Weighing granule bag packaging machine

1. Accurate measurement: Equipped with advanced weighing sensors and precise measurement algorithms, it can weigh granular materials very accurately.

2. High-speed and stable operation: With efficient mechanical transmission and automatic control system, it can realize fast and continuous packaging operations.

3. Stable filling and sealing: In the filling process, the filling speed and amount can be accurately controlled according to the size and weight of the particles, so that the particles can be evenly and quickly filled into the packaging bag.

4. Diverse material types: It can handle various types of granular materials, including but not limited to the food industry, pharmaceutical industry, chemical industry, building materials industry, etc.

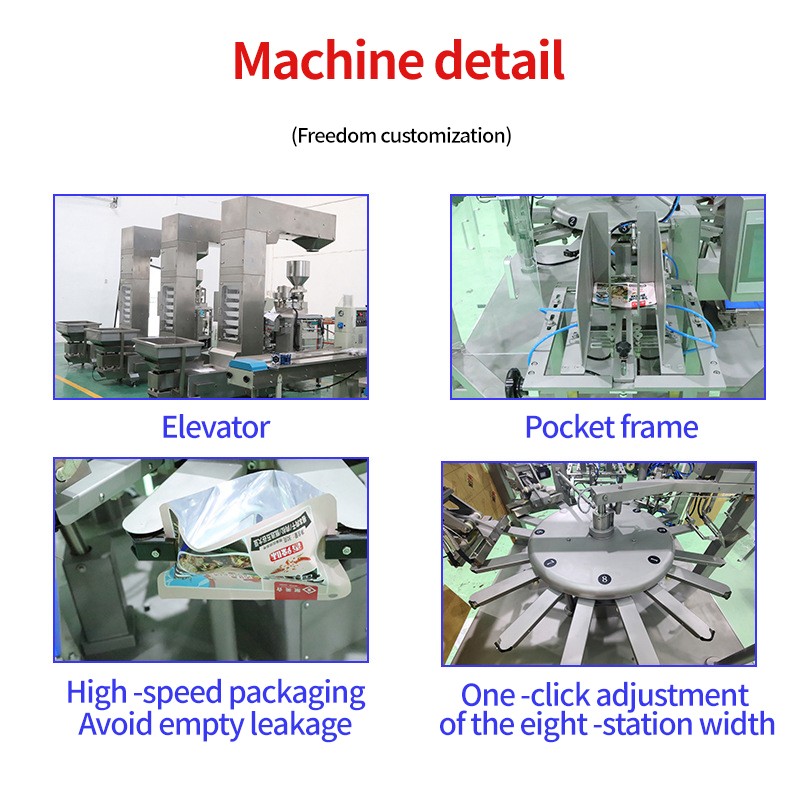

5. Easy maintenance: The equipment structure is reasonably designed, and key components are easy to disassemble and replace. At the same time, it has fault diagnosis and alarm functions.

6. Safety protection: Equipped with complete safety protection devices. During the operation of the equipment, it can effectively prevent accidental injuries to operators and protect the equipment from damage caused by abnormal conditions.

