Liquid filling and capping production line

1. Liquid filling and capping production line integrates advanced filling and capping technologies to achieve fast and continuous production operations.

2. Each link of the production line is highly automated, from liquid delivery, filling to capping, the entire process is seamlessly connected.

3. High-precision filling systems, such as volumetric filling, weighing filling, etc., can accurately control the filling volume of liquid.

4. The capping process ensures that the bottle cap fits tightly with the bottle mouth through precise mechanical structure and pressure control to achieve a good sealing effect.

5. The entire production line can automatically complete most of the operations of liquid filling and capping, basically without direct human participation.

Liquid filling and capping production line is an automated production line that integrates liquid filling and bottle capping functions. It has high production speed and efficiency, and can complete the filling and capping of a large number of products in a short time to meet the needs of large-scale production.

Equipped with high-precision metering devices and capping control systems to ensure accurate liquid filling volume, firm capping and good sealing, effectively guaranteeing product quality..

Product Name:Filling and capping machine (Filling speed) 20-25 bottles/minute

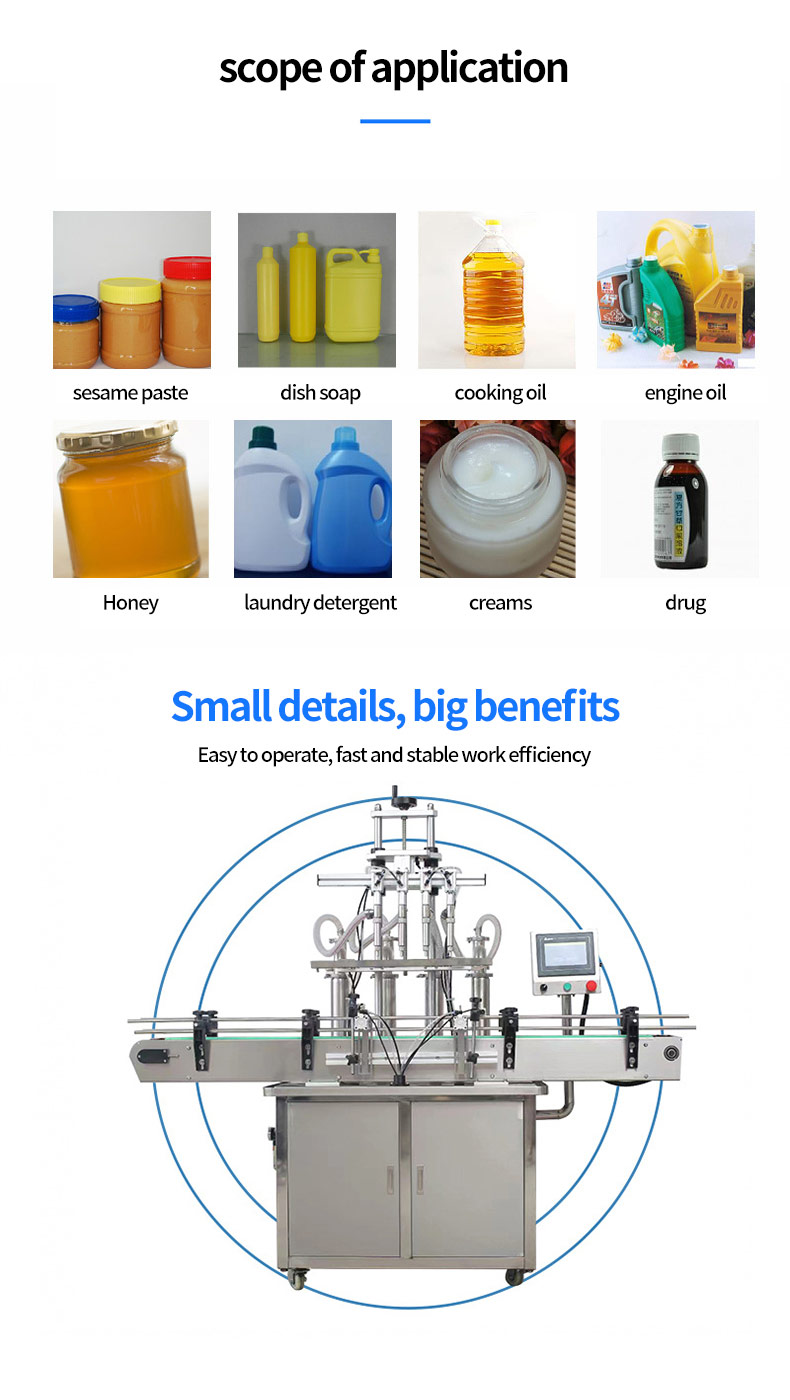

Product material:304 stainless steel/aluminum plate (Filling materials) liquid, semi-fluid, paste

Product features:Automatic feeding, automatic filling, (automatic capping), automatic capping

Product Features:Quantitative dispensing, driven by servo motor, precise filling, automatic capping, saving labor

Product price:Different filling ranges, different output requirements, different prices, please consult customer service for details

Product customization:Products can be customized according to your requirements

It can adapt to bottles and cans of various shapes and sizes, as well as various types of caps. It can also adjust the filling and capping parameters according to different liquid viscosities and characteristics.

The parts that come into contact with liquids and products are usually made of food-grade or pharmaceutical-grade stainless steel, plastics that meet hygiene standards and other materials. They are easy to clean and disinfect and meet strict hygiene standards.

Equipped with advanced control systems and fault diagnosis functions, it can monitor the operating status of the production line in real time, automatically detect and alarm faults, and facilitate maintenance and management by operators.