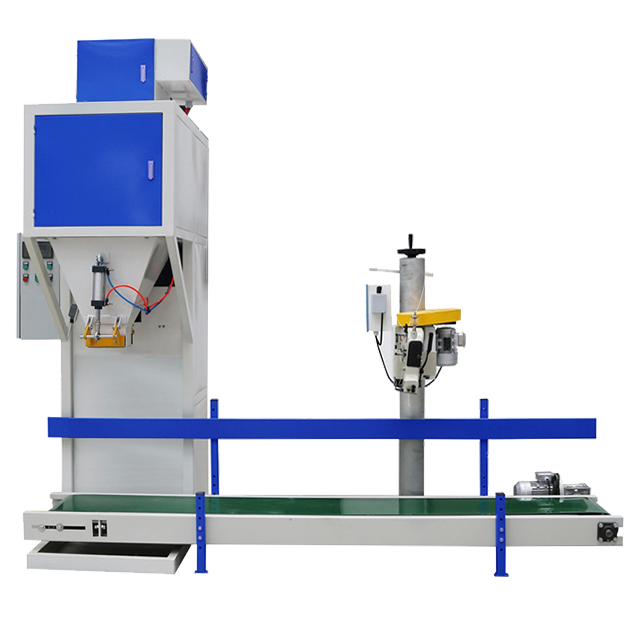

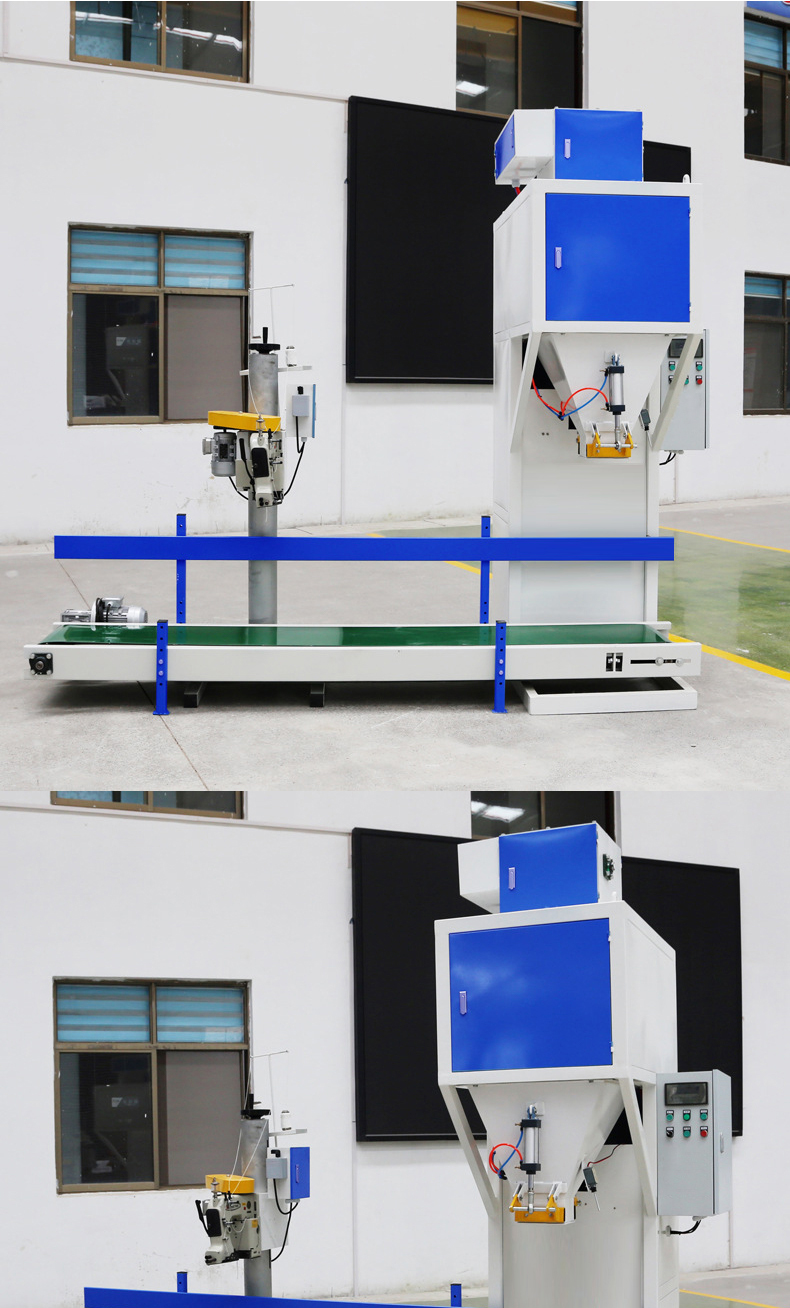

Multifunctional granule packaging machine

1. It can realize three-side sealing, four-side sealing, and other bag packaging, and can also be bottled, canned and other packaging forms to meet the needs of different customers and products.

2. It is not only suitable for various granular materials, but also can effectively package particles of different particle sizes and different fluidity.

3. It adopts high-precision electronic scales, volumetric meters or spiral meters, etc., combined with intelligent metering algorithms, to accurately measure granular materials.

4. It has functions such as automatic drop compensation and zero point tracking, and can be adjusted in real time according to the actual situation of the material during the packaging process.

5. It adopts advanced transmission system and control system, with fast and stable operation speed, and can complete the packaging task of a large number of granular materials in a short time.

Multifunctional Granule Packaging Machine is an excellent equipment that integrates multiple advanced features and is specially designed to meet the needs of granular material packaging in various modern industries.

Its overall shape is both practical and beautiful. The body is made of durable stainless steel and a high-strength alloy frame, which not only ensures stability under high-intensity operations, but also has excellent anti-corrosion capabilities.

It can realize a variety of packaging forms, whether it is common bags, bottles, cans and other special packaging, it can meet the storage, transportation and sales needs of different products. It also has excellent packaging capabilities for particles of different particle sizes and fluidity, and even some powders and small block materials.

With advanced metering technology and automatic compensation algorithms, the metering accuracy of various granular materials is excellent. Whether it is fine particles such as coffee powder or relatively coarse plastic particles, the packaging quantity of each bag can be accurately controlled to ensure the standardization and consistency of product quality.

It adopts advanced transmission system and control system, with fast and stable operation speed, and closely connected packaging process. The packaging quantity can reach dozens or even hundreds of bags per minute, which greatly improves production efficiency.

Equipped with a large-size touch screen, the operation interface is simple and intuitive, and operators can quickly get started without complex training, easily set parameters, monitor operating status, and diagnose faults. The equipment structure is reasonably designed and easy to clean and maintain.

It is equipped with complete safety protection devices, such as overload protection, leakage protection, protective door locking, emergency stop button, etc., to protect the safety of operators in all aspects.