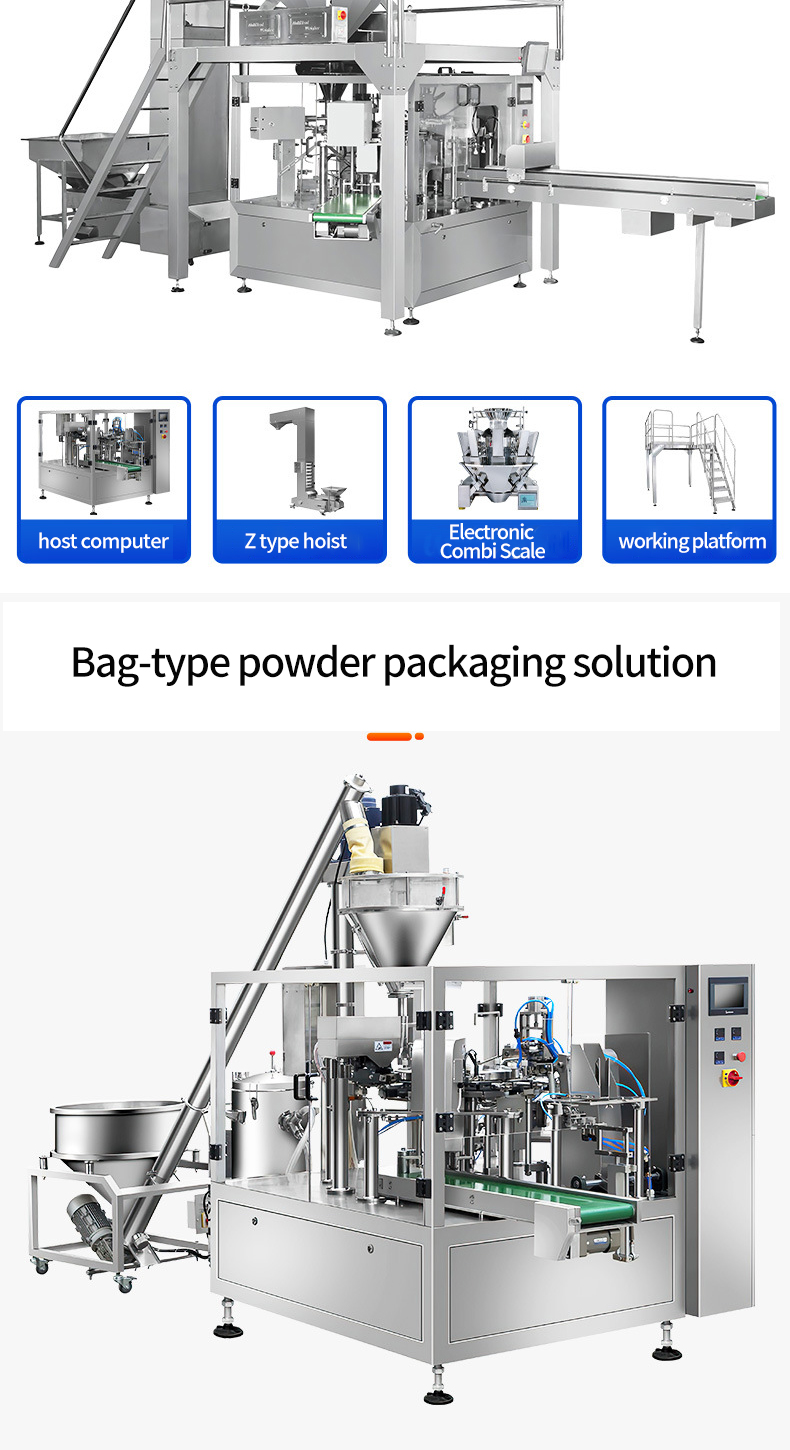

The granule weighing bag packaging machine is an advanced equipment that integrates accurate weighing and efficient packaging functions. It is widely used in many industries such as food, pharmaceuticals, chemicals, and building materials, providing an accurate, stable and efficient solution for the packaging of granular materials. It can ensure that the weight of each bag of product meets the set standard, while ensuring the sealing and integrity of the packaging, meeting the strict requirements of different industries for product packaging quality.

With high-precision weighing sensors and intelligent weighing controllers, accurate weighing of granular materials is achieved to ensure that the weight error of each bag of product is extremely small. This is particularly important in the pharmaceutical industry, which has strict dosage requirements, and the food industry, which has strict quality control, and can effectively avoid product quality problems and customer complaints caused by weight deviation.

The efficient design of the equipment enables it to achieve a high packaging speed while ensuring weighing accuracy, meeting the needs of large-scale production. Whether it is a fast packaging line in a food processing plant or batch production in a chemical company, it can effectively improve production efficiency and reduce production costs.

