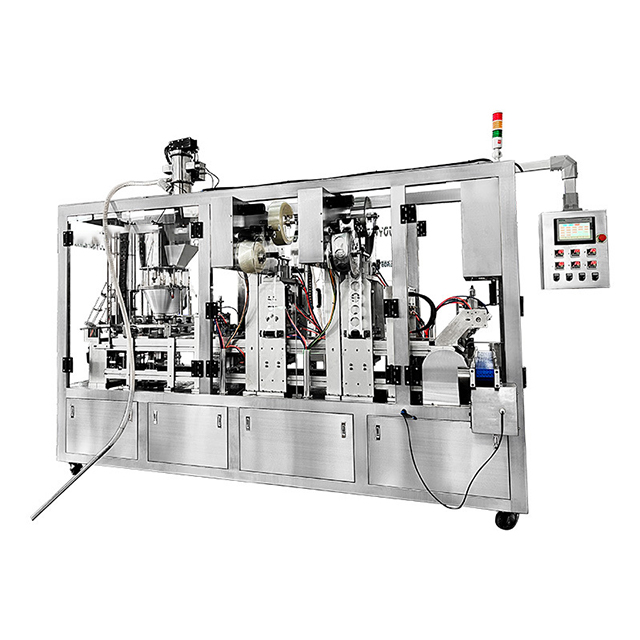

Coffee capsule filling and sealing machine

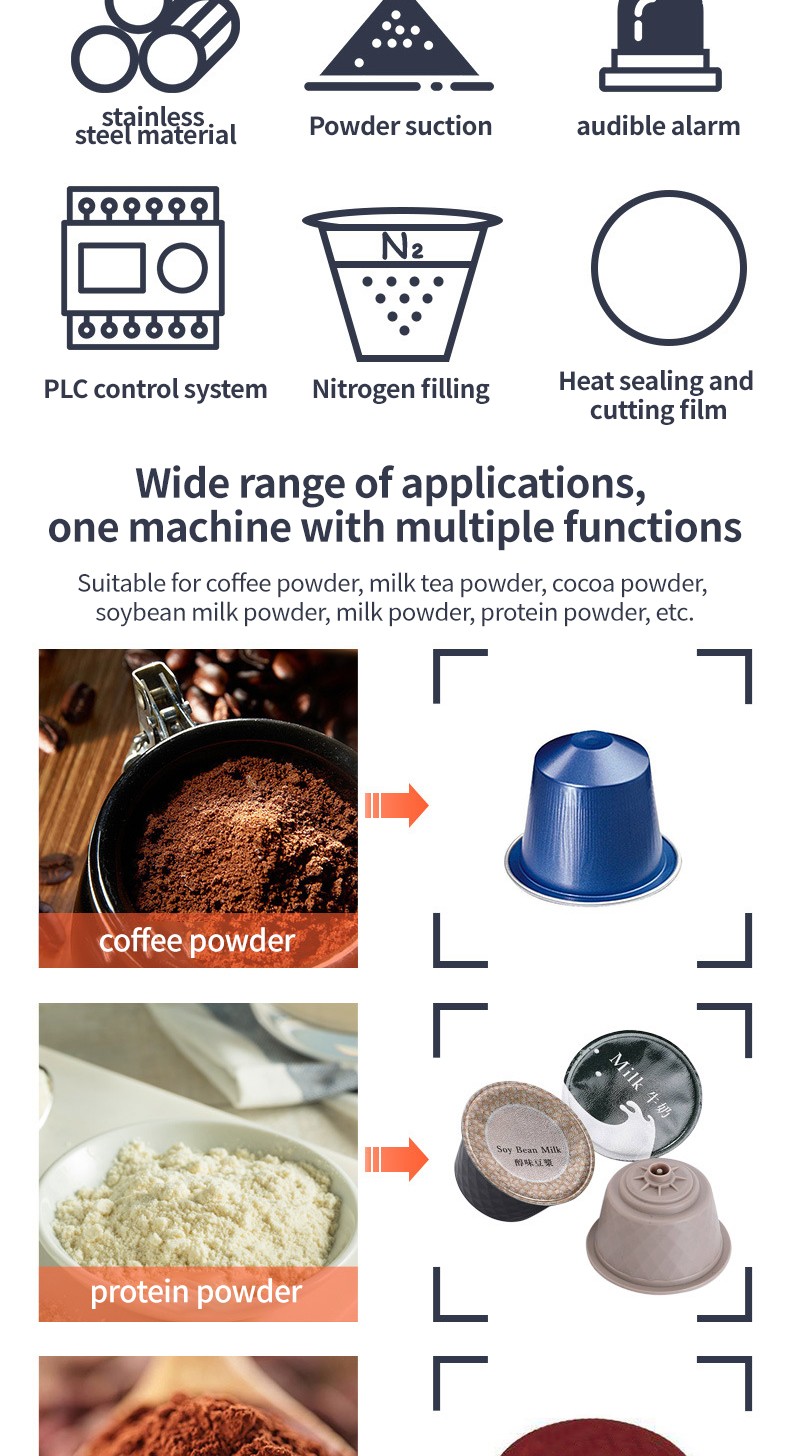

1. Accurate metering system: The coffee capsule filling and sealing machine is equipped with advanced metering devices, which can measure the contents such as coffee powder or concentrated coffee liquid extremely accurately. Whether it is measured by weight or volume, the error can be controlled within a very small range.

2. Compatibility of high-quality sealing materials: The machine is compatible with a variety of sealing materials, such as aluminum foil, composite plastic film, etc. These materials can provide good sealing for coffee capsules after sealing.

3. Reliable sealing process: Using advanced heat sealing or pressure sealing technology, the seal is firm and beautiful. The sealing of the sealing part has been strictly tested and can withstand certain pressure and temperature changes.

3. Automatic feeding and filling: The machine has an automatic feeding function, which can continuously deliver coffee raw materials to the filling position without frequent manual addition.

4. Intelligent control system: Equipped with an intelligent control system, it can achieve precise control and adjustment of parameters such as filling amount, sealing temperature, and pressure.

5. Compatibility with diverse contents: In addition to traditional coffee powder, it can also handle concentrated coffee liquid, coffee mixtures with added creamer or other flavoring agents, etc.

6. Parts in contact with food-grade materials: All parts in contact with coffee raw materials are made of food-grade materials, such as stainless steel, food-grade plastic, etc., to ensure the hygiene and safety of the coffee and meet strict food safety standards.

Coffee capsule filling and sealing machine is an advanced equipment specially used for coffee capsule production. It combines high-precision filling technology and reliable sealing process to provide efficient and high-quality coffee capsule production solutions for the coffee industry.

The frame of the machine is usually made of solid metal, such as stainless steel or high-strength aluminum alloy, to ensure the stability and durability of the equipment. The outer shell is mostly made of food-grade plastic or stainless steel, which is easy to clean and meets food safety standards. The outer shell design fully considers the convenience and safety of operation, and is equipped with a protective door and a viewing window to facilitate the operator to observe the internal working conditions and prevent accidental contact with moving parts.

With high-precision filling and sealing technology, the amount of coffee in each coffee capsule is accurate and the seal is tight, so that the brewed coffee has stable quality and consistent flavor. This high-quality product output helps to enhance the reputation and market competitiveness of the coffee brand.

