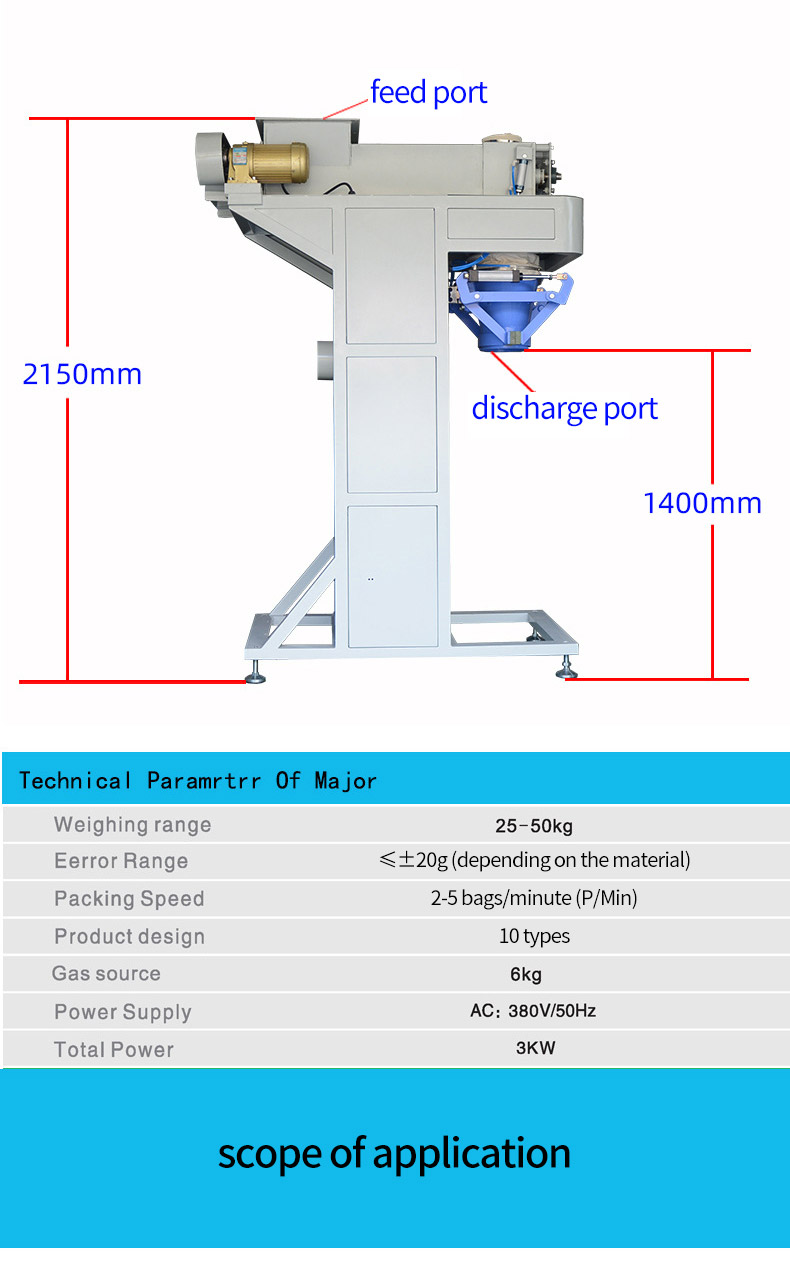

Powder belt weighing packaging machine

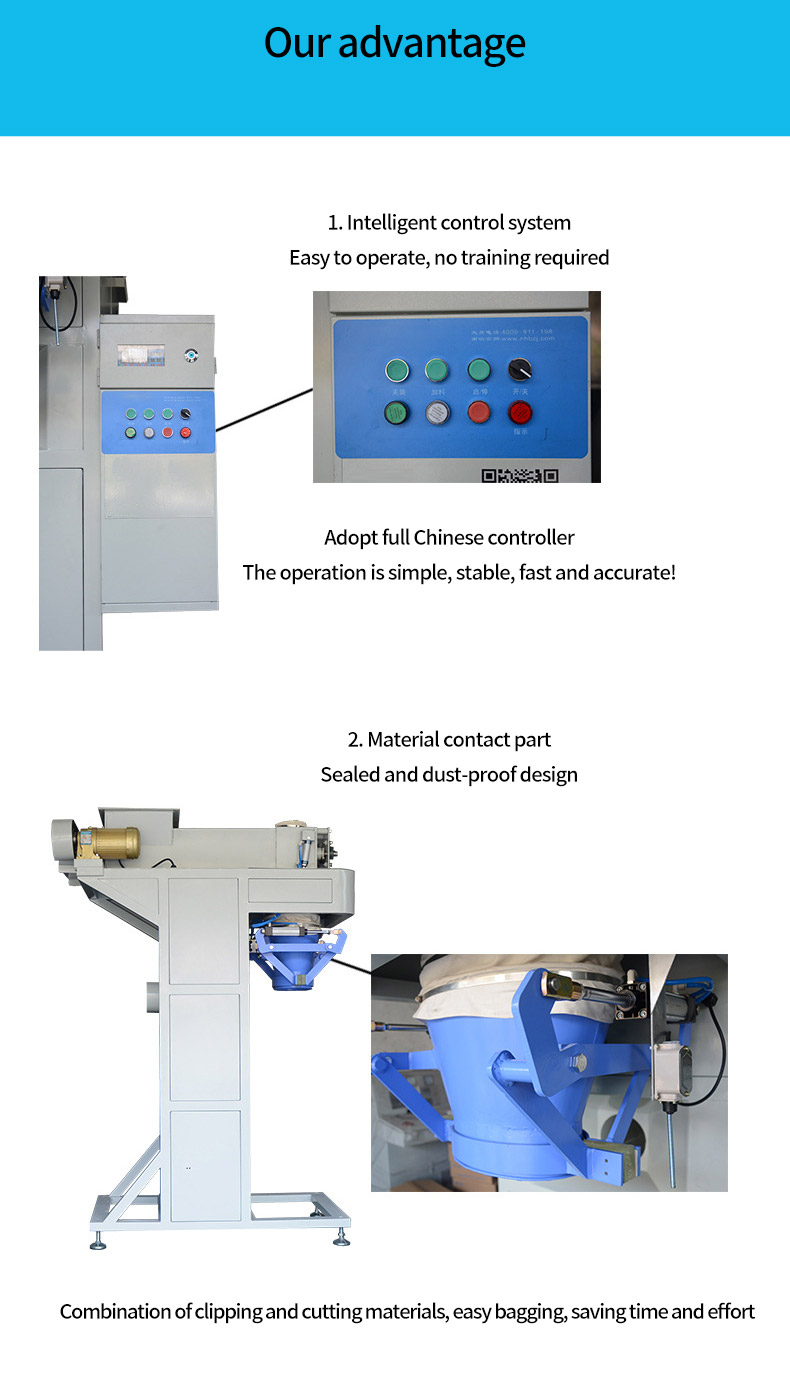

1. Using a high-precision belt scale as a weighing unit, combined with advanced sensors and intelligent control systems, it can accurately measure the weight of powder materials.

2. The belt conveyor structure enables powder materials to enter the packaging link quickly and continuously. Hundreds or even thousands of bags of packaging tasks can be completed per hour.

3. Whether it is fine powder with good fluidity or powder with poor fluidity, the equipment can achieve stable packaging by adjusting parameters.

4. The overall structure of the equipment is sturdy, and the key components are made of high-quality materials with good durability and corrosion resistance.

5. Equipped with a user-friendly operation interface, usually touch screen control, operators only need simple training to easily get started.

In the field of powder material packaging, efficiency, precision and stability are the key. Our powder belt weighing packaging machine combines advanced technology and ingenious design to provide excellent powder packaging solutions for various industries.