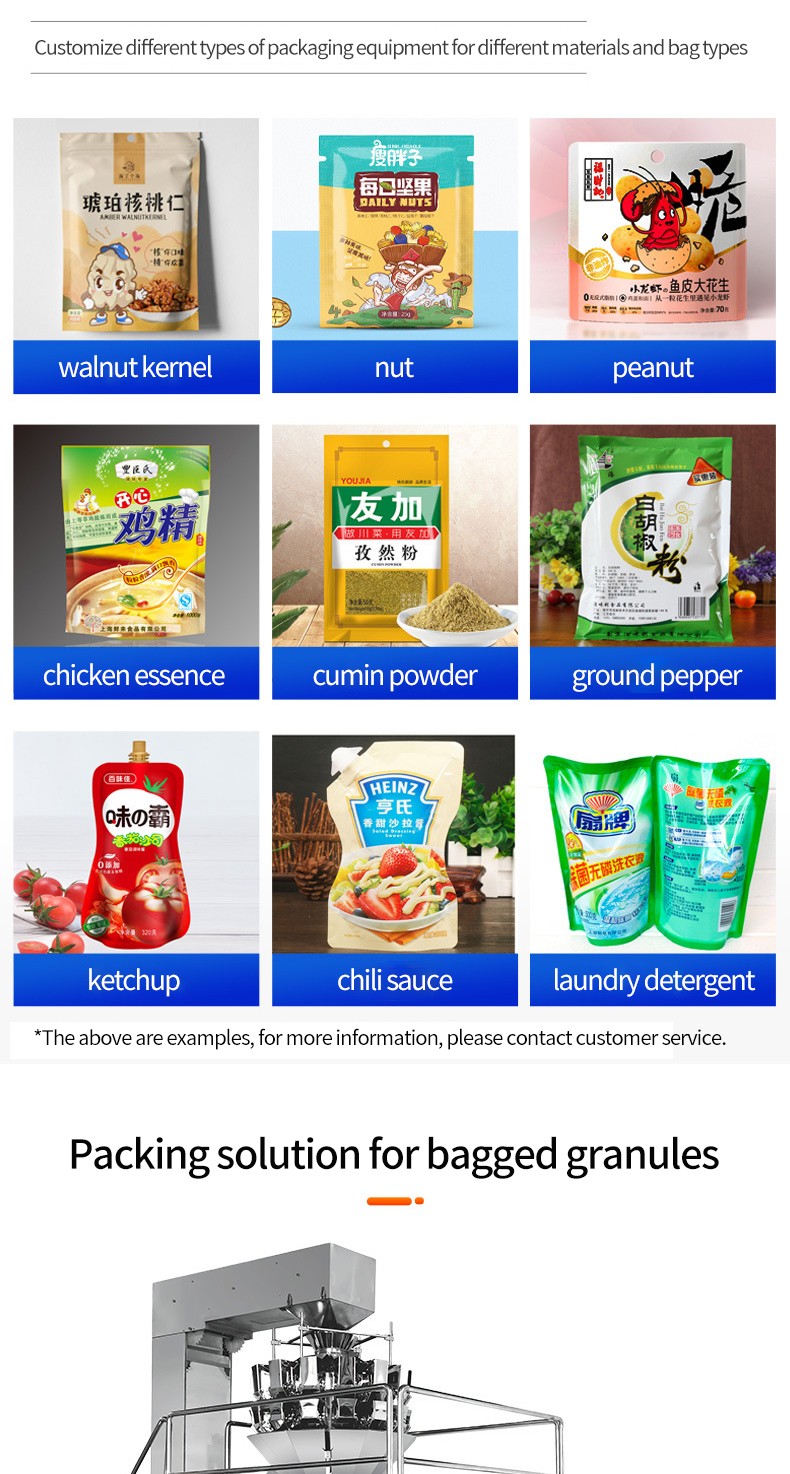

It can process various types of granular materials, including granules of different density, size, fluidity and chemical properties. Whether it is candy and milk powder in food, pills and powder in pharmaceuticals, or plastic granules and fertilizer granules in chemical industry, it can achieve good packaging effect on this equipment without frequent replacement of equipment for different materials.