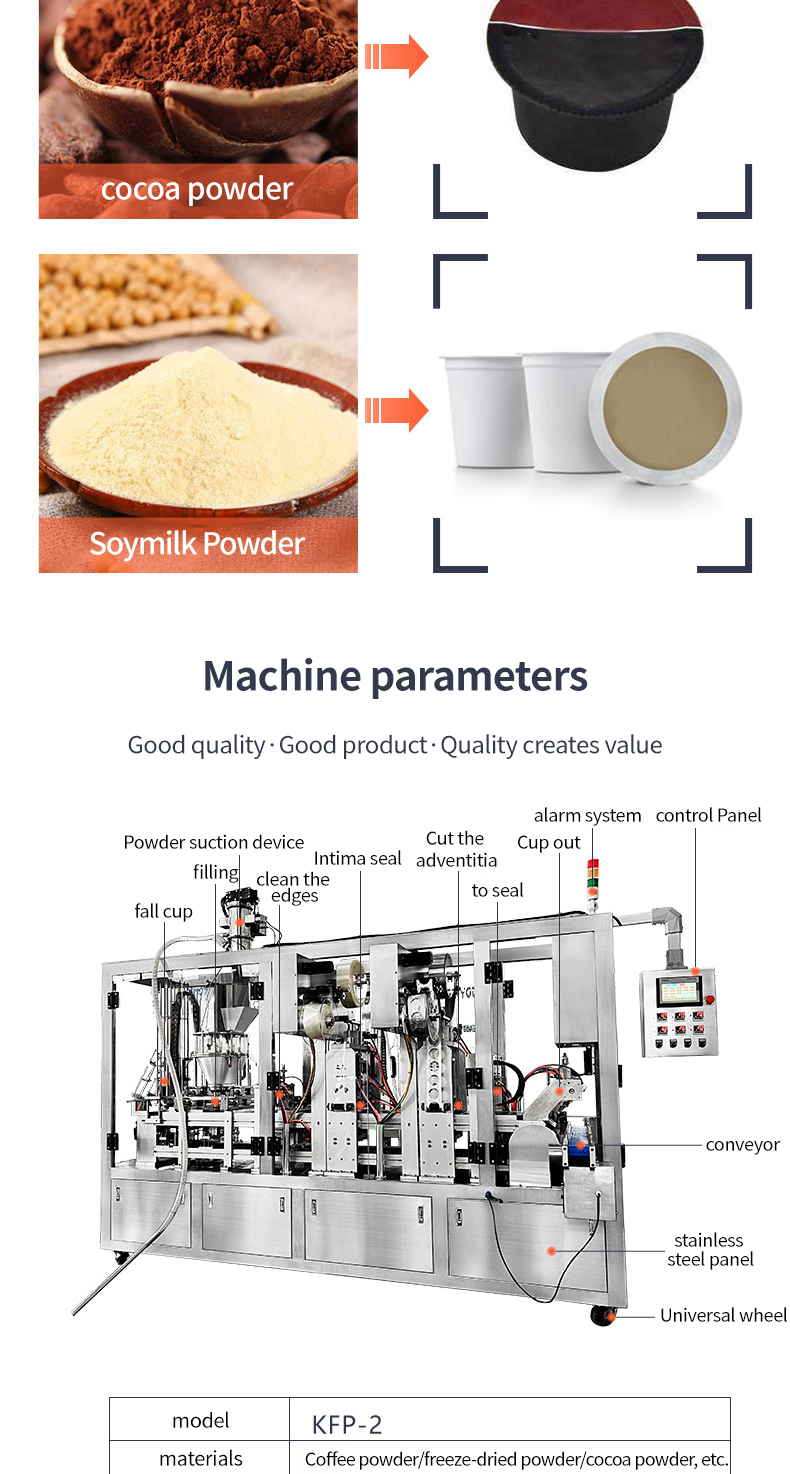

model:KFP-2

materials:Coffee powder/freeze-dried powder/cocoa powder, etc.

material contact part output:Food hygiene grade stainless steel

Filling method:60-90 cups/min CAPSULES/MINUTE

Filling volume:Servo driven screw filling

Filling accuracy:1-30G

Power Specifications:±0.1G,220/380V 50/60HZ 4.5KW.

type:straight line

Air consumption:0.7M3/MIN

Cup drop device,Automatic cup drop, accurate cup drop, saving manpower.

