Multifunctional granule powder packing machine

1. High degree of automation: fully automated operation from material conveying, metering and filling, bag making and sealing to finished product output is realized, without excessive manual intervention, reducing labor intensity and labor costs.

2. High-precision metering: using advanced metering systems, such as electronic scales, measuring cups and other metering methods, can accurately control the filling amount of particles or powders to ensure that the weight or volume of each package is highly consistent.

3. Good packaging quality: through advanced sealing technology and control systems, such as intelligent temperature controllers, photoelectric positioning systems, etc., it can ensure that the sealing of the packaging bag is firm, flat and beautiful, and effectively prevent material leakage and moisture.

4. Save packaging materials: using precise metering and filling technology, it can reasonably control the amount of packaging materials used and avoid excessive packaging.

5. Safe and reliable: safety factors are fully considered in the design and manufacturing process, and multiple safety protection devices are equipped to prevent operators from being accidentally injured during the operation of the equipment.

6. Easy to operate and maintain: usually adopts a human-machine interface control system, the operation is simple and intuitive, the structural design of the equipment is reasonable, easy to clean and maintain, and the maintenance difficulty and cost of the equipment are reduced.

Multifunctional granule powder packing machine is an advanced packaging equipment designed for granule and powder materials. It integrates modern machinery, electronics, automatic control and other technologies to provide efficient, accurate and diversified packaging solutions for various industries.

The whole machine is made of high-quality stainless steel and high-strength alloy materials, which is durable and easy to clean, and meets the hygiene standards of industries such as food and medicine. The machine body is compact in design and occupies a small area, so it can be easily installed in production workshops of different sizes.