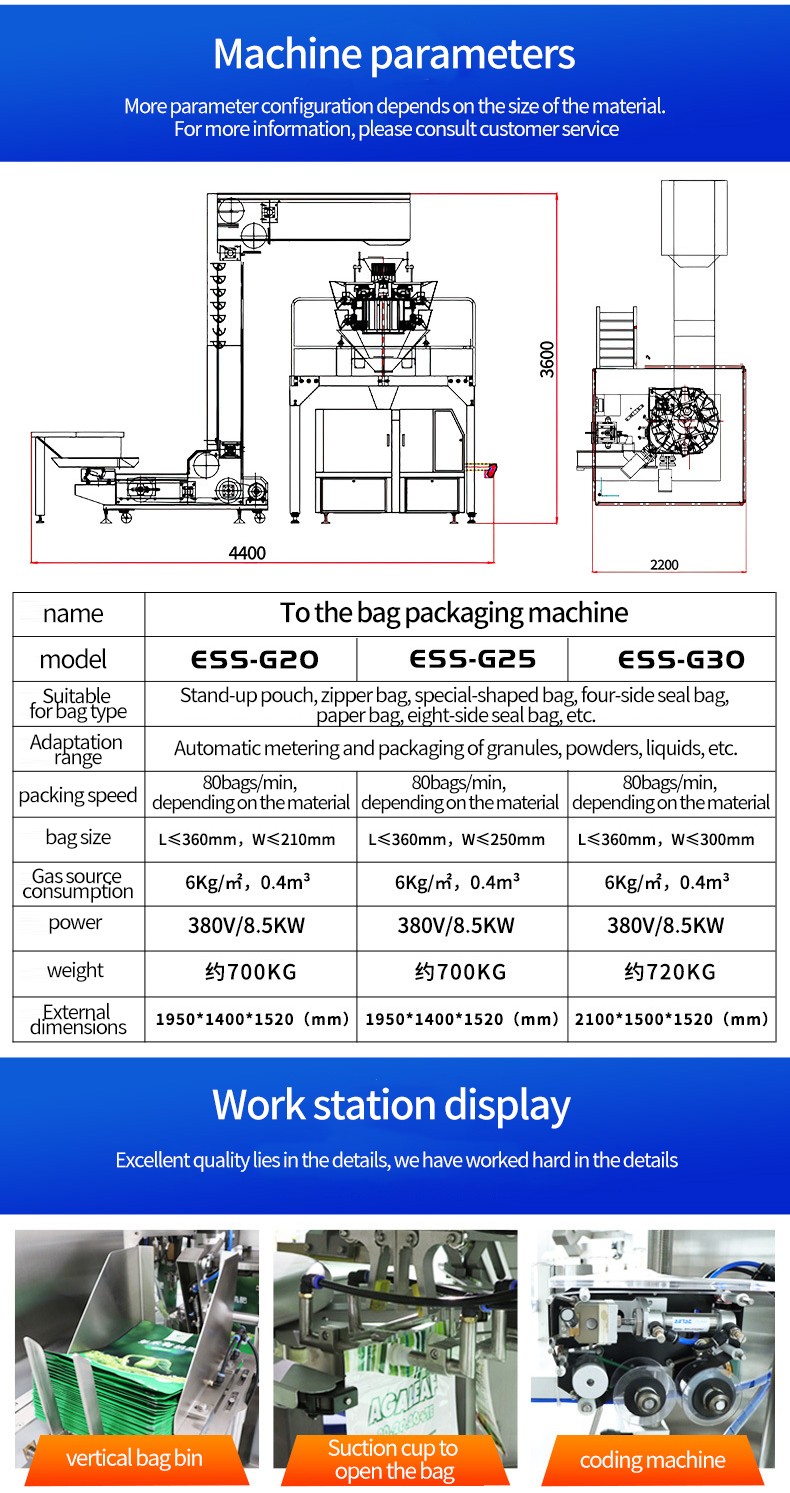

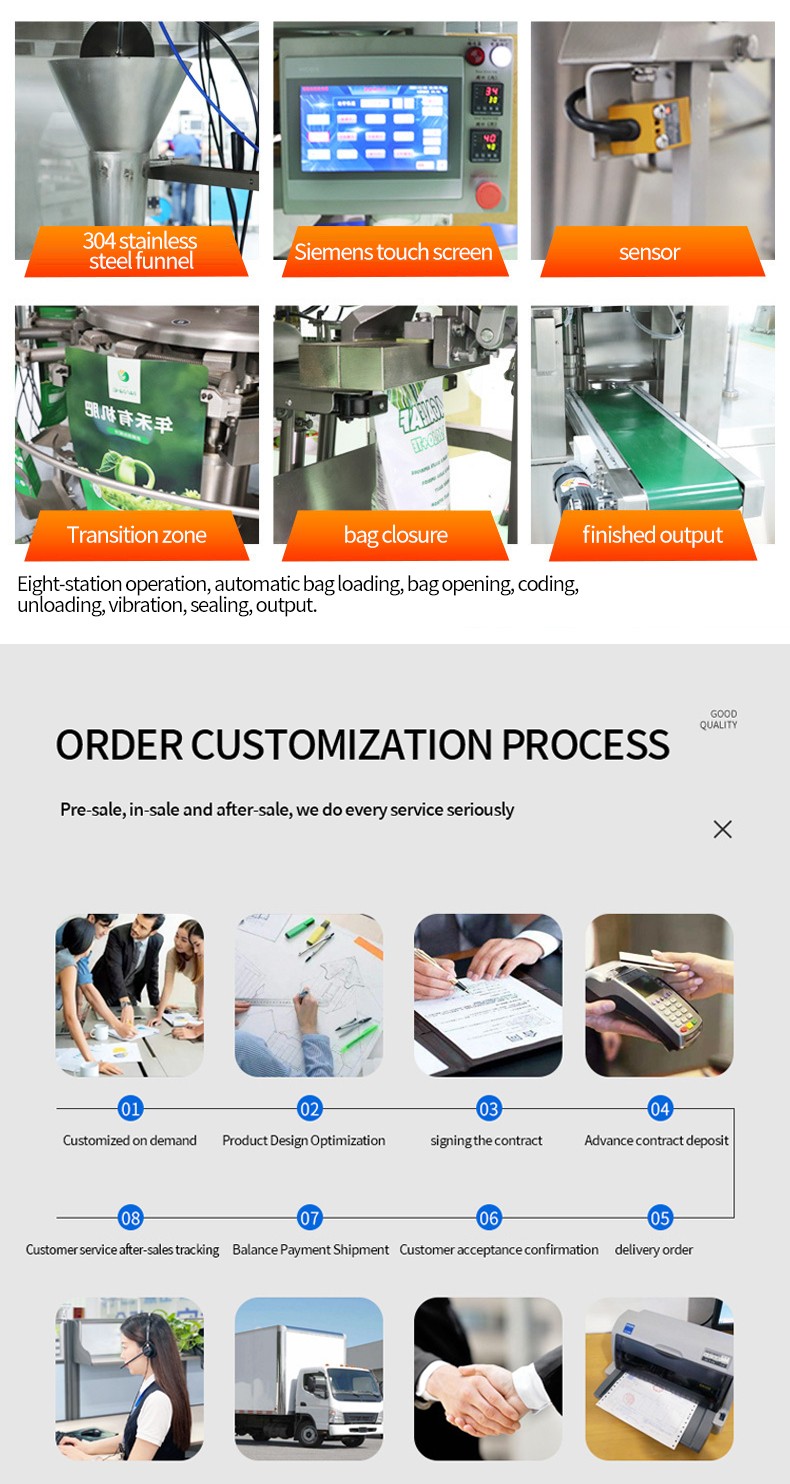

name:To the bag packaging machine

model:ESS-G20,ESS-G25,ESS-G30

Suitable for bag type:Stand-up pouch, zipper bag, special-shaped bag, four-side seal bag, paper bag, eight-side seal bag, etc.

Adaptation range:Automatic metering and packaging of granules, powders, liquids, etc.

packing speed:80bags/min, depending on the material,80bags/min, depending on the material,80bags/min, depending on the material

bag size:L≤360mm, W≤210mm,L≤360mm, W≤250mm,L≤360mm, W≤300mm

Gas source consumption:6Kg/㎡, 0.4m³,6Kg/㎡, 0.4m³,6Kg/㎡, 0.4m³

power:380V/8.5KW,380V/8.5KW380V/8.5KW

weight:About 700KG,About 700KG,About 720KG

External dimensions:1950*1400*1520 (mm),1950*1400*1520 (mm),2100*1500*1520 (mm)

The intuitive operation interface enables operators to easily master the operation of the equipment, reducing the professional skills required of operators. At the same time, the structural design of the equipment is easy to maintain, key components are easy to disassemble and replace, and it has a fault diagnosis function, which can detect and solve problems in time, reduce downtime, and improve equipment utilization.

The parts in contact with the materials are made of materials that meet hygiene standards to prevent material contamination and meet the hygiene requirements of industries such as food and pharmaceuticals. In addition, the equipment is equipped with complete safety protection devices, such as emergency stop buttons, protective door sensors, overload protection, etc., to ensure the safety of operators and the normal operation of the equipment.