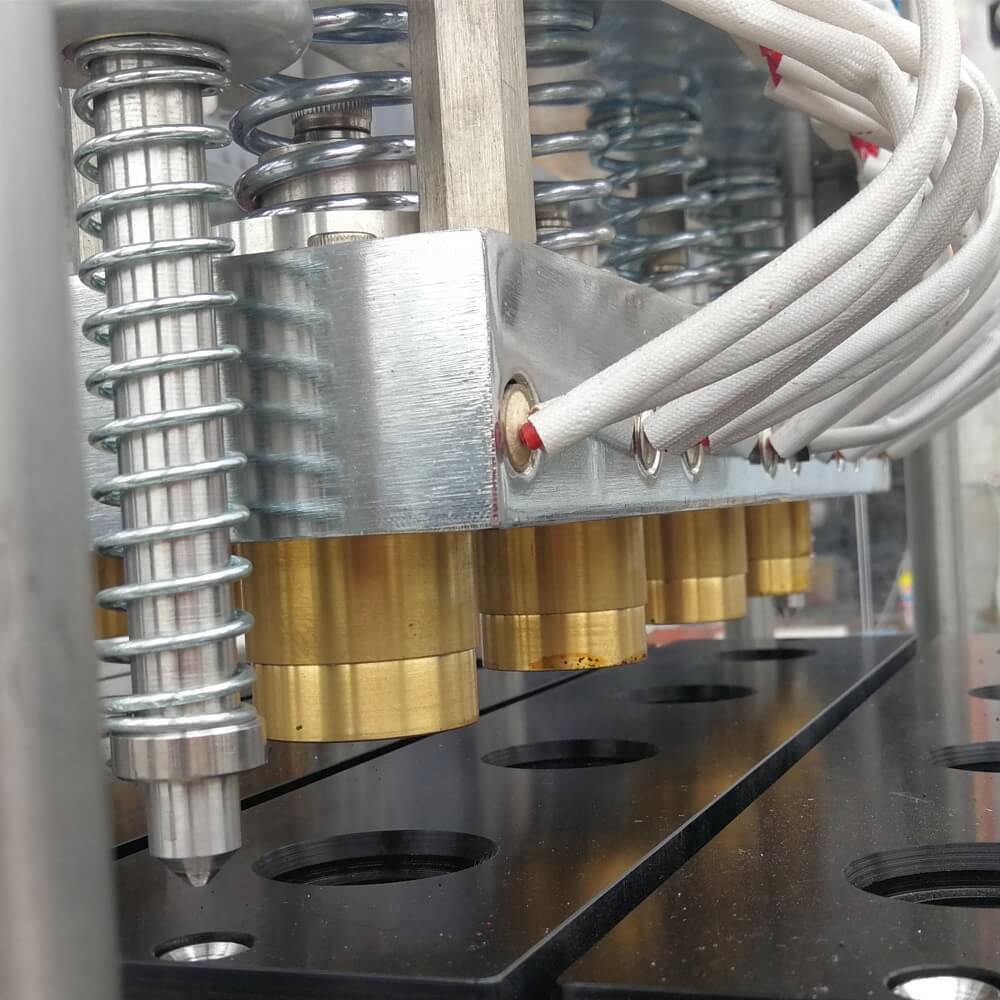

Filling device,Screw-type metering, precise feeding and filling, material contact parts are made of 304 stainless steel, no cup and no filling.