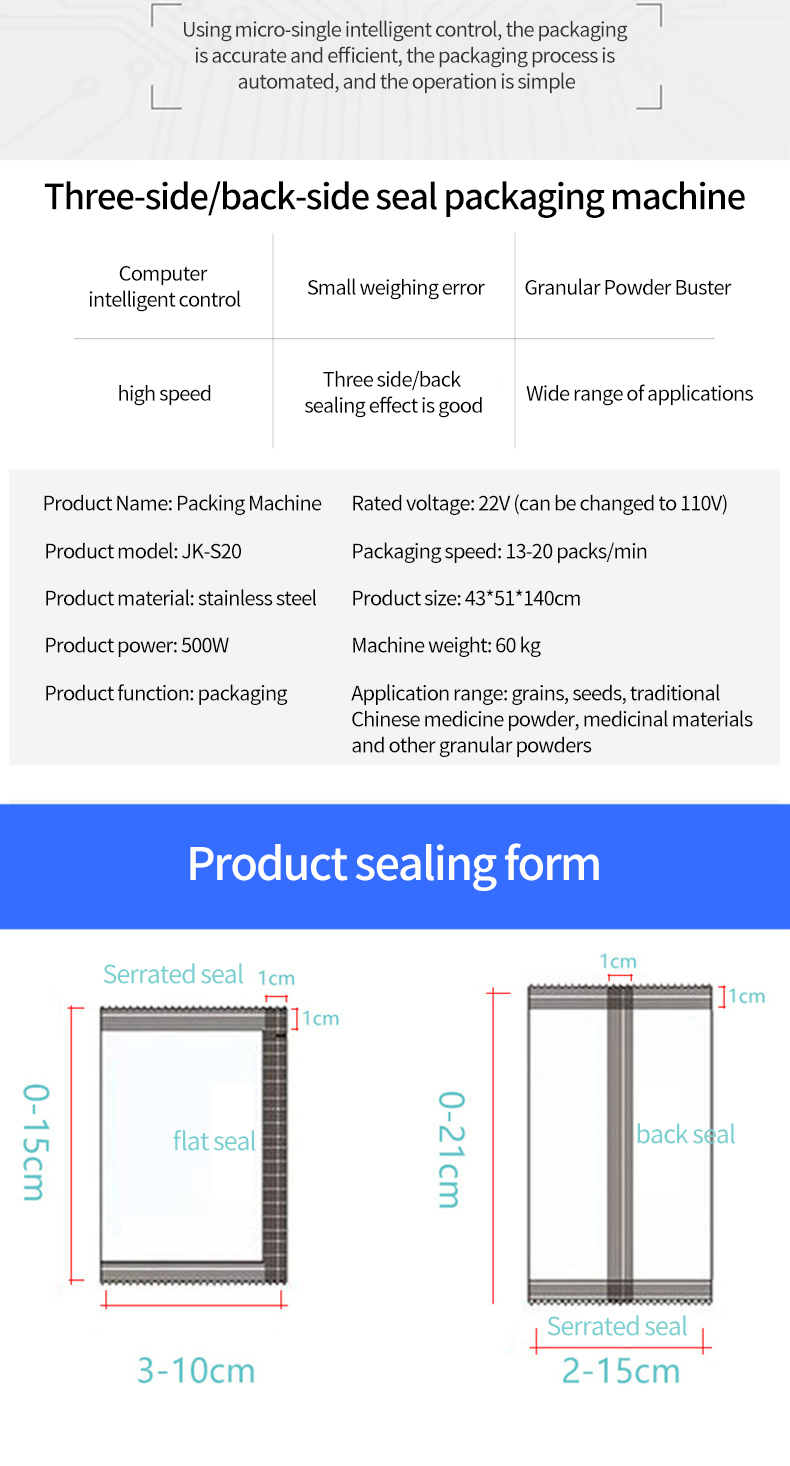

Product Name: Packing Machine

Rated voltage: 22V (can be changed to 110V)

