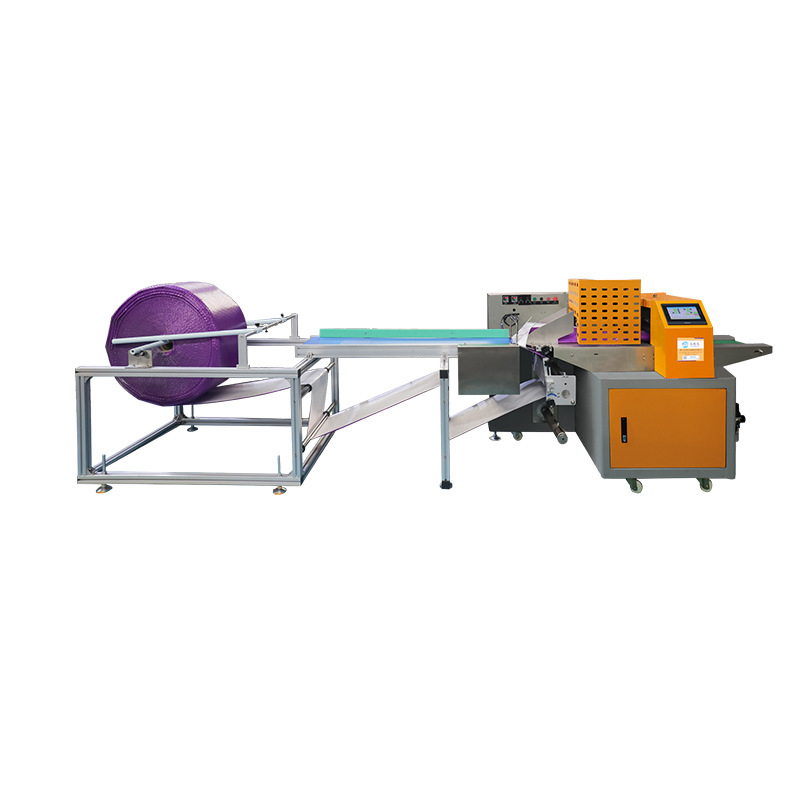

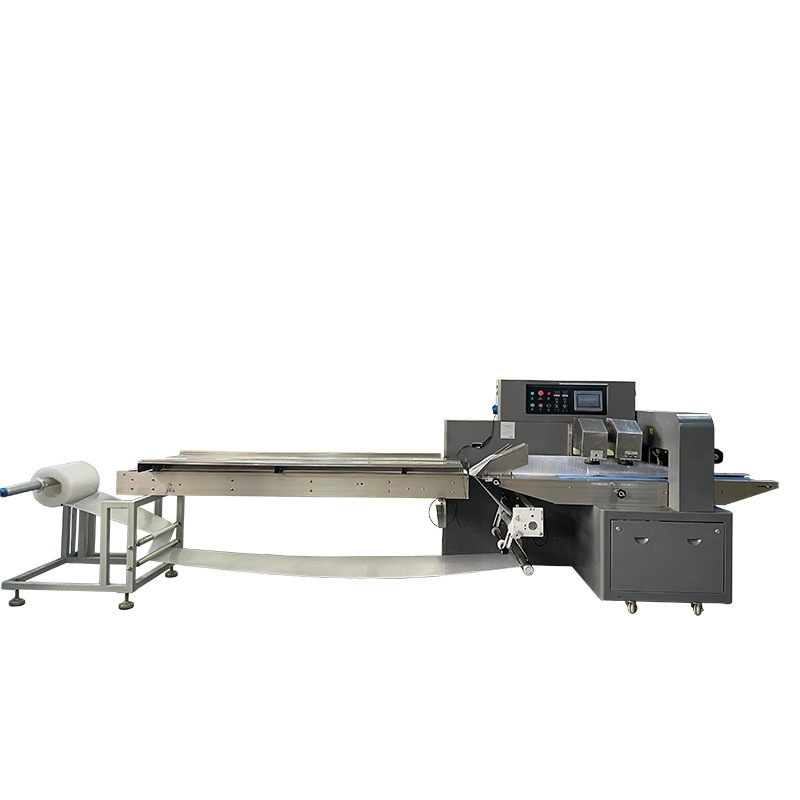

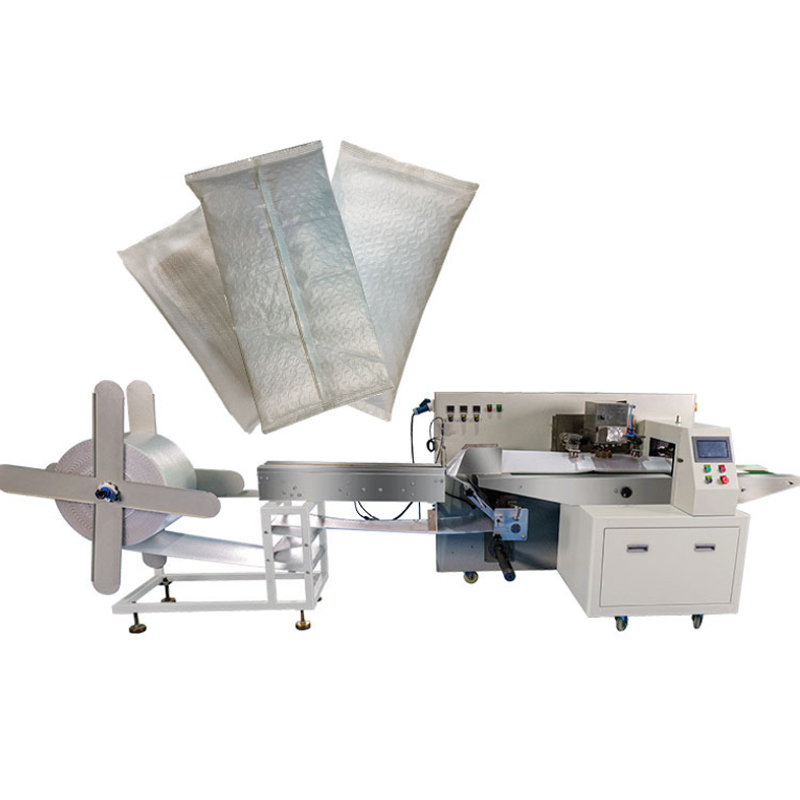

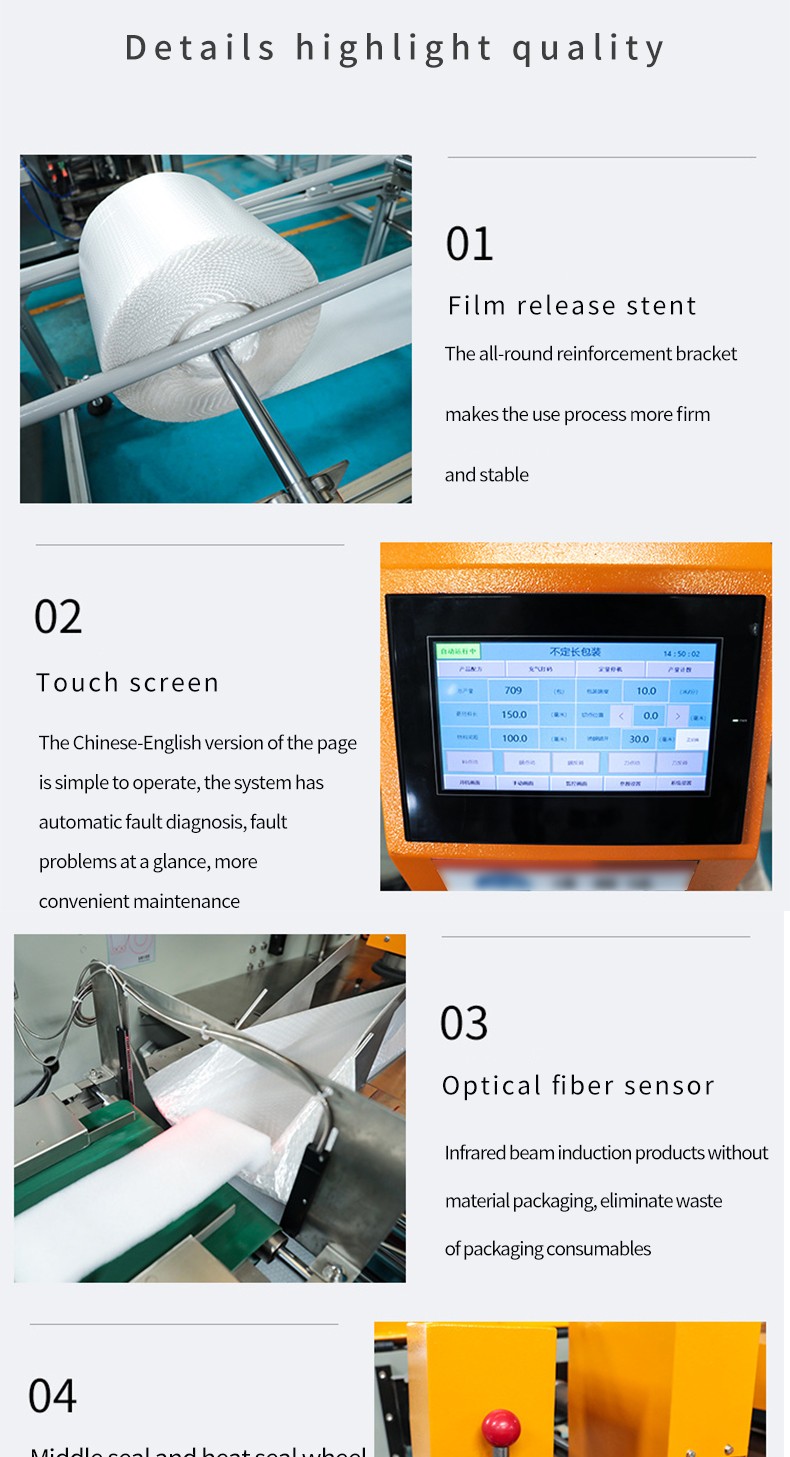

Fully automatic bubble bag packing machine

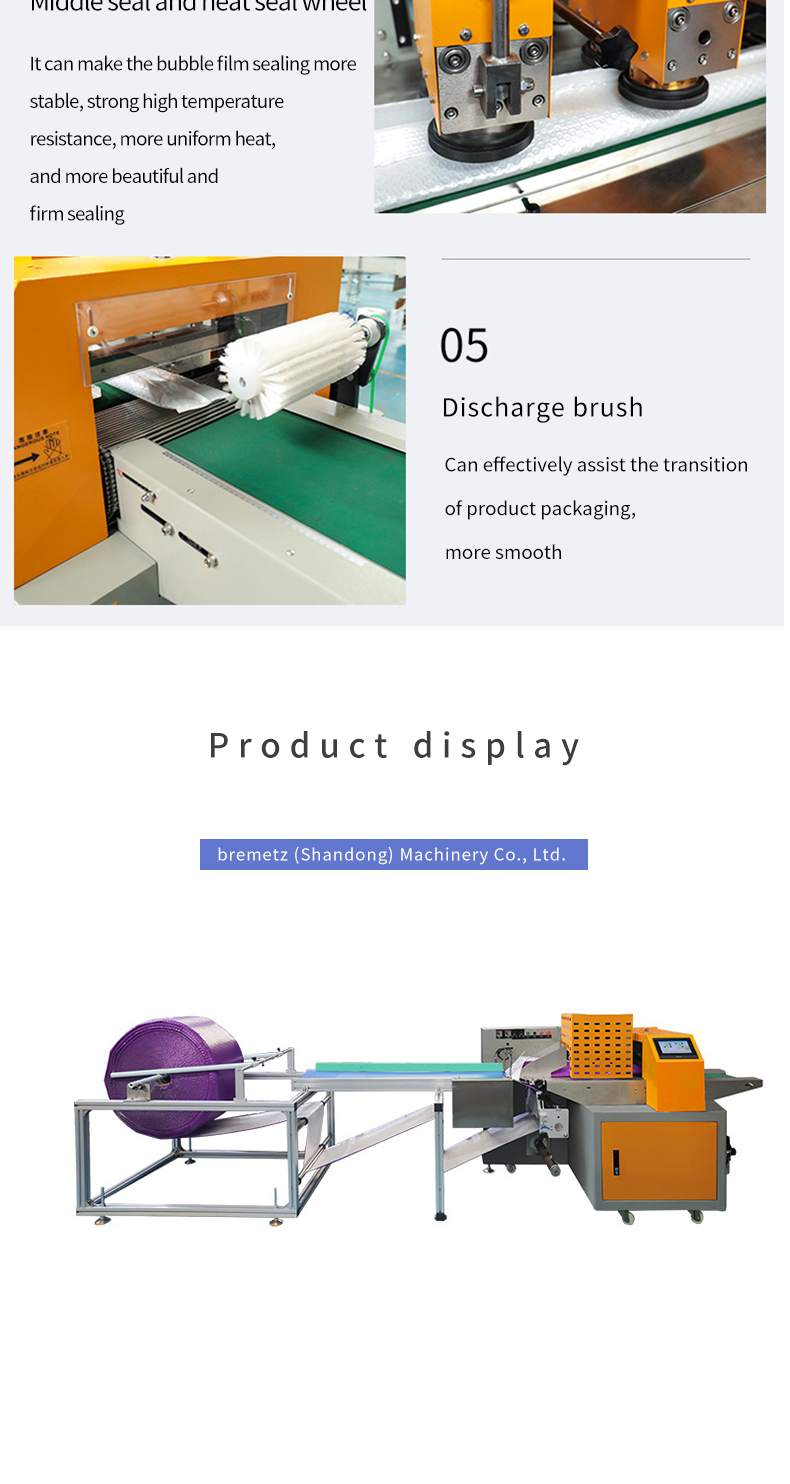

1. It can realize continuous and high-speed packaging operations, greatly improve production efficiency, and save a lot of time and labor costs.

2. When the size of the packaging changes, the adjustment is simple and convenient, without changing the mold and bag maker, and can quickly adapt to the packaging needs of products of different specifications.

