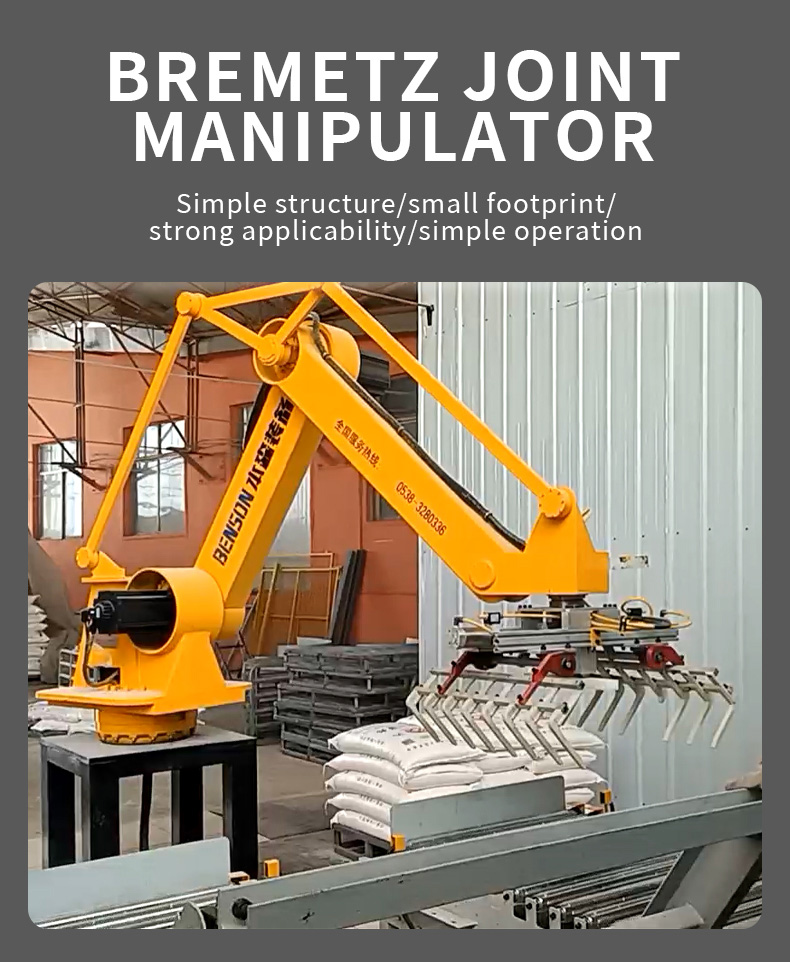

Fully automatic mechanical palletizer multifunctional industrial robot

1. High speed: The grabbing and palletizing actions are fast, and the grabbing speed can usually reach hundreds or even thousands of operations per hour, which is much higher than the manual palletizing speed. For example, in the food processing industry, when faced with a large number of food packages that need to be palletized, the fully automatic mechanical palletizing robot can complete the task quickly, greatly improving production efficiency.