Product model: JK-S20

Packaging speed: 13-20 packs/min

Product material: stainless steel

Product size: 43*51*140cm

Product power: 500W

Machine weight: 60 kg

Product function: packaging

Various bag sizes:(6-32) optional

Roll film width cm:6,8,10,12.5,14,16,18,20

Three side seal width cm:3,4,5,6.25,7,8,9,10

Finished back seal cm:2,3,4,5.5,6,7,8,9

Bag adjustable range cm:0-15,0-15,0-15,0-15,0-15,0-15,0-15,0-15

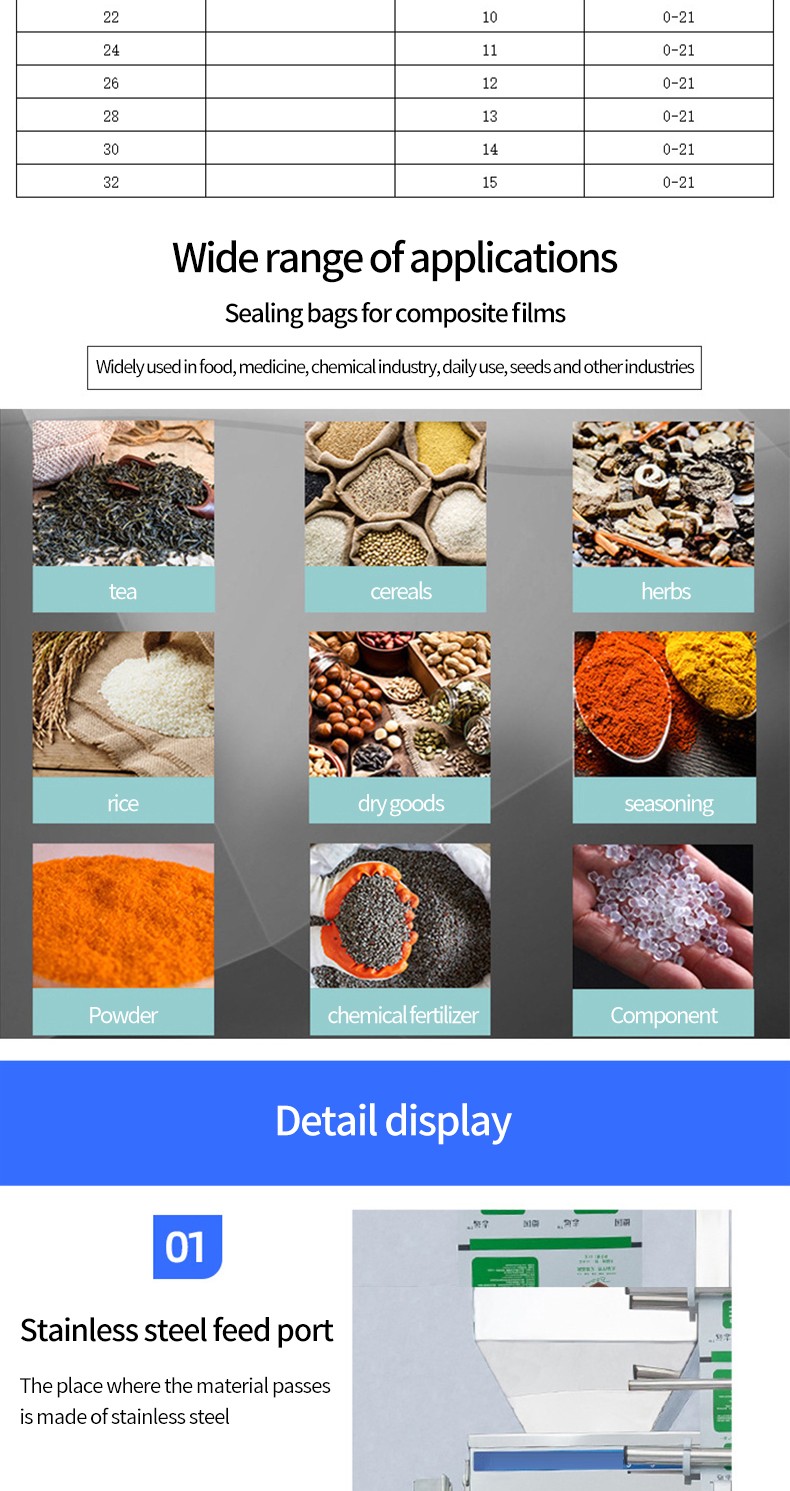

Wide range of applications:Sealing bags for composite films,Widely used in food, medicine, chemical industry, daily use, seeds and other industries,tea,cereals,herbs,rice,dry goods,seasoning,Powder,chemical fertilizer.

