Luggage wrapping machine

1. Prevent luggage from being damaged: During transportation and handling, it can effectively prevent luggage from being damaged or deformed due to collision, friction, extrusion, etc.

2. Moisture-proof and dust-proof: The wrapping film used can form a sealed packaging environment to prevent luggage from being eroded by dust and water vapor, and keep the luggage clean and dry.

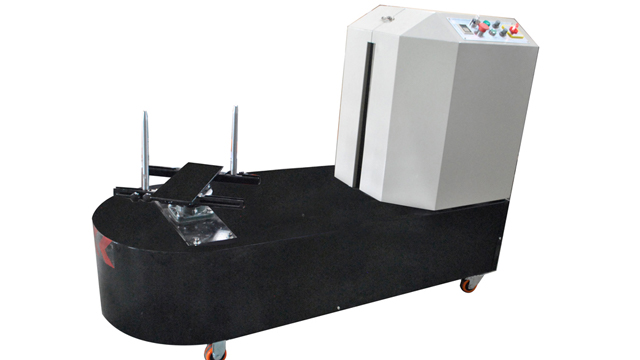

3. Easy to use: The operation process of the machine is simple and easy to understand. Just place the luggage on the turntable, adjust the position of the vertical rod according to the size of the luggage, press the start button, and the machine can automatically complete the packaging work.

4. Flexible adjustment: The number of layers, height, film tension and other parameters of the wrapping can be easily adjusted according to the size, shape and packaging requirements of different luggage.

5. Fast packaging speed: The luggage can be packed in a short time, improving packaging efficiency.

6. Strong mobility: Lightweight design, equipped with brake rollers, easy to move and place, can flexibly adjust the position according to actual needs, and better meet the use requirements of different places.

Luggage Wrapping Machine mainly wraps luggage by rotating and wrapping with film. Place the luggage on the rotating platform of the machine, start the machine, and the platform starts to rotate at a constant speed. At the same time, the film conveying device releases the packaging film, which is evenly wrapped around the rotating luggage surface through a mechanical device.

The body frame is constructed of high-strength metal materials to ensure the overall stability and durability of the machine. Its structural design is reasonable, which facilitates the installation and maintenance of internal components, while also taking into account the aesthetic appearance of the machine.

Model number:Luggage machine

Maximum package size:(180-350) mm* (400-800) mm* (300-600) mm

Turntable bearing:50kg

The weight:200kg

Machine power:1.48 kw

Supply voltage:220v (single item) 50-60 Hz

Rotary speed:20-40 RPM/min

Suitable film:15~35Wrap film for predraw machine (25µ recommended)

Wrap film properties:LLDPE pretension wrap film/resistance wrap film

Wrap film widthInner diameter of 500mm winding film: $76.2mm

Wrap film thickness:0.020 mm to 0.035 mm

Able to complete luggage wrapping in a short time. Taking a standard-sized suitcase as an example, an ordinary Luggage Wrapping Machine can complete the wrapping in 1-2 minutes, which greatly improves the efficiency of luggage handling, especially suitable for places with large passenger flow, such as near the check-in counters at airports or luggage check-in at tourist attractions.

It can work continuously for a long time, and as long as it is properly maintained and serviced, it can ensure stable operation under high-load working environment. This is very important to cope with the large amount of luggage packaging demand during the peak tourist season or logistics peak period.

It can pack luggage of various shapes and sizes, whether it is a regular square suitcase, a round sports equipment bag, or an irregularly shaped backpack, etc. At the same time, it can also adapt to luggage made of different materials, such as leather, plastic, cloth, etc.

A variety of packaging films can be used, such as ordinary polyethylene films, stretch films, etc. These films are easily available in the market and are relatively cheap, making it convenient for users to choose suitable packaging materials according to their needs and budget.

Product after-sales services include: installation and commissioning services to ensure the correct installation and operation of the machine; training operators to enable them to master operation and simple maintenance; setting up an after-sales hotline to respond to fault reports in a timely manner and arrange on-site repairs by technicians; supplying original spare parts to ensure maintenance needs; and providing equipment upgrade services as needed to improve performance and functions.