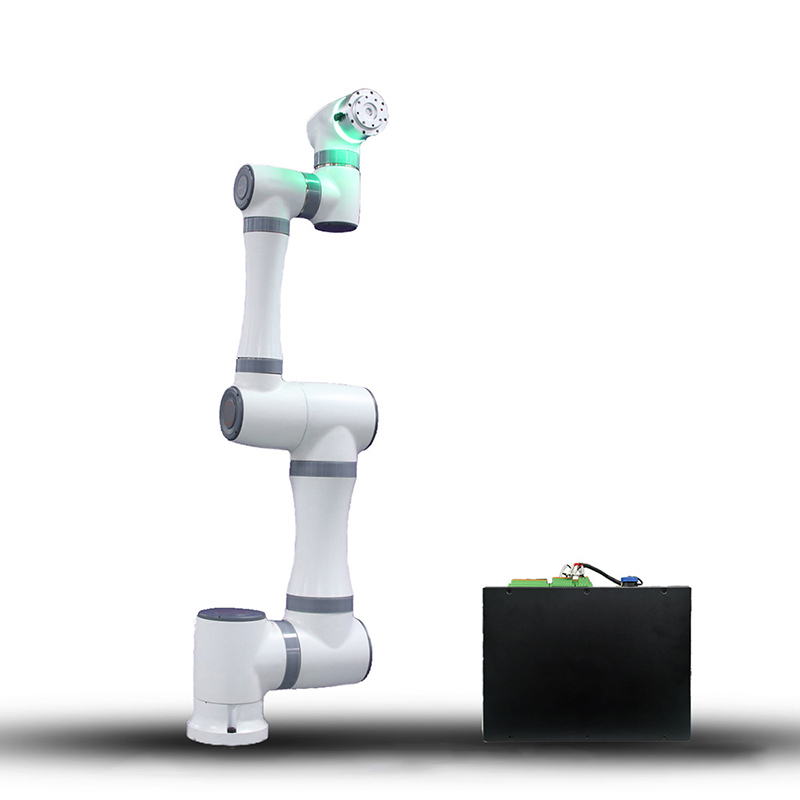

Multifunctional innovative collaborative palletizing robot

1. High efficiency brought by technological breakthroughs: The use of new motion mechanisms makes the robot's movement more flexible and diverse. With higher rigidity and load-bearing capacity, it can achieve more complex movements and complete more precise palletizing operations in a limited space.

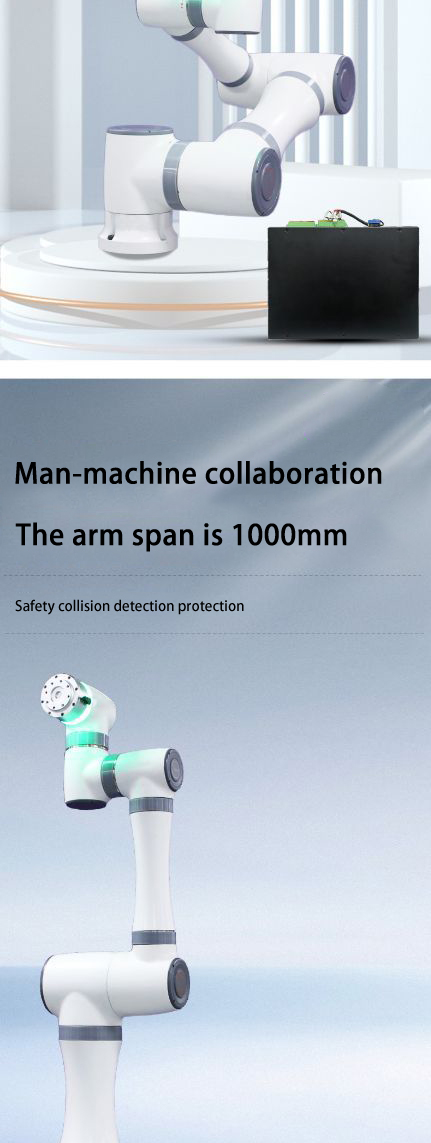

2. Unique design enhances competitiveness: Unique human-machine collaboration mode, operators can command the robot's work through simple gestures or voice, without complex operating interfaces or programming, which greatly improves the convenience and efficiency of human-machine collaboration and reduces the training costs of operators.