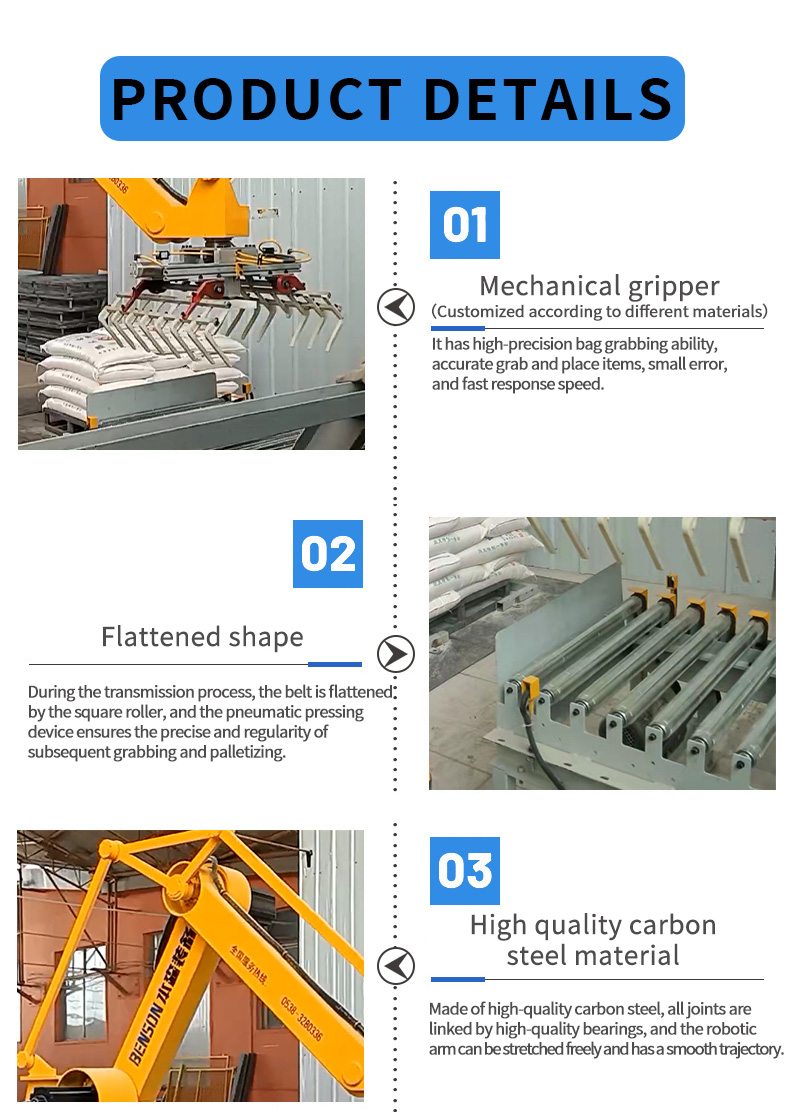

2. Accurate positioning: Through advanced sensors, control systems and precise mechanical structures, the position and grabbing points of the product can be accurately located to ensure the accuracy of each grab and placement.

Labor cost savings: It can replace the repetitive physical labor of multiple workers, reduce the company's dependence on labor, and thus reduce labor costs.

3. Ability to adapt to the working environment: It can work normally in harsh working environments, such as high temperature, low temperature, humidity, dust and other environments.

4. Stable operation: It has high reliability and stability, the mechanical parts have been strictly designed and tested, and the control system has fault diagnosis and self-protection functions, which can detect and solve problems in time, ensure the normal operation of the equipment, and reduce production interruptions and losses caused by equipment failures.

5. Simple maintenance: The structure is relatively simple, the number of parts is small, and most of the parts are standardized and modular, which is easy to maintain and replace.

The fully automatic mechanical palletizing robot is a highly automated industrial equipment designed to efficiently and accurately complete the palletizing tasks of various products. It is widely used in many industries such as food, beverages, chemicals, building materials, logistics, etc. It integrates advanced mechanical technology, electronic technology and control technology, and can achieve continuous, stable and fast palletizing operations, greatly improving production efficiency and logistics operation efficiency, while reducing labor costs and labor intensity.

Palletizer name and model :BENSON-GJ-700,Freedom of motion (axis):4,Maximum load (kg) :130,Repeated positioning accuracy (mm):±0.2mmDrive mode: servo drive,Vehicle: Fixture,Palletizing memory: intelligent memory,Maximum coverage :3100,Weight :1125,Installation method: ground.

Advanced controller: The use of high-performance industrial controllers, such as PLC (programmable logic controller) or motion controller, with powerful computing and processing capabilities and rich input and output interfaces, can real-time control of the robot's various joint movements, grasping actions and collaborative work with peripheral equipment.

Advanced controller: The use of high-performance industrial controllers, such as PLC (programmable logic controller) or motion controller, with powerful computing and processing capabilities and rich input and output interfaces, can real-time control of the robot's various joint movements, grasping actions and collaborative work with peripheral equipment.

Intelligent control algorithm: The built-in advanced control algorithm, such as path planning algorithm, kinematic algorithm, dynamic algorithm, etc., can automatically plan the movement path of the robot according to the preset palletizing task and working scene, optimize the movement speed and acceleration, ensure that the robot works efficiently while maintaining smooth operation, reduce vibration and shock, and improve the palletizing accuracy and equipment life.