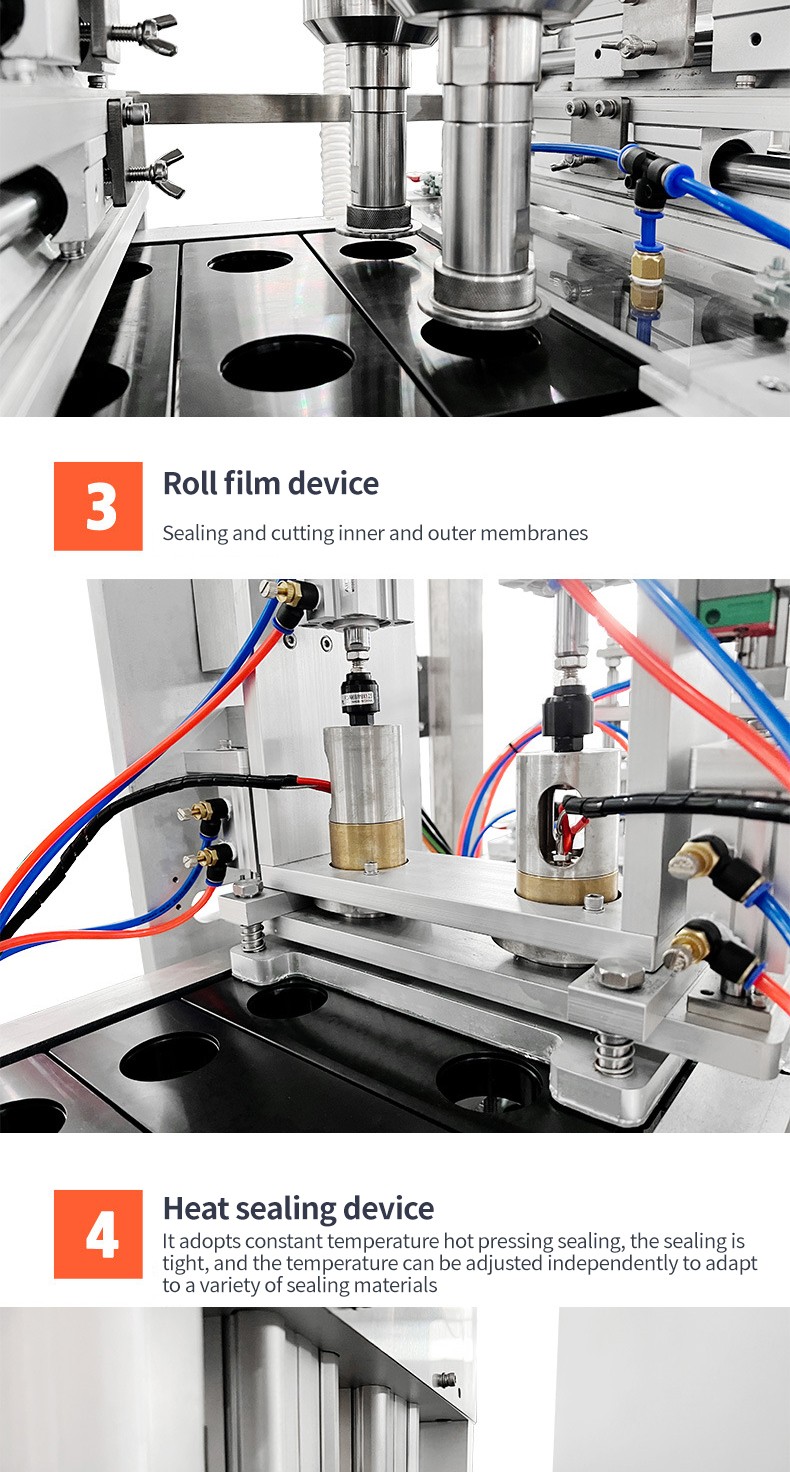

Roll film device,Sealing and cutting inner and outer membranes.

Heat sealing device,It adopts constant temperature hot pressing sealing, the sealing is tight, and the temperature can be adjusted independently to adapt to a variety of sealing materials.