3. Collaborative operation with peripheral equipment: It can achieve seamless collaboration with other robots. Form an efficient automated logistics chain to improve the efficiency and fluency of the entire logistics system. It has cross-platform collaboration capabilities and is compatible with different operating systems and industrial communication protocols.

4. Safe and efficient human-machine collaboration: It supports simultaneous collaboration of multiple people, and different operators can work with robots in different links.

5. Accurate and stable palletizing quality: During the palletizing process, high-precision positioning and precise angle control can be achieved. Ensure the neatness and stability of the palletizing and reduce the risk of damage to goods during handling and storage.

6. Efficient and fast palletizing speed: The optimized motion path and fast grabbing and placing motion design enable the robot to complete more palletizing tasks per unit time. Through the optimization of the robot arm motion trajectory by intelligent algorithm, unnecessary motion time is reduced, the palletizing speed is increased, and the needs of high-volume production environment are met.

In today's rapidly developing industrial automation field, the multifunctional innovative collaborative palletizing robot stands out with its excellent performance and unique design, bringing revolutionary changes to the logistics and production links of enterprises. The robot has an adjustable load capacity, ranging from light to heavy load. The light load mode can be used to handle small, lightweight parts, such as parts of precision instruments, to ensure the accuracy of the operation. In the heavy load mode, it can easily carry large and heavy industrial products, such as components of heavy machinery, to meet the needs of manufacturers of different sizes.

Efficient sorting function: With powerful sorting capabilities, the robot can classify goods according to preset rules. Whether it is based on the attributes of the goods (such as material, color) or the destination information, the robot can sort the goods to different stacking areas. This function is particularly important in scenarios such as e-commerce warehouses, which can effectively reduce the workload of subsequent manual sorting and improve overall operation efficiency.

Easy to program, flexible and collaborative.

Modular, quick installation drive control.

Easy to operate, zero-pressure teaching is easier to use.

Fast deployment, easy installation and flexible deployment.

Application scenarios, widely used in various industries, 3C, manufacturing material flow, automobiles, food and medicine, new retail.

Model; BS5K1000,

Weight: Arm 35kg, Control System 6kg

Maximum Payload: <5kg

Hip Extension: 1000mm

Joint Range: All Joints ±170°

Speed: All Wrist Joints: Maximum 237"/s Other Joints: Maximum 123*/S Linear Speed: 1m/s

Posture Repeatability: ± 0.05 mm

Base Diameter: Bottom Friction Outer Diameter 0.149mm Mounting Hole Center Diameter 0.132mm (M8 Evenly Distributed 4, Recommended Screw Length M8*35 or More)

Freedom Control Box Size (W x H x Door): 6

Control Box I/O Ports: 335 mm * 269.5 mm * 83.5 mm

Communication: 12 Digital Inputs + 2 16-Channel Digital Inputs or 1 Quadrature Encoder (Recommended Model OMRON/E6B2-CWZ6C /2000P/2M), NPN type

Communication: 2 full-duplex 100Mbit/s network ports support TCP/IP, ModbusTCP OPC DA: CANOpen, Modbus RTU protocol 65 dB(A)

Noise: 65 dB(A)

IP level: IP54

Clean room category: Robot handle: ISO5 level, control box: ISO6 level

Material: aluminum and steel

Temperature: 0-50° C

Power supply: 100~240VAC, 50-60Hz

Wired cable: The body comes with a 1.6m power cable and EtherCAT network cable, which are used to connect the controller power output and EtherCAT communication port