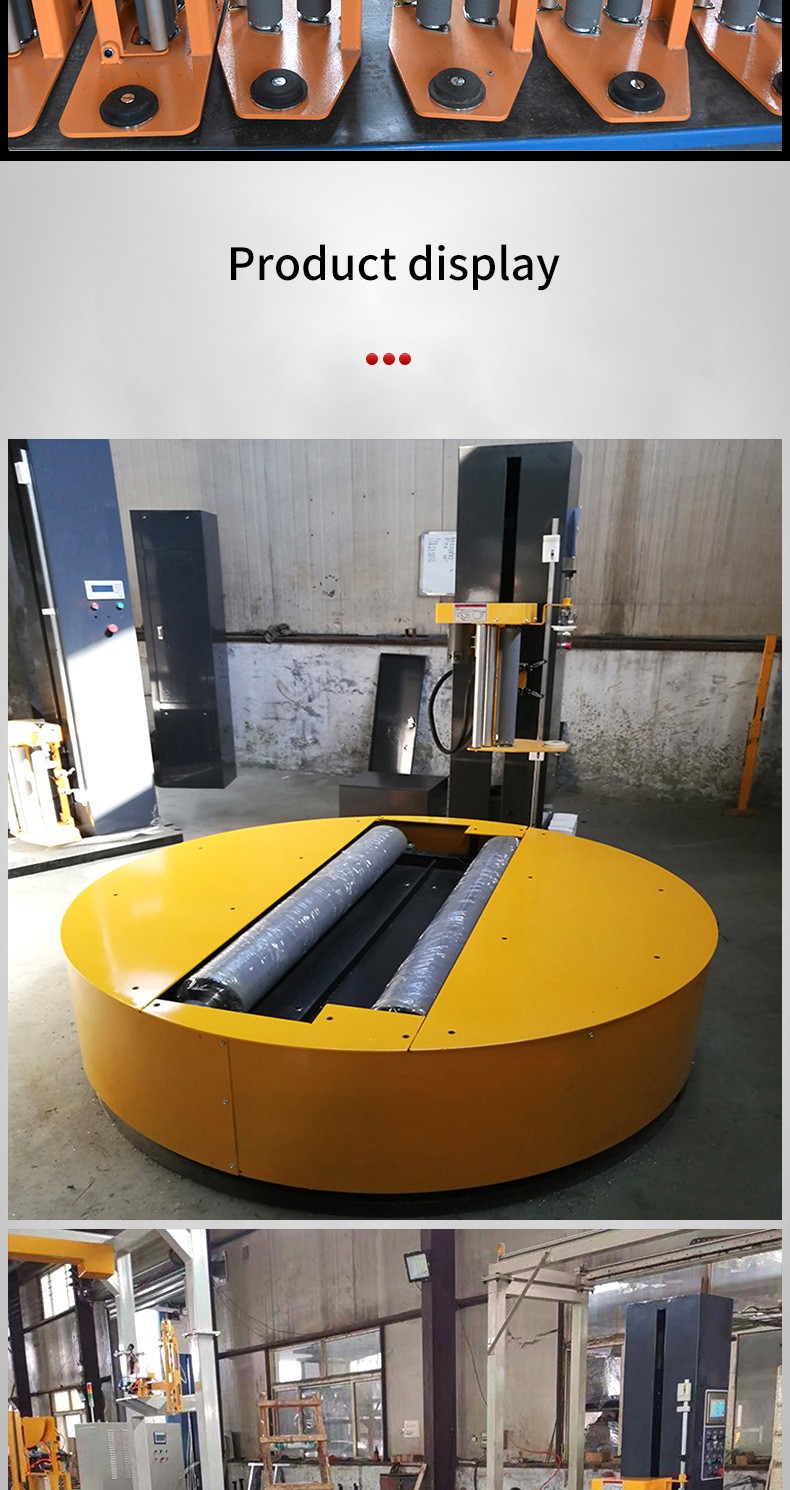

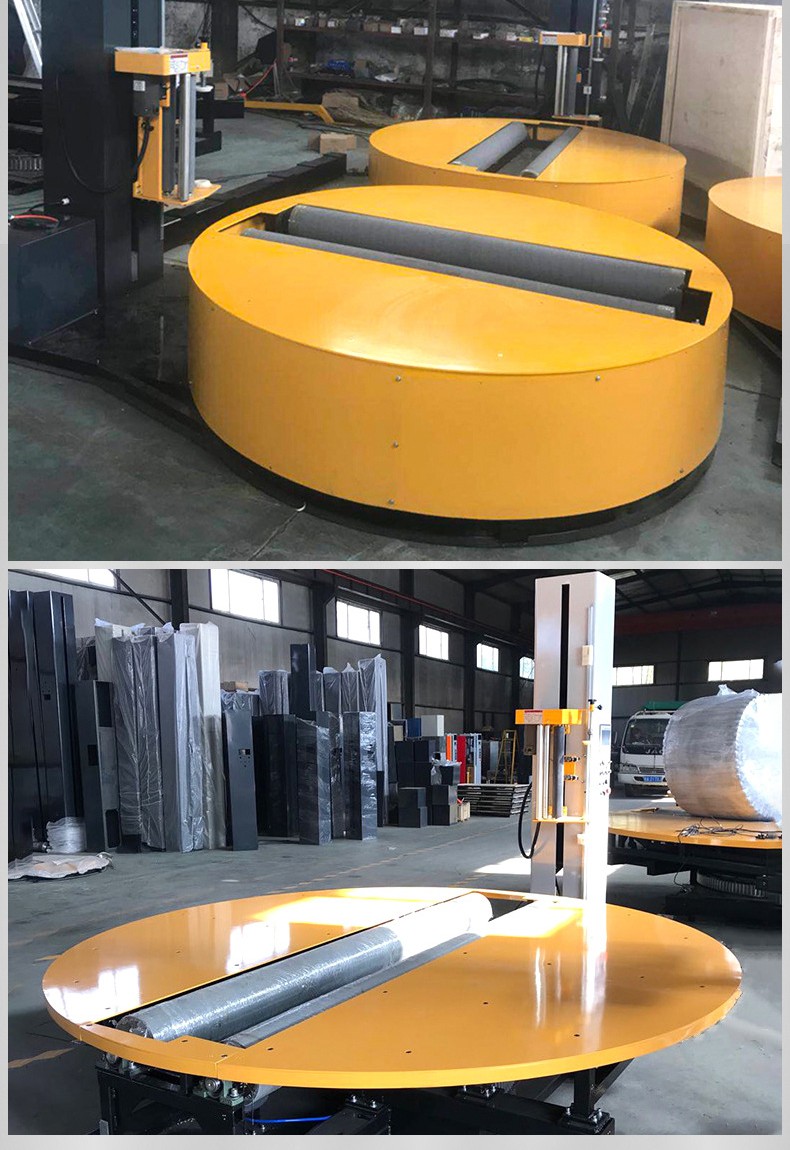

product name:Cylinder Winding Machine

roll size:500-1600mm

roll width:500-1600mm

Maximum weighing:2000kg

Turntable diameter:2000mm

Turntable speed:3-12rpm

Turntable height:460mm

power supply:2.0kw/AC380V

Roll diameter:150mm

Roll center size:420mm

Machine size:2895 ×2000 × 2300 mm

machine weight:1080Kg

Wide range of applications: It can package drums of different materials, sizes and shapes, such as plastic drums, metal drums, wooden drums, etc. As long as the shape of the drum meets the packaging requirements, it can achieve a good packaging effect by adjusting the machine parameters. At the same time, you can also choose stretch films of different widths, thicknesses and materials as needed to meet the packaging needs of different products.

Easy to operate: Equipped with an intuitive human-machine interface, operators can easily start and operate the machine by simply setting relevant parameters through the touch screen or control panel, without the need for complex professional training. In addition, the machine also has automatic diagnosis and alarm functions, which can prompt fault information in time, making maintenance and processing convenient.

Energy saving and environmental protection: Under the premise of ensuring packaging effect and production efficiency, the energy consumption of this machine is relatively low, and energy-saving motors, inverters and other equipment are used to effectively reduce the production costs of enterprises. At the same time, stretch film is usually an environmentally friendly and recyclable material, which can be recycled and reused after use, reducing the pollution of packaging waste to the environment.

Manufacturers usually provide a certain period of quality assurance for Round barrel stretch film packaging machine, usually 1 year. During the warranty period, if the machine has a malfunction or quality problem caused by non-human factors, the manufacturer will repair or replace parts for the user free of charge to ensure the normal operation of the machine.

A professional after-sales service team is the key to ensuring the user's after-sales experience. Manufacturers generally have an experienced and skilled after-sales service team that can respond to customers' after-sales needs in a timely manner and provide customers with fast and efficient maintenance services. The after-sales service team can communicate with customers through various means such as telephone, email, and online customer service to answer customers' questions and handle customers' problems in a timely manner.

In order to ensure the timeliness of equipment maintenance and compatibility, the manufacturer will supply original accessories for a long time to ensure the quality of accessories and the matching degree with the equipment. When users need to replace accessories, they can directly purchase genuine accessories from the manufacturer to avoid equipment failure and safety hazards caused by the use of inferior accessories.