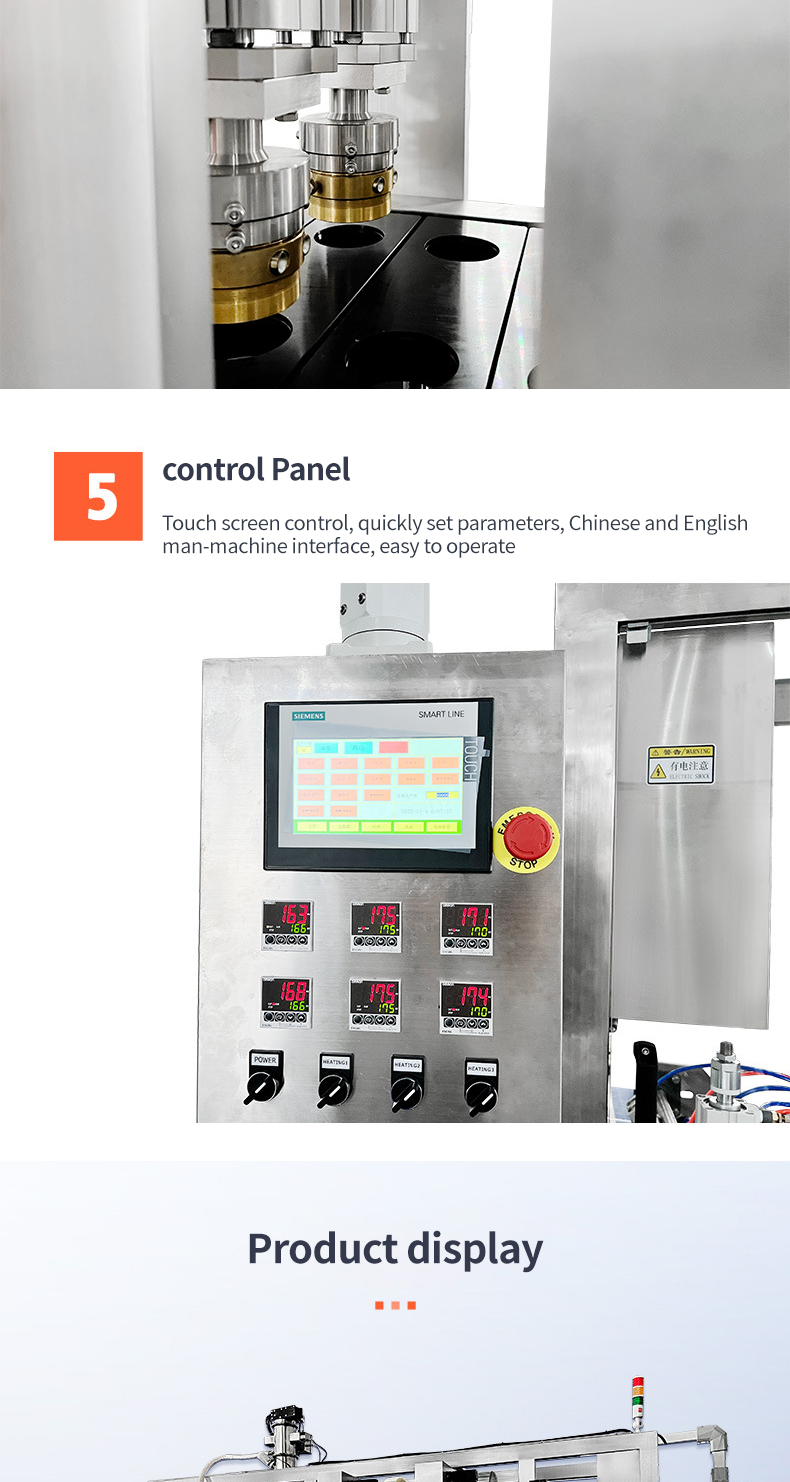

Control Panel,Touch screen control, quickly set parameters, Chinese and English man-machine interface, easy to operate.

Equipped with an intelligent control system, operators can easily set and adjust parameters, and the equipment can run automatically and monitor its own status in real time. This not only reduces the complexity and labor intensity of manual operation, but also can promptly discover and deal with problems in the production process, improving product quality and production efficiency.

Machines of different specifications can meet the production needs of enterprises of different sizes. From small and medium-sized boutique coffee brands to large coffee production enterprises, they can all use their efficient production speed to quickly complete the production of coffee capsules, improve production efficiency, reduce production costs, and enhance market competitiveness.

The company has a professional installation team with rich experience in installing Coffee capsule filling and sealing machines. The installers will install the equipment at the location specified by the customer to ensure that the installation environment meets the equipment requirements, such as ground flatness, space size, power supply, etc. During the installation process, they will strictly follow the steps in the equipment installation manual to ensure that all parts of the equipment are correctly installed and connected.

After the installation is completed, the technicians will conduct the initial commissioning of the machine. First, check the overall operation of the equipment, including whether the various motors, transmission components, heating or pressurizing devices, etc. are operating normally. Then, according to the specifications of the coffee capsules and the type of coffee raw materials used by the customer, optimize and adjust key parameters such as filling volume, sealing temperature, and pressure.

Provide customers with comprehensive operation training courses, including theoretical explanation and on-site practice. The theoretical part covers the basic structure, working principle, functions of each component of the equipment, etc., so that operators can have a deep understanding of the Coffee capsule filling and sealing machine.

We develop personalized regular maintenance plans for customers based on factors such as the frequency of use of the equipment and the production environment. Regular maintenance includes cleaning and lubrication of the equipment, checking the wear of parts, calibrating the metering system and detecting sensors, etc.

Establish multiple customer feedback channels, including customer service hotline, online customer service platform, email, suggestion box, etc., to ensure that customers can promptly feedback any questions, suggestions or opinions during the use of the equipment to the company. Assign a dedicated person to collect and organize customer feedback information, classify and analyze the feedback content, and handle customer questions and suggestions in a timely manner.