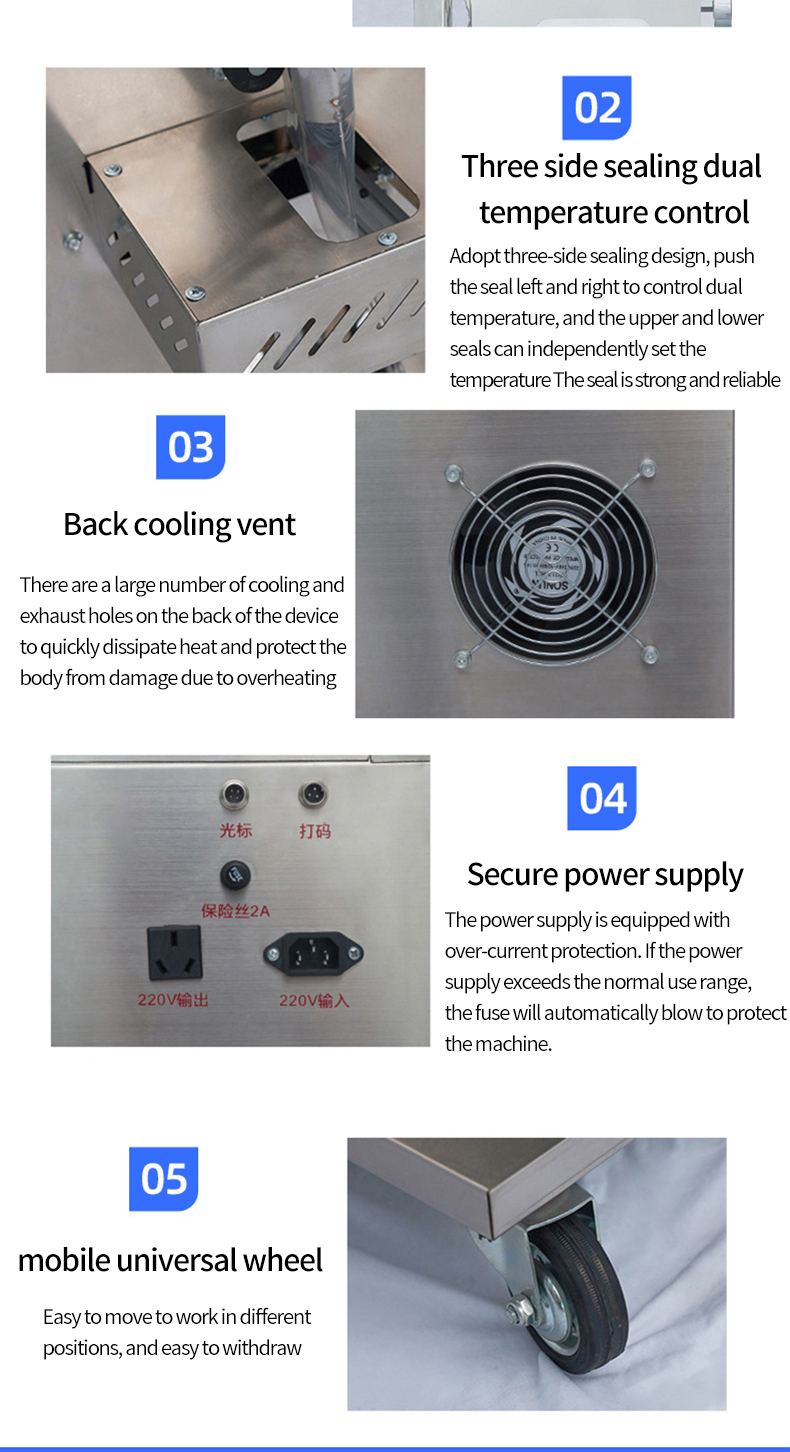

Three side sealing dual temperature control,Adopt three-side sealing design, push the seal left and right to control dual temperature, and the upper and lower seals can independently set the temperature The seal is strong and reliable.

Back cooling vent,There are a large number of cooling and exhaust holes on the back of the device to quickly dissipate heat and protect the body from damage due to overheating.

The power supply is equipped with over-current protection. If the power supply exceeds the normal use range, the fuse will automatically blow to protect the machine.

Easy to move to work in different positions, and easy to withdraw.

The bag former is designed with a special geometric shape, which can smoothly form the film into the required bag shape. The heat sealing device is equipped with high-quality heating elements and a precise temperature control system, which can achieve stable and uniform heat sealing to ensure the sealing quality. In addition, other sealing methods such as cold sealing or ultrasonic sealing can also be equipped to adapt to special packaging materials.