High-precision weighing sensors work together with intelligent control systems to ensure accurate control of material weight and reduce material waste and cost losses.

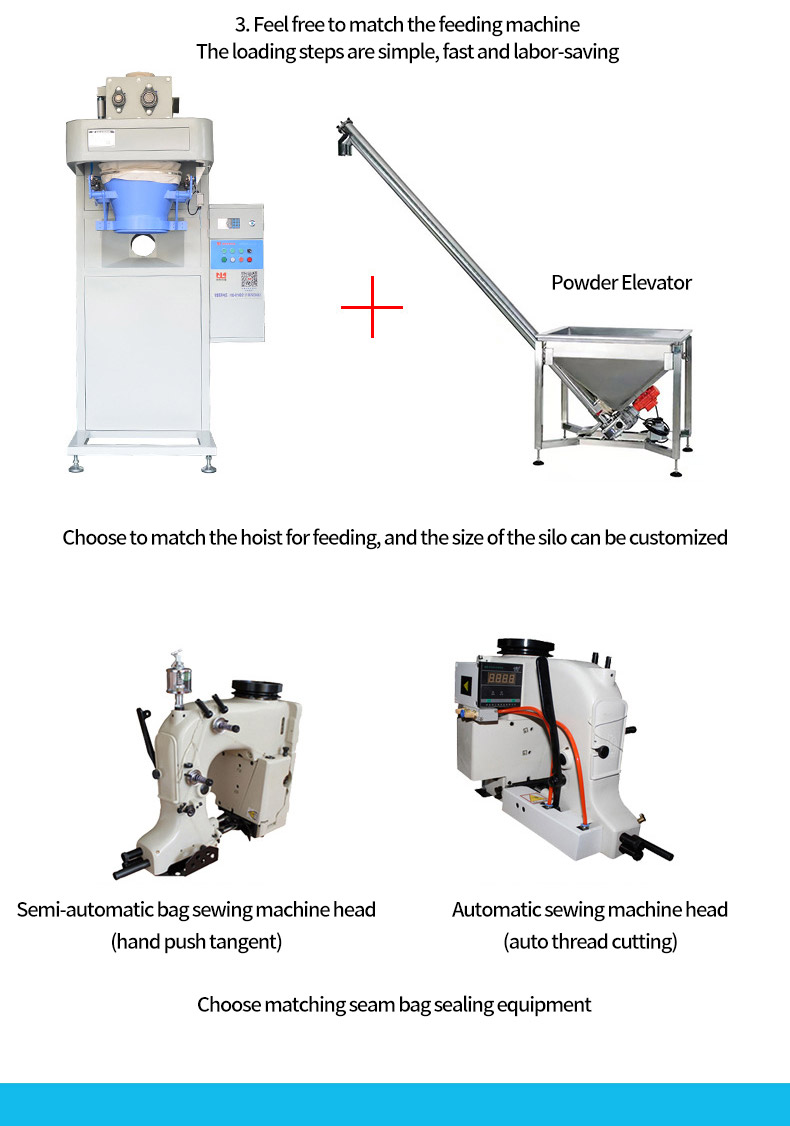

Continuous belt conveyor, combined with a fast unloading device, greatly increases packaging speed and improves production efficiency.

It has good adaptability to various powder materials, such as food powder, chemical raw materials, etc., and can meet the characteristics of different materials by adjusting parameters.

High-quality materials are used to manufacture key components, the structure is sturdy and durable, the electrical system is stable, and equipment failures and downtime are reduced.

Humanized operation interface, simple and intuitive parameter setting, easy for operators to use.

According to the special needs of customers, we can customize packaging specifications and add special functional modules, such as nitrogen filling packaging and automatic labeling.