3. Equipped with advanced metering devices, it can accurately control the filling amount of the product to ensure that the number or weight of products in each bubble bag meets the set requirements.

4. Adopting high-quality sealing and cutting components and precise temperature control system, the sealing knife temperature is extremely sensitive and accurate, and can be set at will, which can ensure a firm and tight seal.

5. The equipment structure is reasonably designed, using high-quality components and advanced manufacturing technology, with good stability and durability.

The fully automatic bubble bag packaging machine is a highly efficient packaging equipment that integrates multiple advanced technologies such as mechanics, electrical, pneumatics, and sensors. It is designed for all kinds of products that need to be packaged in bubble bags.

Model number:bremetz450-900

speed:15-30 packets/min

Bagging length:160-430mm

Bagging width:unlimited

Overall dimension L:5200*W:1050H:1200mm

Film diameter:350-430mm

power:3.8kw

Cutter mode:Rotary knife

It realizes fully automated operation from product delivery to packaging, with fast packaging speed and high efficiency, which can greatly reduce labor costs and labor intensity, and improve the production efficiency and economic benefits of the enterprise.

Equipped with advanced metering devices, both counting and weighing can achieve extremely high accuracy. For counting and weighing, the error can be controlled within a very small range to ensure that the number of products in each bubble bag is accurate.

It can adapt to product packaging of different types, shapes and sizes. By simply adjusting or replacing some accessories, such as metering devices, bag making devices, etc., it can meet the packaging requirements of various products, and has strong versatility and flexibility.