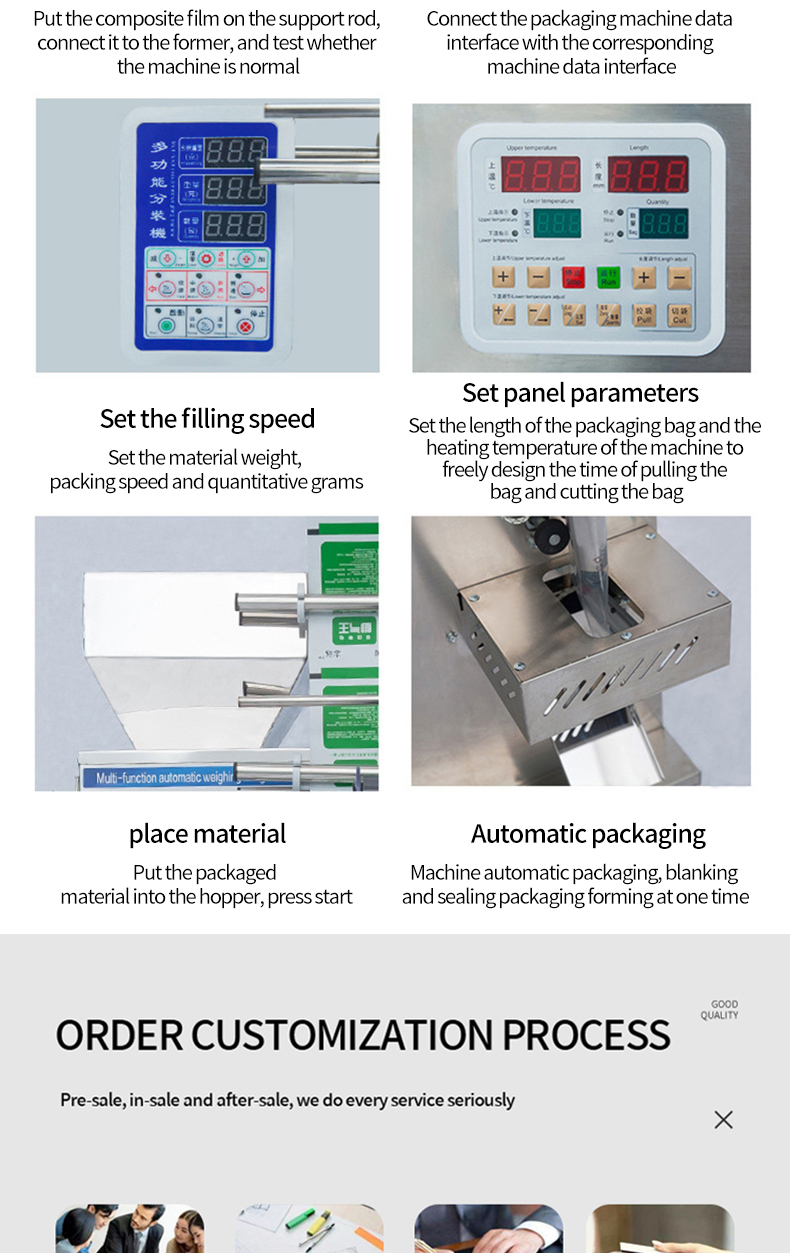

It uses advanced programmable logic controller (PLC) and human-machine interface (HMI). PLC can accurately control each action link of the equipment to ensure the accuracy and stability of the packaging process; HMI provides an intuitive and convenient operation interface, and operators can easily set packaging parameters such as speed, measurement value, bag length, bag width, temperature, etc. At the same time, the control system also has fault diagnosis and alarm functions, which can display the equipment operation status and fault information in real time, making it convenient for maintenance personnel to quickly locate and solve problems.

It can be customized according to the special requirements of customers, such as personalized design of packaging size, metering method, packaging speed, degree of automation, etc., to meet the unique production needs of different industries and enterprises.

The company provides a professional installation team to install the Multifunctional granule powder packing machine to the location specified by the user. During the installation process, strictly follow the installation instructions and safety specifications of the equipment to ensure that all parts of the equipment are installed correctly and firmly, and the electrical connections are safe and reliable.

Provide users with comprehensive training services, including equipment operation training, daily maintenance training and troubleshooting training. Training methods include on-site training and remote training.

On-site training is provided by professional technical engineers who provide one-on-one guidance to operators at the equipment installation site, explaining in detail the equipment operation methods, parameter settings, daily maintenance points, and the judgment and handling methods of common faults. Remote training provides users with follow-up technical support and training through online video conferencing and other means, and answers questions encountered by users during use.

We continue to pay attention to the development of the industry and the progress of technology, and regularly provide users with technical upgrades and optimization services for equipment. Through software updates, hardware improvements, etc., we continuously improve the performance and functions of the equipment, and improve the equipment's conveying efficiency, stability, and material adaptability.