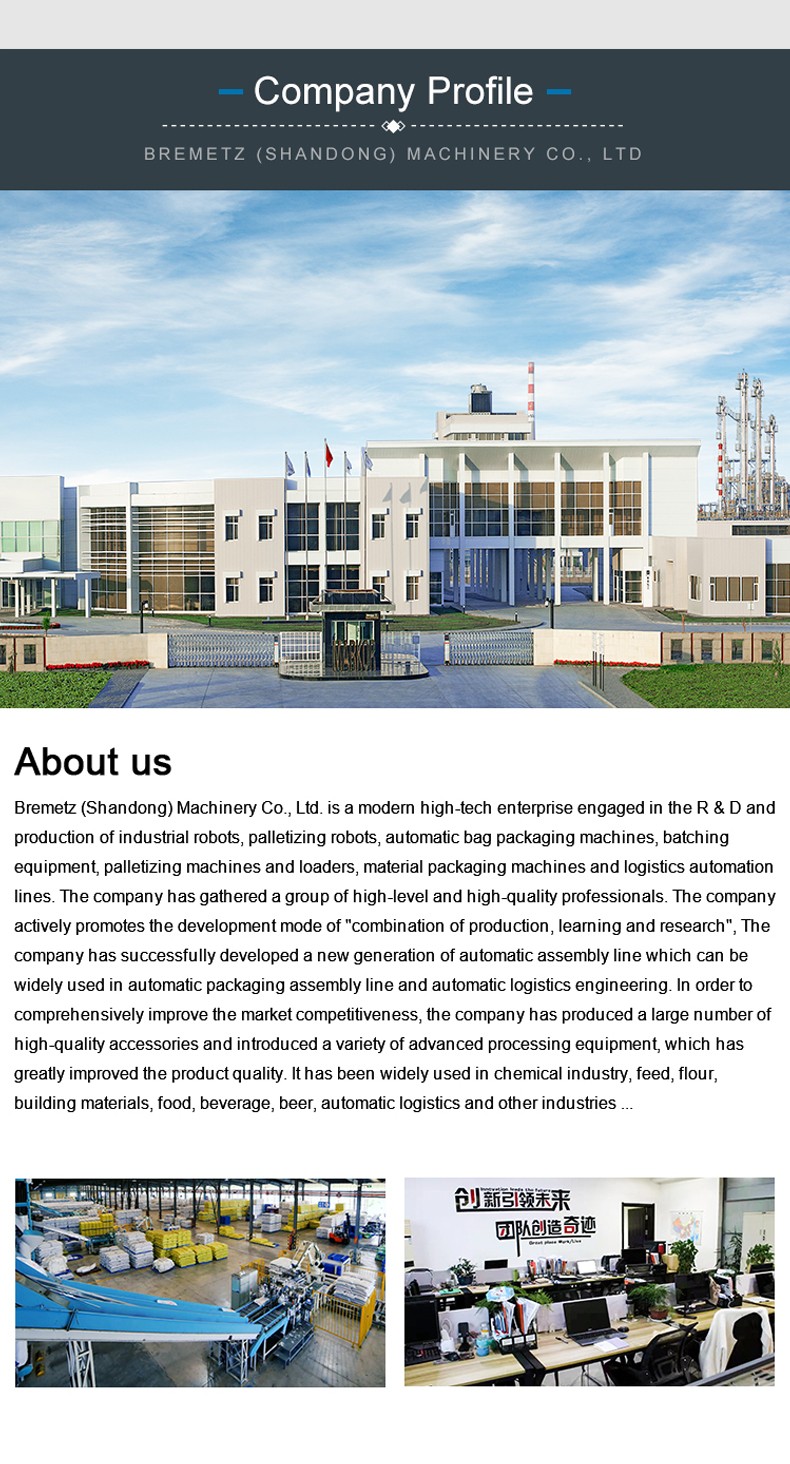

We have an experienced and professional installation team. After you purchase the Weighing granule bag packaging machine, we will dispatch installation personnel to the site in a timely manner according to your arrangement to install the equipment. The installation personnel will strictly follow the equipment installation manual and relevant standards to ensure that all parts of the equipment are correctly assembled and firmly placed to avoid affecting the performance and service life of the equipment due to improper installation.

We have established a complete after-sales maintenance service system and a dedicated after-sales maintenance hotline. If you encounter any equipment problems during use, you can call at any time. Once we receive your maintenance request, we will immediately activate the quick response mechanism.